Professional Documents

Culture Documents

Paper Full

Uploaded by

Shashikanth MohrirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper Full

Uploaded by

Shashikanth MohrirCopyright:

Available Formats

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

PERFORMANCE AND EMISSION

CHARACTERISTICS OF CI DI ENGINE USING

BLENDS OF BIODIESEL (WASTE COOKING OIL)

AND DIESEL FUEL

Rajesh S Gurani1 and B.R.Hosamani2

1 PG Student, Thermal Power Engineering, Department of Mechanical Engineering, B.L.D.E.A’s PGHCET

VIJAYAPUR 586103, Karnataka. India

2 Associate professor, Department of Mechanical Engineering, B.L.D.E.A’s PGHCET VIJAYAPUR 586103,

Karnataka. India

Abstract— the conventional fossil fuels for internal with diesel fuel. The Properties of waste cooked

combustion engines will be available for few years biodiesel are determined and found that its properties

only, due to tremendous increase in the vehicular are nearer to diesel fuel.

population. Moreover, these fuel cause serious

Key words: Biodiesel, Waste cooking oil, CI engine

environmental problems by emitting harmful gases

into the atmosphere at higher rates. Commonly

pollutants released by engines are CO, Unburnt I. Introduction

hydrocarbon, NOx, smoke and limited amount of

Fossil fuels consumption throughout the world is

particulate matter. At present, alternative fuels like

increasing day by day because of increase in number

methyl ester of vegetable oil, alcohols etc. are in the

of automobiles and industries in recent years. With

line of replace the fossil fuels for IC engines. In the

the alarming increase in consumption and increasing

present study and experimental investigation was

prices of fossil fuel has made the researchers to find

carried out with waste cooked oil as an alternative

the alternate fuels which are economical, renewable

fuel in a compression ignition (CI) engine. The

and environmental friendly. Because of increase in

problem associated with vegetable oil are high

consumption of fossil fuels at faster rate, crude oil

viscosity , lowered volatility and high reactivity, but

reserves may be available only for another 3 to 4

at the same time their higher cetane no, lower sulphur

decades. Therefore the scientist and researchers are

content , high oxygen concentration are the desirable

finding an alternate solution to find renewable energy

properties to use as fuel in compression ignition

which can be readily stored and used in automobiles.

engines. The process of transesterification of

The depletion of crude oil would cause a major

vegetables oil with methyl alcohol provides a

impact on the transportation sector. There are various

significant reduction in viscosity, thereby enhancing

sources of energy which may be used in automobiles;

the physical properties of vegetable oil. The present

they are electrical energy, solar energy, fuel cells etc.

paper reports a study carried to investigate the

But this energy are not easy to store on the

combustion, performance and emission

automobiles, most of the time the batteries are to be

characteristics of waste cooked oil methyl ester with

carried on the automobiles that makes again increase

diesel fuel on a single cylinder, four stroke, direct

in weight of automobiles. And some additional

injection and water cooled diesel engine. The study

energy is used in carrying the extra weight. At the

gives the comparative measures of BSFC, BSEC,

same time the emissions from fossil fuel engines are

BTE, Mechanical efficiency, EGT, A/F ratios,

high and harmful to the living things on earth. By

volumetric efficiency, CO, CO2, HC, and NOx &

using the alternate fuels the emissions can be reduced

smoke opacity. Biodiesel can be blended at any ratio

to some extent. These bio fuels may be biodiesel,

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 1

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

biogas, alcohols etc. The various alternate fuels catalyst mixture is poured into the Waste cooking oil

under consideration, biodiesel, derived from .The mixture is heated and mixed. Meanwhile the

vegetable oils, are the most promising alternative fuel temperature and the mixing speed of the Waste

to diesel due to the following reasons. cooking oil, alcohol and catalyst mixture was kept

constant (60 °C and 1250 rpm) during the

1. Biodiesel can be used in the existing engine esterification. When the transesterification is finished

without or with minimum modifications. the mixture is taken to a tank to be settled. After the

2. Biodiesel is made entirely from vegetable sources; settlement of the biodiesel and the glycerin, the

it does not contain any sulfur, aromatic biodiesel washed for 12 hr with pure water to remove

hydrocarbons, metals or crude oil residues alcohol and catalyst residue. When the washing

3. Biodiesels are oxygenated fuel; emissions of process is completed, it must be waited until

carbon monoxide and soot tend to reduce. biodiesel and water were separated into two different

4. Unlike fossil fuels, the use of biodiesel does not phases. Then the water is drained. To eliminate the

contribute to global warming as CO2 emitted is once water in the biodiesel which remains during washing,

again absorbed by the plants grown for vegetable oil it is to be dried by heating it up to 100 0 C for half an

/biodiesel production. Thus CO2 is maintained. hour. The water in the biodiesel was evaporated

5. The occupational safety and health administration during the drying process. Table shows the biodiesel

classifies biodiesel as a non-flammable liquid. properties.

6. The use of biodiesel can extend the life of diesel

engines because it is more lubricating than petroleum

diesel fuel.

7. Biodiesel is produced from renewable vegetable

oils/animal fats and hence improves the fuel or

energy security and economic independence.

II. Objectives

In this paper importance of injection pressure on a

performance & other emission characteristics of CI

engine are studied. However the objectives are

summarized as follow.

Investigating the properties of the bio-diesel as well

Fig.a shows solving of catalyst mixture in oil (600C

as combinations of bio-diesel with diesel.

Experimental investigation of the performance on 1250rpm)

single cylinder four stroke CI engine using WCOME

bio-diesel & its blends.

Smoke & various emissions are measured by the use

of smoke meter & AVL gas analyzer.

Evaluating the optimized performance variables for

the max efficiency & min pollution.

III. Biodiesel extraction

Waste cooking oil is selected for producing biodiesel.

The biodiesel production method is shown in Fig,

where 5.5 Grams potassium hydroxide (KOH) and

100ml Methanol (CH3OH) were used for

esterification of 250ml of Waste cooking oil. The

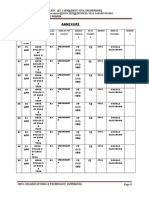

catalyst is dissolved in the alcohol then the alcohol Table shows the biodiesel properties with diesel.

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 2

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

IV. Experimental setup and methodology pressure, cylinder pressure. With these recorded data

the pressure crank angle diagram can be drawn, to

know the variation of pressure with change in crank

angle.

The eddy current dynamometer is mounted

on base frame & interfaced with engine. The load on

the engine is varied with the help of dynamometer.

A pipe in pipe type calorimeter is fitted on the

exhaust gas outlet line of the engine. The calorimeter

cooling water flow is measured & adjusted by the

rotameter. Temp sensors are fitted at the inlet &

outlet of the calorimeter for temp measurement. The

pump is provided for supplying water to eddy current

dynamometer, engine cooling & calorimeter. The

water is to be supplied continuously to the engine, to

cool the sensors. There are two fuel tanks fitted on to

the engine set up, one is for bio-diesel & another is

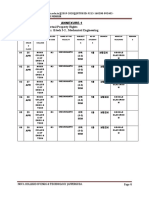

Fig. 1. Line diagram of experimental Setup for diesel fuel, to supply the fuel to the engine.

