Professional Documents

Culture Documents

Corro-Coat EP TDS

Uploaded by

Shahroze IlyasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corro-Coat EP TDS

Uploaded by

Shahroze IlyasCopyright:

Available Formats

Technical Data Sheet

VValidationDate).

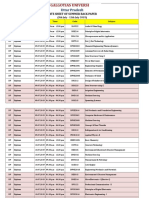

16280 18280;16281;16282;16283;16284;16285;16286;16287;16288;16289 3

1

Corro-Coat EP, Series 9

PRODUCT DESCRIPTION

This product is developed to combine attractive finishes with superior protection performance in aggressive

environments where mechanical and chemical resistance are required. The product offers a high level of surface

hardness and resistance to wear and tear.

Application areas

This product is recommended for interior use only.

Typical application areas:

Machinery

Heavy duty machinery and tools

Laboratory equipment

Automotive coil springs

Brake pads

Cable ducting

Pallet-racks

Tools

POWDER PROPERTIES

Storage

Keep in a dry cool area. Maximum temperature 25 °C. Maximum relative humidity 60 %. If stored longer than 12

months a quality test is recommended.

APPLICATION

Pretreatment

The overall performance of the coating system is largely dependent on the nature of the substrate and the type and

quality of the pretreatment. For optimal results, it is recommended to follow the pretreatment supplier's instructions

and recommendations.

The recommended types of pretreatment for the most frequently used substrates are:

Substrate Pretreatment

Aluminium Chromate conversion

Steel Zinc phosphate

Zinc coated steel Zinc phosphate or chromate conversion

Final rinse (deionized) The last running water from the object should be tested at 20 °C.

The readings obtained should measure below 30 µS/cm.

Powder application

This product can be formulated for curing temperatures from 160 °C to 200 °C object temperature.

Equipment

Suitable for Corona or Tribo charging equipment.

APPEARANCE

Date of issue: 27 June 2014 by Jotun Group Page: 1/3

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) for this product. For

your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Corro-Coat EP, Series 9

Colour The product is available in a wide assortment of custom-made colours, including

RAL and NCS.

Gloss EN ISO 2813 (60°) All gloss levels

Finish Smooth and textured finishes

If the significant surface is too small or unsuitable for the gloss to be measured with the glossmeter, the gloss should

be compared visually with the reference sample (from the same viewing angle).

PERFORMANCE

The technical data provided below are typical for this product when applied as following:

Substrate Zinc-phosphated cold rolled steel panels

Substrate thickness (mm) 0,8

Film thickness (µm) 60

Typical values when tested have not necessarily been recently revised.

Property Standard Result

Adhesion EN ISO 2409 (2 mm) Cross-cut rating Gt0 (100 % adhesion)

Impact resistance ASTM D2794 (5/8 '' ball) Most grades exceed 60 inch-pounds without

film cracking

Cupping test EN ISO 1520 Most grades exceed 5 mm without film

cracking

Flexibility EN ISO 1519 Cylindrical Mandrel bend test, 3-12 mm

without film cracking

Film hardness EN ISO 2815 Excellent Indentation resistance according

to Buchholz: > 80

Salt spray resistance ASTM B117 Excellent No blistering or loss of adhesion

after 1000 hours

Resistance to humid DIN 50017 Excellent No blistering or loss of adhesion

atmospheres after 1000 hours

Heat resistance (Colour ASTM G 154 (UVB-313) Yellowing of light colours

stability)

Disclaimer

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and practical

experience. Jotun's products are considered as semi-finished goods and as such, products are often used under

conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the product itself. Minor product

variations may be implemented in order to comply with local requirements. Jotun reserves the right to change the

given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their needs and

specific application practices.

If there is any inconsistency between different language issues of this document, the English (United Kingdom) version

will prevail.

Date of issue: 27 June 2014 by Jotun Group Page: 2/3

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) for this product. For

your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Corro-Coat EP, Series 9

Date of issue: 27 June 2014 by Jotun Group Page: 3/3

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) for this product. For

your nearest local Jotun office, please visit our website at www.jotun.com

You might also like

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Principles of Drug DistributionDocument55 pagesPrinciples of Drug DistributionSunil100% (3)

- Heavy Metal Toxicity EbookDocument33 pagesHeavy Metal Toxicity Ebooklouminn89% (9)

- Ar15 Barrel Extension NewDocument1 pageAr15 Barrel Extension NewGeoff Crook100% (4)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- 0.5 Pretest Day2Document15 pages0.5 Pretest Day2Janica Palangeo100% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Agma 926-C99Document16 pagesAgma 926-C99Mehul Bansal100% (2)

- Jotatemp 1000 Ceramic High-Heat Protective Coating TDSDocument5 pagesJotatemp 1000 Ceramic High-Heat Protective Coating TDSGurdeep Sungh AroraNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Pilot ACR: Technical Data SheetDocument4 pagesPilot ACR: Technical Data SheetBiju_PottayilNo ratings yet

