Professional Documents

Culture Documents

Steelmaster 120Sb: Technical Data Sheet

Uploaded by

kalstarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steelmaster 120Sb: Technical Data Sheet

Uploaded by

kalstarCopyright:

Available Formats

Technical Data Sheet

Approved 15400 1 15400 acrylic ^(ValidationDate) 1

SteelMaster 120SB

Product description

This is a one component solvent based acrylic thin film intumescent coating. Independently approved for fire

protection of structural steel exposed to cellulosic fire. Can be used as mid coat or finish coat in atmospheric

environments. Suitable on approved primers on carbon steel substrates.

Typical use

Specially designed as a reactive fire protection system for steel constructions. Suitable for structural steel

exposed to internal environments up to corrosivity category C4 (ISO 12944-2), with a compatible topcoat. For a

detailed coating specification please contact your local Jotun representative.

Other

Approvals and certificates

BS 476 part 20/21: Certifire CF 845

Cellular beams RT1356

Chinese GB14907:2018

ASTM E84: Class A

Additional certificates and approvals may be available on request.

Colours

white

Product data

Property Test/Standard Description

Solids by volume ISO 3233 72 ± 3 %

Flash point ISO 3679 Method 1 25 °C

Density calculated 1.3 kg/l

VOC-US/Hong Kong US EPA method 24 (tested) 323 g/l

(CARB(SCM)2007, SCAQMD rule 1113, Hong Kong)

VOC-EU IED (2010/75/EU) (theoretical) 351 g/l

VOC-China GB/T 23985-2009 (tested) 348 g/l

The provided data is typical for factory produced products, subject to slight variation depending on colour.

Volume solids measured according to ISO 3233 and ASFP-BCF Guidance Method

Film thickness per coat

Typical recommended specification range

Dry film thickness 200 - 720 μm

Wet film thickness 280 - 1000 μm

Date of issue: 31 August 2020 Page: 1/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

SteelMaster 120SB

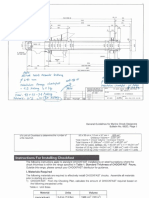

All steel sections must be coated with correct film thickness to achieve the required fire rating. Please refer to

the current loading tables. For further advice please contact your local Jotun office.

Note: The film thickness is only achievable by airless spray application in one coat.

Surface preparation

To secure lasting adhesion to the subsequent product all surfaces shall be clean, dry and free from any

contamination.

Refer to the Application Guide (AG) for additional information.

Surface preparation summary table

Surface preparation

Substrate Minimum Recommended

Coated surfaces Clean, dry and undamaged compatible Clean, dry and undamaged compatible

coating coating

Application

Application methods

The product can be applied by

Spray: Use airless spray.

Brush: Recommended for stripe coating and small areas, care must be taken to achieve the

specified dry film thickness.

Refer to the Application Guide (AG) for additional information.

Product mixing

Single pack

Thinner/Cleaning solvent

Do not add thinner. The product is ready to use and should not be thinned.

Cleaning solvent: Jotun Thinner No. 7

Guiding data for airless spray

Nozzle tip (inch/1000): 19-23

Pressure at nozzle (minimum): 200 bar/2900 psi

Date of issue: 31 August 2020 Page: 2/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

SteelMaster 120SB

Drying and Curing time

Substrate temperature 5 °C 10 °C 23 °C 40 °C

Surface (touch) dry 2h 1h 30 min 20 min

Dry to handle 48 h 24 h 16 h 8h

Dry to over coat, minimum 24 h 16 h 8h 6h

For maximum overcoating intervals, refer to the Application Guide (AG) for this product.

All drying times have been measured at a wet film thickness of 1000 μm under controlled temperature and

relative humidity below 85 %.

Topcoating

The minimum overcoating interval of this product with approved topcoats is 48 hours. The system should be dry

to handle and coating thickness gauge should not to leave an indentation on the coating. Drying

time/overcoating interval may be extended if there is a drop in temperature or if multi-coat system is applied.

Prior to application of topcoat, the applicator must ensure that the specified dry film thickness has been

achieved.