Engine is fitted with number of sensors to measure

Make : Kirloskar Engine the different parameters to find the performance of

engine. Engine is also fitted with a two way control

Bore & stroke : 87.5mm x110mm

valve to supply the fuel. An air box is powered for

Type of cooling : Water cooled damping pulsation in airflow line. An orifice meter

Speed : 1500 rpm with manometer is fitted at the inlet of air box

for air flow measurement. Piezo-electric type sensor

Compression ratio : 17.5.1 with water cooled adapter is fitted in cylinder head

Number of cylinder : 1 for combustion pressure measurement. This sensor

is connected to an engine indicator fitted in

Rated power : 5.2 kW control panel, which scans the pressure & crank-

Start of injection : 23˚ bTDC angle data is interfaced with computer through COM

port. The sensor is mounted on dynamometer

Injection pressure : 205 bar shaft & connected to engine indicator.

Table 1.1 Engine specifications Thermocouples are fitted on to the engine to measure

the temp of cooling water inlet, outlet & exhaust

The experiments are carried out on single cylinder, temps. These temps are digitally indicated on

4-stroke Kirloskar CI engine. The schematic indicator situated on control panel. Opacity meter to

experimental setup is shown in fig. 1. Engine is measure diesel smoke is used. The exhaust gas

interfaced with computer for measuring the different analyzer is used to measure the relative volumes of

parameters. Engine soft software is used in computer gaseous constituents in the exhaust gases of the

to carry out the measurements. Its other physical engine. The computer is interfaced with engine. The

dimensions are bore 87.5 mm & stroke 110 mm, PCI 1050 IC card is connected to COM port of CPU.

compression ratio of 17.5, & constant injection Engine soft is the software used to control the

pressure of 200bar at 230 BTDC injection time. The entire engine readings. It is lab view based

engine is coupled with an eddy current software. The engine is evaluated at rated speed of

dynamometer, & AVL 444 make (5-gas analyzer) 1500 rpm its power range by the use of WC0, WC20,

exhaust gas analyzer & AVL-437 smoke meter are WC40, WCJ60, WCJ80 & WC100 & diesel blends

used to measure the emissions & smoke density. The & also with pure diesel.

engine is fitted with sensors to measure the injection Experiments are conducted on the engine at different

loads from 0 kg to rated load i,e 18.3 kg at an

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 3

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

interval load of 2.5kg. Blends WC0, WC20, WC40, content of bio-diesel (WCOME) fuel. Because of the

WC60, WC80 & WC100 are tested for 23˚BTDC & less heating value of bio-diesel (WCOME) fuel,

at an injection pressure of 190, 205 & 220 bar more bio-diesel fuel is to be supplied to get the same

(advanced, normal & retarded) respectively. power output as that of pure diesel fuel. BSFC of

WC20 blend is nearer to that of diesel fuel, where as

V. Results and discussions that of B0 has the lowest BSFC. BSFC of all other

blends are in between the pure diesel & pure bio-

The performance of CI DI engine using the bio-diesel diesel (WCOME) fuel. The variation of BTE for

namely WCOME bio-diesel with diesel blends & different bio-diesel blends with diesel are (WC0,

pure diesel are studied at different loads & at WC20, WC40, WC60, WC80 & WC100) presented

different injection pressure. The performance & here as 3.57%, 8.09%, 12.34%, 14.27% & 17.76%

emissions of different blends & for pure diesel is respectively.

works on different loads & compared the results of

various blends of bio-diesel & diesel with pure diesel 1.1.2. BTE for WCOME blends at 190bar:

fuel.

1. a. Performance characteristics:

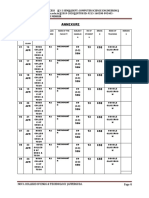

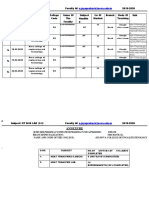

1.1.1 BSFC for WCOME blends at 190bar:

Fig 1.1.2 variation of the BTE with BP for diesel &

WCOME blends at 190bar.

Fig 1.1.1 variation of the BSFC with BP for diesel & The variations of BTE with change in BP at 190 bar

WCOME blends at 190bar injection pressure are presented in fig.1.1.2. As the

BP increases the BTE increases, this is the

characteristic of diesel engines. The BTE for the

The variation of BSFC with change in BP at the 190 bio-diesel (WCOME) & diesel blends are

bar injection pressure is presented for all the bio- comparable with pure diesel.

diesel & diesel blends are & also for pure diesel are

presented in fig.1.1.1. It has seen from fig. that as the BTE of diesel is seen to highest compared with other

BP increases the BSFC decreases. The BSFC for all blends. More BTE in case of diesel fuel may be

the bio-diesel (WCOME) & diesel blends are because of high heating value of diesel fuel. BTE of

comparable with that of pure diesel fuel. It can be WC20 is nearer to that of pure diesel, this may be

seen from fig. that as the volume % of bio-diesel because of the O2 present in the bio-diesel may take

(WCOME) in the blends increases the BSFC part in complete combustion of WC20 blend this

increases. This may be because of the less energy may produce the same ηth as that of pure diesel. BTE

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 4

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

of pure bio-diesel (WCOME) is the least. BTE of observed, Compared to B0, the EGT increases for

other bio-diesel (WCOME) & diesel blends in B20 by 1.36% and reduces for B100 and B40 by

between the pure diesel & pure bio-diesel 1.19% and 0.92% respectively.

(WCOME). The BTE is found to be high for pure

diesel fuel which is 27.53%. The BTE for 100% bio- 1.2. b. Emission Characteristics

diesel blends is the least. The % variation of BTE for

different blends are as presented here, for WC100, 1.2.1 CO for blends of WCOME at 190bar:

WC80, WC60,WC40 & WC20 is reduced by 8.86%,

6.83%, 6.68%, 4.10% & 1.38% respectively

comparing that of diesel.

1.1.3. EGT for WCOME blends at 190bar:

Fig 1.2.1 variation of the CO with BP for diesel &

WCOME blends at 190bar.

The variation of CO emission with change in BP at

190 bar injection pressure is presented in fig. 1.2.1. It

is seen from fig. that the emission of CO at less loads

for all the blends of bio-diesel (WCOME) & diesel

Fig 1.1.3 variation of the EGT with BP for diesel & blends & also for pure diesel are less. The emission

WCOME blends at 190bar. of CO for all the bio-diesel (WCOME) & diesel

blends are less comparing that of pure diesel at less

The effect of brake power on exhaust gas temperature loads. This may be because of the presence of O2 in

at 190bar injection pressure for diesel and biodiesel the molecular structure of bio-diesel. The presence of

(S75+J25) blends are shown in fig 1.1.3. EGT for all O2 in the blends converts CO to carbon dioxide.

the diesel and biodiesel (S75+J25) blends are more in Hence the emission of CO is less than that of diesel.

comparison with diesel. The more EGT may because At 4.2 kW power output the emission of CO is less

of delayed combustion of biodiesel (S75+J25) and for WC20 & WC40 blends comparing that of diesel

diesel blends due higher viscosity of biodiesel where As for other blends namely WC60, WC80 &

(S75+J25) blends, that forms larger droplet size, take WC100 blends are emitting more CO comparing that

more time to evaporate and burn due this region the of pure diesel fuel. This increase in CO emission

