Professional Documents

Culture Documents

1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NB

Uploaded by

Rodrigo TeodoroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NB

Uploaded by

Rodrigo TeodoroCopyright:

Available Formats

FERRITIC STAINLESS STEEL

ACX 555

EN DESIGNATION ASTM DESIGNATION

1.4521 444

X2CrMoTiNb18-2 S44400

DESCRIPTION ACX 555 is a low carbon variation of ACX 500 with addition of molybdenum, titanium and niobium. This steel has better

pitting and intergranular corrosion resistance than conventional ferritic and austenitic stainless steels. It has good ductility

and hardness properties, as well as sensitization resistance in welding works.

CHEMICAL C Si Mn P S Cr Mo Ti Nb

COMPOSITION

≤0.025 ≤1.00 ≤1.00 ≤0.040 ≤0.015 17.50-18.50 1.80-2.00 0.12-0.40 0.25-0.50

APPLICATIONS - Food industry

- Heat exchangers and hot water appliances

- Solar panels, kitchenware and automotive elements

- Decoration and architecture

MECHANICAL Rp0.2 > 320 N/mm2

PROPERTIES AFTER

COLD ROLLING AND Rm 420 - 640 N/mm2

FINAL ANNEALING Elongation min 28%

Hardness max 217 HB

PHYSICAL At 200C it has a density of 7.7 kg/dm3 and a specific heat of 460 J/kg·K

PROPERTIES 200C 1000C 2000C 300 C 0

4000C 5000C

Modulus of elasticity (GPa) 220 215 210 205 195 -

Mean coefficient of linear

expansion between 200C - 10.4 10.8 11.2 11.6 11.9

(10-6 x K-1) and

Thermal conductivity

23 24.8 27.3 29.5 31 32

(W/m·K)

Electrical resistivity

(Ω·mm2/m) 0.80 - - - - -

WELDING The recommended consumable electrodes are:

Shielded electrodes Wires and rods Hollow electrodes

W 19 12 3 L (GMAW)

E 19 12 3 L W 19 12 3 L (GRAW) T 19 12 3 L

P 19 12 3 L (PAW)

316L S 19 12 3 L (SAW) 316L

316L

CORROSION ACX 555 has better pitting corrosion resistance than conventional ferritic and austenitic stainless steels. Intergranular

©Madrid, 2013 ACERINOX, S.A. All rights reserved/by Cedinox0313

RESISTANCE corrosion resistance is improved by double stabilization (titanium and niobium). It is not sensitive to stress corrosion cracking.

SURFACE CLEANING Wash the surface with neutral soap and water applied with a cloth or a brush without scratching the stainless steel. Then,

always rinse the stainless steel with water to remove completely the cleaning agent. Finally, it is recommended to dry the

surface to preserve a good superficial condition. In severe environments, a frequent cleaning is strongly recommended.

SPECIFICATIONS It can be delivered according to EN 10088-2 and ASTM A-240 standard requirements.

You might also like

- 1 4509Document2 pages1 4509Umesh KotadiaNo ratings yet

- En Designation Astm Designation: 1.4307 1.4301 304L 304 X2Crni18-9 S30403Document2 pagesEn Designation Astm Designation: 1.4307 1.4301 304L 304 X2Crni18-9 S30403Magico NinoNo ratings yet

- 1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm DesignationDocument2 pages1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm Designation池边树No ratings yet

- 1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationDocument2 pages1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationCarlos SerranoNo ratings yet

- 1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationDocument2 pages1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationshravyaNo ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- ABB - Filament Wound ComponentDocument4 pagesABB - Filament Wound ComponentAbu Haydar Amin MustanginNo ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- 31CrMo23 Data SheetDocument2 pages31CrMo23 Data SheetOrnella MancinelliNo ratings yet

- Stainless Steel 321 Technical DataDocument2 pagesStainless Steel 321 Technical Datasmith willNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Document2 pagesAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdDocument10 pagesSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

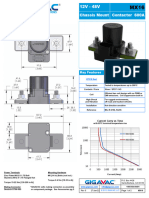

- Sensata Gigavac Mx16 Series Open Contactors Datash-3077712Document4 pagesSensata Gigavac Mx16 Series Open Contactors Datash-3077712Dragan M.No ratings yet

- 2594 TigDocument1 page2594 TigAnonymous skBAwexNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- 1 Ceramic Fiber BoardsDocument2 pages1 Ceramic Fiber BoardsMahesh MishraNo ratings yet

- Data Sheet: 304/304L Stainless SteelDocument2 pagesData Sheet: 304/304L Stainless SteelFranco SwanepoelNo ratings yet

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- AB0034 Alloy25Document12 pagesAB0034 Alloy25Scott LongmireNo ratings yet

- Ampcoloy 972: Technical Data SheetDocument1 pageAmpcoloy 972: Technical Data SheetmazaherramazaniNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- Carbo 4842 Ac-E310Document1 pageCarbo 4842 Ac-E310ali torabiNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Cuco2Be: Applications PropertiesDocument2 pagesCuco2Be: Applications PropertiestestNo ratings yet

