Professional Documents

Culture Documents

ISO 7005-1-Steel-Flanges PDF

Uploaded by

wwceng100%(1)100% found this document useful (1 vote)

2K views88 pagesOriginal Title

ISO 7005-1-Steel-Flanges.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

2K views88 pagesISO 7005-1-Steel-Flanges PDF

Uploaded by

wwcengCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 88

ISO 7005 PT*} 92 MM 4851903 0562283 TOL Mm

INTERNATIONAL ISO

STANDARD 7005-1

First edition

1902.04.15,

Metallic flanges —

Part 1:

Steel flanges

Brides métaliques —

Partie 1: Brides en acier

Reference number

1S0 7005-1. 1982 (E}

ISO 7005 PT*1 92 MH 4851903 OSb2284 942

1SO 7006-1 : 1992 (E)

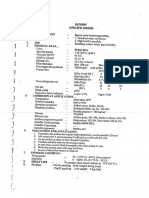

Contents Page

Section 1: General 1

; 14 Scope 1

1.2 Normative references . 1

13 Definitions 2

1.4 Designation of types, components and facings 2

Section 2: General requirements. . 3

2.1. Prossure/temperature ratings 3

2.2. Materials and bolting... 3

23 3

2.4 Dimensions ....... 3

28. Facings 4

2.8 Spot-facing or back facing 5

27° Tolerances : : 5

28 Marking : 5

2.9 Inspection and test 6

2.10. Information to be supplied by the purchaser 6

Section3: Dimensions "

Section 4: Tolerances . a

© 180. 1982

[Allrghts reserved. No partof this publication may be reproduced or utlizedin any form or by any

‘means. electronic of mechanical, including photocopying and microti, without permission in

‘writing from the publisher.

International Organization for Standardization

Case postal $6 « CH-1211 Gentve 20 « Switzerland

Printed in Switeertand

eee

ISO 2005 PT) 92 MH 4851903 0562285 389 a

1SO 7005-1 : 1992 (E)

Annexes

A_ Bevel for specified wall thicknesses from § mm to 22 mm inclusive and

‘greater than 22 mm cy

B Acceptable bevel designs for unequal wall thicknesses

(pipeline applicatons) cy

© _ Recommended bevel for equal wall thicknesses / at the end of the flange

hhub from $ mm to 22 mm inclusive and greater than 22 mm (pipeline applications). 81

1D Guidance on flange materials 82

E Guidance on pressure/ temperature ratings @

F Design eter pipetine applications *

G Bibliography. ”

. Tablos

1 Surface finish for facings types A, 8 and E/F (large) 5

2 Surface finish values fo facings types C/O. €/F (smal), G/H and J 5

3. Synoptic table ”

4 Dimonsions of flange facings for PN 2,6, PN 6, PN 10, PN 16, PN 25

and PN 40 5

5 Dimensions of flange facings up to nominal size DN 900 for PN 20,

N50, PN'T10, PN 180, PN'260 and PN 420 ”

6 Dimensions of flange facings for nominal sizes ON 960 to DN 1 00,

for PN 20, PIVEO, PN 110 and PN 150 ”

7. Dimensions of ring joint facings 9

8 Dimensions of PN2,5 flanges 23

9 Dimensions of PN'6 flanges: 2

10 Dimensions of PN 10 flanges 2

11. Dimensions of PN 16 flanges Fe

12. Dimensions of PN 20 anges 31

13. Dimensions of PN 25 flanges 33

14 Dimensions of PN 40 flanges 35

18 Dimensions of PN50 flanges . 37

16 Dimensions of PN 110 flanges 39

17 Dimensions of PN 150 flanges. a

18 Dimensions of PN 260 fares e

19 Dimensions of PN 420 flanges «6

20 Tolerances a

21. Minimum hub radius after backtacing 4

ISO 7005 PT¥} 92 MM 4852903 O5b228b 715

1SO 7005-1 : 1992 (E)

.1_ Basic properties and reference standards for materials used for PN 2,5,

PN6, PN 10, PN 16, PN25.and PN 40 flanges 53

D.2_ Reference standards for materials used for PN 20, PN 50, PN 110,

PN 180, PN 260 and PN 420 flanges 57

D.3_ Materials applicable to tables 12, 15, 16 and 17 covering PN 20,

PN 50, PN 110 and PN 150 flanges types 05 and 11 in the size

range DN 300 and larger for pipeline applications 0

1 Prossure/temperature (P/T) ratings for flanges made using material

‘groups 1E0 to GEO 8

E.2._Prassura/temperature (P/T) ratings for flanges made using material

‘groups 7E0 to 9EO 6

E.3._Pressure/temperature (PT) ratings for flanges made using austenitic

stainless steels (based on 0,2 % proof stress), material groups 1060 to 15E0 6

E.4 Pressure/temporature (P/T) ratings for flanges made using austenitic

4 stainless steels (based on 1 % proof stress), material groups 10E0 to 15E0. 6

ES. Pressure/temperature (P/T) ratings for flanges made using group 1A

materials. : a

£6 Preseue/temperture (F/T) ratings for anges made using group 1A2

materials... . 67

E.7_Pressure/ temperature (P/T) ratings for flanges made using group 1A3

materials a

E.8_ Pressure/temperature (P/T) ratings for flanges made using group 1A4

materials Cy

£.9. Pressure/ temperature (P/T) ratings for flanges made using group 1A5

materials «

E10 Pressure/temperature (P/T) ratings for flanges made using group 1A7

materials 2

E.11._Pressure/temperature (P/T) ratings for flanges made using group 189

rmateria's 7

E.12_ Pressure/temperature (P/T) ratings for flanges made using group 1A10,

materia. 7

E.13_Pressure/temperature (P/T) ratings for flanges made using group 1A13,

materials eee n

EW _reeure/trmpertre 1/7) ratings for flanges mode wing group VAT

materials n

15 Preesure/ temperature (P71 ratings for flanges made using group 2A

materials : n

E.16 Pressure/temperature (P/) ratings for flanges made using group 2A2

materials 73

.17 Pressure/temperature (P/T) ratings for flanges made using group 2A3.

materials 3

.18 Pressure/temperature (P/T) ratings for flanges made using group 284 :

materials : %

E.19Preseure/temperature (P/T) ratings for flanges made using group 2A5

materials... 6

E.20 _Prescure/temperature (P/T) ratings for flanges made using group 2A6

materials : %

ISO 7005 PT*1 92 MMH 4851903 O5b2287 65) a

1SO 7005-1 : 1982 (E)

E.21._Pressure/temperature (PT) ratings for flanges made using group 2A7

materials 7

€.22. Pressure/temperature IP/T) ratings for pipeline flanges 7

Figures

1 Flanges — Types0 1005 7

2 Flanges — Types 1110 15, 8

3. Flange ~ Type 21 8

4. Ancilary components for flanges — Types 320 34. 9

5 illustration of flange facings Itypes A to.) 10

6 PN2,5, PNG, PN 10, PN 16, PN 25 and PN 40 flange facing dimensions “

7. PN.20, PN'50, PN 110, PN 150, PN 260 and PN 420 flange facing dimensions... 16

8B Minimum hub radius after back-facing. 8

‘A.1. Bovel for specified wall thicknesses 1 49

B.1_ Acceptable bevel designs for unequal wall thicknesses. Ey

€.1 Recommended bevel for equal wall thicknesses / at the end

of the flange hub 51

Iso 7005 PT# 92 MM 4851903 O5b2288 598 A

ISO 7005-1 : 1992 (E)

Foreword

180 {the International Organization for Standardization) is a worldwide federation of

national standards bodies (ISO member bodies). The work of preparing Intemational

Standards is normally carried out through ISO technical committees. Each member

body interested ina subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern:

‘mental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all

‘matters of electrotechnical standardization.

Draft international Standards adopted by the technical committoes are circulated t0

the member bodies for voting. Publication as an Intemational Standard requires

approval by at least 75 % of the member bodies casting @ vote,

International Standard ISO 7005-1 was prepared by Technical Committee ISO/TC 5,

Ferrous metal pipes and metalic ftings, Sub-Committee SC 10, Metalic flanges and

their joints.

This fist edition of ISO 7005-1, together with ISO 7006-2 and ISO 7008-3, cancels and

replaces ISO 2084 : 1974, 'SO 2229 : 1973 and ISO 2441 : 1975, of which they con-

stitute @ technical revision.

180 7005 consists of the following parts, under the general title Metallic Hanges:

— Part 1: Stee! flanges

= Part 2: Cast iron flanges

= Part 3: Copper alloy and composite flanges

‘Annexes A and B form an integral part ofthis part of ISO 7006. Annexes C to Gare for

information only.