EGT is more i.e., higher for biodiesel (S75+J25) may be because of the increased blend % of bio-

blends which is differ from diesel. Higher EGT diesel increases the viscosity of blends. The

shows that the indication of converting heat energy increased viscosity will form the larger atom size of

into mechanical energy is less. More of the heat is fuel particles when injected; it takes more time for

going waste in the form of exhaust. The increase of evaporation & formation of mixture. This may

exhaust temperature for diesel and pure biodiesel is increase the ignition delay & hence the combustion

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 5

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

duration hence CO emission increases. After 4.8 kW 1.2.3 Nitrogen oxides (NOx) for WCOME blends

power output the CO emission increases for all the for 190bar:

bio-diesel (WCOME) & diesel blends comparing that

of diesel. This may be because of high viscosity of The variation of emission of oxides of nitrogen with

bio-diesel (WCOME) & diesel blends & also change in power output at 190 bar injection pressure

because of the less injection pressure. is presented in fig.1.2.3. It is seen from fig. that the

emission of oxides of nitrogen for all the bio-diesel

1.2.2 Hydro carbons for WCOME blends for (WCOME) & diesel blends are less comparing pure

190bar: diesel fuel. This may be because of the less

combustion temp of bio-diesel (WCOME) & diesel

blends because of less energy content of bio-diesel

fuel. The less nitrogen oxides may be also because of

the absence of aromatics in the bio-diesel fuel. The

aromatics are main content of fuel causes the

nitrogen oxide emissions. Emission of oxides of

nitrogen for all the bio-diesel & diesel blends is high

than that of diesel fuel. This may be because of the

delayed combustion of bio-diesel & diesel blends

may have less combustion temp. The increase in

NOx comparing diesel & for blends WC20 & WC40

by is increased by 3.62% & 3.08%.

Fig 1.2.2 shows the variation of BP on hydro

carbon (HC) for diesel & WCOME blend at

190bar injection pressure.

The variation of emission of unburned hydrocarbon

with the change in BP at 190 bar injection pressure is

presented in fig.1.2.2. It is seen from fig. that the

emission of hydrocarbon for bio-diesel (WCOME) &

diesel blends are less comparing that of diesel. The

emission of UBHC for WC100 is more than that of

diesel up to 4.2 kW power output or 15 kg. Load.

This may be due incomplete combustion of bio-diesel

fuel because of high viscosity bio-diesel fuel

comparing that of diesel. High viscosity of bio-diesel

fuel forms the larger atoms of fuel during injection Fig 1.2.3 shows the variation of BP on Nitrogen

which takes longer time for evaporation & mixture oxides (NOx) for diesel & WCOME blend at 190

preparation these results in delayed combustion. bar injection pressure.

Delayed combustion results in high emission of

UBHC. At 4.8 kW power output & at rated power the 1.2.4 Smoke opacity for WCOME blend at

emission of UBHC is less for bio-diesel (WCOME) 190bar:

& diesel blends comparing that of pure diesel fuel.

This may be because of the presence of O2 in bio- The variation of smoke density for the blends of bio-

diesel fuel may aid the combustion of bio-diesel diesel (WCOME) & diesel & pure diesel at 190 bar

(WCOME) & diesel blends. This may reduce the injection pressure is presented in fig.1.2.4.

emission of UBHC at high power output.

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 6

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

blends as well as for pure diesel fuel. For other bio-

diesel & diesel blends the max pressures are

comparable with that of diesel. The delay period in

case of bio-diesel (WCOME) & diesel blends are less

comparing pure diesel fuel this may be due high

Cetane number of bio-diesel (WCOME) fuel. It can

be also seen that as the volume % of bio-diesel in the

blend increases the delay period decreases. The

decrease in delay period means smooth operation of

the engine.

Fig 1.2.4 shows the variation of BP on smoke

opacity for diesel & WCOME blend at 190bar

injection pressure.

It is seen from fig. that the smoke density for the bio-

diesel (WCOME) & diesel blends less comparing

that of pure diesel fuel at less loads. The less smoke

density may be due complete combustion of bio-

diesel (WCOME) & diesel fuel blends comparing

that of diesel. As the volume % of bio-diesel in the

blend increases there is increase in smoke density.

At 4.2 kW power output & at 15 kg, Load smoke

Fig 2 shows the comparison of In-Cylinder pressure

density for all the blends of bio-diesel & diesel are

at 190bar injection pressure for blends WCOME at

high comparing pure diesel fuel. High smoke density

rated load.

may be because of the incomplete combustion of bio-

diesel & diesel blends. The incomplete combustion It can be seen that the peak pressure for WC80 is

may be because of less injection pressure which 74.73 bar & occurs at 11° ATDC. Whereas, for pure

gives larger atoms of fuel are injected in to the diesel peak pressure is 76.25 bar & occurs at

combustion chamber. The larger atoms of fuel may 9°ATDC. The shift of peak pressure location from

because of the less injection pressure & high TDC with increase in bio-diesel proportion may be

viscosity of bio-diesel fuel because of better combustion because of O2 presence

in the bio-diesel. It is also seen that, the peak pressure

2. Effect of In-Cylinder combustion pressure decreases with decrease of WC in the fuel.

The variation of cylinder pressure with change in

crank angle for 190 bar injection pressure is shown in 1. a. Performance characteristics:

fig 2. It can be seen from fig. that max pressure for 1.1.1 BSFC for WCOME blends at 220bar:

all bio-diesel (WCOME) & diesel blends are less

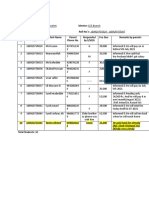

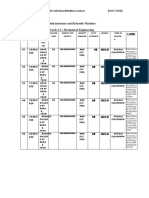

The variation of BSFC with change in BP at 220 bar

comparing that of diesel. But the peak pressure for

injection pressure is presented in fig.1.1.1. It is seen

bio-diesel (WCOME) & diesel blends are comparable

from fig. that as power output of the engine

with that of pure diesel fuel. For WC40 blend the

increases the BSFC decreases. BSFC of all the bio-

max pressure is seems to be less comparing other

diesel (WCOME) & diesel blends are high

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 7

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

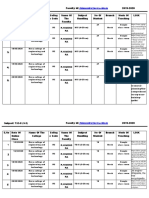

comparing that of pure diesel fuel. The high BSFC the net diesel fuel & bio-diesel. The less BTE of bio-

of bio-diesel (WCOME) & diesel blends may be due diesel & diesel may be due the less heating value of

less heating value of bio-diesel fuel. It can be seen bio-diesel (WCOME) fuel. As the volume % of bio-

from fig. that the BSFC of pure diesel fuel is the diesel in the blend increases, there is decrease in

least & that of bio-diesel (WCOME) is the highest BTE of the blends. The BTE is found to be high for

& for other blends of bio-diesel & diesel are in diesel which is 27.22%. The BTE is found to be less

between the pure diesel & pure bio-diesel. The for WCOME. This may because of less energy

BSFC of WC20 bio-diesel blend is close to that of content of bio-diesel fuel compared that of diesel. &

pure diesel. & for all other blends BSFC is high. also may be because of the smaller atoms fuel is

Lowest BSFC is for diesel. Comparing B0, BSFC formed because of high injection pressure. Because

for WC20, WC40, WC60, WC80 & WC100 blends of the smaller atoms of fuel may not penetrate

increases by 3.57%, 5.38%, 9.61%, 13.11% & combustion this may cause incomplete combustion

17.11% respectively. This may because of high of blends because of high viscosity, high density &

density, viscosity & less calorific value of the fuels. less (Calorific value) heating value of the fuel.