- Crude Distillation and Hydrogen Production Process RequirementsDocument14 pagesCrude Distillation and Hydrogen Production Process RequirementskrishnaNo ratings yet

- Water SupplyDocument37 pagesWater SupplyGTS100% (1)

- Complete Steel Plant SpecificationDocument250 pagesComplete Steel Plant SpecificationJesus SevillaNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Technical Data Sheet for Zinc Epoxy Barrier CoatingDocument5 pagesTechnical Data Sheet for Zinc Epoxy Barrier CoatingSanjay PatelNo ratings yet

- Hardtop Pro: Technical Data SheetDocument5 pagesHardtop Pro: Technical Data SheetBiju_PottayilNo ratings yet

- Investigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFDocument13 pagesInvestigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFCarlosNo ratings yet

- Mothballing Requires More Than Idle ThoughtDocument4 pagesMothballing Requires More Than Idle Thoughtfawmer61No ratings yet

- Corro-Coat PE Series 50: Technical Data SheetDocument3 pagesCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNo ratings yet

- Corro-Coat PE Series 50 TDSDocument3 pagesCorro-Coat PE Series 50 TDSBiju_PottayilNo ratings yet

- Esd Jotun PaintDocument3 pagesEsd Jotun PaintMohd Ridzuan Abdul AzizNo ratings yet

- Lacqare Technical DataDocument3 pagesLacqare Technical DataMahmoud MassadNo ratings yet

- TDS Guard Style E T - UKDocument3 pagesTDS Guard Style E T - UKBudiJuwiNo ratings yet

- Tds - Jotun - Guard Classic EtDocument3 pagesTds - Jotun - Guard Classic Etvijh van niemannNo ratings yet

- Jotun Facade TGIC-free powder coatingsDocument4 pagesJotun Facade TGIC-free powder coatingsWan Mohd ThariqNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument2 pagesProduct Data Sheet: Akzonobel Powder CoatingsigorciNo ratings yet

- Technical Data Sheet for Barrier 80 S Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 S Zinc Epoxy PrimerHung Mai VanNo ratings yet

- Steel Master 1200 WF PDSDocument5 pagesSteel Master 1200 WF PDSshameelNo ratings yet

- Barrier Smart Pack Jotun PaintDocument5 pagesBarrier Smart Pack Jotun PaintGurdeep Sungh AroraNo ratings yet

- JotundatasheetsDocument172 pagesJotundatasheetsAli MudhafarNo ratings yet

- TDS 31002 Primax Protect Euk GBDocument3 pagesTDS 31002 Primax Protect Euk GBBalaji Guru0% (1)

- Technical Data Sheet for Steelmaster 1200WF Fire Protection CoatingDocument4 pagesTechnical Data Sheet for Steelmaster 1200WF Fire Protection CoatingHarmandeep BhattiNo ratings yet

- TDS 36962 SteelMaster 600WF Euk GBDocument5 pagesTDS 36962 SteelMaster 600WF Euk GBRamesh RathinamNo ratings yet

- TDS SteelMaster 1200WF GB English ProtectiveDocument5 pagesTDS SteelMaster 1200WF GB English Protective폴로 쥰 차No ratings yet

- Aluminium Paint HR Technical Data SheetDocument4 pagesAluminium Paint HR Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotun Steelmaster 600WF - TDSDocument5 pagesJotun Steelmaster 600WF - TDSAmine ait talebNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- P68 M13 Painting Documents PDFDocument708 pagesP68 M13 Painting Documents PDFJohn TerryNo ratings yet

- Corro-Coat PE Series 50Document4 pagesCorro-Coat PE Series 50Biju_PottayilNo ratings yet

- Aluminium Paint H.R.: Technical Data SheetDocument4 pagesAluminium Paint H.R.: Technical Data SheetBiju_PottayilNo ratings yet

- Aluminium Paint HR TDSDocument4 pagesAluminium Paint HR TDSRaja S0% (1)

- TDS - Resist 65Document5 pagesTDS - Resist 65Teknik produksi wikonNo ratings yet

- Technical Data Sheet for Epoxy Floor CoatingDocument5 pagesTechnical Data Sheet for Epoxy Floor CoatingWilliam SukyonoNo ratings yet

- Technical Data Sheet for Tankguard Storage CoatingDocument5 pagesTechnical Data Sheet for Tankguard Storage Coatingabdulgafoor54No ratings yet

- Jotafloor TC EDocument6 pagesJotafloor TC ERidwanSalminNo ratings yet

- Tankguard StorageDocument5 pagesTankguard StorageBiju_PottayilNo ratings yet

- Jotatemp 540 Zinc Technical Data SheetDocument5 pagesJotatemp 540 Zinc Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Technical Data Sheet for Barrier 80 Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 Zinc Epoxy PrimerBalaji GuruNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Steelmaster 120Sb: Technical Data SheetDocument4 pagesSteelmaster 120Sb: Technical Data SheetkalstarNo ratings yet

