Professional Documents

Culture Documents

Parkers: BS EN 10029: 1991

Parkers: BS EN 10029: 1991

Uploaded by

JeganeswaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parkers: BS EN 10029: 1991

Parkers: BS EN 10029: 1991

Uploaded by

JeganeswaranCopyright:

Available Formats

BS EN 10029 : 1991

Tolerances on dimensions, shape and mass for hot rolled steel plates 3mm thick or above

Tolerances on dimensions

Thickness At the time of enquiry and order the purchaser shall indi-

Tolerances on thickness are given in table 1. Plates may cate if class A, B, C or D tolerances are required.

be supplied with either:

- class A: for minus thickness tolerances depending Additionally and within the tolerance limits in nominal

on the nominal thickness; thickness, the tolerances between minimum and maxi-

- class B: for a fixed minus tolerance of 0.3mm; mum thickness of an individual plate given in table 1 shall

- class C: for all plus tolerances depending on the apply to class A, B, C and D tolerances.

nominal thickness;

- class D: for symmetrical tolerances depending on For permissible limits concerning surface imperfections

the nominal thickness. and requirementsfor repair EN 10163 Parts 1 and 2 apply.

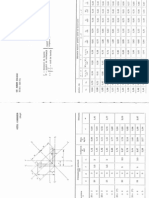

Table 1. Tolerances on thickness - dimensions in mm

Nominal Tolerances on the nominal thickness 1) Maximum thickness difference within a plate

thickness Class A Class B Class C Class D Nominal plate width

Lower Upper Lower Upper Lower Upper Lower Upper > 600 > 2000 > 2500 > 3000 > 3500 > 4000

< 2000 < 2500 < 3000 < 3500 < 4000

> 3 < 5 - 0.4 + 0.8 - 0.3 + 0.9 - 0 + 1.2 - 0.6 + 0.6 0.8 0.9 0.9 - - -

> 5 < 8 - 0.4 + 1.1 - 0.3 + 1.2 - 0 + 1.5 - 0.75 + 0.75 0.9 0.9 1.0 1.0 - -

> 8 < 15 - 0.5 + 1.2 - 0.3 + 1.4 - 0 + 1.7 - 0.85 + 0.85 0.9 1.0 1.0 1.1 1.1 1.2

> 15 < 25 - 0.6 + 1.3 - 0.3 + 1.6 - 0 + 1.9 - 0.92 + 0.92 1.0 1.1 1.2 1.2 1.3 1.4

> 25 < 40 - 0.8 + 1.4 - 0.3 + 1.9 - 0 + 2.2 - 1.1 + 1.1 1.1 1.2 1.2 1.3 1.3 1.4

> 40 < 80 - 1.0 + 1.8 - 0.3 + 2.5 - 0 + 2.8 - 1.4 + 1.4 1.2 1.3 1.4 1.4 1.5 1.6

> 80 <150 - 1.0 + 2.2 - 0.3 + 2.9 - 0 + 3.2 - 1.6 + 1.6 1.3 1.4 1.5 1.5 1.6 1.7

>150 <250 - 1.2 + 2.4 - 0.3 + 3.3 - 0 + 3.6 - 1.8 + 1.8 1.4 1.5 1.6 1.6 1.7 -

1)

These thickness tolerances apply outside ground areas

Width

Tolerances on width are given in table 2.

Table 2. Tolerances on width - dimensions in mm

Tolerances on width for plates with untrimmed edgs

(NK) shall be the subject of agreement between the Nominal width Tolerances

manufacturer and purchaser at the time of enquiry and Lower Upper

order.

> 600 < 2000 0 + 20

Length > 2000 < 3000 0 + 25

Tolerances on length are given in table 3. > 3000 0 + 30

Tolerances on shape

Edge camber and out-of squareness

The edge camber and the out-of squareness of a plate Table 3. Tolerances on width of sheet and wide

shall be limited so that it shall be possible to inscribe strip - dimensions in mm

a rectangle with the dimensions of the ordered plate

Nominal length Tolerances

within the delivered size.

