Professional Documents

Culture Documents

Application:: Properties Test Method English SI

Uploaded by

Phung LucOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application:: Properties Test Method English SI

Uploaded by

Phung LucCopyright:

Available Formats

3360

APPLICATION:

3360 is a white S-B-S thermoplastic elastomer formulated for applications that require

rubber-like properties and a good surface finish. 3360 is heat sealable and well suited for

consumer goods and extruded tubing and profile applications. 3360 can be overmolded

and/or coextruded onto polystyrene.

English SI

Properties Test Method

Units Values Units Values

Physical/Thermal Properties

Durometer Hardness, 10 sec. ASTM D2240 Shore A 60 Shore A 60

Density ASTM D792 g/cm3 .95 g/cm3 .95

Mechanical Properties

Tens ile Strength ASTM D412 ps i 536 MPa 3.7

100% Modul us ASTM D412 ps i 388 MPa 2.7

El ongation ASTM D412 % 377 % 377

Tea r Strength ASTM D624 pl i 151 N/Cm 264.40

Our staff is available to answer questions and provide technical assistance at 978.537.8261

The information presented here is, to our best knowledge, true and accurate. However, since conditions of use are beyond our control, all recommendations or suggestions are presented without

guarantee or responsibility on our part. We disclaim all liability in connection with the use of information contained herein or otherwise. All risks of such use are assumed by the user. Furthermore,

nothing contained herein shall be construed as an inducement or recommendation to use any process or to manufacture or use any productin conflict with existing or future patents.

REVISION DATE: 0 6 -13-2019

© 2018 Aurora Plastics LLC. All rights reserved. All marks are the property of Aurora Plastics LLC.

140 Leominster-Shirley Road ❘ Suite 100 ❘ Lunenburg, Massachusetts 01462

phone: 978.537.8261 ❘ fax: 978.537.5310 www.auroraplastics.com

3360

DESIGN & PROCESSING:

Suggested Extrusion Processing Conditions

Barrel Temperatures English SI

Zone 1 310-320F 154-160C

Zone 2 320-340F 160-171C

Zone 3 340-350F 171-177C

Zone 4 360-370F 182-188C

Zone 5 350-360F 177-182C

Die 320-340F 160-171C

Screw Speed 75-125 RPM 75-125 PRM

Suggested Processing Conditions

Barrel Temperatures English SI

Rear 350F 177C

Center 370-390F 188-199C

Front 380-400F 193-204C

Nozzle 390-400F 199-204C

Melt 390-400F 199-204C

Mold Temperature 100-120F 37.8-49C

Back Pressure 50-150 psi .34-1.03 MPa

Injection Rate Slow- Moderate Slow- Moderate

Aurora Plastics’ 3360 thermoplastic elastomer compound does not require drying.

Aurora Plastics’ thermoplastic elastomers are not compatible with flexible PVC and should not

be blended with or used in an application where direct contact is intended.

Our staff is available to answer questions and provide technical assistance at 978.537.8261

The information presented here is, to our best knowledge, true and accurate. However, since conditions of use are beyond our control, all recommendations or suggestions are presented without

guarantee or responsibility on our part. We disclaim all liability in connection with the use of information contained herein or otherwise. All risks of such use are assumed by the user. Furthermore,

nothing contained herein shall be construed as an inducement or recommendation to use any process or to manufacture or use any product in conflict with existing or future patents.

© 2018 Aurora Plastics LLC. All rights reserved. All marks are the property of Aurora Plastics LLC. REVISION DATE: 0 6 -14-2019

140 Leominster-Shirley Road ❘ Suite 100 ❘ Lunenburg, Massachusetts 01462

phone: 978.537.8261 ❘ fax: 978.537.5310 www.auroraplastics.com

You might also like

- 17-7 Material PDFDocument5 pages17-7 Material PDFJothi ManiNo ratings yet

- Guide To Polyolefin Injection Molding 5979Document50 pagesGuide To Polyolefin Injection Molding 5979brijeshmaurya2100% (1)

- Iec 60243-1Document58 pagesIec 60243-1Michel Bouquet100% (1)

- Boosting Mold Design With ZW3D CADCAMDocument9 pagesBoosting Mold Design With ZW3D CADCAMbadboys123100% (1)

