Professional Documents

Culture Documents

Metal Oxide Varistors: Electronics

Metal Oxide Varistors: Electronics

Uploaded by

Gonzales NavarroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Oxide Varistors: Electronics

Metal Oxide Varistors: Electronics

Uploaded by

Gonzales NavarroCopyright:

Available Formats

ELECTRONICS

Metal

Oxide

Varistors

10D Series

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information.

Metal Oxide Varistors - 10D Series

Features

1. Wide operating voltage (V1mA) range from 8V to 1800V.

2. Fast responding to transient over-voltage.

3. Large absorbing transient energy capability.

4. Low clamping ratio and no following-on current.

General Information

The MOV-10DxxxK Series of 10 mm radial leaded varistor devices protects against overvoltage transients such as lightning,

power contact and power induction. The metal oxide varistors offer a choice of varistor voltages from 18 V to 1800 V and Vrms

voltages from 11 V to 1000 V. The devices have a high current handling, high energy absorption capability and fast response

times to protect against transient faults up to rated limits.

General Characteristics

No Radioactive Material Storage Temperature: -55ºC to +125ºC

Operating Temperature: -55ºC to +85ºC

Body: Nickel Plated

Leads: Surface-mount, Axial Devices: Tin Plated

Devices with No Leads: Nickel Plated

Product Name

1 0 D 4 7 1 K

Disc Diameter Type Nominal Varistor Voltage Varistor Voltage

Tolerance

10=10MM D: Disk

471=47*101V K = 10 %

S: Square

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information. Page:1

Metal Oxide Varistors - 10D Series

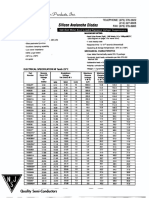

Electriacl Characteristics

Maximum Typical

Maximum Withstanding Maximum Energy Rated

Type Number Varistor Voltage Clamping Capacitance

Allowable Voltage Surge Current (10/1000μs) Power

Voltage (Reference)

Standard High Surge VAC(V) VDC(V) V1mA(V) IP(A) VC(V) I(A) I(A) (J) (J) (W) @1KHz(pf)