Surface (touch) dry: The state of drying when slight pressure with a finger does not leave an imprint or reveal

tackiness.

Dry to handle: Minimum time before the coated objects can be handled without physical damage.

Dry to over coat, minimum: The recommended shortest time before the next coat can be applied.

Product compatibility

Depending on the actual exposure of the coating system, various primers and topcoats can be used in

combination with this product. Some examples are shown below. Contact Jotun for specific system

recommendation.

Previous coat: alkyd, epoxy, epoxy zinc phosphate, zinc epoxy (with epoxy tie coat)

Subsequent coat: approved list of topcoats

To ensure fire performance, primers and topcoats must be compatible with:

SteelMaster 120SB

Contact your local Jotun office for a list of approved Jotun primers and topcoats.

Packaging (typical)

Volume Size of containers

(litres) (litres)

SteelMaster 120SB 20 20

The volume stated is for factory made colours. Note that local variants in pack size and filled volumes can vary

due to local regulations.

Storage

Date of issue: 31 August 2020 Page: 3/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

SteelMaster 120SB

The product must be stored in accordance with national regulations. Keep the containers in a dry, cool, well

ventilated space and away from sources of heat and ignition. Containers must be kept tightly closed. Handle

with care.

Shelf life at 23 °C

SteelMaster 120SB 18 month(s)

In some markets commercial shelf life can be dictated shorter by local legislation. The above is minimum shelf

life, thereafter the paint quality is subject to re-inspection.

Caution

This product is for professional use only. The applicators and operators shall be trained, experienced and have

the capability and equipment to mix/stir and apply the coatings correctly and according to Jotun's technical

documentation. Applicators and operators shall use appropriate personal protection equipment when using this

product. This guideline is given based on the current knowledge of the product. Any suggested deviation to suit

the site conditions shall be forwarded to the responsible Jotun representative for approval before commencing

the work.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do

not inhale spray mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable

cleanser, soap and water. Eyes should be well flushed with water and medical attention sought immediately.

Colour variation

When applicable, products primarily meant for use as primers or antifoulings may have slight colour variations

from batch to batch. Such products may fade and chalk when exposed to sunlight and weathering.

Colour and gloss retention on topcoats/finish coats may vary depending on type of colour, exposure

environment such as temperature, UV intensity etc., and application quality. Contact your local Jotun office for

further information.

Disclaimer

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are often

used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the product

itself. Minor product variations may be implemented in order to comply with local requirements. Jotun reserves

the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their needs

and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United Kingdom)

version will prevail.

Date of issue: 31 August 2020 Page: 4/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

You might also like

- Technical Data Sheet for Steelmaster 1200WF Fire Protection CoatingDocument4 pagesTechnical Data Sheet for Steelmaster 1200WF Fire Protection CoatingHarmandeep BhattiNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- TDS SteelMaster 1200WF GB English ProtectiveDocument5 pagesTDS SteelMaster 1200WF GB English Protective폴로 쥰 차No ratings yet

- TDS 36962 SteelMaster 600WF Euk GBDocument5 pagesTDS 36962 SteelMaster 600WF Euk GBRamesh RathinamNo ratings yet

- Steel Master 1200 WF PDSDocument5 pagesSteel Master 1200 WF PDSshameelNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Jotun Steelmaster 600WF - TDSDocument5 pagesJotun Steelmaster 600WF - TDSAmine ait talebNo ratings yet

- Barrier Smart Pack Jotun PaintDocument5 pagesBarrier Smart Pack Jotun PaintGurdeep Sungh AroraNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Technical Data Sheet for Penguard TopcoatDocument5 pagesTechnical Data Sheet for Penguard TopcoatajuhaseenNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- PFP Coating INformationDocument6 pagesPFP Coating INformationKhairul Rizal Zainal BadriNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Technical Data Sheet for Barrier 80 S Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 S Zinc Epoxy PrimerHung Mai VanNo ratings yet

- Galvanite: Technical Data SheetDocument4 pagesGalvanite: Technical Data SheetBiju_PottayilNo ratings yet

