0% found this document useful (0 votes)

113 views8 pagesSurface Hardening of Steels for Gears

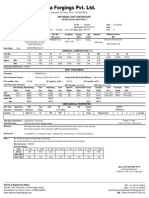

This document summarizes an experiment on surface hardening of steels through carburizing. Key points:

- Hardness testing found a hardened surface layer with hardness of 164 HV, decreasing to 127 HV at 4.6 mm depth.

- Calculations based on temperature (925°C) and time (2 hours) give a predicted case depth of 0.035 inches (889 μm).

- Micrographs show high carbon martensite near the surface, transitioning to ferrite and pearlite in the core.

- The hardness and microstructure profiles match the predicted case depth from the carburizing parameters.

Uploaded by

Shadman RahmanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

113 views8 pagesSurface Hardening of Steels for Gears

This document summarizes an experiment on surface hardening of steels through carburizing. Key points:

- Hardness testing found a hardened surface layer with hardness of 164 HV, decreasing to 127 HV at 4.6 mm depth.

- Calculations based on temperature (925°C) and time (2 hours) give a predicted case depth of 0.035 inches (889 μm).

- Micrographs show high carbon martensite near the surface, transitioning to ferrite and pearlite in the core.

- The hardness and microstructure profiles match the predicted case depth from the carburizing parameters.

Uploaded by

Shadman RahmanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd