Professional Documents

Culture Documents

Special Steels A320 L43: American Standards Astm

Uploaded by

samirfun2006Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Steels A320 L43: American Standards Astm

Uploaded by

samirfun2006Copyright:

Available Formats

SPECIAL

L43 - 4340 STEELS

STANDARD REFERENCE:

ASTM A320/A320M

RODACCIAI REFERENCES AND COMPARABLE STANDARDS

EUROPE ITALY GERMANY FRANCE UK USA

- (UNI 7847 - 78) (DIN) (NF A 35-552-86) (BS 970 pt. 1 - 96) ASTM A 29

Grade N° Werkstoff N°

(40NiCrMo7) (1.6565) (40NiCrMo7) (40NiCrMo8-4) (1.6562) - (817M40) 4340

CHEMICAL COMPOSITION (CAST ANALYSIS) (%)

C Si Mn P / max S / max Cr Mo Ni Al

0,38 ÷ 0,43 0,15 ÷ 0,35 0,60÷0,85 0,035 0,040 0,70 ÷ 0,90 0,20 ÷ 0,30 1,65 ÷ 2,00 0,020 ÷ 0,050

MECHANICAL PROPERTIES

Quenched and tempered (+QT)

Size

mm Rp0,2 (MPa) min Rm (MPa) min A5 (%) min Z (%) min HB / max KV-101°C / min

≤ 100 725 860 16 50 321 27J

Minimum tempering temperature 593°C

HARDNESS LIMITS (JOMINY TEST)*

Limits Hardness HRC at a distance from quenched end of test pieces (mm)

of range 1,5 3 5 7 9 11 13 15 20 25 30 35 40 45 50

Max 60 60 60 60 60 60 60 60 59 58 58 58 57 56 56

+H

Min 52 52 52 52 52 52 52 52 51 50 49 48 47 45 44

*For reference only

WORKING TEMPERATURES RECOMMENDED

Operazione Hot forgings Isothermal annealing Normalizing Quenching Tempering

deformation in water or oil

°C 900÷1100 800÷900 640 860÷880 830÷860 550÷650

rev. 10/2018

Mark Rodacciai Download APP

SPECIAL STEELS

A320 L43

AMERICAN STANDARDS ASTM

You might also like

- A320l7 L7M - A320l7 A320l7m EngDocument1 pageA320l7 L7M - A320l7 A320l7m EngNarimane BentyNo ratings yet

- RK1B7 A193b7m - A193b7 A193b7m EngDocument1 pageRK1B7 A193b7m - A193b7 A193b7m EngNarimane BentyNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- Special Steels SB4: For Cold Deformation and BearingsDocument1 pageSpecial Steels SB4: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- 16 Ni CR 11Document2 pages16 Ni CR 11ceca nikolicNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Special Steels CB10FF: For Cold Deformation and BearingsDocument1 pageSpecial Steels CB10FF: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- No VII Engine Oil PDSDocument1 pageNo VII Engine Oil PDSylk1No ratings yet

- 40NiCrMo3 PDFDocument1 page40NiCrMo3 PDFAmy GriffinNo ratings yet

- SUPERDUPLEXDocument7 pagesSUPERDUPLEXM RNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- Pebax Product Range and PropertiesDocument2 pagesPebax Product Range and Propertiesabhishek_negi_41No ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- RK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFDocument2 pagesRK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFAnonymous yshOO0tEjKNo ratings yet

- UK Custom455 - FT038Document2 pagesUK Custom455 - FT038MusfiqAtifNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Omega Amide Nylon Pa CatalogueDocument5 pagesOmega Amide Nylon Pa Cataloguesoni10483No ratings yet

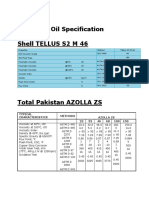

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- 48CrMoNi4 10Document4 pages48CrMoNi4 10FernandoiNo ratings yet

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- Moly WhiteDocument1 pageMoly WhiteLuis EduardoNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- CLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)Document4 pagesCLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)PeterWayNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Fiches Full Power Katana enDocument1 pageFiches Full Power Katana enZeljko AcimovicNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- 40NiCrMo7 PDFDocument2 pages40NiCrMo7 PDFAmy GriffinNo ratings yet

- Annealed Engineering Steel C45E / 1042 (ASTMDocument2 pagesAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahNo ratings yet

- Nitronic® 40 Stainless Steel: Chemical CompositionDocument2 pagesNitronic® 40 Stainless Steel: Chemical CompositionBagus WicaksanaNo ratings yet

- Sae 1045Document1 pageSae 1045Martin UrrizaNo ratings yet

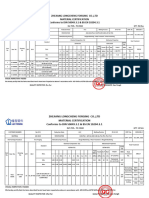

- Certificados - Mtc-Po 23040-Req 14989Document98 pagesCertificados - Mtc-Po 23040-Req 14989MissionPetroleum InfoNo ratings yet