- GM14444 TraduzidaDocument39 pagesGM14444 TraduzidaJefferson CruzNo ratings yet

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YDocument2 pagesHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuNo ratings yet

- SABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingDocument2 pagesSABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingAnas AbdoNo ratings yet

- Mold and Die - PPTDocument110 pagesMold and Die - PPTThaloengsak Kucharoenpaisan100% (2)

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- Injection Molding MachineDocument3 pagesInjection Molding MachinechrisofomaNo ratings yet

- STAMOD Engineering ServicesDocument40 pagesSTAMOD Engineering ServicesvikasgodageNo ratings yet

- User's Manual: Babk, CDC, CDK, HM, TM Unilog B2Document150 pagesUser's Manual: Babk, CDC, CDK, HM, TM Unilog B2MOHD NASIR KAMARUDDINNo ratings yet

- Moldmaking With 3D Printing Formlabs White PaperDocument13 pagesMoldmaking With 3D Printing Formlabs White PaperVincenz LachnerNo ratings yet

- Enersyn MP-S RangeDocument2 pagesEnersyn MP-S RangecarmaNo ratings yet

- Alpha SP Range: DescriptionDocument3 pagesAlpha SP Range: Descriptionvicky kNo ratings yet

- Iso 559-77 Welded or Seamless Steel Tubes For Water Sewage and GasDocument2 pagesIso 559-77 Welded or Seamless Steel Tubes For Water Sewage and GasDejan KostadinovicNo ratings yet

- Alphasyn GS: DescriptionDocument2 pagesAlphasyn GS: Descriptioncool_ddNo ratings yet

- Elastron TPE DatasheetDocument2 pagesElastron TPE DatasheetMateria by Purple AvenueNo ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- Pla - FC 60025 Cristal - ErtDocument2 pagesPla - FC 60025 Cristal - ErtfernandoincesaNo ratings yet

- Ficha Técnica - FRAYÖL GEAR S 2 EP - 680Document2 pagesFicha Técnica - FRAYÖL GEAR S 2 EP - 680Julio Oliveira Goncalves JuniorNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- Alphasyn Ep 220Document2 pagesAlphasyn Ep 220Atika AtikaNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Ezprene 9085aDocument2 pagesEzprene 9085aalejandrocharlescollNo ratings yet

- Synthetic Gear Oil Data SheetDocument2 pagesSynthetic Gear Oil Data SheetDiegoNo ratings yet

- Hyspin AWS 15Document2 pagesHyspin AWS 15nargueNo ratings yet

- PGS SSWG Data-SheetDocument5 pagesPGS SSWG Data-Sheetazeem bilalNo ratings yet

- (EN) Alpha EP RangeDocument1 page(EN) Alpha EP RangemartinNo ratings yet

- Datasheet TC5YCA-743Document2 pagesDatasheet TC5YCA-743AdrenalNo ratings yet

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 pagesCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuNo ratings yet

- Special Steels A320 L43: American Standards AstmDocument1 pageSpecial Steels A320 L43: American Standards Astmsamirfun2006No ratings yet

- Castrol Magna SW D - 150 PDFDocument2 pagesCastrol Magna SW D - 150 PDFPabloNo ratings yet

- P&T Products Guide To Understanding ASTM SpecsDocument1 pageP&T Products Guide To Understanding ASTM SpecsNuno Telmo LopesNo ratings yet

- Spheerol Epl GreaseDocument2 pagesSpheerol Epl GreaseRaja YadavNo ratings yet

- 052 Submission Australianindustry OnesteelmanufacturingptyltdDocument3 pages052 Submission Australianindustry OnesteelmanufacturingptyltdVõ Thi Minh YếnNo ratings yet

- Special steels - American standards ASTM A193 B7 and B7MDocument1 pageSpecial steels - American standards ASTM A193 B7 and B7MNarimane BentyNo ratings yet

- REPSOL GXR PlatinumDocument1 pageREPSOL GXR PlatinumAankz AnggoroNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- 20% Glass Fiber Reinforced PC/PBT Product Data SheetDocument1 page20% Glass Fiber Reinforced PC/PBT Product Data SheetsrinivasaNo ratings yet