Standard High Surge Standard High Surge

10D180K 10D180KJ 11 14 18(15~21.6) 5 36 500 1000 2.1 3.0 0.05 5600

10D220K 10D220KJ 14 18 22(19.5~26) 5 43 500 1000 2.5 5.0 0.05 4500

10D270K 10D270KJ 17 22 27(24~30) 5 53 500 1000 3.0 6.0 0.05 3700

10K330K 10K330KJ 20 26 33(29.5~36.5) 5 66 500 1000 4.0 7.0 0.05 3000

10D390K 10D390KJ 25 31 39(35~43) 5 77 500 1000 4.6 9.0 0.05 2400

10D470K 10D470KJ 30 38 47(42~54) 5 93 500 1000 5.5 11.0 0.05 2100

10D560K 10D560KJ 35 45 56(50~62) 5 100 500 1000 7.0 13.0 0.05 1800

10D680K 10D680KJ 40 56 68(61~75) 5 135 500 1000 8.2 15.0 0.05 1500

10D820K 10D820KJ 50 65 82(74~90) 25 135 2500 3500 12.0 17.0 0.4 1200

10D101K 10D101KJ 60 85 100(90~110) 25 165 2500 3500 15.0 18.0 0.4 1000

10D121K 10D121KJ 75 100 120(108~132) 25 200 2500 3500 18.0 21.0 0.4 830

10D151K 10D151KJ 95 125 150(135~165) 25 250 2500 3500 22.0 25.0 0.4 670

10D181K 10D181KJ 115 150 180(162~198) 25 300 2500 3500 27.0 30.0 0.4 560

10D201K 10D201KJ 130 170 200(180~220) 25 340 2500 3500 30.0 35.0 0.4 500

10D221K 10D221KJ 140 180 220(198~242) 25 360 2500 3500 32.0 39.0 0.4 450

10D241K 10D241KJ 150 200 240(216~264) 25 395 2500 3500 35.0 42.0 0.4 420

10D271K 10D271KJ 175 225 270(243~297) 25 455 2500 3500 40.0 49.0 0.4 370

10D301K 10D301KJ 190 250 300(270~330) 25 500 2500 3500 40.0 54.0 0.4 330

10D331K 10D331KJ 210 275 330(297~363) 25 550 2500 3500 40.0 58.0 0.4 300

10D361K 10D361KJ 230 300 360(324~396) 25 595 2500 3500 43.0 65.0 0.4 280

10D391K 10D391KJ 250 320 390(351~429) 25 650 2500 3500 47.0 70.0 0.4 260

10D431K 10D431KJ 275 350 430(387~473) 25 710 2500 3500 60.0 80.0 0.4 230

10D471K 10D471KJ 300 385 470(423~517) 25 775 2500 3500 65.0 85.0 0.4 210

10D511K 10D511KJ 320 415 510(459~561) 25 845 2500 3500 70.0 90.0 0.4 200

10D561K 10D561KJ 350 460 560(504~616) 25 925 2500 3500 70.0 92.0 0.4 180

10D621K 10D621KJ 385 505 620(558~682) 25 1025 2500 3500 70.0 95.0 0.4 160

10D681K 10D681KJ 420 560 680(612~748) 25 1120 2500 3500 70.0 98.0 0.4 150

10D751K 10D751KJ 460 615 750(675~825) 25 1240 2500 3500 70.0 100.0 0.4 130

10D781K 10D781KJ 485 640 780(702~858) 25 1290 2500 3500 80.0 105.0 0.4 130

10D821K 10D821KJ 510 670 820(738~902) 25 1355 2500 3500 85.0 110.0 0.4 120

10D911K 10D911KJ 550 745 910(819~1001) 25 1500 2500 3500 93.0 130.0 0.4 110

10D102K 10D102KJ 625 825 1000(900~1100) 25 1650 2500 3500 102.0 140.0 0.4 100

10D112K 10D112KJ 680 895 1100(990~1210) 25 1815 2500 3500 115.0 155.0 0.4 90

10D182K 10D182KJ 1000 1465 1800(1620~1980) 25 2970 2500 3500 133.0 250.0 0.4 70

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information. Page:2

Metal Oxide Varistors - 10D Series

Electrical Rating

ltem Test Condition / Description Requirement

The voltage between two terminals with the specified measuring current 1mA.

Varistor Voltage

DC applied is call Vb.

Maximum Allowable

The recommended maximum sine wave voltage (RMS) or the maximum DC

Voltage

voltage can be applied continuously. To meet

the specified

value

The maximum average power that can be applied within the specified ambient

Rated Wattaget

temperature.

The maximum energy within the varistor voltage change of ±10% when one impulse

IEnergy

of10/1000μsec. or 2 msec. is applied.

Withstanding Surge

The maximum current within the varistor voltage change of ±10% with the standard

Current

impulse current (8/20μsec.) applied one time.

The change of Vb shall be measured after the impulse listed below is applied 10,000

times continuously with the interval of ten seconds at room temperature.

180K to 680K 10A (8/20μsec.)

5D series

820K to 751K 20A (8/20μsec.)

180K to 680K 25A (8/20μsec.)

7Dseries Vb

<+10%

_

820K to 821K 50A (8/20μsec.) Vb

Surge Life

180K to 680K 50A (8/20μsec.)

10D series

820K to 182K 100A (8/20μsec.)

180K to 680K 75A (8/20μsec.)

14D series

820K to 182K 150A (8/20μsec.)

180K to 680K 100A (8/20μsec.)

20D series

820K to 182K 200A (8/20μsec.)

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information. Page:3

Metal Oxide Varistors - 10D Series

Current Energy and Power Dissipation Ratings

Should transients occur in rapid succession, the average power dissipation is the energy (watt-seconds) per pulse times

the number of pulses per second. The power so developed must be within the specifications shown on the Device Ratings

and Specifications Table for the specific device. The operating values of a MOV need to be derated at high temperatures as

shown above. Because varistors only dissipate a relatively small amount of average power they are not suitable for repetitive

applications that involve substantial amounts of average power dissipation.