ISO 7005 PT#) 92 MM 4851903 0562289 424

1SO 7005-1 : 1992 (E)

Introduction

Various flange systems based on differing design criteria have been in use throughout

the world for many years. Recognizing the increasing difficulties ating from such @

situation, representatives of ISO/TC 5, Ferrous metal pipes and metalic fitings,

ISO/TC 67, Materiais and equipment for petroleum and natural gas industries, and

1SO/TC 183, Valves, established principles for the preparation of an International Stan:

dard for a single series of flanges.

This part of 1SO 7006 is based on the American and European stee! flange systems

combined with some changes to the dimensions specified in the two systems, PI 20,

PN 60, PN 110, PN 180, PN 260 and PN 420 steel flanges are designed to be inter-

changeable with flanges to American standards ANSI/ASME B16.5 and MSS SP44,

they are not identical but are deemed to comply with dimensions specified in

ANSI/ASME 816.5 and MSS SP44 as appropriate.

‘This part of ISO 7005 takes into account unpublished work of the European Committee

for Standardization CEN/TC 74, Flanges, up to 1972 and the amendments that would

have been necessary to 1S 2229 arising from the revision of ANSI/ASME B16.5 up to

1988 and MSS SP44 : 1985, plus amrendments due to the changes in pressure desig

ration. In the American system, flanges are designated by a Class rating, but these

ratings have now been converted to nominal pressure (PN) designations, The

equivalent PN designations are as follows:

Class 160: PN 20

Class 300: PN 60

Class 600: PN 110

Class 900: PN 180,

Cass 1500: PN 260

Cass 2500: PN 420

This part of ISO 7006 does not specity materials or pressure/ temperature ratings of

flanges, but guidance is given in annexes D and € on selected materials and press

ure temperature ratings of flanges (see note 10 to tables 8, 9, 10, 11, 13 and 14,

page 46) using the materials listed, Annex D lists German (DIN) steels on which the

European flange system is based and American (ASTM) steels on which the American

flange system is based, together with international (ISO) steels given in published and

draft Intemational Standards. Users of this part of ISO 7006 may wish to use steels

specified in national standards in preference to those given in annex D. Annex E gives

the pressure/temiperature ratings for certain flanges rrade using the materials given in

‘annex D. (See E.1 and tables E.1 to E.4 for restrictions on the applicability of

pressure’ temperature ratings to flanges.)

Ultimately its the intention that only {SO materials and pressure/temperature ratings

of flanges made using ISO materiats willbe specified in this part of ISO 7005: this will

be achieved in a revision and when work on standardizing the ISO materials and their

elevated temperature properties has been completed,

Flange details in all three parts of SO 7006 are such as that flanges having the same PN,

designations and nominal size (DN) designations and compatibie flange facings will

mate together,

ISO 7005 PTx) 92 MM 4851903 0562290 146 a

1SO 7006-1 : 1992 (E)

‘The method of specitying tolerances has been to combine the existing DIN and ANSI

specified tolerances into one table (table 20).

To avoid possible confusion in giving descriptive names to flanges, all flanges are

designated by a type number and flange facings by a letter.

Users of this part of ISO 7006 should satisfy themselves that the flanges comply with

any statutory requirements.

It should be noted that, in general, flanges previously manufactured to ISO 2084,

180 2229 and 1S 2441 will mate with flanges manufactured to ISO 7006.

ISO 7005 PT*} 92 MM 4852903 O5b2291 082 am

INTERNATIONAL STANDARD

1SO 7006-1 : 1992 (E)

Metallic flanges —

Part 1:

Steel flanges

Section 1: General

1.1. Scope

This part of ISO 7008 for a single system of flanges specifies re

quirements for circular steel flanges in the following PN

designations

Series

PN 10

PN 16

PN 20

PN 50

PN 110

PN 150

PN 260,

PN 420

It specifies the types of steel flanges and their facings, dimen-

sions, tolerances, threading, bolt sizes, flange face surface

finish, marking, testing and inspection,

It does not specify pressure/temperature ratings or materials

{or see! flanges. However, annex D gives guidance on selected

materials and annex E gives guidance on the pressure/

‘temperature ratings for some flanges made from the materials

listed in annex O.

This part of ISO 7005 does not apply to flanges made from bar

stock by turning

Nor does it apply to flanges of types 11, 12, 13, 14 and 15 made

from plate material

The various gasket types, dimensions, design characteristics

and materials used are not within the scope of this part of

180 7006.

NOTE — Dimensions of gaskets are given in 1S 7489,

1.2 Normative references

The following standards contain provisions which, through

reference in this text, constitute provisions of this part of

ISO 7005. At the time of publication, the editions indicated

‘were valid, All standards are subject to revision, and parties to

agreements based on this part of !SO 7005 are encouraged to

investigate the possibility of applying the most recent editions

of the standards indicated below. Members of IEC and ISO

maintain registers of currently valid International Standards.

'S0 7-1 ; 1982, Pipe threads where pressure-tight joints are

‘made on the threads ~ Part T: Designation, dimensions and

tolerances.

1SO 7.2 : 1982, Pipe threads where pressure-tight joints are

‘made on the threads — Part 2: Ventication by means of int

gouges.

180 261 : 1973, SO general purpose meric screw threads —

General plan.

'SO 887 : —", Plain washers for metric bolts, screws and nuts

for general purposes — General pan.

1SO 6708 : 1980, Pipe components — Definition of nominal

'SO 7268 : 1983, Pipe components — Definition of nominal

pressure.

1S0 7489 : 1991, Dimensions of gaskets for use with flanges to

180 7006.

ANSI/ASME B1.20.1

finch)

1989, Pipe threads, gemers! purpose

| Series 1 Hanges are the basic Ranges; series 2 flanges may have a limited application in the future

11 Tobe pubiened. (Revision of 1SO.887 : 1983.)

ISO 7005 PTxL 92 MM 4853903 OSb2292 719 Mm

ISO 7005-1 : 1982 (E)

1.3. Definitions

For the purposes of this part of ISO 7005, the definitions of

‘nominal size {DN} as given in [SO 6708, and nominal pressure

(PN) as given in ISO 7268 and the following definition apply.

1.3.1. pipeline: Cross-country fluid transmission line, ¢.9.

{or oll or gas.

1.4 Designation of types, components and

facings

Figures 1 to 4 illustrate flanges and flanged components

grouped according to type and figure iltustrates facing types.

Figure 1: Flanges — Types 01 to 05 inclusive, comprising

flanges generally manufactured from plate materials.

NOTE — Types 02 and 08 are identical: itis their ancitay com:

Ponents which differ (see igure 8)

Figure 2: Flanges — Types 11 to 18 inclusive, comprising

flanges generally manufactured from forgings or castings.

Figure 3: Flange — Type 21 integral flange, as part of some

other equipment or component.

Figure 4: Ancilary components for flanges — Types 32 to

34 inclusive, comprising parts or components for use with

flange types 02, 03 and 04

Figure 5: Facings — Types A to, inclusive, comprising the

various types of flange facings which may be used where

applicable in conjunction with the groups of flanges or

flanged components in figures 1 to 4,

NOTE — Type numbers are not consecutive to permit possible

future additions to any pantcular group.

ISO 7005 PT*) 92 MM 4852903 0562293 955 mw

1SO 7005-1 : 1992 (E)

Section 2: General requirements

2.1 Pressure/temperature ratings

Guidence on pressure/ temperature ratings of flanges forming

the subject of this part of 1SO 7008 is given in annex € for some

flanges made from the materials listed in annex D.

2.2.1 Range of mate

Guidance on selected materials is given in annex D.

222 Gaskets

See the note in 1.1

2.23 Bolting

‘The material of the bolting should be chosen by the user ac

cording to the pressure, temperature, flange material and the

selected gasket so thatthe flanged joint remains tight under the

‘expected operating conditions,

For PN 20, PIN 50, PIN 110, PN 180, PN 260 and PN 420 flanges

Up 0 and including bolt size M48, coarse series bolts to |S0 261

shall be used; from bolt size Mé8 upwards, the fine series hav-

ing a uniform 4 mm pitch shall be used.

23° Repairs

2.3.1. Where not otherwise prohibited by the applicable

‘material standard, repairs by welding are permitted when there

is a proven method. All welding shall be in accordance with a

‘witten procedure.

2.3.2 _Any filler rod used for weld repairs shal be such as to

produce a weld having characteristics similar to those of the

parent metal, Flanges shall be heat treated after repair welding

‘when the material specification requires such treatment

24 Dimensions

2.4.1. Range of nominal sizes

The range of nominal sizes applicable to each flange type and

‘each nominal pressure shall be as specified in table 3.

242 Tables giving dimensions

Dimensions of flanges shall be in accordance with the following

tables, as appropriate,

Tables 4, 5, 6 and 7: Dimensions of flange facings

Series 1 flanges

Table 10: Dimensions of PN 10 flanges

Table 11; Dimensions of PN 16 flanges

Table 12: Dimensions of PN 20 flanges

Table 15: Dimensions of PN 50 flanges

Table 16: Dimensions of PN 110 flanges

Table 17: Dimensions of PN 150 flanges

Table 18: Dimensions of PN 260 flanges

Table 19: Dimensions of PN 420 flanges

Series 2 flanges

Table 8: Dimensions of PN 2,5 flanges

Table 9: Dimensions of PN 6 flanges

Table 13: Dimensions of PN 25 flanges

Table 14: Dimensions of PN 40 flanges

2.4.3 Threads for threaded flanges

2.4.3.1 The threads shall be taper or parallel threads in ac.

‘cordance with 180 7-1 or taper threads in accordance with

ANSI/ASME B1,20.1 as appropriate

NOTE ~ Uniess otherwise specified, paral Yeas in accordance with

1507-1 will be supplied for fanges PN 2.5, PN 5, PN 10, PN 16, PN 25

‘and PN 40 and taper threads in ancordance with ANSI/ASME 81 20 1

for flanges PN 20, PN 50, PN 110, PN 150, PN 260 and PN 420,

2.43.2 The threads shall be concentric with the axes of the

flanges and variations in alignment shall not exceed § mmm,

Flanges up to and including PN 40 shall be manufactured

without a counterbore. The threads shall be chamfered p-

proximately to the major diameter of the threads at the back of

the flanges at an angle of approximately 45° with the axes of

the threads. The chamfers shall be concentric with the threads

‘and permitted to be included in the measurement of the thread

lengths provided that the chamfers do not exceed one pitch in

length.

Flanges PN 50 and above shall be provided with a counterbore

at the back. The threads shall be chamfered to the diameters of

the counterbores at an angle of approximately 45° with the

‘axes of the threads. The counterbores and chamfers shall be

concentric with the threads,

2.4.3.3 Gauging shall be in accordance with ISO 7-2 or

ANSI/ASME 81.20.1 as appropriate

2.4.4 Hubs — General applications

24.4.1 The hub of threaded (type 13;, slip-on (type 12,

socket weld (type 14) and lapped (type 15) flanges shall be

cylindrical or alternatively shall have a draft of not more than 7°

Con the outside surface for forging or casting purnoses. For the

limiting profile of weld neck hubs, see annex A

ISO 7005 PT#) 92 MM 4852903 0562294 69] ml

1SO 7006-1 : 1992 (E)

2.4.4.2. The hub dimensions of threaded (type 13) and slip-on

(type 12) flanges having a reduced bore shall beat least as large

‘as those of the standard flange of the size to which the re-

duction is being made. For welding neck (type 11) flanges

having a reduced bore, the hub dimensions shall be the same as

those of the standard flange of the size to which the reduction

is being made.

2.4.5 Hubs — Pipeline applications

2.45.1. The hub diameter and wall thickness at the welding

tend shall be determined as specified in 2.4.6.1.1 102.4.5.1:3 5

appropriate

2.45.1. When the minimum yield strength of the hub

orton of any flange or its representative test specimen is the

same as that of the mating pipe, the minimum thickness at the

welding end shall be the same as that of the mating pipe.

2.48.12 When the minimum yield strength of the hub

Portion of any flange or its representative test specimen is less

than that specified for the pipe to be matched, the minimum

thickness of the hub at the welding end shall be such that the

product of its thickness times its yield strength (at the welding

end) shall at least equal the product of the specified wall

thickness and the minimum specified yield strength of the pipe

to be matched.

2.45.1. When the hub thickness at the welding end is

‘greater than the wall thickness of the adjoining pipe, the joint

design shall be as shown in any of the three sketches in

figure 8.1

2.452 The minimum hub outside diameter at the point of

Weld shall be determined by adding twice the minimum wall

thickness determined in 2.4.1.1 or 2.4.1.2 to the bor

specified by the customer.

2.48.3. For sizes DN 300 to DN 600, when the mechanical

(minimum yield strength) properties of all sections of the

flanges are equal to or higher than those of the pipe to be

‘matched, the hub dimensions are permitted to be the same as

those of the general flanges as indicated in annex A.

2.46 Welding end preparation

For welding type 11 flanges to pipe, the typical end preparation

(of the flange shall be as shown in annex A. When PN 20,

PN 50, PN 110 and PN 150 flanges are used in pipeline appli

cations the typical welding end preparations are as shown in

annex C,

NOTE ~ Other welding end preparations agreed between monulac:

turer and purchaser do not invakdate compliance with this par of

180 7005.

2.5 Facings

2.5.1. Range of facings

‘The range of flange facings and flange face designations shall

be as given in figure 6. Dimensions of facings according to the

PN designation shall be in accordance with figures 6 and 7 and

tables 4, 5, 6 and 7, as appropriate.

ores

1 For types & (a shown in figute 6 only), D, F, Gand J the transition

from the raised face diameter tothe flange face is at the option of he

manufacturer:

2. For PN20 and PN 0 to PN 420 there are large and small versions of

C, DE and F types of facing, In such cases two sets of dimensions

have been given in the related tables. For smal male and female joints

‘care should be taken to ensure that the inate diameter of the pipe is

small enough to permit suicient bearing surace

3. The type B raised face on steel flanges may be removed when

bolted t cast itn oF copper alloy flanges for designations up to and in

‘cluding PN 50 in order to provide full-face gosketing f such be re

‘uired. On a flanged component of fiting this wil reduce the thickness

‘and the oveal length accoxiingy

25.2 Facing height/depth

For PN 25, PN 6, PN 10, PN 16, PN'2S and PN 40 flanges al facing

heights shall be included in the minimum flange thickness and

‘are measured from the face of the flange, The same require

‘ment applies for PN 20 and PN 50 flanges when they have the

(type B1) raised face. For PN 20, PN 50, PN 110, PN 150,

PN 260 and PN 420 flanges with other facings, e.g. type B2, spigot

and recess, tongue and groove, the height or depth shall be added

{0 the minimum flange thickness. For PN 110 to PN 420 flanges

all facings shall be added to the minimum flange thickness

Special requirements apply to ring-joint facings (see 2.5.3)

2.5.3 Ringjoint facings

‘The bottom of the ring-joint groove shall not encroach below

the plane of the flange edge of the appropriate minimum

thickness flange. Where the depth of the ring-ype joint groove

‘would violate this requirement, sufficient metal shall be added

to the flange thickness or raised face height so that the bottom

of the groove shall be in the same plane as the flange edge of a

minimum thickness flange

2.5.4 Lapped joints

For type 33 ancillary components for flanges, the finished

hhoight of the facing shall be not less than the pipe thicknoss

sed. If @ tongue, groove or ring-joint face is required, the

thickness of the lap remaining after machining the facing shall,

‘not be less than the specified thickness of the pipe used

2.8.8 Surface finish of flanges

2.5.5.1 All flange jointing faces shall be finished in accord

{ance with table 1or table 2, as appropriate. The surface finishes

Of the faces shall be compared by visual or tactile means with

reference specimens which conform to the R, and R, values

siven in tables 1 and 2.

ISO 7005 PT*) 92 MM 4851903 0562295 728 Mm

Table 1 — Surface finish for facings types A, B and E/F (large)

ee ‘in th

Tanna a0 7s 08 fas 3a) Bs

Cie ha

tuming dias 63

TI R, and R, are detined in 1S0 468

21_The term “turing!

serrated spiral grooves,

ores

1 It not intondes that instrument measurements are taken on the

ftange faces, and the R, and R, values as defined in 1S0 468 relate to

the reference specimens

2. Other finishes may be agreed benween the manufacturer and our

‘chaser,

2.5.5.2 The dimensions given for facings (particularly tongue

and groove types) in this part of ISO 7005 apply to flanges in

the condition as delivered,

When special coatings oF finishes are required this should be

stated in the order so that an appropriate allowance may be in-

corporated in the machining of any relevant mating dimen-

255.3 Flat face, raised face and large spigot! recess facings

(ie. types A, B and €/F (large)| shall be turned. Turning shall

be carried out with a round-nosed tool in accordance with

table 1.

2.84 For tongue/groove, small spigot/recess, "0"-ring

recess/groove and ringjoint facings lie. types C/D, E/F

(small, G/H and J} the gasket surfaces shall be machined in

accordance with the values shown in table 2.

Table 2 — Surface finish values for facings

types C/D, E/F (small), G/H and J

Rr Rr

Facing type en um

Tongue/groove (G70) and small

spigow recess (E/F) 32 | 128] o8 | a2

Ring joint (J) fincluding sie walle)

and “0"-rng recess/groove (G/M) | 1.6 | 63] 04 | 16

TR, and R, ave defined in 150 668,

2.6 Spot-facing or back-facing

Any spotfacing o- back-facing required shall not reduce the

flange thickness to less than the thickness specified. When

‘spotfacing is used, the diameter shall be large enough to ac

includes any method of machine operation producing either serated concentric or

NOTE — For certain applications, e.g for searching media such a lw temperature gasus, and fr flanges of

PN 150 anc above, it may be necessary to stipulate closer contol a the surface finish,

‘commodate the outside diameter of the equivalent normal series,

of ISO washers complying with ISO 887 for the metric bolt size

being fitted. When a flange is back-faced, itis permissible for

the file radius to be reduced but it shall not be eliminated en-

trely. The bearing surfaces for the bolting shall be parallel to

the flange face within the limits shown in table 20,

When a flange is back-faced a minimum fillet radius at the hub,

Ren (508 figure 8), shall be maintained as given in table 21

2.7 Tolerances

Flange dimensions shall comply with the tolerances specified in

table 20

2.8 Marking

2.8.1 Flanges other than integral flanges

Flanges other than integral flanges shall be marked with the

following information

2a) the number of this part of ISO 7006 (i... 1S 7006-1);

) the nominal size (ON) and the PN designation;

©} the material designation (see 2.8.2);

} the manufacturer's name or trade-mark

©) the thread identification where appropriate (see 2.8.3);

the heat (cast) number or suitable quality control

number traceable to the heat number.

Notes

1 Additionally, flange facing designations may be civen (see

also 2.84),

2. Whore a flange is subsequently used to form an integral part of a

Comporent and the component has a lower pressure ating than that of

the flange, the lower ‘ating should be clearly marked on the com:

2.82 Material designation

‘The material designation shall be as specified in 2.8.2.1, 28.22

and 2.8.2.3, as appropriate.

ISO 7005 PT#1 92 MM 4851903 OSb22%b bb4 me

1SO 7005-1 : 1992 (E)

2.8.2.1 The material designation shall be the minimum infor.

mation required to identity the material, e.g. the grade identi-

fication, preceded by the specification (standard) number

where necessary.

EXAMPLES (for materials in tables D.1 and 0.2)

2) 16M03

b) C2652H

©) X7-CrNiNb 18 10

2822 For flanges of nominal size DN 300 and greater,

manufactured specifically for pipeline applications, the material

designation shall be the material group and grade identification

number in accordance with table D.3.

EXAMPLE

4.8.250

2823 For flanges manufactured in accordance with

2.48.1.2, the material designation shall comprise the material

‘group and grade identification number for the flange and the

Strength grade of the pipe for which the flange has been made,

presented as shown in the following example.

EXAMPLE

4.8.20) XXX

where XXX isthe strength grade of the pipe, taken from the ap-

propriate steel tube standard

2.8.3 Identification of internally threaded flanges

Internally threaded flanges shall be marked to indicate the type

of thread used.

‘Threads to ISO 7-1 shall be designated by the letter symbols Re

‘or Rp, a8 appropriate, in accordance with 1SO 7-1 followed by

the nominal size, e.g. Re 3/4. Threads to ANSI/ASME B1.20.1,

shall be designated by the nominal size, number of threads per

inch and the letters NPT, e.g. 3/4-14NPT.

2.8.4 Groove number

Flanges grooved for standard ring joints shall be marked with

the letter "R” and the corresponding ring number.

285 Stamping

Where stee: _iamps are used, the marking shall be applied to

‘the rim of the flange,

2.9 Inspection and test

NoTes

1 The PN 20, PN'50, PN 110. PN 150, PN 280 and PN 420 flanges

specified are designed to be interchangeable wath Cass rated flanges

to ANSI/ASME B16.5 and MSS SP44, but they are not dential in all

respects; for inspection purposes, i is recommended that the dimen

Sions of PN 20, PND, PN 110, PN 160, PN 260 ane PN 420 flanges a2

Seemed to comply with the dimensions specified in ANSI/ ASME

B16. or MSS SPA4 as appropriate

2 This part of 1S0 7006 does not make provision for routine inspec

tion or pressure testing of soparae flanges. However, flanges may be

requited to be pressure tested after attachment of a pipe or other

tauipment or when forming an intogra part of such equipment, The

{eat pressure than dependent onthe requirements of the appropriate

Standard of code of practice in accordance with which the equipment

has been manufactured. Any test pressures should not exceed 1,5

times the maximum allowable working pressure at 20 °C rounded of (0

the next higher 1 bat increment.

2.10. Information to be supplied by the

purchaser

The following information should be supplied by the purchaser

in the enquiry and/or order

a) the number of this part of ISO 7006 (i.e. 1SO 7005-1);

b) the nominal size — DN followed by the appropriate

number (see 1.3);

the PN designation — PN followed by the appropriate

umber (see 1.3);

4) the flange type number (see 1.4), together with reference

+o the ancillary component type number if appropriate;

the facing type letter (see 1.4);

f)_ the material designation by reference to a national star

dard of International Standard and grade of steel (see

2.82), if appropriate;

4) the internal thread designation (see 2.4.3)

hy) the external diameter and thickness of pipe:

|) material certification requirements;

i) details of special coatings (see 25.5.2);

1 the neck thickness S where appropriate;

I) the bore diameter B where appropriate;

‘m)_ the bore diameter for welding neck (type 11) or socket

weld (type 14) flanges, if different from those specified in

this part of ISO 7006;

‘)_ for pipeline flanges, the mating pipe wall thickness ang

vield strength (see 2.4.5.1.3) and weld preparation (see an-

ex 8);

‘o) the bolting material when bolts are ordered with the

flangels)

ISO 7005 PT*1 92 MMH 4851903 0562297 STO mm

1SO 7006-1 : 1992 (E)

Typeot

Plate flange for velaing

Type 02

Loose plate range with weld-en plate cottar

(see type 32),

Type 03

Loose plate rlange with tapped pipe end

(see type 33)

Type of

Loose flange with wetding neck colar

(see type 36)

Z

NOTE — These sketches are diagrammatic only.

T

Types

Blank flange

Figure 1 — Flanges — Types 01 to 05

ISO 7005 PT¥1 92 MM 4851903 O5b2298 437 a

1SO 7006-1 : 1982 (E)

te

|

|

| +

aa

Typett Type 2

‘Welding neck range ued stip-on flange fer welding

witem eteee

Type 3 Type %

Hutbed threaded flange Hubhed socket welding Flange

Tes

Loose nubbed flange for Lapped plpe end

NOTE — Thee sketches are diagrammatic onl.

Figure 2 — Flanges — Types 11 to 15

ISO 7005 PT) 92 MMH 4852903 0562299 373 mM

1SO 7005-1 : 1992 (E)

nt

|

|

|

i

|

| YI

A

Type

Integral flange, showing alernctive formes

NOTE ~ This sketch is ciagrammatic only

Figure 3 — Flange — Type 21

| i

T

Type32" Typen3”

Weld-on phate colar Lapped pipe ene

NOTE ~ These sketches are diagrammatic ony

1) ype 82 corresponds to type 02 fange.

2) Type33 corresponds to type 03 flange

3). Type 38 comesponds to type 08 fange.