- Ficha Técnica Castrol Synthetic CT 320Document2 pagesFicha Técnica Castrol Synthetic CT 320el pro jajaja GonzalezNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangecarmaNo ratings yet

- E 9018-B9 Product-SheetDocument1 pageE 9018-B9 Product-SheetjuanNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Lushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingDocument2 pagesLushan L-5R Polyethylene Copolymer Adhesive For Steel Pipe CoatingelsobkiNo ratings yet

- MSS PJ PJMaterialsDataSheetDocument2 pagesMSS PJ PJMaterialsDataSheetAndreNo ratings yet

- STPG370 - SteelJIS - Datasheet, Chemical Composition, Standards and PropertiesDocument2 pagesSTPG370 - SteelJIS - Datasheet, Chemical Composition, Standards and Propertiesvalli rajuNo ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- STPG370 - SteelJIS - Datasheet, Chemical Composition, Standards and PropertiesDocument1 pageSTPG370 - SteelJIS - Datasheet, Chemical Composition, Standards and PropertiesSali Purwandi サリNo ratings yet

- Castrol Alpha SP 150 Data SheetDocument2 pagesCastrol Alpha SP 150 Data SheetRonny Ali Ochoa YucraNo ratings yet

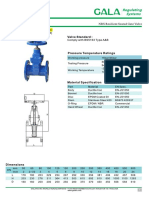

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- Royal 760 Polyplate EP GreasesDocument2 pagesRoyal 760 Polyplate EP GreasesRoger ObregonNo ratings yet

- 'Invoice 12341231Document1 page'Invoice 12341231pateldhiraj532No ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangeAlin BAMNo ratings yet

- EN FC 3D600 Technical Data Sheet - PETG for 3D PrintingDocument3 pagesEN FC 3D600 Technical Data Sheet - PETG for 3D PrintingHelio Coelho JuniorNo ratings yet

- EN FC 3D600 Technical Data Sheet: Physical Properties & Guidelines For UseDocument3 pagesEN FC 3D600 Technical Data Sheet: Physical Properties & Guidelines For UseheliocoelhojrNo ratings yet

- Wepp bpzs8fDocument2 pagesWepp bpzs8fArthur Sanda LayukNo ratings yet

- SRCB-III Saturating ResinDocument2 pagesSRCB-III Saturating Resintimmo510No ratings yet

- Api 603 Stainless Steel Valves: Gate, Globe & Check Valves Y-StrainersDocument12 pagesApi 603 Stainless Steel Valves: Gate, Globe & Check Valves Y-StrainerszzapiecheNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- Datasheet STERLING NSPDF PDFDocument2 pagesDatasheet STERLING NSPDF PDFhery siregarNo ratings yet

- TD 285 4PG BW Oct2015Document4 pagesTD 285 4PG BW Oct2015ingenieriavfloresNo ratings yet

- Manual EP 80W-90 transmission fluidDocument1 pageManual EP 80W-90 transmission fluidvicky kNo ratings yet

- Ugima 4404 HMDocument3 pagesUgima 4404 HMReginaldoNo ratings yet

- Technical Data Sheet: High Performance Rail Grease With GraphiteDocument1 pageTechnical Data Sheet: High Performance Rail Grease With GraphiteDon HowardNo ratings yet

- Castrol Syngear: Americas DescriptionDocument2 pagesCastrol Syngear: Americas Description80ALLA86iNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Tribol GR 3020 PDDocument3 pagesTribol GR 3020 PDMiana BodeanNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- Asia Lanneret 2630Document1 pageAsia Lanneret 2630Phung LucNo ratings yet

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucNo ratings yet

- Asia Lanneret EPDM-2019Document2 pagesAsia Lanneret EPDM-2019Phung LucNo ratings yet

- ALTECH PE-HD A 2010/550 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/550 GF10: Technical Data SheetPhung LucNo ratings yet

- Basell HDPE Start-Up PDFDocument1 pageBasell HDPE Start-Up PDFPhung LucNo ratings yet

- Tech Topic Mold Shrinkage PDFDocument2 pagesTech Topic Mold Shrinkage PDFPhung LucNo ratings yet

- High Density Polyethylene Conduit Grade Melt Index 0.30 Density 0.949Document1 pageHigh Density Polyethylene Conduit Grade Melt Index 0.30 Density 0.949Phung LucNo ratings yet