Figure 1A - Power Derating for Epoxy Coated Figure 1B - Power Derating for Pholenic Coated

100 100

90 90

PERCENT OF RATED VALUE

PERCENT OF RATED VALUE

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

0 0

-55 50 60 70 80 90 100 110 120 130 140 150 -55 50 60 70 80 90 100 110 120 130 140 150

AMBIENT TEMPERATURE ( o C) AMBIENT TEMPERATURE ( o C)

Peak Pulse Current Test Waveform

PERCENT OF PEAK VALUE

100

90 01

T1

50

T2

Example µs Current Waveform:

8µ 1

10 20µ 2

O1 T TIME

Figure 2 T1

T2

Packaging

Component Packaging

Part Number Quantity Packaging Specification

Package Option

10D 10.0 500 BOX 1000

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information. Page:4

Metal Oxide Varistors - 10D Series

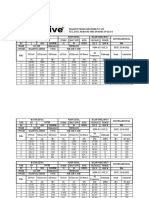

Package Dimensions

Unit:mm

H1

K<3.0 K<3.0

d1 d

L1

D1 D1

TABLE 1 TABLE 2

Symbol Dimensions Model T(max.) Model T(max.)

H(max.) 12.0 180K 4.5 221K 4.5

H1(max.) 13.5 220K 4.6 241K 4.6

L(min.) 20.0 270K 4.7 271K 4.9

L1(min.) 15.0 330K 4.9 301K 5.0

D(max.) 9.0 390K 4.8 331K 5.1

D1(±0.8) 5.0 470K 4.9 361K 5.2

T(max.) TABLE 2 560K 5.0 391K 5.4

d(±0.05) 0.6 680K 5.2 431K 5.7

d1(±0.4) 1.2 820K 4.1 471K 6.0

101K 4.3 511K 6.2

121K 4.5 561K 6.5

151K 4.8 621K 6.4

181K 4.3 681K 6.5

201K 4.4 751K 6.5

Warehouse Storage Conditions of Products

· Storage Conditions:

1. Storage Temperature: -10°C~+40°C

2. Relative Humidity:≤75%RH

3. Keep away from corrosive atmosphere and sunlight.

· Period of Storage: 1 year

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information. Page:5

RuiLongYuan Electronics Co., Ltd.

· Reproducing and modifying information of the document is prohibited without permission from

Ruilongyuan International Inc.

· Ruilongyuan International Inc. reserves the rights to make changes of the content herein the document anytime

without notification. Please refer to our website for the latest document.

· Ruilongyuan International Inc. disclaims any and all liability arising out of the application or use of any product

including damages incidentally and consequentially occurred.

· Ruilongyuan International Inc. does not assume any and all implied warranties, including warranties of fitness

for particular purpose, non-infringement and merchantability.

· Applications shown on the herein document are examples of standard use and operation. Customers are responsible

in comprehending the suitable use in particular applications.Ruilongyuan International Inc. makes no representation or

warranty that such applications will be suitable for the specifed use without further testing or modifcation.

· The products shown herein are not designed and authorized for equipments requiring high level of reliability or relating to

human life and for any applications concerning life-saving or life-sustaining, such as medical instruments, transportation

equipment,aerospace machinery et cetera. Customers using or selling these products for use in such applications do so at

their own risk and agree to fullyindemnify Ruilongyuan International Inc. for any damages resulting from such improper use or

sale.

Tel: +86-755-8290 8296 Fax: +86-755-8290 8002 E-mail: jack@ruilon.com

Circuit Protection Specifications are subject to change without notice.