- Stellite 21Document2 pagesStellite 21Mohsen ParpinchiNo ratings yet

- 1.4462 SpecificationDocument2 pages1.4462 SpecificationSergeyNo ratings yet

- Datasheet Sanicro 72hpDocument2 pagesDatasheet Sanicro 72hpphillipskincaidNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- 92ML Data SheetDocument4 pages92ML Data SheetEduardo Ruiz PalominoNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- RD 360 1post File 2019 12 10 161048Document1 pageRD 360 1post File 2019 12 10 161048Adityo Bambang WNo ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Datasheet Sanicro 60Document2 pagesDatasheet Sanicro 60Ismail JamaluddinNo ratings yet

- Unit 1Document19 pagesUnit 1SafjrocnNo ratings yet

- Mild Steel Mig Welding WireDocument2 pagesMild Steel Mig Welding WireDheebika MurugesanNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- High Conductivity Copper, Hard, UNS C10200 (MatWeb)Document3 pagesHigh Conductivity Copper, Hard, UNS C10200 (MatWeb)jlmeseguerNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Datasheet Sandvik 2212htDocument2 pagesDatasheet Sandvik 2212htDarryl007No ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- Setting Up A MATLAB TCPIP Server SessionDocument5 pagesSetting Up A MATLAB TCPIP Server SessionPritesh GuptaNo ratings yet

- Fabric DropsDocument5 pagesFabric DropsSivaraman AlagappanNo ratings yet

- 0-Wd110-Em300-00004 - 0 - Explanation of Boiler Strength CalculationDocument25 pages0-Wd110-Em300-00004 - 0 - Explanation of Boiler Strength Calculationraul gonzalezNo ratings yet

- SY-365 SANSY365KEE100208 - 14SY036B07888 - enDocument356 pagesSY-365 SANSY365KEE100208 - 14SY036B07888 - enSodalita Mineração71% (7)

- Orme 8 2018Document60 pagesOrme 8 2018sureshmechanical86No ratings yet

- Godrej Industries Limited: Material Safety Data Sheet (MSDS)Document4 pagesGodrej Industries Limited: Material Safety Data Sheet (MSDS)Ndi FarhanNo ratings yet

- Exp2 Amplitude Modulation and Demodulation W2015Document12 pagesExp2 Amplitude Modulation and Demodulation W2015Bulmi Hilme100% (1)

- Unit of WorkDocument8 pagesUnit of Workapi-314709847No ratings yet

- Efficiency of Infrastructure: The Case of Container Ports: Santiago HerreraDocument30 pagesEfficiency of Infrastructure: The Case of Container Ports: Santiago HerreraCristina Steliana MihailoviciNo ratings yet

- Emotion MouseDocument5 pagesEmotion MouseprincegirishNo ratings yet

- At Us700Document2 pagesAt Us700Jeisson BeltranNo ratings yet

- FREUND Ernst The Police Power Public Policy and Constitucional RightsDocument923 pagesFREUND Ernst The Police Power Public Policy and Constitucional RightsGustavZatelliNo ratings yet

- Test 1 Unit 5 - Grade 10Document9 pagesTest 1 Unit 5 - Grade 10Hường NgôNo ratings yet

- Abb Servi̇s Çanta Malzemeleri̇ 2021Document4 pagesAbb Servi̇s Çanta Malzemeleri̇ 2021Hasan Yiğit Demir100% (1)

- Policy GuideDocument3 pagesPolicy GuideTheresa Jane Huerte ArpilledaNo ratings yet

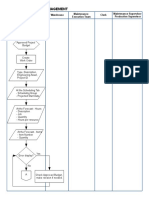

- EAM - Process Flow - Work Order ManagementDocument3 pagesEAM - Process Flow - Work Order ManagementjoyxeniaNo ratings yet

- EPS Ovens BrochureDocument1 pageEPS Ovens BrochureEPSovensNo ratings yet

- Curriculum Vitae: Umamahesh .MavuluriDocument3 pagesCurriculum Vitae: Umamahesh .MavuluriUmamahesh MavuluriNo ratings yet

- Tda 4858Document44 pagesTda 4858utilscNo ratings yet

- Arm ShowDocument38 pagesArm Showselva33No ratings yet

- Civil Engineer Entry LevelDocument1 pageCivil Engineer Entry LevelAli Shan KhawajaNo ratings yet

- UAE - Requirements For Cladding - Peremeter Wall ContractorsDocument1 pageUAE - Requirements For Cladding - Peremeter Wall Contractorsclarkie_bdNo ratings yet

- B, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoDocument10 pagesB, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoSuhel PathanNo ratings yet

- Attachment 10Document4 pagesAttachment 10dianNo ratings yet

- Induction Motor BasicsDocument19 pagesInduction Motor BasicsPUSHPAN DAHARWALNo ratings yet

- Smart Specialisation Strategy of Montenegro 2019-2024Document65 pagesSmart Specialisation Strategy of Montenegro 2019-2024Portal Senat.meNo ratings yet

- Iris Recognition vs. Retina Scanning - What Are The Differences?Document8 pagesIris Recognition vs. Retina Scanning - What Are The Differences?Vladan MilojevićNo ratings yet

- D785T007Document11 pagesD785T007LLNo ratings yet

- Pig Traps Launcher 2016428 CriDocument7 pagesPig Traps Launcher 2016428 CriKrishna KusumaNo ratings yet

- Remote Control Using Infrared With Message RecordingDocument107 pagesRemote Control Using Infrared With Message RecordingBASEER AHMADNo ratings yet