Figure 4 — Ancillary components for flanges — Types 32 to 34

ISO 7005 PT) 92 MMH 4852903 0562300 915 mm

1SO 7005-1 : 1992 (E)

NOTE ~ These sketches are diagrammatic ony

Figure 5 — Illustration of flange facings (types A to J)

ISO 7006-1 : 1992 (E)

0 ach 01 9#2ddE ION. (4

ISO 7005 PT* 92 MMH 4851903 0562301 85]

| J TT CEE telex [x 7 _

- TEP BeBe be be i fx Pfc ff q

I x fof fe x pe he eo Tx [x xx fe

peas i x pepe be Pe fe fx he De x Pe fe fe Px ee pe x 0

| “| Pee pe he fx fx Pe be be ee efx x pe fx fox i

Coo PTT Te x] x [x |x [x [x [x Tx xe bx

“Cr 1 pe bef fx fx [x fa

Pe Pa Pe fae Pa foo Poe oe ox J Px

[ TIT he Behe pee eT px pe pee fx ce ic

~ x px fx fx Pepe Pe fe fx fe [x [x Px

SE ee Bei he bee fc be feb Tee be be pe fx

1 Paco he] De fae fF ong oe

7 “LLU xP RR RR ww

r CLO x pe ee fx fe fx

TE ei fe be i be fe fc fi |

Tree Pf fe fe fx fx fx fae a

oo “Pe be fe fe be be ffx m

L “EE ~ ~T pep fe fe x foe fx fie x ca 0

xf Po fo fx fx fx xx i

minialale 7 ~ Bop Pe be fe fx foe be bx foe PJ fo x be ee eT | oe zt

as CL pT pe fx fe xe [ie fie fx fx [x |x [xx [x = oF Ng 88! —>f a | iu

| - | - % | [x [x fx [x [x [x [x oN ey Ton |

i: Cele phe [be foe fe bx fe fx [eI fe Du x [ee eee]

i xxx |x -—— onan —— — ee

a [elelelelelslefelels| =| -|-]— | eel T] na

8/8)8|8)8)8 8/8/8/8)5/8)/8]8/8 8) (8)/8)8 |e )/a/8|a|s|z/e)ala|s|y|nie|a|s owes

iia | Na

suolsuawig :¢ uonDeg

ISO 7005 PTX) 92 MMH 4851903 OSb2302 798 Mm

: 1992 (E)

4 je ian I

{ | efx fe fe be be Be Pee fe fe fe

t iz Paracaraca ca cacacacacacd

ffx fe fie ff fe fx fe fa fc — 0 na 0

[- a ee pet feb bebe be ee

Ch PTE pec ee po Pa po fic cbc oe ofc

| pfx fe fee be

| — nan

HL Pm Pf a fo fe Pe Pa YY fc a fe [I

CC C cr bee fe fe fx ef

- ———~ 9 Nd 26

TEE rex fe x Pe PJ

{ CoCo “CT Tel bebe lx ~

TTT Cor Xf) Pp oe foe fx [a [x [x — mea sn

220 Sfp fae fi fie fa fo fa x foe foc fo fo J x x Je a

~ Tobe px fe fee fe bc x fe ec fo oe fc

Le EEE 4

CEP i Dep Tbe x fx] fe [xe ——— ovo

SCE The foe fo c he f ] Fa

rt Tobe bet pec fc ac

bef pe bec fx bef

| Be Behe pe bef

“co | | c hex x] bfx ~

Crt cr ~ pel pepe be be phe fe xx

Ct pe be be Peevey Pex fox fx fx fx -— omenaeen

de Pe pe fe pe fo fx Pe x fo fc fa fe fe

Tope eb epee be ef fe a Pa fae x Poe Pc Pax x

z rr TL T XL Dex px x [x x fx

CEE EE bebe heb be ef efx x Po Px

px fe fe fe a fa fe fee Pop fe fa fe

xx pepe fx x fe fe epee foe fe [x fx fx

fe fe fx bx x efx x fx Pe Px oe Pe [> Pe [x [> fe

pee pe Pa ep Papa x oe oo ox [x fx [Dec fx x Px

Depeche pe fae ee ei be pepe [ee =

2/8/8|8|3/8/8\8/8/8 8/8 |8/8|8/8/8|8)8|3/8|8)8)8)8 /8| 8/8/38 ON oak,

1SO 7005-1

(panuquos) ¢ o1aes,

Table 3 (concuded)

ISO 7005 PT#]) 92 M@M™ 4851903 0562303 bey a

1SO 7008-1 : 1992 (E)

wf a :

ait :

a i

008 H p<

=

00 T x KTR x

08E Toe Toe 5 Toe TST 5]

| oe artes

Oz pede

= pet

Ost [x|xpe

sz. Pepe

2 =Eb

8 [xTx) x

| 99 KD

: =r

: ae

: ai

rt

B/ ] ed ||

8/8 2 gissizisigig|=

i |||

:

ISO 7005 PT*) 92 MH 4851903 0562304 SLO mm

1SO 7006-1 : 1992 (E)

hy fn t

2

Ix} os}

4

Type AePiat face “Type Bs Ralsed face Type Spigot Type Recess

johny

© © fe c

Lf h fe Pa

a} slats eee sl

o al

Biles n fe

Type C: Tongue Type 0: Groove Type: “0"-ring groove Type G:"O"-ring recess

Figure 6 — PN 2.5, PN6, PN 10, PN 16, PN 25 and PN 40 flange facing dimensions

ISO 7005 PT#1 92 MM 4852503 O5b2305 47? A

— Dimensions of flange facings for PN 2.5, PN 6, PN 10, PN 16, PN 25 and PN 40 (se0 figure 6)

Dimensions in miimetres

250

gas

70

1000

1200

1400

1600

1200

2.000

2200

2.400

2600

2 800

3.000

3.200

3 400

3.600

380

4.000

Faas [PNO|N WLP

BEE

zal oa] os.

al x) 0

3s] so) st

23] 7] sa

si] 65] 96

61] 75] 76

| a7) ae

96] 100] 110

16} 120} 121

vz] 149] 150

195] 175] 176

183] 203) 204

238} 250) 280

222) 312] 31

343] 380] 364

98] aan] 422

a7] an] a7

eo7| 52a] s2e

519} 575] 576

eo) 675| 676,

781| 77] 78

6) saz] 583

ssi] 967) 968

1 062) 1 092] 1 094

1262] 1 282] 1 298

162] 1 492] 1 494

1662] 1 652] 1 694

1 962| 1 692] 1 898

2.062| 2 092| 2 094

Le

1SO 7006-1 : 1982 (E)

ISO 7005 PT#) 92 M@™ 4852503 O5b230b 333 Ml

1SO 7005-1 : 1992 (E)

c ‘ c

J | | ,

— + -

4

Type A Flat face Type BeRalsed face Type 2: Roses face Type Ft Large recess

. @NIandPNSDonIy) — ON ZDANAPNSD only) Type EH Large spigot

£, c c c

[Be h f

=| 7e]s) {LE . \ as} | | | tf

| | |

4 fe 4

TypeE2/Small spigot Type FZ: Smal recess Type CLarge tongue Type 0% Large groove

c of x

fe hn

a3

ry *

— jas} Sls} J aye

f h

Type C2 Smal tongue Type 02 Smal groove Type Ring jolnt

1) Jy applias to PN 20 and PN 50 and

2) fa. apples to PN 110, PN 180, PN 260 and PN 420, and is ational to flange thickness C.

3) dy. is larger than dj for DN 18, ON 20, ON 25 and ON 32; otherwise is equal 10d

4) xy is equal oj for DN 18 and ON 20.

5). Height of raised portion £ is equal to groove depth E but is not subject 10 tolerance (see 2.5.)

ld in flange thickness C

Figure 7 — PN 20, PN 50, PN 110, PN 150, PN 260 and PN 420 flange facing dimensions

ee

ISO 2005 PTxL 92 MM 4851903 0562307 277 Mm

1SO 7005-1 : 1992 (E)

Table § — Dimensions of flange facings up to nominal size DN 900 for PN 20, PN 60, PN 110, PN 160, PN 260 and PN 420

see figure 7)

Oimensons in iirates

Outside diameter Cutside diameter Heian

Raises 7

‘ace. | Inside | Large Inside Large

Nominal | Large | Smaii| smau | “ameter | recess" smaut| smet| “2M | poised | coral

pa ‘fiarge of arge

Sia Joc sgt] onaue| ott | tare, | em oaore)| oueas, | “ce | cme

ars, tongue | 3 ‘sroove etl] recone “portion

oN a; ay % ww ve z A? f8'| fh fy aa | ah

i |» | ws] = | a8 ws] f2l7)7]s |e ]e

» | ox |e | zs ws) 2 |2l7)7|s5 lele

3 | 3 | xs] | x ws! xs |2|7| 7 | 5 |o|@

2 | os) | | as ss! « |[2}7| 7 | 8 le@| x

o | 3) ws) ws] se w& | ss |2/7) 7 | 8 |o | a

so | 2 | 9s) ws] 7 a | ons f2l7| 7 | 8 |e lu

% | 15 | a5) os] os ov | a fal7| 7 | |e lite

| i | a | ns] soe v9 | wes J 27) > | 8 iar jis

1 | ts) 1098 | wes | te we | wos fa) 7) 7 | 5 fiers te

15 | tas | ias8 | | tos ms} io [2/7] 7 | 8 ia lar

10 | 26 | ie? | 2005] 1905 xs | wo |2)7| 7 | 8 lowe ian

200 ‘Z| 213, | 254 ae 25.5 236.5 2/7 7 5 |270 281

zo | me | 267 | a5 | 2a6 wos} zs |2|7| 7 | 5 fax ize

wo | an | ans} ae | ae was] ans | 2/7) 7 | 8 fost se

xo | 4 | ues | | tras wes] gs |2]7/ 7 | 8 fan ie

ao | oo | aw | airs | ass wo | a f2l7) 7 | 8 fa jar

@o | sas las | sis] ao sis | as | 2/7) 7 | 5 |oaas|sue

500, 5845 | 601,5 | 569 833,5 560.5 532, 2/7 7 5 | 584,5/ 595

so | ea 2/7 |

eo | sozs| eo | oor | oars sss} so | 2) 7) 7 | 5 Jonas] 7005

so | 70 2/7

wo | a0 2|7

wo | oer 2/7

wo | ou 2|7 '

ao | oes 2/7]

sco__| 022 | 2{7|

2) f, applies to PN 20 and PN 60, ands included in the minimum flange thickness

3) fy applies to PN 110, PN 160, PN 260 and PN 420, and is adstional to the minimum flange thickness