System Please refer to http://www.ruilon.com for current information. Page:6

You might also like

- Simple Diy Induction CircuitDocument13 pagesSimple Diy Induction CircuitSalim BlognetNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Hamilton Sundsrand AC Gen 24-20-77Document182 pagesHamilton Sundsrand AC Gen 24-20-77David ObiNo ratings yet

- Volvo-Wiring Diagram FL6 PDFDocument144 pagesVolvo-Wiring Diagram FL6 PDFAnonymous OrZIZ1Bpg93% (14)

- Interview Questions For Eee StudentsDocument11 pagesInterview Questions For Eee StudentsAli ZafarNo ratings yet

- Easy 3000 Installation ManualDocument52 pagesEasy 3000 Installation ManualHalit Yalçınkaya100% (1)

- 132 KV Industrial Grid Station GridReportDocument22 pages132 KV Industrial Grid Station GridReportMuhammad Noman AslamNo ratings yet

- Metal Oxide Varistors: ElectronicsDocument7 pagesMetal Oxide Varistors: ElectronicsquangNo ratings yet

- Radial Lead Varistor (MOV) : 10D Series 14D SeriesDocument4 pagesRadial Lead Varistor (MOV) : 10D Series 14D SeriesHenrique M de PaulaNo ratings yet

- Datasheet Varistor DetalhadoDocument6 pagesDatasheet Varistor Detalhadorafael penaNo ratings yet

- Mengenal Komponen Elektronik - VaristorDocument4 pagesMengenal Komponen Elektronik - Varistorsyaiful imronNo ratings yet

- Datasheet 2Document2 pagesDatasheet 2Dung TranNo ratings yet

- 14D180L HitanoDocument2 pages14D180L Hitanoromulao2010No ratings yet

- 07D271K PDFDocument3 pages07D271K PDFLordvir GrijalvNo ratings yet

- 14Φ Series Metal Oxide Varistor (MOV) Data Sheet: FeaturesDocument7 pages14Φ Series Metal Oxide Varistor (MOV) Data Sheet: FeaturesVladimir MartynovNo ratings yet

- 14Φ Series Metal Oxide Varistor (MOV) Data Sheet: FeaturesDocument12 pages14Φ Series Metal Oxide Varistor (MOV) Data Sheet: Featuresirensy vivasNo ratings yet

- Radial Lead Varistor (MOV) : 10 - D - XXX - K - X - X - XDocument6 pagesRadial Lead Varistor (MOV) : 10 - D - XXX - K - X - X - XYCCA 2015No ratings yet

- Varistores Uxell DatasheetDocument4 pagesVaristores Uxell DatasheetJorge Adalberto Lugo QuinteroNo ratings yet

- Metal Oxide Varistors: ElectronicsDocument5 pagesMetal Oxide Varistors: ElectronicscarlosgnNo ratings yet

- Varistores+VDR MOV-Catálogo+parcial PDFDocument1 pageVaristores+VDR MOV-Catálogo+parcial PDFBaltazar VargasNo ratings yet

- Metal Oxide Varistors Datasheet PDFDocument1 pageMetal Oxide Varistors Datasheet PDFHernàn NùñezNo ratings yet

- VARISTOR - Metal Oxide Varistors Datasheet PDFDocument1 pageVARISTOR - Metal Oxide Varistors Datasheet PDF4685752No ratings yet

- C5BB09 20mm Disc VaristorDocument1 pageC5BB09 20mm Disc VaristorIgor PNo ratings yet

- Datasheet 10D471K Varistor Maq de Lavar PDFDocument11 pagesDatasheet 10D471K Varistor Maq de Lavar PDFRenato MartinsNo ratings yet

- 20ø JVR VARISTORDocument2 pages20ø JVR VARISTORzoranNo ratings yet

- Varistors Data SheetDocument11 pagesVaristors Data SheetEdilsonMatiasdeCastroNo ratings yet

- DokumentacjaDocument6 pagesDokumentacjaPiotr SzaryNo ratings yet

- LG FA-3000AWE Service Manual AudioDocument22 pagesLG FA-3000AWE Service Manual Audioafsl01No ratings yet

- RM84 / RM85 / RM87: Miniature Electromagnetic RelaysDocument2 pagesRM84 / RM85 / RM87: Miniature Electromagnetic RelaysErasmo Franco SNo ratings yet

- Surface Mount Multilayer Varistor: SC0805ML - SC2220ML SeriesDocument8 pagesSurface Mount Multilayer Varistor: SC0805ML - SC2220ML SeriesTalebNo ratings yet

- C5BB10 20mm High Surge Disc VaristorDocument1 pageC5BB10 20mm High Surge Disc VaristorIgor PNo ratings yet