- Jota Floor Top Coat TDSDocument5 pagesJota Floor Top Coat TDSthar gyiNo ratings yet

- Jotafloor Top Coat PDFDocument5 pagesJotafloor Top Coat PDFJay Ram DhakalNo ratings yet

- Technical Data Sheet for Jotaprime 265Document4 pagesTechnical Data Sheet for Jotaprime 265Mudassar BhachranaNo ratings yet

- JotundatasheetsDocument172 pagesJotundatasheetsAli MudhafarNo ratings yet

- TDS 49082 AF Max Guard Euk GBDocument4 pagesTDS 49082 AF Max Guard Euk GBtebongedeNo ratings yet

- Technical Data Sheet for Barrier 80 Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 Zinc Epoxy PrimerBalaji GuruNo ratings yet

- Datasheet Penguard TopcoatDocument5 pagesDatasheet Penguard Topcoatabdulgafoor54No ratings yet

- Technical Data Sheet for Zinc Epoxy Barrier CoatingDocument5 pagesTechnical Data Sheet for Zinc Epoxy Barrier CoatingSanjay PatelNo ratings yet

- Barrier SmartpackDocument5 pagesBarrier SmartpackMhd EbalNo ratings yet

- TDS 641 Pioner Topcoat Euk GBDocument4 pagesTDS 641 Pioner Topcoat Euk GBchusnadiantyNo ratings yet

- TDS 11480 Pilot ACR Euk GBDocument5 pagesTDS 11480 Pilot ACR Euk GBeeng gilangNo ratings yet

- Technical Data Sheet for Protective CoatingDocument5 pagesTechnical Data Sheet for Protective CoatingBiju_PottayilNo ratings yet

- Hardtop CA PDFDocument5 pagesHardtop CA PDFBiju_PottayilNo ratings yet

- Jota TC Gloss Data SheetDocument4 pagesJota TC Gloss Data SheetMuhammad ArizNo ratings yet

- TDS Jotamastic 70 GB English ProtectiveDocument4 pagesTDS Jotamastic 70 GB English ProtectiveSatish VishnubhotlaNo ratings yet

- Quality Control CheckListDocument7 pagesQuality Control CheckListAlpha DekoNo ratings yet

- TDS 15520 Jotaguard 630 Euk GBDocument5 pagesTDS 15520 Jotaguard 630 Euk GBNilu RohmanNo ratings yet

- Marathon 1000 GF Technical Data SheetDocument5 pagesMarathon 1000 GF Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Conseal Touch-Up: Technical Data SheetDocument4 pagesConseal Touch-Up: Technical Data SheetSyilla ShopeNo ratings yet

- Penguard Tiecoat 100Document5 pagesPenguard Tiecoat 100Raja SNo ratings yet

- TDS 5340 Penguard HB II Euk GBDocument5 pagesTDS 5340 Penguard HB II Euk GBmybottle6996No ratings yet

- Hardtop XPL: Technical Data SheetDocument5 pagesHardtop XPL: Technical Data SheetRACHED ABBOUDNo ratings yet

- TDS 30682 Jotachar 1709 Euk GBDocument6 pagesTDS 30682 Jotachar 1709 Euk GBArya Kemal Pratama PutraNo ratings yet

- Alkyd Primer Technical Data SheetDocument5 pagesAlkyd Primer Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Alkyd Topcoat Technical Data Sheet Jotun PaintDocument4 pagesAlkyd Topcoat Technical Data Sheet Jotun PaintGurdeep Sungh Arora0% (1)

- Technical Data Sheet SummaryDocument5 pagesTechnical Data Sheet SummaryAndi BagusNo ratings yet

- Jotachar 1709 PDFDocument5 pagesJotachar 1709 PDFBiju_PottayilNo ratings yet

- Jotafloor Topcoat: Technical Data SheetDocument5 pagesJotafloor Topcoat: Technical Data SheetAgung Budi UtomoNo ratings yet

- TDS 765 Vinyguard Silvergrey 88 Euk GBDocument5 pagesTDS 765 Vinyguard Silvergrey 88 Euk GBlasse.hamre98No ratings yet