- BASF Ultrason E 2010 G4Document2 pagesBASF Ultrason E 2010 G4Phung LucNo ratings yet

- Kibilac PW-957Document1 pageKibilac PW-957Phung LucNo ratings yet

- Ultramid B3G8Document2 pagesUltramid B3G8Phung LucNo ratings yet

- Ecoflex C1200Document3 pagesEcoflex C1200Phung LucNo ratings yet

- BASF Elastollan TPU PDFDocument3 pagesBASF Elastollan TPU PDFPhung LucNo ratings yet

- BASF Elastollan TPU PDFDocument3 pagesBASF Elastollan TPU PDFPhung LucNo ratings yet

- BASF Elastollan TPU PDFDocument3 pagesBASF Elastollan TPU PDFPhung LucNo ratings yet

- BASF Ultradur B 4300 G2 ISO SpecDocument2 pagesBASF Ultradur B 4300 G2 ISO SpecPhung LucNo ratings yet

- Ultradur B2550Document2 pagesUltradur B2550Phung LucNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Blendfor A4000 GF20Document2 pagesBlendfor A4000 GF20Phung LucNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Tenac C 4520Document2 pagesTenac C 4520Phung LucNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Colorfast Pba2000Document2 pagesColorfast Pba2000Phung LucNo ratings yet

- Petra 130Document2 pagesPetra 130Phung LucNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- Ecoflex C1200Document3 pagesEcoflex C1200Phung LucNo ratings yet

- Ultramid 8202C: ® Polyamide 6Document2 pagesUltramid 8202C: ® Polyamide 6Phung LucNo ratings yet

- Ultraform H 4320 ProDocument2 pagesUltraform H 4320 ProPhung LucNo ratings yet

- Tooling Standard (Die Casting)Document39 pagesTooling Standard (Die Casting)Kmilo GiraldoNo ratings yet

- 1410 2022t04 Rajat Rathore Saugata enDocument9 pages1410 2022t04 Rajat Rathore Saugata enshimelis TameneNo ratings yet

- Delrin Molding GuideDocument40 pagesDelrin Molding GuideWagner Tadeu RibeiroNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- Syllabus for Plastic Processing Operator TradeDocument13 pagesSyllabus for Plastic Processing Operator Tradeswami061009No ratings yet

- 2017 Queen S Awards Press BookDocument106 pages2017 Queen S Awards Press BookFazila KhanNo ratings yet

- Six Sigma Through Poka-Yoke: A Navigation Through Literature ArenaDocument13 pagesSix Sigma Through Poka-Yoke: A Navigation Through Literature Arenaprabhulean14No ratings yet

- Manufacturing of Plastic ComponentsDocument50 pagesManufacturing of Plastic ComponentsrameshwarmaNo ratings yet

- Recent Case Studies of Engineering Thermosets For Under-The-Hood ApplicationsDocument8 pagesRecent Case Studies of Engineering Thermosets For Under-The-Hood ApplicationsLeventNo ratings yet

- Introduction To Injection Mold Design: Learning ObjectivesDocument82 pagesIntroduction To Injection Mold Design: Learning ObjectivesVignesh WaranNo ratings yet

- Asnakew Final MSC Thesis Approved@DOE11Document84 pagesAsnakew Final MSC Thesis Approved@DOE11zewdu mekonnenNo ratings yet

- Autoclave moulding process guideDocument16 pagesAutoclave moulding process guidevaniNo ratings yet

- Feed System DesignDocument6 pagesFeed System DesignLEV JAMARENo ratings yet

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- Wiz T PDFDocument6 pagesWiz T PDFJohan SneiderNo ratings yet

- Die Casting With TypesDocument4 pagesDie Casting With TypesAdarsh TiwariNo ratings yet

- Bobbin Deisgn PDFDocument100 pagesBobbin Deisgn PDFPaul JosephNo ratings yet

- 1200e Husky PDFDocument5 pages1200e Husky PDFzarasettNo ratings yet

- P640JDocument2 pagesP640JTan Chen TatNo ratings yet

- Group Structured Wall Piping STI GuidelinesDocument8 pagesGroup Structured Wall Piping STI GuidelinesMarketing Dept APEL 1100% (1)