- Varistor S14Document24 pagesVaristor S14digaocaixetaNo ratings yet

- JFR Ratings Available PDFDocument1 pageJFR Ratings Available PDFMarcosNo ratings yet

- Myg 05K180 EtcDocument4 pagesMyg 05K180 EtcArmando HernandezNo ratings yet

- Varistor Data SheetDocument11 pagesVaristor Data SheetesetengenhariaNo ratings yet

- Film/Foil Radial Leaded High Frequency Precise ValuesDocument3 pagesFilm/Foil Radial Leaded High Frequency Precise Valuesgrasia77No ratings yet

- MYG Varistors Data SheetDocument4 pagesMYG Varistors Data SheetPedro Giménez100% (1)

- Impedance MeasurementsDocument11 pagesImpedance Measurementsaseel rayan100% (1)

- Ieee 9 PDFDocument3 pagesIeee 9 PDFBhavik PrajapatiNo ratings yet

- Varistor 2Document3 pagesVaristor 2dkelicNo ratings yet

- Control Transformers: Technical DataDocument2 pagesControl Transformers: Technical DataEngineerOmarNo ratings yet

- HRL12500W Feb 2006 PDFDocument2 pagesHRL12500W Feb 2006 PDFenzoNo ratings yet

- Datasheet: Proven ReliabilityDocument9 pagesDatasheet: Proven ReliabilitybansalrNo ratings yet

- 50 Watt Zener Diode: F A M - RDocument2 pages50 Watt Zener Diode: F A M - RLuís GuerreiroNo ratings yet

- Inverter Grade Screw TerminalDocument4 pagesInverter Grade Screw TerminalPower System StabilityNo ratings yet

- Johnson Motor Stock Products PDFDocument60 pagesJohnson Motor Stock Products PDFJhon Jeiwer SantosNo ratings yet

- Si23 Solar Pump Inverter ManualDocument7 pagesSi23 Solar Pump Inverter ManualEduardo ZuletaNo ratings yet

- Macmasterpricelist PDFDocument2 pagesMacmasterpricelist PDFRad CowNo ratings yet

- Ma Emf Mag1000 MT101-KFL-VN180907-2018.09.07Document24 pagesMa Emf Mag1000 MT101-KFL-VN180907-2018.09.07NO BOTHERNo ratings yet

- Lab - Elea1 Practicas1.5 ImprimirDocument10 pagesLab - Elea1 Practicas1.5 ImprimirRamon Eduardo Sanchez ZapataNo ratings yet

- NIC Components NSPE-H SeriesDocument3 pagesNIC Components NSPE-H SeriesNICCompNo ratings yet

- Water Flow SwitchDocument2 pagesWater Flow SwitchraviNo ratings yet

- Specifications (018-001) : WarningDocument6 pagesSpecifications (018-001) : WarningRómulo Simón Lizarraga LeónNo ratings yet

- 1N56 Series: Silicon Avalanche DiodesDocument2 pages1N56 Series: Silicon Avalanche DiodesabolfazlNo ratings yet

- DQW Quarter Turn Electric ActuatorDocument23 pagesDQW Quarter Turn Electric ActuatorBUDI SETIAWANNo ratings yet

- 7 Transformer Protection DevicesDocument16 pages7 Transformer Protection Devicesyalewlet tarekeggnNo ratings yet

- DP1 Panasonic Electrolytic CapacitorDocument1 pageDP1 Panasonic Electrolytic Capacitorexia0012No ratings yet

- Opzv Series /24 Opzv 3000 2V3000Ah: Advantages ApplicationDocument2 pagesOpzv Series /24 Opzv 3000 2V3000Ah: Advantages Applicationdiecm83No ratings yet

- Stage Shut Off MFG: FrequencyDocument2 pagesStage Shut Off MFG: FrequencyTanmayShrivastavaNo ratings yet

- MOV14D471K VaristorDocument4 pagesMOV14D471K VaristorRuben NinaNo ratings yet

- CSB TPL 121800Document2 pagesCSB TPL 121800Lê Hữu ÁiNo ratings yet

- Ateco - Kendeil k01 TypeDocument7 pagesAteco - Kendeil k01 TypeYESSYKA HERVIANANo ratings yet