NOTE ~ For small spigot and recess joints care shouldbe taken inthe use ofthese dimensions to ensure that he inside ciamter of the fiting or

pe is mall enough to ensure aufciont bearing surfaces,

TT” Large spigot and recess feces and lage tongue and groove are not applicable ta PN 20 because of potential mersional confiews

Table 6 — Dimensions of flange facings for nominal sizes DN 960 to DN 1 500

for PN 20, PN'50, PN 110 and PN 150

Dimensions in itimetres

‘Outside diameter of raised face

Nominol size 4,

oN PND | PNB] PNTIO | PNiso A |

360 Tors] 1029) 1058] 1 oem z |?

1 000 re) oe | nat fa t62 2 7

1050 tase | oy | ite | i2r3 2 7

1100 16) ri | 1m5 | 120 2 7

1180 125 | 1258 | 126 | tam 2 7

1200 139 | 1308 | 1gae | 13a 2 7

1250 vaio | 1359 | 1388 2 7

1x0 rao | rao | 14s 2 7

1360 rst | tasr | 1499 2 7

140 ims | isa | 15a 2 | 7

1450 tes | 1575 | 1600 2 7

1500 see _| 16s | 1657 2 z

TF apps 19 PR and PND.

2)_frapoles to PN 110 and PN 180.

ISO 7005 PT#1) 92 MMH 4851903 0562308 10b Ml

1SO 7006-1 : 1982 (E)

\

nN

Li;

1SO 7005-1 : 1992 (E)

ISO 7005 PT* 92 MM 4851903 0562309 O42 mm

| ~ = ~ tye. tee vo ove - ~ 5

e - | «| = | #0 we a |

>| = 5 || az| 0 ou } ost

’ wwe =| - | “le au | sa | - | -

: | = | oe | oz 80 oe a | aja! -

yy = fot- wi | 0 on

-fef-]-]- = | vet 20 cu | —

+ |=] - - ee S st seu | on

*]i}e}s)e}-]? w | a] - | 0 au |

(2 eet et |e |e us| #9 ou | —

[= 7 i i - i: cy a a = 80 se a

-]2}-]s)e}-]- |") =] wl = | 2 wu

eae) ete ra eee va | 30 eu | —

e - a} | - st acu | 0

-|e|s[s]-]= es | om! — | eo tu |

=T=7-,-T=T-1]=1-)2 Po) ew | ~

=} ]-]- rt-|-]- eu | 80 eu

este 2} om] - = st au | so

zJe a - | 20 w |= |e | - | -

ef-|-|sfeol-|m| “| - | a| - | 2 su | os | = ole | -

=| = fw} - | - #0 mw) - fof -|}-]-]*

ef-]|-|s]s wi} - | — | eo 80 au | o | - | os | o¢

-|+ = | 0 Se tS ls os

e{-|-|-[-|-* | - |B] a vu | ze | Sea

=Pep= pre |= ze soe | = | ao eu o c | | =

ee ee : sae | eo aia = 1 | ow

ele l|-lele|* [ow] w st a0 au | sz | ze a |e

See eed - |" | a] a aw | = | = ~ | = | =

+ |e vie afew | - | #0 au | o | a|a |=

=[- [> p= Tee | eo aw} =P] @

=e }=] =} i] 2] = fom | = a mu | - | @ =| =

+ | - vie oe] | — Jew] - | au] | = w |e | -

-|e}-)-}-]- se a0 aw a = |= | =

=|- ele|-|- - |e] = | ws [ne fw | - | ~ | - js | | -

| we | cos | 08 |

ebee ie

uns won

> na] ow na] ot was na] oa | one | oer |onens | ost na | oe’ | cena | | wom | yusoa cov | ox | os | ou na | ose | cena

on son

aston unemueq sourime murrordey | consoa pty su waar enced a exe pumuou eta

‘Showa u SvORUINEG

(s8ujpe) supof-Buy yo suojsueung — 2 914e,

ISO 7005 PT#1 92 MM 4852503 0562330 864 ml

1SO 7006-1 ; 1982 (E)

=TaT-{-7-T= 4 sino

° Si ~ |u| - on |

-|-]-]e]e]-]- or as | 00

-|-|-|- e|-|-|- | - - =| oo

or == cr ToT

-|-]s]-]-]-]- cS os | - =

sfef-|-]- | - |= os | 0 | ~

-|-]-]-Je - | = | ow ie 08

e|-|- a9 ee

5 =l-7-]7-)>e[-|- room eral em e

-;-|-]a]o]- - | = | sae] - ma berate

- Je - os - = | 0

-}e}-]}-];-|-]-]o}-]-]- =|} -]| -

-[-[+[-|-|- ws | - | - ow | - | - | -

=~-T-{s]e]- = [oe = =| ow [om | =

7 Alle cw = | = | ow

-fol]- -|-]-]e@])-]-]- - | - =

S5lelallo = | ow | = | = ose =

- -| so - | = | » | - =| owe | oe | -

st- Ts =[-[Te?-T-]-T- == =

SPT P ty tp type fp PP oy olole ~ - | ox

s]-|-|- = |e} --) -] - = | - -

-}-]e]s]o ]-]- | - | ow] ew} - one | coe | ove

eee ee rs = oe

ef-)-l-1-1- |= = =T=>7-

’ =] = ue} — | - | - - -

-|e}s}o]- | - | - | aw | o ox | ox | oz | -

~-|-]-]- ’ | oe foe | aaeee | ere (Om

s{-|[-|-|-|- || -|-|-|- ee

y?-7?-)-l- |-)«f-]— ={-|[-|-

-|-|e}sfos soe | ze ow | one | oo | =

-|- -{+{-]-]-]-]e = | = | o

* -|-|-]-]e]-] - - =| ae

e\l6 | |e |e eee Z{i]}ift

|

| |

ous

cxrna | one na | os na | hoe” | oc na gonna} ou na | osm | oem

ene

{uoquod peste yo se1ewma suoreuow noo

(panunuo2) 4 ore,

ISO 7005 PTxL 92 MM 4851903 0562311 770 mm

1SO 7006-1 : 1992 (E)

‘pen aq Aes sno309 ane}

3} SU. 5 704 29U8HmOH a4 01 TOEIQNE YOU 8 NG :7 SHOOH Jo yLdap auA ox eNO 1 oRLOd pos

Ui DLL Na PU OG Nal Say pode Hm

061 Nd 10) 99 NG OV St NG SeUE UH ODE Nd eS

‘sivawennbos Burew 20

BZ

7 =—]-])- pe soe

-]- = &

= “ SJ LSice a

u = re ee ea ise

-|- - 2/272 @

‘ a

= |e = toot wee

SP oyr ys ell

eet “| ie

~ | o a = =| 96 weve | writ =

= : seat

- [> 9 | swt | cz

=| = oe weer | over =

- f= B swt | cz

= | 9 | swt | cz

= [8 = = ~-[- [= ave | ovat =

5 = = || set | ez

=}- 9 i otaeodle swat | cat =

8

rox | 8

| ou na

ose na | ost na | “our vem | gudea coz | ts na} ou ns | cars | cons

ons

ww suorsuousp ono ors yeunwou od

‘vowed peste yo se10wwa Hp 970019 a #7 eunwou ig

(wepnjovos) ¢ o1ae,

ISO 7005 PTL 92 MM 4851903 0562312 637

1SO 7006-1 : 1992 (E)

Twent

1S 7005-1 : 1982 (E)

IS0 7005 PT#) 92 MM 4852903 0562323 573

1 oes Suomuoun Buse) 195 — HON

sen we | 6 | ov | sev | oor

con | a | a | owe | ar | owe

: son | 2 | os | owe | owe | ome

= con | a | sie | ome | ocoe | ome

male cw | z | sae | oe | ove | owe

- |} ew | @ | os aze | ome

_— 8 cw cd se oxo e | cee

7 ~ | 4 cow |e see sooz | oo

5 2 on | ss | sz soz | omz

2 zg on | a | sa soz | ooze

® s | z aw | | se oaz | owe

s z LN w se 008 |

ws | 3 an | o | se om

er i aw | a | se Orb

* a | a | se oor

a aw | 2 | se ont

or wn | we | se i

ee an | wz | se one

eS ! * ww je |e | m_]

ana sen 00 3 on

a Ts aT

owen

‘Sahumya I suosUOWIG

9p a6ed uo saiou ou 29s)

sebuey 6'2 Nd so SuOIsUOWG — B aIGeL

ISO 7005 PT) 92 MM 4851903 0562314 4OT Mm

ISO 7006-1 : 1992 (E)

2

<=

Type 21

g

Tren

ISO 7005 PT#) 92 MM 4851903 O5b2315 34b

1SO 7005-1 : 1992 (E)

Dimensions in mitimettes

(See the notes on page 46.)