Lower Upper

Additionally, if agreed at the time of the enquiry and < 4000 0 + 20

order, edge camber shall be limited to 0.2% of the > 4000 < 6000 0 + 30

actual length of the plate and out-of squareness to 1% > 6000 < 8000 0 + 40

of the actual width of the plate (G). > 8000 < 10000 0 + 50

> 10000 < 15000 0 + 75

Flatness > 15000 < 20000 1) 0 + 100

Tolerances on flatness are given in table 4 for normal 1)

Tolerances on plates with a nominal length > 20000 mm shall

tolerances and in table 5 for special tolerances. Unless be agreed at the time of the enquiry and order.

otherwise specified in the order, the plates shall be

supplied with normal tolerances.

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9002 : 1994

The steel types according to tables 4 and 5 are defined as follows.

Steel type L: Products with a specified minimum yield strength < 460 N/mm2, neither quenched nor quenched

and tempered.

Steel type H: Products with a specified minimum yield strength > 460 N/mm2 and < 700 N/mm2 and all grades of

quenched and quenched and tempered products.

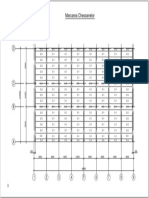

Table 4. Normal tolerances for atness, Class N If the distance between the points of contact of the

dimensions in mm straight-edge and the plate is < 1000 mm the permissible

Nominal thickness Steel type L Steel type H

deviation from flatness shall comply with the following

Measuring length

requirements:

1000 2000 1000 2000

for steel type L max. 1% or for steel type H max. 1.5%

>3<5 9 14 12 17 of the distance between points of contact on the plate

>5<8 8 12 11 15 between 300 mm to 1000 mm, but not exceeding the

> 8 < 15 7 11 10 14 values given in table 4.

> 15 < 25 7 10 10 13

> 25 < 40 6 9 9 12

> 40 < 250 5 8 8 11

Table 5. Special tolerances for atness, class S - dimensions in mm

Nominal thickness Steel type L 1) Steel type H

Plate width

< 2750 > 2750

Measuring length

1000 2000 1000 2000 1000 2000

>3<8 4 8 5 10 Shall be agreed at the

> 8 < 250 3 6 6 6 time of enquiry and order

1)

Tighter tolerances shall be the subject of special agreement at the time of enquiry and order

If the distance between the points of contact of the straight-edge and the plate is < 1000 mm the permissible deviation

from flatness shall comply with the following requirements:

max. 0.5% of the distance between the points of contact, but not exceeding the values in table 5 and not < 2 mm.

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9002 : 1994

You might also like

- Formular Comanda Armatura 1Document6 pagesFormular Comanda Armatura 1Marinoiu MarianNo ratings yet

- Tabel Corniere SREN 10056Document1 pageTabel Corniere SREN 10056abys86No ratings yet

- EN 10025 - 2019 - ChangesDocument7 pagesEN 10025 - 2019 - ChangesJulienNo ratings yet

- Boiler Inox Tank in Tank Acv Hle100 Termoelectric Fisa TehnicaDocument1 pageBoiler Inox Tank in Tank Acv Hle100 Termoelectric Fisa TehnicamondorolaNo ratings yet

- RSM02 - ANSAMBLURI As1-As7 - R1 - 10.07.2015Document1 pageRSM02 - ANSAMBLURI As1-As7 - R1 - 10.07.2015zgrouproNo ratings yet

- Profile Laminate Otel-Beton Prop Mecanice Compozitie ChimicaDocument12 pagesProfile Laminate Otel-Beton Prop Mecanice Compozitie ChimicaVantu-Voiculescu CristiNo ratings yet

- 3 Profile Metalice LaminateDocument3 pages3 Profile Metalice LaminateGiusca Valerian0% (1)

- DIN18516 Back Ventilated ENGDocument12 pagesDIN18516 Back Ventilated ENGznahar02No ratings yet