- Jotafloor Rapid DryDocument4 pagesJotafloor Rapid DryMazenNo ratings yet

- Tankguard HB Classic Jotun PaintDocument5 pagesTankguard HB Classic Jotun PaintGurdeep Sungh AroraNo ratings yet

- TDS 32766 Jotafloor Sealer HS Euk GBDocument5 pagesTDS 32766 Jotafloor Sealer HS Euk GBgazzali ..No ratings yet

- Jota Epoxy Filler For Crack RepairDocument5 pagesJota Epoxy Filler For Crack RepairAbdul samee MianNo ratings yet

- Tds - TDS 480 Jotafloor Coating Euk GBDocument5 pagesTds - TDS 480 Jotafloor Coating Euk GBmajidhajnasrNo ratings yet

- TDS Penguard HSP ZP GB English ProtectiveDocument5 pagesTDS Penguard HSP ZP GB English Protective폴로 쥰 차No ratings yet

- Technical Data Sheet for Epoxy Floor CoatingDocument5 pagesTechnical Data Sheet for Epoxy Floor CoatingWilliam SukyonoNo ratings yet

- TDS 16480 Hardtop AX Euk GBDocument5 pagesTDS 16480 Hardtop AX Euk GBsendyNo ratings yet

- Technical Data Sheet for Hardtop HB Polyurethane CoatingDocument5 pagesTechnical Data Sheet for Hardtop HB Polyurethane CoatingHassan OmerNo ratings yet

- TdsDocument4 pagesTdsSatish VishnubhotlaNo ratings yet

- Aluminium Paint HR Technical Data SheetDocument4 pagesAluminium Paint HR Technical Data SheetGurdeep Sungh AroraNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Post COVID 19 Opportunistic Candida Retinitis A.43Document3 pagesPost COVID 19 Opportunistic Candida Retinitis A.43kalstarNo ratings yet

- Ciaa 1597Document2 pagesCiaa 1597kalstarNo ratings yet

- Jurnal 14Document18 pagesJurnal 14kalstarNo ratings yet

- Risks and Features of Secondary Infections in Severe and Critical Ill COVID 19 PatientsDocument8 pagesRisks and Features of Secondary Infections in Severe and Critical Ill COVID 19 PatientsM ANo ratings yet

- Secondary Infections in Hospitalized COVID-19 Patients: Indian ExperienceDocument11 pagesSecondary Infections in Hospitalized COVID-19 Patients: Indian ExperiencedebarshidasguptaNo ratings yet

- Du 2020Document8 pagesDu 2020noniinnNo ratings yet

- Jurnal 8Document9 pagesJurnal 8kalstarNo ratings yet

- Jurnal 9Document10 pagesJurnal 9kalstarNo ratings yet

- Jurnal 6Document2 pagesJurnal 6kalstarNo ratings yet

- Jurnal 1Document3 pagesJurnal 1kalstarNo ratings yet

- Jurnal 5Document7 pagesJurnal 5kalstarNo ratings yet

- Jurnal 3Document8 pagesJurnal 3kalstarNo ratings yet

- Jurnal 4Document7 pagesJurnal 4kalstarNo ratings yet

- Jurnal 2Document11 pagesJurnal 2kalstarNo ratings yet

- Elevating and Its Significance To Business234Document3 pagesElevating and Its Significance To Business234kalstarNo ratings yet

- Raising and Its Significance To BusinessDocument3 pagesRaising and Its Significance To BusinesskalstarNo ratings yet

- Technical Data Sheet Application Guide SummaryDocument12 pagesTechnical Data Sheet Application Guide SummarykalstarNo ratings yet

- Representing Enthalpy Changes OtherDocument4 pagesRepresenting Enthalpy Changes OtherJennifer LohNo ratings yet

- Gears NBH FinalDocument75 pagesGears NBH FinalSaikat Bhowmick100% (1)

- (B) Van Der Waals Equation of StateDocument3 pages(B) Van Der Waals Equation of StateOmkar NathNo ratings yet

- 6036 Printing Blankets - Handling and MaintenanceDocument24 pages6036 Printing Blankets - Handling and MaintenanceM Aamir AsgharNo ratings yet