Table 9 — Dimensions of PN 6 flanges

lis eealane|sea/eeg apg lage age eae lage ageless see §

i | RRS RGR BRE RGR BRRISE ERS

ii] -

FH |

Veea|

si]

Pe OR

E

:

g a

ds a

[+] ge |nnclenulecclecclemeleomloeiifirificifiritir a:

é t | |__| eeal|

AAA RKK seelsa5)

; +

i |

"7

Fe | I -

| i | 5 Teele elses Sewers Sle\RRs|SSANKS|FFARSI BLL 3

aif | ¢ |Feclexsjzzeleee IB2N|NNA 3

I 1 § :

|g 2ggise3 es

Bee S88 geg[gge 3

| = g

bee feas(ses ses agalneslege 2

| :

ISO 7005 PT) 92 MM 4851903 OSb23)b 262 mm

1SO 7006-1 : 1992 (E)

Type 04

reo

fs]

e

g

7 i T T =|

ep T + sf

L "rth, « (Oe

7 t

| ae ae oer

ql e

ISO 7005 PTx1 92 MM 4853903 0562317 115 a

1SO 7005-1 : 1982 (E)

acer ae Suasuounp BUDE) pue

Ton

© ome

s mn

- o om 2

s oe 2

zs | 002

a oe

= * ost |

7 or ot

= se oor

= onc |

7 = 00+

= % oo

: oe ooo

= Fc ‘on

lz % oo

le oe os _|

se o oor

| sr cor

oe a ose

le z one

ee a oe

ta a fig

i

Ei

ou wa e8n oo

oe

2

aes eee Sane Ce

or

=

&

ov wa 2en =

st

a

wee

1%

na |S ¥

ere (222 copes

reat [sseuone | mee

Te

sereue 920N

peemeus|

«wm v0 | 20 [zo 10

4 ola le

“meV ropuews| “eaenit | anaue oe

ez uw Ow0

‘ino

sonounus wi SuersvouNG

9» 98ed uo saiou ay) 298)

sobue}) OL Nd Jo suoisueunG — OL ore.

ISO 7005 PTL 92 MM 4851903 0562318 OSS mm

1SO 7006-1 : 1992 (E)

“sayay 1909 J0 sequrw 4284003

nq yusuabveso aut 24

wm

ISO 7005 PT*) 92 M™ 4851903 0562329 19) a

ISO 7005-1 : 1982 (E)

Dimensions in

20]

+

“478 [73] 90] 16] 545] 869 | “ore;

~ |109| 18] 750/ | 760

os |e3| 6] 18| esa ene

670

egiaaslaaalaa:)i ci [isi]

[as [SNa aaa [ane [sae laRsle |

f 2/939 [383/82

[RR ARR R88 858 535 gou lean las

Use PN 40

(See the notes on page 46,

Table 11 — Dimensions of PN 16 flanges

ing dimensiona, see table 4

2 |

Peieas see See BRS lReg |RBE

L 1

ISO 7005 PT*) 92 MM@ 4852903 0562320 703 ml

1SO 7006-1 : 1992 (E)

+ :

TA

12%. ZT

biG ii

wy || Yat

ji

¥ + Se

. 7

ea

HY | x

I .

' rane

Tat

T

kA B | \

'| DW °

i Z tat co Was

1SO 7005-1 : 1982 (E)

honeres

mm

ELEEEEEEEEE EMEA

lsagnasereagess:

OD Ny poise ss oBoeg

319

ISO 2005 PT) 92 MMH 4852903 056232) b4T mm

‘Shou o SuOSuAIEG

(9p o6e¢ uo saiou ou 295)

sobuey oz Nd 40 suoH

uid — ZL e1aeL

‘put 95 19a 5 “suCUouN Bure) 704

BESRSSERRE ENS:

PRRSSSSSSRSERSSISRES SRASESRSESE

setededseecdavegseae

ISO 7005 PT#} 92 MMH 4853903 O5b2322 58h a

180 7006-1 : 1992 (E)

Type 21

Rg

A

.

7

Type

Wy

&

Ce

Type 02

&

Type

fe

Table 13 — Dimensions of PN 25 flanges

{See the notes on page 46.)

Dimensions in milimetres

ISO 7005 PT*) 92 MM 4851903 0562323 412 mm

1SO 7006-1 : 1992 (E)

pealene pee ago lags |eag lage ae

on

112

a ee [AWE |RSe BE

gaffes

ae (Bag) |

RRR NAS

eas aee lee

| 3[aa8 [Res |e

aaa Ree ee

see Fea Re

R88 (88s iBs ft

Sag 898 um

Use PN 40

si

sa

<2

ing dimensions, S86 table 4

wore Fi

5 A988

ISO 7005 PTx) 92 MM 4851903 O5b2324 359

1SO 7006-1 : 1992 (E)

Type os

Ss

he

Type 21

Tyee0a

INS

[5

a

e

a

Type 02

FlG

Tye

Se

|

SS,

is

Tent

Types

ISO 7005 PTxL 92 MMH 4851903 0562325 295 mm

1SO 7006-1 : 1992 (E)

are Bos ‘sun Raminp Bupa) pu ip 10g ~ SION

om | su [us pe [es | x ey on a | one

os sw | o | a | ao fa een aw | oo | se

os ze | » | 2 | 4 |x| sen ce | oo | seo

oor -| % | a | 3 | o% |o| sen fe 09

OE see_| & | a | oF os ew ss_| ois | oes

0 wz | ve | o | zw Ie cew sz | o» | as

Ose sz | o | & | a |e cw se | Ose

oz | 8 we |-| on | a | 9 | oe oe an Se_| ce | Se

ot fiz | 8 sz [esl owt 2 | a (ce van wz | os | oe

si | eo | 8 |e] Si a | x |e vn w | oe | oz

wm | es | 8 53 |] 05 ee ed oa z_| on | se

we fos | 9 25 foo] oe o | fe en a | oo | aoe

Ey) s | 3 25 jae] 95 a | & |z| on as | sn | su

ow | + | 5 o> [ve] s | oc |e Bi a | si | oe

3 foe | s sy [ze] ¢ af on | os

z@ [oe | § ee foe] — s a | oo | on

& | ze | + op fee] — e wo | | os

a [ze | or lor ® a fe | oo

st] te | ee jz] — e wn | o | SS

cfs ate ce se {ez t oo

we

we «2 |wa eee um om D0

so fos [ow D>]? 7 Py [a | xo

eum 10

oon nou yoy | araye | -eewen [soon oe “ os

enon fae seen] Gioumn | Mpmous | sem a mre | son

SSiraumyu vy SUOHUONTO

(9p 26ed uo

‘s0Buey op Nd J0 Su

ISO 7005 PTx) 92 MMH 4851903 OSb232b 12) Me

1SO 7005-1 : 1992 (E)

ISO 7006-1 : 1992 (E)

ISO 7005 PTx} 92 MM 4851903 0562327 Ob8 a

_ ~ vot T 9s ae 8 zi} owt

: em eaete cee le

: acres

: - E eeh las

aS i lz=|-]-|S/8/ 3

= Sealer teen:

: - |: aa lea ss

Sie - : Ee en lee it

eo Ee lee es ail

Se c|i} 2 |e] 3 wat

: 2} Ps [= m2 at

: : 7 =| mle oe

=| rH : alg | $s

= | By =) 2] Rye fs

= sa : alee oa

ee = pe = |S gE oe

= f=]: = fed |e =| =| a8) s ee

Jeti l- a =|: |e i s |

i na Pangea ang :

om] ane onime: wa] Fae Taw |e Seal =nlie=

= Ay os : Sire Seales lice

ca ates 2 a sae eet a

a |e se 4 ade 3H 1S

i a | 3 a a sls les |e

ee eee 4 mae pe ees IE

= e/a 4 oa teal

ts gio a eaalae 2S |e

fe B & wis mlm |e

at a s | ala ae |e

a le . ealae eal eee alc

a Bie 7 P| g ie eee fe ete

fe Wie & “| & aula |e

3 eis 7 g| € cited: wie ie

e : % g fel eset ronal (ae mie 2

% ; % E elie | ae et |e

% a 8 of ie [eels gat at

Hi ee 7 =| 8 #218 [an |S e 8

fe fi}: 8 eee reese enelay ale le

7 fi: a =| elleeelennelas 2 le ls

Z

poe “any 40 wiBueT sas s9poy o6uey 10}

o- ee mee semunp ag , Ss

ae oan ae Ee

ees a

9» a8ed uo saiou oui 295)

s06u0)) 0S Nd Jo Suojsueuig — SL aIgey

ISO 7005 PT) 92 MM 4851903 0562328 TTH mm

ISO 7006-1 : 1992 (E)

0 0

7 iH

7

ql iv Laas eli

FAI 7

4

; AWA || VA:

\ j | z '

jae | hema

7 Z

ql z

0 A a

re an Zee Ze Hast

x y) .