The high BSFC with the bio-diesel (WCOME) & Amongst all the blends WC20 shows the high BTE

diesel blends may be because of more fuel is to be that values matches nearly to diesel which is found to

supplied to get the same power output as that of be 26.84% at 4.2kw BP. Comparing WC0, the BTE

pure diesel fuel. More quantity of bio-diesel fuel for WC100, WC80, WC60, WC40 & WC20 is

supply is due its less energy content of bio-diesel reduced by 1.39%, 2.53%, 3.78%, 5.54% & 8.04%

fuel. respectively

Fig 1.1.1 shows the variation of BP on BSFC for

diesel & WCOME blend at 220bar injection Fig 1.1.2 shows the effect of BP on BTE for diesel &

pressure. WCOME blend at 220bar injection pressure.

1.1.2. BTE for WCOME blends at 220bar: 1.1.3. EGT for WCOME blends at 220bar:

The variation of BTE with change in BP at 220 bar The variation of EGT with change in BP at 220 bar

injection pressure is presented in fig.1.1.2. It is seen injection pressure is presented in fig.1.1.3. It can be

from fig. that as the BP increases the BTE increases. seen from fig. that the EGT of diesel is the highest

The BTE of pure diesel fuel is the highest & that of compared bio-diesel (WCOME) & diesel blends. The

bio-diesel (WCOME) is the least. The BTE of other less value of EGT may be due better combustion in

bio-diesel (WCOME) & diesel blends are in between case of bio-diesel (WCOME) & diesel blends. The

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 8

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

complete combustion may because of the presence of blends the emission of CO is comparable to that of

O2 in the bio-diesel, may help in better combustion pure diesel fuel. For some of the bio-diesel & diesel

of bio-diesel (WCOME) & diesel blends comparing blends the emission of CO is more than that of pure

that of pure diesel fuel. This may be also because of diesel. This may be because of incomplete

the reduced delay period with bio-diesel (WCOME) combustion of bio-diesel & diesel blends. The

& diesel blends because of high Cetane number of incomplete combustion may be because of smaller

bio-diesel fuel. Because of the reduced ignition delay atoms of fuel formed during the injection of fuel. The

in case of bio-diesel & diesel blend combustion smaller atoms fuel droplet may be because of high

injection pressure. The smaller atoms fuel may not

penetrate in to the combustion chamber; this may

take more time for fuel to come in contact with O2

particles this may delay the combustion & hence CO

emissions are high. At high power output the CO

emissions are less for all the bio-diesel & diesel

blends comparing that of pure diesel. This may be

due the presence of O2 in the molecular structure of

bio-diesel, takes part in combustion. This may be due

conversion of CO to carbon dioxide. Amongst all the

blends, the blend diesel & WC20 have shown highest

CO comparing other blends. This because of

incomplete combustion at high loads which results in

high CO emissions. It is also seen that the CO

emission decreases with increase in % of bio-diesel

Fig 1.1.3 variation of the EGT with BP for diesel & in the blends. From the graph it is clear that the pure

WCOME blends at 220bar. WCOME blend has lowest CO up to 4.2kw because

of complete combustion & increases because of

incomplete combustion.

1.2. b. Emission Characteristics

1.2.1 CO for blends of WCOME at 220bar:

1.2.2 Nitrogen oxides (NOx) WCOME at 220bar:

Fig 1.2.1 shows the variation of BP on CO for diesel

& WCOME blend at 220bar injection pressure.

Fig 1.2.2 shows the variation of BP on nitrogen

The variation of CO with change in BP at 220 bar oxides (NOx) for diesel & WCOME blend at 220bar

injection pressure is presented in fig.4.3.b.1. It is injection pressure.

seen from fig. that for all the bio-diesel & diesel

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 9

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

The variation of emission of oxides of nitrogen at with diesel. This may be due the smaller atoms are

220 bar injection pressure is presented in fig 1.2.2. It injected. Smaller atoms of fuel may be because of the

is seen that emission of oxides of nitrogen is less for high injection pressure. Smaller atoms of fuel formed

the all the bio-diesel & diesel blends comparing the during injection have lesser inertia; because of this

pure diesel at all the loads. The lesser emission of the atoms cannot penetrate the combustion chamber.

oxides of nitrogen may be because of the absence of This may take longer time for combustion or even

aromatics in the bio-diesel. The aromatics are the there is an incomplete combustion, because of this

main component of fuel in formation of oxides of there is an increase in smoke density in case of bio-

nitrogen. At less power output the formation of NOx diesel & diesel blends at all the loads. Because of the

for all the bio-diesel & diesel blends are less increase in fuel consumption the smoke density

comparing that of pure diesel. At 4.2KW the increases from the engine. It can been seen that from

reduction in NOx comparing diesel & for blends S20 graph that the smoke density decreases for WCOME

& S40 by is increased by 12.41% & 4.32%. as comparing diesel, this is because of better

combustion of blends because of the presence of O2

1.2.3 Smoke opacity for WCOME blend at in the WCOME.

220bar:

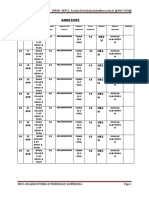

2. Effect of In-Cylinder combustion pressure

Fig 1.2.3 shows the variation of BP on smoke density

for diesel & blend at 220bar injection pressure.

Fig 2 shows the comparison of In-Cylinder pressure

The variation of smoke density with change

at 220bar injection pressure for blends WCOME at

in BP at 220 bar injection pressure is presented in

rated load.

fig.1.2.3. It is seen from fig. that smoke density is

less at the less BP. This may be because of the less The variation of cylinder pressure with

fuel is supplied to the engine at the less loads. As the change in crank angle for 220 bar injection pressure

load on the engine increases, the smoke density is presented in fig.2. It is seen from fig. that the

increases for all the bio-diesel & diesel blends & for cylinder pressure is max for the bio-diesel comparing

pure diesel as well. The smoke is formed because of pure diesel. This may be because of the complete

incomplete combustion of fuels supplied. As the load combustion of bio-diesel fuel. Complete combustion

on the engine increases, smoke density for all the of bio-diesel may be because of inherent O2

bio-diesel & diesel blends increases in comparison molecules present in bio-diesel fuel. The inherent O2

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 10

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

molecules will help in better combustion & As volume percentage of biodiesel

conversion chemical energy of fuel in to heat energy. (WCOME) in the blends increases the brake thermal

This increases the max pressure. The ignition delay efficiency is higher.

for the bio-diesel blends less comparing that of pure The emissions such as CO, UBHC and NOx

diesel & blend WC20. The less ignition delay may are lower compared to that of diesel fuel.

be because of the high Cetane No of bio-diesel fuel As the percentage of biodiesel in the blend

comparing that of diesel. increases the reduction in emissions are higher.