- Total-EDC Range Data SheetDocument2 pagesTotal-EDC Range Data SheetJose AlejandroBlancoNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)Document1 pageNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)GLORIA MONSALVE SALAZARNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- 13CrMo45 P12 T12 Engl PDFDocument3 pages13CrMo45 P12 T12 Engl PDFYankMulya MusaNo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Document4 pagesCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- 3b - FlowCon SM50 150 Dec05Document7 pages3b - FlowCon SM50 150 Dec05ramon duldulaoNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- The Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyFrom EverandThe Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyNo ratings yet

- 193 - Din - Handbook BASICDocument1 page193 - Din - Handbook BASICsamirfun2006No ratings yet

- 2014 MW - enDocument1 page2014 MW - ensamirfun2006No ratings yet

- Comparison of International Standards: Product DIN ISO Ansi BS UNI ENDocument1 pageComparison of International Standards: Product DIN ISO Ansi BS UNI ENsamirfun2006No ratings yet

- BRD - Klee-Datablad DIN 7603Document2 pagesBRD - Klee-Datablad DIN 7603samirfun2006No ratings yet

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocument8 pagesCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdNo ratings yet

- Sealant Checklist: But Longer Cure Time / ExpensiveDocument5 pagesSealant Checklist: But Longer Cure Time / ExpensiveAhmed DawodNo ratings yet

- FullDocument39 pagesFullKayeNo ratings yet

- BR PU High Gloss Enamel PaintDocument2 pagesBR PU High Gloss Enamel PaintPavul RajNo ratings yet

- Efficient Process For LIB RecyclingDocument5 pagesEfficient Process For LIB Recyclingvenugopalan srinivasanNo ratings yet

- fcc10 IndexDocument27 pagesfcc10 IndexNaisadh PatelNo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- Experiment 8 The Preparation of AcetanlideDocument12 pagesExperiment 8 The Preparation of AcetanlideRadhwanNo ratings yet

- Depliant MYSOL381Document6 pagesDepliant MYSOL381Shishir Kumar SinghNo ratings yet

- D2093-03 (2011) Standard Practice For Preparation of Surfaces of Plastics Prior To Adhesive BondingDocument3 pagesD2093-03 (2011) Standard Practice For Preparation of Surfaces of Plastics Prior To Adhesive Bondingjose floresNo ratings yet

- Astm C 582Document4 pagesAstm C 582Solo MosaabNo ratings yet

- 21 April 2023Document4 pages21 April 2023devNo ratings yet

- June 2021 MS - Paper 1 Edexcel Chemistry As-LevelDocument29 pagesJune 2021 MS - Paper 1 Edexcel Chemistry As-Levelbeyofar644No ratings yet

- Di-Pi Methane RearrangementDocument8 pagesDi-Pi Methane RearrangementSengottaiyan M MuruganNo ratings yet

- CHEMISTRY Question Paper 2022Document16 pagesCHEMISTRY Question Paper 2022Bornil PaulNo ratings yet

- Best Periodic TableDocument1 pageBest Periodic Tablemuxi rongNo ratings yet

- Class X - MCQ ChemistryDocument6 pagesClass X - MCQ ChemistrySulekha Rani.R.60% (10)

- Life Cylce Analysis of ToothbrushDocument11 pagesLife Cylce Analysis of ToothbrushKaran Champaklal Arya PGP Mumbai 2017-1950% (2)

- EQA-Industrial-Effluent 5th-ScheduleDocument2 pagesEQA-Industrial-Effluent 5th-Scheduleraman.kNo ratings yet

- AQA A Level Chemistry Textbook AnswersDocument158 pagesAQA A Level Chemistry Textbook AnswersShilat BentataNo ratings yet

- Precipitation Reaction of ProteinsDocument7 pagesPrecipitation Reaction of ProteinsMissy Arabella PameNo ratings yet

- Alkyl Benzene Sulfonate SDocument26 pagesAlkyl Benzene Sulfonate SvahidNo ratings yet

- Astm D 3517Document12 pagesAstm D 3517Rostarina AnggrainiNo ratings yet

- Chemistry Class 10Document8 pagesChemistry Class 10Ruchika RastogiNo ratings yet

- Advanced Level Craft RoastingDocument8 pagesAdvanced Level Craft RoastingStijn Braas75% (4)

- Bartlett-Snow™ Rotary Kilns: For High Temperature ApplicationsDocument2 pagesBartlett-Snow™ Rotary Kilns: For High Temperature Applicationsmick hughesNo ratings yet

- IgtDocument2 pagesIgtPeter AndrewNo ratings yet

- William F Hosford-Iron and Steel-Cambridge University Press (2012) PDFDocument310 pagesWilliam F Hosford-Iron and Steel-Cambridge University Press (2012) PDFJulian Sihombing50% (2)

- 1593194938141-Low Density Polyethylene Production ProjectDocument249 pages1593194938141-Low Density Polyethylene Production ProjectTeena Alawad100% (1)

- Wayne - Simmons - Sundrop FuelsDocument24 pagesWayne - Simmons - Sundrop Fuelsandrew_savage5387No ratings yet