- W1Document641 pagesW1Morosanu AndreiNo ratings yet

- Caracteristici Geometrice Profile LaminateDocument7 pagesCaracteristici Geometrice Profile LaminateMoca AlexNo ratings yet

- Securope NEO - Certificate - CE Type N°0082.1084.160.04.14.0116 PDFDocument1 pageSecurope NEO - Certificate - CE Type N°0082.1084.160.04.14.0116 PDFLouise StrutsNo ratings yet

- Catalog Tevi Arcelor MittalDocument4 pagesCatalog Tevi Arcelor MittalPaul FlorianNo ratings yet

- Eurocod 2Document358 pagesEurocod 2Don Adrián Oniga100% (1)

- Caracteristici Tehnice Pod Rulant PDFDocument1 pageCaracteristici Tehnice Pod Rulant PDFCristian PaladeNo ratings yet

- DIN-472 - Inele de Siguranta Pentru AlezajeDocument5 pagesDIN-472 - Inele de Siguranta Pentru AlezajeJhonny BNo ratings yet

- 2010 05 20 Reabilitare Pe DN2 M La Reghiu PDFDocument573 pages2010 05 20 Reabilitare Pe DN2 M La Reghiu PDFGabrielBarbuNo ratings yet

- Calcul Imbinari MetaliceDocument1 pageCalcul Imbinari MetaliceBoureanu VictorNo ratings yet

- Profile LaminateDocument34 pagesProfile LaminateSepciu ClaudiuNo ratings yet

- SR 6898 1 Tevi de Otel PDFDocument1 pageSR 6898 1 Tevi de Otel PDFCRISTIAN SILVIU IANUCNo ratings yet

- Deviz Local 01/2019Document5 pagesDeviz Local 01/2019IonCotrutaNo ratings yet

- Profile Zincate Calcul PaneDocument2 pagesProfile Zincate Calcul PanecazilauNo ratings yet

- Tehnologia Edificarii Constructiilor - Proiect N 5 N 3 New - Recover-ModelDocument1 pageTehnologia Edificarii Constructiilor - Proiect N 5 N 3 New - Recover-ModelDianaLupascoNo ratings yet

- Anexa 1: Caracteristici Secţionale Ale Profilelor LaminateDocument26 pagesAnexa 1: Caracteristici Secţionale Ale Profilelor LaminatealexNo ratings yet

- Profil Hidraulic Apa, Namol Si Conducte By-PassDocument1 pageProfil Hidraulic Apa, Namol Si Conducte By-PassCretu DanNo ratings yet

- Stas 6482-1-73 RDocument6 pagesStas 6482-1-73 ROvidiu PruteanuNo ratings yet

- Diametre Uzuale Tevi Si TubulaturiDocument3 pagesDiametre Uzuale Tevi Si TubulaturiSandra SirbescuNo ratings yet

- Detalii Rigola Carosabila PDFDocument1 pageDetalii Rigola Carosabila PDFBarbulescu CiprianNo ratings yet

- Fisa Tehnica de Securitate ADEZIV EDR-finalDocument1 pageFisa Tehnica de Securitate ADEZIV EDR-finalSilviuNo ratings yet

- Denumire StasuriDocument60 pagesDenumire StasuriRoxana Muresan0% (1)

- Tabel Profile L InegalDocument2 pagesTabel Profile L InegalPal BarniNo ratings yet

- Purlins Type ZDocument85 pagesPurlins Type ZPhilip WalkerNo ratings yet

- Chrysler Switches To OAT Antifreeze For Longer Service IntervalDocument2 pagesChrysler Switches To OAT Antifreeze For Longer Service IntervalDanno NNo ratings yet

- Greutate Tabla AluminiuDocument2 pagesGreutate Tabla AluminiuAdry AnayrdaNo ratings yet

- About The Network ArchDocument36 pagesAbout The Network ArchSergio Adolfo ParedesNo ratings yet