It is seen that the peak pressure for WC100 is 73.05

bar & occurs at 11° ATDC. Whereas, for pure diesel VII. REFERENCES

peak pressure is 72.2 bar & occurs at 9°ATDC. The

shift of peak pressure location from TDC with [1] B.R.Hosamani Y.U.Biradar, (BLDEA’s CET

increase in bio-diesel proportion may be because of Vijayapur , India) Experimental investigation of

better combustion because of O2 presence in the bio- Thermal performance and Emission characteristics of

diesel. CI DI Engine Using Blends of Pongamia biodiesel ,

Journal of Mechanical Engineering Research and

VI. Conclusions technology Volume 2, @delton Books, (BLDEA’s

College of Engg & Tech Bijapur.)

Experimental investigation is carried out by using the www.deltonbooks.com

waste cocking oil biodiesel (WCOME) in

compression ignition engine. From the above [2] B.R. Hosamani ,Y. U. Biradar, S.B. Koulagi, Dr.

experimental results the following conclusions are V.V. Katti (BLDEA’s CET Vijayapur , India)

drawn. Experimental Investigation of Thermal Performance

and Emission Characteristics of CI DI Engine Using

Neat waste cooking oil has higher viscosity Blends of Pongamia biodiesel and Diesel. Journal of

and lower volatility makes the oil not suitable for Mechanical Engineering Research and technology

diesel engine. Volume 2, @delton Books, www.deltonbooks.com.

The viscosity of oil can be reduced by

process. [3] Mohammed EL-Kasaby, Medhat A. Nemit-allah,

Waste cocking oil biodiesel (WCOME) are Experimental investigations of ignition delay period

having lower heating value compared to that of diesel and performance of a diesel engine operated with

fuel. Jatropha oil biodiesel, Alexandria Engineering

Flash point and fire point of waste cocking Journal, Feb. 2013, Vol 52, pp 141-149, 2013.

oil biodiesel (WCOME) are higher compared to that

[3] Gvidonas Labeckas, Stasys Slavinskas, Tomasz

of pure biodiesel.

Lus, Oleh Klyus, Marius Mažeika, Combustion and

By transesterification process the waste

performance parameters of a Diesel engine operating

cocking oil is converted to biodiesel.

on ethanol-Diesel fuel blends, Scientific Journals

Biodiesel fuel properties are very close to

Zeszyty Naukowe Maritime University of Szczecin

that of diesel fuel.

Akademia Morska w Szczecinie, 2013, 36(108) z. 2

The waste cocking oil biodiesel (WCOME)

pp. 102–109, 2013, 36(108) z. 2 s. 102–109

is tested in diesel engine to evaluate performance and

emission characteristic of the engine. [4] R. Senthil Kumar, M. Prabu, experimental

The brake specific fuel consumption of investigation of a di diesel engine using tyre

biodiesel (WCOME) and diesel blends higher are pyrolysis oil-diesel blends as a biodiesel,

higher compared to diesel fuel. International Journal of Mechanical Engineering and

The brake thermal efficiency of waste Technology (IJMET), ISSN 0976 – 6340(Print),

cocking oil biodiesel (WCOME) is less compared to ISSN 0976 – 6359(Online), Volume 5, Issue 2,

that of diesel. February (2014), pp. 74-90, © IAEME.

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 11

© October 2015 | IJIRT | Volume 2 Issue 1 | ISSN: 2349-6002

[5] Santosh Kumar Kurre, Shyam Pandey, Mukesh [13] Rajneesh Kumar, Anoop Kumar Dixit, Shashi

Saxena, Effect of Compression Ratio on Diesel Kumar Singh, Gursahib Singh, Rohinish Khurana,

Engine Performance and Emission with Diesel- Performance characteristics of Jatropha ethyl ester as

Ethanol Blends, International Journal of Scientific & diesel engine fuel at different compression ratios,

Engineering Research, Volume 4, Issue 10, October- Agric Eng Int: CIGR Journal, 15(3): 95-100. ,2011-

2013 775 ISSN 2229-5518 11-0

[6] M.S.Graboski, R.L.McCormic,Combustion of fat [14] Sharun Mendonca, John Paul Vas , Influence of

and vegetable oil derived fuels in diesel Engines, Injection Timing on Performance and Emission

Progress in Energy and Combustion Science Characteristics of Simarouba Biodiesel Engine,

24(1998) 125-164. International Journal of Scientific and Research

Publications, Volume 3, Issue 4, April 2013 1 ISSN

[7] J.Van Gerpen, Biodiesel processing and 2250-3153.

production, Fuel Processing Technology, 86 (2005)

1097-1107. [15] B.R.Hosamani & C S Naveen , (BLDEA’s

CET Vijayapur , India) Experimental investigation of

[8] A.M. Liaquat, H.H. Masjuki, M.A. Kalam, I.M. Performance and Emission characteristics of CI

Rizwanul Fattah, M.A. Hazrat, M. Varman, M. Engine Using Blends of Two biodiesel (Pongamia

Mofijur, M. Shahabuddin, Effect of coconut and Jatropha) By, Journal of Mechanical Engineering

biodiesel blended fuels on engine performance and Research and technology Volume 2, @delton

emission characteristics , Procedia Engineering 56 ( Books, www.deltonbooks.com

2013 ) 583 – 590 , 2013

[9] Mallikarjun Navindagi (PDACE Gulbarga,

Karnataka, India) an Experimental Analysis of

Performance, Combustion and Emission

Characteristics of Simarouba Biodiesel and Its

Blends on CI Engine IJMER | ISSN: 2249–6645 |.

Vol. 4 | Iss.8| Aug. 2014 | 85|.

[10] Gaurav Paul et al, Ambarish Dattab, Bijan

Kumar Mandal, An Experimental and Numerical

Investigation of the Performance, Combustion and

Emission Characteristics of a Diesel Engine fueled

with Jatropha Biodiesel, Feb. 2013 Energy Procedia

54 ( 2014 ) 455 – 467.

[11] Jagannath Hirkude, Atul Padalkar, Deepa

vedartham, An Investigations on the effect of waste

fried oil methyl ester blends and loads on

performance and smoke opacity of diesel engine

using response surface methodology. Energy

Procedia 54 ( 2014 ) 606 – 614 2013.