- Cone Crusher BrochureDocument2 pagesCone Crusher BrochuretomasNo ratings yet

- Tabla de Impedancia Cables Media TensionDocument7 pagesTabla de Impedancia Cables Media Tensionvcontrerasj72No ratings yet

- Acon (Radial Thru-Hole) GFE SeriesDocument2 pagesAcon (Radial Thru-Hole) GFE Seriesxyz99No ratings yet

- Transmisor Version ModernaDocument2 pagesTransmisor Version ModernaWilder GomezNo ratings yet

- Presentasi Raytech wr50Document31 pagesPresentasi Raytech wr50yori arifNo ratings yet

- Earthing For Telephone ExchangeDocument18 pagesEarthing For Telephone Exchangesanjay1009No ratings yet

- Z-Source Inverter For Grid-ConnectedDocument5 pagesZ-Source Inverter For Grid-ConnectedAsad HameedNo ratings yet

- MFJ-969 Versa Tuner II Instruction Manual: General InformationDocument10 pagesMFJ-969 Versa Tuner II Instruction Manual: General InformationsoapytitwankNo ratings yet

- Switch Machines m23Document2 pagesSwitch Machines m23Salvatore JimenoNo ratings yet

- Price List PDFDocument28 pagesPrice List PDFSudhir SinhaNo ratings yet

- CCEC-Lec08-Electrical Works-Ch 17Document13 pagesCCEC-Lec08-Electrical Works-Ch 17Muhammad AbubakerNo ratings yet

- GRMP 2Document18 pagesGRMP 2dhinakaranNo ratings yet

- QN3107M6N: General Description Product SummaryDocument5 pagesQN3107M6N: General Description Product SummarylalukurniawanNo ratings yet

- Capacitor Contactors: DescriptionDocument10 pagesCapacitor Contactors: DescriptionAngela PolotaicoNo ratings yet

- A Safety-First Priority: Manual Motor Controllers and DisconnectsDocument12 pagesA Safety-First Priority: Manual Motor Controllers and DisconnectstejoNo ratings yet

- OX 110 5 EnglishDocument6 pagesOX 110 5 Englishghosia electromedicalNo ratings yet

- DMOS Transistors (P-Channel) : FeaturesDocument5 pagesDMOS Transistors (P-Channel) : FeaturesNoam AyaouNo ratings yet

- AC-DC & DC-DC Converters For DC Motor Drives PDFDocument8 pagesAC-DC & DC-DC Converters For DC Motor Drives PDFaswardiNo ratings yet

- Altronics DISN800C IOM 11-1997 PDFDocument18 pagesAltronics DISN800C IOM 11-1997 PDFSMc67% (3)

- IEC Numeros Normas NuevosDocument9 pagesIEC Numeros Normas NuevoszerferuzNo ratings yet

- Ac 6500-UkDocument4 pagesAc 6500-UkyongNo ratings yet

- E1-42 Pin AssignmentDocument3 pagesE1-42 Pin AssignmentAhmed Jamal KhanNo ratings yet

- Data Shet IC Rectifire Bridge Vishay General Semiconductor Kbl005Document4 pagesData Shet IC Rectifire Bridge Vishay General Semiconductor Kbl005Putra JambakNo ratings yet

- Analog Electronics - Final Assignment - American International University BangladdeshDocument5 pagesAnalog Electronics - Final Assignment - American International University BangladdeshSHAHRIAR SHOVANNo ratings yet

- 04 Battery-Level IndicatorDocument3 pages04 Battery-Level IndicatorsumathiloganathanNo ratings yet

- Siemens Power Engineering Guide 7E 92Document1 pageSiemens Power Engineering Guide 7E 92mydearteacherNo ratings yet

- Ficha Tecnica Cable Solar Multicontac Staubli FLEX-SOL-EVO-MCDocument2 pagesFicha Tecnica Cable Solar Multicontac Staubli FLEX-SOL-EVO-MCLuis OrtizNo ratings yet