- Weston 399 TdsDocument3 pagesWeston 399 TdsFreddyPerazaNo ratings yet

- Taller Balance Sin RXN QCADocument4 pagesTaller Balance Sin RXN QCAValentina BaldovinosNo ratings yet

- One Pager TextileCoatings WB CrosslinkerDocument4 pagesOne Pager TextileCoatings WB CrosslinkerahmetNo ratings yet

- Jones, 1964Document6 pagesJones, 1964andrea.cipagautaNo ratings yet

- E1061 E1063 HW Installation EnglishDocument26 pagesE1061 E1063 HW Installation EnglishAxicelNo ratings yet

- All NDE ProcedureDocument35 pagesAll NDE ProcedureArun Karthikeyan100% (2)

- TiO2 NPs - Daun Jarak PagarDocument4 pagesTiO2 NPs - Daun Jarak PagarselviraNo ratings yet

- Glass Evidence CollectionDocument3 pagesGlass Evidence CollectionGeraldine DelacruzNo ratings yet

- Chockfast Stern TubeDocument2 pagesChockfast Stern Tubeakhmad harisNo ratings yet

- Chapter 1. Intro & Group PropertiesDocument111 pagesChapter 1. Intro & Group PropertiesJoylyn BaligodNo ratings yet

- Title: Relationship Between PH and Chemiluminescence of Luminol Author: Rolando Efraín Hernández RamírezDocument2 pagesTitle: Relationship Between PH and Chemiluminescence of Luminol Author: Rolando Efraín Hernández RamírezEfraínNo ratings yet

- New Testing ChargesDocument11 pagesNew Testing ChargesRay MrinalNo ratings yet

- Stabilization of Pavement Subgrade Soils Containing Rich Chloride SaltsDocument13 pagesStabilization of Pavement Subgrade Soils Containing Rich Chloride Saltskamrul_07No ratings yet

- BT-303 Lab ManualDocument21 pagesBT-303 Lab ManualZakaullah Akhtar50% (2)

- Botanical Rust Remover From Macopa Fruit Extracts and Vinegar - Chapter 1Document8 pagesBotanical Rust Remover From Macopa Fruit Extracts and Vinegar - Chapter 1Samuel VillajuanNo ratings yet

- National Science Talent Search Examination: SyllabusDocument4 pagesNational Science Talent Search Examination: SyllabusankitabindalNo ratings yet

- Characterization of Erythritol Tetranitrate. Part I: Physical PropertiesDocument5 pagesCharacterization of Erythritol Tetranitrate. Part I: Physical PropertiesBernard ShamNo ratings yet

- Kidney Function & Urine FormationDocument15 pagesKidney Function & Urine FormationGene PabayosNo ratings yet

- Full Download Test Bank For Organic Chemistry 11th Edition Francis Carey Robert Giuliano Janice Smith PDF Full ChapterDocument36 pagesFull Download Test Bank For Organic Chemistry 11th Edition Francis Carey Robert Giuliano Janice Smith PDF Full Chapterdumose.animose.h8wp100% (17)

- Lab Report 1Document24 pagesLab Report 1Jaymac100% (1)

- Periodic Table of ElementsDocument4 pagesPeriodic Table of ElementsAbidan Patrick (COOL DUDE PRO)No ratings yet

- CUSA SPEC FRP-001AA-11-11 Pipe FittingsDocument10 pagesCUSA SPEC FRP-001AA-11-11 Pipe FittingsAbbasNo ratings yet

- HD Smooth Geomembrane Technical Data SheetDocument1 pageHD Smooth Geomembrane Technical Data SheetAndreas Erdian WijayaNo ratings yet

- Wa0007Document13 pagesWa0007Amogh R.GowdaNo ratings yet

- Cement Structure & HydrationDocument12 pagesCement Structure & HydrationbookNo ratings yet

- Tricks & Formulas of Chemistry-I (NUST+NUMS) PDFDocument57 pagesTricks & Formulas of Chemistry-I (NUST+NUMS) PDFHamair Ali100% (1)