[12] Venkata ramesh, Dr. G.Laxmi Narayanrao, An

Effect of Combustion Chamber Design on a DI

Diesel Engine Fuelled with Jatropha Methyl Esters

Blends with Diesel Procedia Engineering 64 ( 2013 )

479 – 490 , 2013

IJIRT 100001 INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 12

You might also like

- Review Article: SciencedirectDocument15 pagesReview Article: SciencedirectjullyNo ratings yet

- Biodiesel Production From Waste Chicken Fat Based Sources and Evaluation With MG Based Additive in A Diesel EngiDocument7 pagesBiodiesel Production From Waste Chicken Fat Based Sources and Evaluation With MG Based Additive in A Diesel EngiwhutecompressorNo ratings yet

- Production and Analysis The Properties of Mahua Methyl EsterDocument7 pagesProduction and Analysis The Properties of Mahua Methyl EsterIJAERS JOURNALNo ratings yet

- Load and Emission Characteristics of Pongamia Pinnata Oil in ACI EngineDocument9 pagesLoad and Emission Characteristics of Pongamia Pinnata Oil in ACI EngineJournals MECNo ratings yet

- Nanoparticles As Fuel Additives in Biodiesel A ReviewDocument7 pagesNanoparticles As Fuel Additives in Biodiesel A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Effect of Biodiesel On Compression Ignition Engine Vibration - A ReviewDocument14 pagesAn Effect of Biodiesel On Compression Ignition Engine Vibration - A ReviewTJPRC PublicationsNo ratings yet

- Biodiesel Production Using Second-Generation Feedstocks: A ReviewDocument18 pagesBiodiesel Production Using Second-Generation Feedstocks: A ReviewPadelisgiNo ratings yet

- Effect of Fuel Injection Pressure On Performance Ci Engine Using Simarouba As BiodieselDocument6 pagesEffect of Fuel Injection Pressure On Performance Ci Engine Using Simarouba As BiodieselShashikanth MohrirNo ratings yet

- Experimental Investigation On Performance Emission and Combustion Characteristics of Single Cylinder Diesel Engine Running On Desert Date Balanites Aegyptiaca Biodiesel IJERTV3IS081030 PDFDocument7 pagesExperimental Investigation On Performance Emission and Combustion Characteristics of Single Cylinder Diesel Engine Running On Desert Date Balanites Aegyptiaca Biodiesel IJERTV3IS081030 PDFTonya WhitneyNo ratings yet

- 21 Ab 10amDocument21 pages21 Ab 10amCJ PerezNo ratings yet

- 2013 SK Nayak Et Al. Experimental Investigation On A Diesel Engine Fuelled With Biodiesel Produced From Waste Cooking OilDocument7 pages2013 SK Nayak Et Al. Experimental Investigation On A Diesel Engine Fuelled With Biodiesel Produced From Waste Cooking OilBP PattanaikNo ratings yet

- Influence of Injection Timing On Performance, Emission and Combustion Characteristics of A DI Diesel Engine Running On Fish Oil BiodieselDocument12 pagesInfluence of Injection Timing On Performance, Emission and Combustion Characteristics of A DI Diesel Engine Running On Fish Oil BiodieselSubhadip DasNo ratings yet

- FileserveDocument9 pagesFileserveCao Đào NamNo ratings yet

- Performance and Emission Study of Castor-Mustard Oil Blends in CI EngineDocument9 pagesPerformance and Emission Study of Castor-Mustard Oil Blends in CI EngineSrini VasanNo ratings yet

- L.R. Monisha Miriam, Ajith J. Kings, R. Edwin Raj, M. Adhi ViswanathanDocument1 pageL.R. Monisha Miriam, Ajith J. Kings, R. Edwin Raj, M. Adhi ViswanathanajithjkingsNo ratings yet

- Calophyllum inophyllum methyl ester biodiesel blend as an alternate fuelDocument9 pagesCalophyllum inophyllum methyl ester biodiesel blend as an alternate fuelridho febriNo ratings yet

- Performance evaluation of a diesel engine using biodiesel-diesel blendsDocument3 pagesPerformance evaluation of a diesel engine using biodiesel-diesel blendssmkmigas bmrNo ratings yet

- IJETR021975Document6 pagesIJETR021975erpublicationNo ratings yet

- Experimental Investigation of Effects On Performance Emissions and Combustion Parameters of Biodiesel Diesel Butanol Blends in A Direct Injection CIDocument15 pagesExperimental Investigation of Effects On Performance Emissions and Combustion Parameters of Biodiesel Diesel Butanol Blends in A Direct Injection CIBalaji BhukyaNo ratings yet

- Effect of Pyrogallol As An AntioxidantDocument8 pagesEffect of Pyrogallol As An AntioxidantRegina ChristiantyNo ratings yet

- Uamerica 23 05589Document8 pagesUamerica 23 05589Rimy Cruz GambaNo ratings yet

- Ab 02417411746Document6 pagesAb 02417411746IJMERNo ratings yet

- Compression RatioDocument15 pagesCompression RatioVenkateshNo ratings yet

- Literature Review On Diesel EngineDocument5 pagesLiterature Review On Diesel Enginec5nazs86100% (1)

- NanthagopalDocument11 pagesNanthagopalMohammad SaqlainNo ratings yet

- Evaluation of Emission Characteristics of Green Diesel in A Single Cylinder CI Engine - CertifiedDocument4 pagesEvaluation of Emission Characteristics of Green Diesel in A Single Cylinder CI Engine - CertifiedManu J NairNo ratings yet

- Pirolisis ProyectoDocument10 pagesPirolisis Proyectoluis fernando castillo castellanosNo ratings yet

- Characterization of Mahua Methyl Ester in DI Diesel EngineDocument7 pagesCharacterization of Mahua Methyl Ester in DI Diesel EngineIJAERS JOURNALNo ratings yet

- Lemon Essential Oil A Partial SubstituteDocument9 pagesLemon Essential Oil A Partial SubstituteAyesha JaireNo ratings yet

- 1 s2.0 S2214785322000396 MainDocument5 pages1 s2.0 S2214785322000396 MainBalaji BhukyaNo ratings yet

- Örnek Makale BiodieselDocument9 pagesÖrnek Makale BiodieselAtakanNo ratings yet

- Conversão de Nergia 2Document6 pagesConversão de Nergia 2Ricardo PereiraNo ratings yet

- Performance analysis of CI engine fueled with diesel and used vegetable oil blendDocument8 pagesPerformance analysis of CI engine fueled with diesel and used vegetable oil blendYohannes AlemuNo ratings yet

- Evaluation On Performance and Exhaust Emissions With Bio-Diesel and Ethanol Blending On A Diesel EngineDocument7 pagesEvaluation On Performance and Exhaust Emissions With Bio-Diesel and Ethanol Blending On A Diesel EngineChethan GowdaNo ratings yet

- JournalNX-Biodiesel Engine PropertiesDocument7 pagesJournalNX-Biodiesel Engine PropertiesJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- 01 - Review Suresh2018Document12 pages01 - Review Suresh2018Chirag PatidarNo ratings yet

- 1 s2.0 S2590174522000794 MainDocument13 pages1 s2.0 S2590174522000794 Mainrabie letaifNo ratings yet

- Review of Bio Diesel From Waste Cooking OilDocument4 pagesReview of Bio Diesel From Waste Cooking OilCeleste ZapataNo ratings yet

- Karanja OilDocument16 pagesKaranja OilM tejaswiniNo ratings yet

- Aydin 2010Document6 pagesAydin 2010Tech RulerNo ratings yet

- Experimental Investigations On A Four Stoke Diesel Engine Operated by Karanja Bio Diesel Blended With DieselDocument5 pagesExperimental Investigations On A Four Stoke Diesel Engine Operated by Karanja Bio Diesel Blended With DieselInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Four Stroke Single Cylinder Compression Ignition Engine Operated With Blends of Waste Cooking Oil Biodiesel DieselDocument6 pagesAnalysis of Four Stroke Single Cylinder Compression Ignition Engine Operated With Blends of Waste Cooking Oil Biodiesel Dieselshreshthagandhi13No ratings yet

- IEEE CogMob 2023 Paper 34v2Document5 pagesIEEE CogMob 2023 Paper 34v2Imre ZsombokNo ratings yet