- Technical Data Sheet for Zinc-Rich PrimerDocument5 pagesTechnical Data Sheet for Zinc-Rich PrimerJayaraman KamarajNo ratings yet

- Technical Data Sheet for Jotaprime 265Document4 pagesTechnical Data Sheet for Jotaprime 265Mudassar BhachranaNo ratings yet

- Barrier SmartpackDocument5 pagesBarrier SmartpackMhd EbalNo ratings yet

- Thermosolo GS: Description and Scope of ApplicationDocument2 pagesThermosolo GS: Description and Scope of ApplicationCatalin FilipNo ratings yet

- Tds - TDS 480 Jotafloor Coating Euk GBDocument5 pagesTds - TDS 480 Jotafloor Coating Euk GBmajidhajnasrNo ratings yet

- TDS 429 Conseal Touch-Up Euk GBDocument4 pagesTDS 429 Conseal Touch-Up Euk GBGalih WicaksonoNo ratings yet

- TDS 11480 Pilot ACR Euk GBDocument5 pagesTDS 11480 Pilot ACR Euk GBeeng gilangNo ratings yet

- JT TDSDocument5 pagesJT TDSKingsman 86No ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Conseal Touch-Up: Technical Data SheetDocument4 pagesConseal Touch-Up: Technical Data SheetSyilla ShopeNo ratings yet

- Technical Data Sheet for Epoxy CoatingDocument5 pagesTechnical Data Sheet for Epoxy CoatingPablo Ahumada G.No ratings yet

- Technical Data Sheet for Penguard TopcoatDocument5 pagesTechnical Data Sheet for Penguard TopcoatajuhaseenNo ratings yet

- Technical Data Sheet for Zinc PrimerDocument4 pagesTechnical Data Sheet for Zinc PrimerBiju_PottayilNo ratings yet

- Technical Data Sheet for Silicone Acrylic CoatingDocument5 pagesTechnical Data Sheet for Silicone Acrylic CoatingGurdeep Sungh AroraNo ratings yet

- Homework Conservation of Mass Answer KeyDocument6 pagesHomework Conservation of Mass Answer Keycfmmpnh6100% (1)

- March 2019 (v2) MS - Paper 5 CIE Biology A-LevelDocument8 pagesMarch 2019 (v2) MS - Paper 5 CIE Biology A-Leveleric sivaneshNo ratings yet

- E 378 - 97Document4 pagesE 378 - 97ruben carcamoNo ratings yet

- OGA - Chemical Series - Soda Ash Market Outlook 2019-2025Document20 pagesOGA - Chemical Series - Soda Ash Market Outlook 2019-2025ambarish ramNo ratings yet

- MC-250 Physical SpecificationsDocument2 pagesMC-250 Physical SpecificationsTally AnuNo ratings yet

- A Seminar Report On: BoilersDocument15 pagesA Seminar Report On: Boilersshubhama434No ratings yet

- Experiment No-3 To Study Biogas PlantDocument4 pagesExperiment No-3 To Study Biogas PlantANUP KUMARNo ratings yet

- CAFAM BasicReportDocument135 pagesCAFAM BasicReportDaniel R. CC AIRESNo ratings yet

- Summer Back Paper Date SheetDocument85 pagesSummer Back Paper Date SheetKaustubh RatanNo ratings yet

- A) Linear Sweep VoltammetryDocument2 pagesA) Linear Sweep VoltammetryGIRMA SELALE GELETANo ratings yet

- Synthesis and characterization of copper(II) complexesDocument4 pagesSynthesis and characterization of copper(II) complexesichdsNo ratings yet

- Reaction MechanismDocument19 pagesReaction Mechanismtapas kunduNo ratings yet

- Inv Chem 1Document24 pagesInv Chem 1Animesh kanjilalNo ratings yet

- Bacillus Cereus Agar ISO Test (MYPDocument2 pagesBacillus Cereus Agar ISO Test (MYPLong ManNo ratings yet

- Lubri-Bond 220: Technical Data (Spec Qualified)Document2 pagesLubri-Bond 220: Technical Data (Spec Qualified)Santaj TechnologiesNo ratings yet

- Elasto-Plastic Cylinder CollapseDocument8 pagesElasto-Plastic Cylinder CollapseHalef Michel Bou KarimNo ratings yet

- Editable Welding Resume TemplateDocument6 pagesEditable Welding Resume TemplatejeyesbelmenNo ratings yet

- Material Safety Data Sheet: Production IdentificationDocument6 pagesMaterial Safety Data Sheet: Production IdentificationFarmaceuticaNo ratings yet

- Method for Determining Thermo-Flow Parameters for Steam BoilersDocument8 pagesMethod for Determining Thermo-Flow Parameters for Steam BoilersElena RadanNo ratings yet

- Astm A 722 PDFDocument4 pagesAstm A 722 PDFRyan LasacaNo ratings yet