- Stas 6605 78 R PDFDocument10 pagesStas 6605 78 R PDFadinabNo ratings yet

- 4.7 IMPERFECTIUNI SI CRITERII DE ACCEPTARE Curs 1 - Def - Accept - Design 2014 - ALEXANDRINA MIHAI PDFDocument119 pages4.7 IMPERFECTIUNI SI CRITERII DE ACCEPTARE Curs 1 - Def - Accept - Design 2014 - ALEXANDRINA MIHAI PDFAlexandra Bolog67% (3)

- ANTIEFRACTIEDocument11 pagesANTIEFRACTIEAdrian FilipNo ratings yet

- KG/M Masa (KG) Pozitie Denumire Grosime (MM) Latime (MM) Lungime (MM) Nr. BucDocument3 pagesKG/M Masa (KG) Pozitie Denumire Grosime (MM) Latime (MM) Lungime (MM) Nr. BucVlad GavriliucNo ratings yet

- Metoda Deplasarilor - Model RezolvatDocument64 pagesMetoda Deplasarilor - Model RezolvatAlex MandeaNo ratings yet

- PD Cen TR 15276-1-2009Document50 pagesPD Cen TR 15276-1-2009Jorge SalasënNo ratings yet

- Agrement Tehnic ProfileDocument18 pagesAgrement Tehnic ProfileVALERYA_LUPU100% (1)

- R02 - A2 - Detalii FundatiiDocument1 pageR02 - A2 - Detalii FundatiiSergiu CostinNo ratings yet

- Gard Strada - 39 PDFDocument1 pageGard Strada - 39 PDFAlina TNo ratings yet

- C29-85 Normativ Privind Imbunatatirea Terenurilor de Fundare Slabe Prin Procedee MecaniceDocument59 pagesC29-85 Normativ Privind Imbunatatirea Terenurilor de Fundare Slabe Prin Procedee MecaniceGeorge LazarNo ratings yet

- Anexa Coduri ConstructiiDocument4 pagesAnexa Coduri ConstructiiSilviu Adrian IANANo ratings yet

- Extras Armare Plasa SudataDocument2 pagesExtras Armare Plasa SudataLici001100% (1)

- Detalii de Executie Porotherm 38Document3 pagesDetalii de Executie Porotherm 38Alexandra StoicaNo ratings yet

- Plan Control Calitate PCCVIDocument24 pagesPlan Control Calitate PCCVIlimpsize0074161No ratings yet

- ArcelorMittal TR 153 - 290 - Roof - Decking - Datasheet - EN PDFDocument1 pageArcelorMittal TR 153 - 290 - Roof - Decking - Datasheet - EN PDFBogdan TeodorescuNo ratings yet

- AllPlan Nemetchek 3d Tutorial 2005Document190 pagesAllPlan Nemetchek 3d Tutorial 2005ČovjeknNo ratings yet

- Megaprofil - Profile GalvanizateDocument43 pagesMegaprofil - Profile GalvanizateSebastian PopNo ratings yet

- Chery Fengyun 2 Service Manual (Power Assembly)Document29 pagesChery Fengyun 2 Service Manual (Power Assembly)CarlosLauferNo ratings yet

- Constructii Metalice III - Stilpi PDFDocument12 pagesConstructii Metalice III - Stilpi PDFGhitulescu Catalin GabrielNo ratings yet

- 64.cheson Armare CircularDocument1 page64.cheson Armare CircularAnonymous kqcev0No ratings yet

- Bricscad V16Document4 pagesBricscad V16JAS-Designer100% (1)

- Prop Chimice :oteluri Aliate PT Piese TratateDocument2 pagesProp Chimice :oteluri Aliate PT Piese TratateCiprian NitaNo ratings yet

- Standard EN10029Document4 pagesStandard EN10029Florin JipaNo ratings yet

- Thikness TolerenceDocument5 pagesThikness TolerencemuneeshwaraperumalNo ratings yet

- En 10029 (Detail)Document3 pagesEn 10029 (Detail)muhammad chilmiNo ratings yet

- En 10029Document3 pagesEn 10029Nuran ZorNo ratings yet