- A Review On Feasibility of Diesel/ Biodiesel/ Ethanol/ Bio-Ethanol Blend As CI Engine FuelDocument4 pagesA Review On Feasibility of Diesel/ Biodiesel/ Ethanol/ Bio-Ethanol Blend As CI Engine FuelInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sai Kishore ReddyDocument16 pagesSai Kishore Reddysatwik reddyNo ratings yet

- 1827 ApprovedpaperDocument20 pages1827 ApprovedpaperMahtab SajnaniNo ratings yet

- Who Will Cry When You Die 180348Document22 pagesWho Will Cry When You Die 180348Suresh KumarNo ratings yet

- Nauti Yal 2019Document12 pagesNauti Yal 2019Tanu SharmaNo ratings yet

- Blended Fuel Effects on CI Engine PerformanceDocument4 pagesBlended Fuel Effects on CI Engine PerformanceDiyar NezarNo ratings yet

- A Review On Variable Compression Diesel Engine With Turmeric Leaf Oil-Based BiodieselDocument6 pagesA Review On Variable Compression Diesel Engine With Turmeric Leaf Oil-Based BiodieselSanjeevi PrakashNo ratings yet

- A Technical Seminar ON: "Bio Diesel and Its Importance"Document18 pagesA Technical Seminar ON: "Bio Diesel and Its Importance"Dhinesh GanesanNo ratings yet

- Synthesis and Performance Analysis of Acetylene For Dual Fuel Mode Using S.I EngineDocument6 pagesSynthesis and Performance Analysis of Acetylene For Dual Fuel Mode Using S.I EngineMARVEL STUDIOSNo ratings yet

- A Detailed Review of The Impacts of Diesel Biofuel Mixes With Nanofluid AdditionsDocument5 pagesA Detailed Review of The Impacts of Diesel Biofuel Mixes With Nanofluid AdditionsEditor IJTSRDNo ratings yet

- 1 s2.0 S0196890414007584 MainDocument17 pages1 s2.0 S0196890414007584 MainMuhammad RonaldoNo ratings yet

- Review - Selvan2017Document26 pagesReview - Selvan2017Chirag PatidarNo ratings yet

- Energy: E. Sukjit, J.M. Herreros, K.D. Dearn, R. García-Contreras, A. TsolakisDocument11 pagesEnergy: E. Sukjit, J.M. Herreros, K.D. Dearn, R. García-Contreras, A. TsolakisNiti KlinKaewNo ratings yet

- Thermal Barrier Coating Improves Performance and Reduces Emissions of CI Engine Fueled with Citrus Medica BiodieselDocument14 pagesThermal Barrier Coating Improves Performance and Reduces Emissions of CI Engine Fueled with Citrus Medica BiodieselManivannan AyyasamyNo ratings yet

- Applications of BiofuelsDocument21 pagesApplications of BiofuelsSatish HSNo ratings yet

- Green Carbon Dioxide: Advances in CO2 UtilizationFrom EverandGreen Carbon Dioxide: Advances in CO2 UtilizationGabriele CentiNo ratings yet

- Phone Calls To Parents Report IT-C Format 2020-21 SEM-2Document4 pagesPhone Calls To Parents Report IT-C Format 2020-21 SEM-2Shashikanth MohrirNo ratings yet

- Ibrahim Calling Report Tuition Fee ECE 024-047Document1 pageIbrahim Calling Report Tuition Fee ECE 024-047Shashikanth MohrirNo ratings yet

- FP 3-2 (Cse) Jntuh-SheshikanthDocument1 pageFP 3-2 (Cse) Jntuh-SheshikanthShashikanth MohrirNo ratings yet

- Ibrahim Calling Report Tuition Fee2 ECE 024-047Document1 pageIbrahim Calling Report Tuition Fee2 ECE 024-047Shashikanth MohrirNo ratings yet

- Ibrahim Calling Report Tuition Fee ECE 024-047Document1 pageIbrahim Calling Report Tuition Fee ECE 024-047Shashikanth MohrirNo ratings yet

- JNTU FOMAT FMHM (MECH 2-2-Bahauddin)Document1 pageJNTU FOMAT FMHM (MECH 2-2-Bahauddin)Shashikanth MohrirNo ratings yet

- Ipr 3-2 Mech Jntuh-SheshikanthDocument4 pagesIpr 3-2 Mech Jntuh-SheshikanthShashikanth MohrirNo ratings yet

- Jayapraksh 15th To 20 Classes of HT PDFDocument2 pagesJayapraksh 15th To 20 Classes of HT PDFShashikanth MohrirNo ratings yet

- Subject Name: Design of Machine Members II Class & Specialization: B.tech 3-2, MechanicalDocument1 pageSubject Name: Design of Machine Members II Class & Specialization: B.tech 3-2, MechanicalShashikanth MohrirNo ratings yet

- Subject Name: Class & Specialization: B.tech 2-2, Mechanical EngineeringDocument1 pageSubject Name: Class & Specialization: B.tech 2-2, Mechanical EngineeringShashikanth MohrirNo ratings yet

- Department Name: Mechanical Department DATE:29/04/2020 SL - No. Name of The Hod & Staff Classes No. OF Students Present Screen Shots EnclosedDocument2 pagesDepartment Name: Mechanical Department DATE:29/04/2020 SL - No. Name of The Hod & Staff Classes No. OF Students Present Screen Shots EnclosedShashikanth MohrirNo ratings yet

- R Himendra LINKS AS ON 15-5-2020 TO 20-5-2020Document2 pagesR Himendra LINKS AS ON 15-5-2020 TO 20-5-2020Shashikanth MohrirNo ratings yet

- FP 3-2 (Cse) Jntuh-SheshikanthDocument1 pageFP 3-2 (Cse) Jntuh-SheshikanthShashikanth MohrirNo ratings yet

- FP 3-2 (Civil) Jntuh-SheshikanthDocument1 pageFP 3-2 (Civil) Jntuh-SheshikanthShashikanth MohrirNo ratings yet

- Online class attendance by department and yearDocument2 pagesOnline class attendance by department and yearShashikanth MohrirNo ratings yet

- Subject Name: Strength of Material Ii Class & Specialization: B.tech 2-2, CIVILDocument1 pageSubject Name: Strength of Material Ii Class & Specialization: B.tech 2-2, CIVILShashikanth MohrirNo ratings yet

- Mech On 27-04-2020Document2 pagesMech On 27-04-2020Shashikanth MohrirNo ratings yet

- Mech On 17-04-2020Document2 pagesMech On 17-04-2020Shashikanth MohrirNo ratings yet

- Mech On 15-04-2020Document2 pagesMech On 15-04-2020Shashikanth MohrirNo ratings yet

- Mech On 28-04-2020Document2 pagesMech On 28-04-2020Shashikanth MohrirNo ratings yet

- Department Name: Mechanical Department DATE:14/04/2020 SL - No. Name of The Hod & Staff Classes No. OF Students Present Screen Shots EnclosedDocument2 pagesDepartment Name: Mechanical Department DATE:14/04/2020 SL - No. Name of The Hod & Staff Classes No. OF Students Present Screen Shots EnclosedShashikanth MohrirNo ratings yet

- List The Objectives of Intellectual Property Law.: (Common To AE, EEE, ECE, EIE, IT, ME, MIE)Document2 pagesList The Objectives of Intellectual Property Law.: (Common To AE, EEE, ECE, EIE, IT, ME, MIE)Shashikanth MohrirNo ratings yet

- Intellectual Property Rights Anil 1 23Document23 pagesIntellectual Property Rights Anil 1 23vdyjnnNo ratings yet

- Production of Biodiesel From Waste Cooking Oil and Factors Affecting Its Formation: A ReviewDocument7 pagesProduction of Biodiesel From Waste Cooking Oil and Factors Affecting Its Formation: A ReviewShashikanth MohrirNo ratings yet

- Production of Biodiesel From Waste Cooking Oil and Factors Affecting Its Formation: A ReviewDocument7 pagesProduction of Biodiesel From Waste Cooking Oil and Factors Affecting Its Formation: A ReviewShashikanth MohrirNo ratings yet

- Characterization of Waste Frying Oils Obtained From Different FacilitiesDocument7 pagesCharacterization of Waste Frying Oils Obtained From Different FacilitiesAhmed SajitNo ratings yet

- Online class attendance by Mechanical Dept staff and studentsDocument2 pagesOnline class attendance by Mechanical Dept staff and studentsShashikanth MohrirNo ratings yet

- Waste Cooking Oil Transesterification: Influence of Impeller Type, Temperature, Speed and Bottom Clearance On FAME YieldDocument16 pagesWaste Cooking Oil Transesterification: Influence of Impeller Type, Temperature, Speed and Bottom Clearance On FAME YieldShashikanth MohrirNo ratings yet

- Bio Diesel ProductionDocument13 pagesBio Diesel ProductionShashikanth MohrirNo ratings yet

- Produksi Etanol Menggunakan Kluyveromyces MarxianusDocument8 pagesProduksi Etanol Menggunakan Kluyveromyces MarxianusDaeng AriefNo ratings yet

- Us3479310 PDFDocument7 pagesUs3479310 PDFKhoi Nguyen DangNo ratings yet

- NamcongHandBooktoDesign PartB Topostpublic PDFDocument50 pagesNamcongHandBooktoDesign PartB Topostpublic PDFTam Phan100% (1)

- Microscopy REMOTE Quiz QuestionsDocument2 pagesMicroscopy REMOTE Quiz QuestionsadamNo ratings yet

- GSAP - Shell HelixDocument16 pagesGSAP - Shell HelixJoseph Rubyanto SudrajadNo ratings yet

- Improving Separation of Basic Compounds by Reversed-Phase HPLC Using Chaotropic AgentsDocument7 pagesImproving Separation of Basic Compounds by Reversed-Phase HPLC Using Chaotropic AgentsKriti TyagiNo ratings yet

- (Topics in Chemical Engineering) Martyn S. Ray, David W. Johnston - Chemical Engineering Design Project - A Case Study Approach Topics in Chemical Engineering - Volume 6-Routledge (1989)Document2 pages(Topics in Chemical Engineering) Martyn S. Ray, David W. Johnston - Chemical Engineering Design Project - A Case Study Approach Topics in Chemical Engineering - Volume 6-Routledge (1989)Pratiwi Puji Ajeng LestariNo ratings yet

- Jared Ledgard - The Preparatory Manual of Explosives - Radical, Extreme, Experimental Explosives Chemistry Vol.1-Jared Ledgard (2010)Document349 pagesJared Ledgard - The Preparatory Manual of Explosives - Radical, Extreme, Experimental Explosives Chemistry Vol.1-Jared Ledgard (2010)Santiago U. NarváezNo ratings yet

- Kathmandu Water Purification Filters TestDocument1 pageKathmandu Water Purification Filters TestManish ThapaNo ratings yet

- Jazeera Deco Primer-MsdsDocument5 pagesJazeera Deco Primer-MsdsMahmoud FlefilNo ratings yet

- 3M Polyurethane Sealant 540Document7 pages3M Polyurethane Sealant 540vivek jayswalNo ratings yet

- WEB 20302 Professional English 2 UniKL MICET Assignment 2: Technical Lab ReportDocument46 pagesWEB 20302 Professional English 2 UniKL MICET Assignment 2: Technical Lab ReportSiti Hajar Mohamed100% (2)

- Module 1 Unit 1Document12 pagesModule 1 Unit 1Mia Lorena JandocNo ratings yet

- Water Potential Ap Bio 2012-2013Document18 pagesWater Potential Ap Bio 2012-2013Keshav RaoNo ratings yet

- Biology Yearly Lesson Plan Form 4Document4 pagesBiology Yearly Lesson Plan Form 4Hisyam Deraman100% (1)

- White1971 - Vapor Dominated Hydrotermal Systems Compared With Hot-Water SystemDocument23 pagesWhite1971 - Vapor Dominated Hydrotermal Systems Compared With Hot-Water SystemNino PumaNo ratings yet

- Simulaciones Numericas Detalladas de Reactores de Lechofijo CataliticoDocument13 pagesSimulaciones Numericas Detalladas de Reactores de Lechofijo CataliticoSanchez JorgeNo ratings yet

- Millers Anesthesia - Sixth Edition - ANESTHESIA APPARATUS - 18Document6 pagesMillers Anesthesia - Sixth Edition - ANESTHESIA APPARATUS - 18Adriana VickNo ratings yet

- Final 26 42 14 Cathodic ProtectionDocument42 pagesFinal 26 42 14 Cathodic ProtectionPrabuNo ratings yet

- BME 301: Biomedical Sensors: Lecture Note 3: Bioelectric Potentials and Biopotential ElectrodesDocument67 pagesBME 301: Biomedical Sensors: Lecture Note 3: Bioelectric Potentials and Biopotential ElectrodesDewi Cahya FitriNo ratings yet

- 09-08-15 SR - Iit-Iz-Co-Spark Jee Adv Rpta-2 (2013 p2) Q'paperDocument33 pages09-08-15 SR - Iit-Iz-Co-Spark Jee Adv Rpta-2 (2013 p2) Q'paperKumar Prasad100% (1)

- Desorption PhenomenaDocument42 pagesDesorption PhenomenaJose Fernandez AdellNo ratings yet

- Lecture 4Document160 pagesLecture 4Ahmed ShahabiNo ratings yet

- Transparent Bar Soap Composition Comprising Glycerine Derivative US6656893 PDFDocument15 pagesTransparent Bar Soap Composition Comprising Glycerine Derivative US6656893 PDFpertmasterNo ratings yet

- Grade 10 BUDGET OF WORK ScienceDocument4 pagesGrade 10 BUDGET OF WORK ScienceYanika BarasNo ratings yet

- Product Bulletin: (Microcrystalline Zinc-PhosphateDocument2 pagesProduct Bulletin: (Microcrystalline Zinc-PhosphateJason SonidoNo ratings yet

- Atomic Structure PacketDocument11 pagesAtomic Structure PacketJaznMonNo ratings yet

- Feasibility Study of Ethylene Glycol ProductionDocument4 pagesFeasibility Study of Ethylene Glycol ProductionIntratec SolutionsNo ratings yet

- Test Report Needle Oil PerformanceDocument4 pagesTest Report Needle Oil Performancedimaster_jarkoNo ratings yet