Hq Ls

1 | VA

ISO 7005 PTxi 92 MM 4851903 0562329 930 Mm

1SO 7006-1 : 1982 (E)

v

t

=

ale]> >]

oe | we

ae | Se =

ote | aie =

toe | ote

te S|5

sa] = | =

05

oe

or

os

oe

oe

oz

os

04

on

00

86

006

088

08

oe

00

59

008

058

008

oe

oor

ose

oe

oe

002

et

set

ot

8

so

0

cd

ze

se

iva

5

Fo 0 NO ian a ues

| \peRsssseagscessess

BEaEne

=ea8

#3

BSSERRRSE

ISRARAS

za | - | 99] 90

as

aagyedeseeeas

v0

NENARRAAERI SSS,

wane uD

No. 7 ° @ [Ww No.

. a amy yo wouey ea aneump 910g eaten

mc so usec) ‘sp1sno

su0suaNG

(9p a6ed uo saiou oui 995)

OLI Nd Jo suo}suewig — 91 e191,

ISO 7005 PTx1 92 MMH 4851903 0562330 b52 mm

180 7006-1 : 1992 (E)

ISO 7005-1 : 1992 (E)

ISO 7005 PT) 92 MM 4851903 0562331 599 mm

pu 9 Sa; BBE

cow | ve 8 002

oom | Fe sit | 8

son | vz 6 cat | cot

ow | oz ve | tect | oogt | oor

ow | ve | v6 | oes | ost | oot

ow | ce | be | eaet | oot | 086

ow | oz | ve | eat | coi | 006

aw | oc | o¢ | seer) sei | os

aw | o | s@ | oat] a 08

gun | oc | 0¢ | sot | ort | ose

sun | oe | zor| sox | oo

ow | o | w | 26 | sor | om |

ww ] @ |e | sos | or | 009

cw | se | see | so | 005

an | oe is | "on | sa | om

zw | oz | se | oi | so | om

ew | a | 95 | or | ose

sew | se |sees | a9 | oo

sow | ot ee | ow | os | ose

OW |) a ee | rece | ou | ooz

ow | a | eze |szie | oe | os

tn | ae | ase | sez | oe | sa

ow | @ | sze | sez | om | oo

ww | 2 | ‘sz |socr | oz |

9

w

or

z

&

o

si

so tans wanaus

va n we [aw] 2 > 7 ¥ a | xo

om one | oBuey 0

yo usuey | ‘ana } semuronn reston | sequin joao. | samen | 4c

ae snwmp | M957 V pinoys | ebueLs Se moa | saat | eto

eunton, een

‘nat | “tm - _ |__| __

vw | env “worvewip Banen

Sang 1 SUORRIOUNG

(9p abed uo sarou tp 998)

s06uels 0S1 Nd JO Suo!suoWiG ~ LL e1aeL

ISO 7005 PT*1 92 MM™ 4851903 0562332 425 mm

1SO 7006-1 : 1982 (E)

ISO 7005 PT*1 92 MM@ 4852903 0562333 3b] am

+ 1992 (E)

1SO 7005-1

toorevounp Bae

009 - et aL | 90F tly s'e02 T os] — | S609 WN

Sle te eae (oe coe ier ae |e ree a

S - fa |e |e ce peat [ee |e | a

o» | - | - am [ue ced eer | |e toed |

=| ]-|- sm fece|ire| | ex [ow | — | ox| | soe | ome

oe | =| | aw | a | om few =ilae cee tea |e

ce fone | — | om | ee | oe foelealon] cx | ar | — fous) | ce | om

oe | soe Z| oa | oe faclorln| a | eed eee

om | sa a | mf oa | fewl =| oe | om

a em| - | = lea eect S

cad eed | te |e lea ee atie =

= fee] - |e ena mle a

colette aa let ale S

o | oe = ella rete a

z | ow if 5 |e allele im

aria fe ale a i

ele = peel t= ee S

a |e z |e [e [e se | om

alee ele de 2 eee

Na on Ww a te v na

pa | si | meron toere| | meonon | Stil as

‘sonounma W SuomuOURG

(9p a6ed uo satou ap 205}

so6uey 092 Nd 40 suoIsuOW ~ BL 91901

1SO 7006-1 : 1992 (E)

ISO 7005 PTxL 92 MM 4851903 0562334 27S mm

._ aL

5 | 1

roa || ZAI

evi

ANZ a :

. 3 a =

; Ta

| ZILLI .

i aa

1992 (E)

1SO 7005-1

ISO 7005 PTx1 92 MMH 4852903 0562335 134 Me

sem feet [eon eon ee meee ame oe me | oe

oz |r| | a | oe leo we] tee | lm | a | oe | eee | ae | ox

eel eee pester ese | [ae [ae | ow | on | we | oe | on | om

aed ecea | esta [eet fet ee a ere feed |e aialad fetter ood | os

we |sz | wo | o | ex fon wo | - [sw | o | ew) s | see soe | 0

a eest | trae ttatee [etal a lea ello es | alta

Oy 0s tb 9 el un ‘sity ~ os oy oew , sze | wz Ov

fe [tet (eee atet lt ete se | il feo |'o | aw |e | ae atlas

ep leet | eee eee |e ea ete neta ese ea fea miles

ee ee eta teeta cde fe Petre | coral eal lte ora |e

fe |e |e aoe ia [trcetd |e | re eteen Atede ed es

ua [Tata a T 7 [a] no

s6uay {ig e100 90s] |

son | sc | es os surns | “Campace [zeus [matin [enum | sstis | sa. [totes | tm

reumon, wf oemel 08 Levownia |seeweig | epysing | MYNON

sworsuowip Conew |

-9p 060d uo sarou at 298)

s06uey Ozy Nd #0 suoIsuEWG — GL OGL

ISO 7005 PT*) 92 MM 4851903 0562336 070 mw

1SO 7006-1 : 1982 (E)

Notes to tables 8, 9, 10, 11, 13 and 14

1 For tolerances, see 2.7 and section 4

For facings, see 25, figure 6 and table 4

2

3. For spotfacing,s00 26.

4 For reducing threaded, slip-on and weld neck flanges, see 2.44.2

5. For threads in threaded flenges, see 2.4.3.

16 The neck thickness dimension S is applicable to the majority of

flanges, but fo sizes above DN 600 or for flanges tobe used with other

pine wall thicknesses, the neck thickress is subject to agreement be

‘ween the manufacturer and purchaser

7 The neck diameter Ns the theocetcal maximum which wil permit

the use of ISO ring soanners or the fitting, if required, of the normal

series of ISO washers {ISO 887) without some form of adcitonal

‘machining such as spotfacing see 2.6). The washer, fused, may

theoretically overlap slighty the comer radius but in practice itis

deemed that there is sufficient space to fit the washer satisfactory.

8 The bore diameter B in sizes generally above DN 600 should be

specified by the purchaser

‘The bore for a welding neck (type 11) oF a socket weld ype 14) lange

should be specified by the putchaser if roquted to difer trom the

imensions given in tables 8 1011, 13 nd 16

9 In respect of thresded flanges, the outside diameters of ON 65,

[ON 125 and DN 150 pipes should be as shown in the folowing table.

Dimensions in mitimettes

‘Guts diameter

Nominal size | sreaded to Threaded 10

mom | anette Sans

e 71 | 7

15 1337 ia

150 165.1 jee

10 Up to and including nominal size ON 600, the flanges have been

recalculated recenty according tothe relevant German (DINI calcu

lation method. For this reason it wes necessary to increase certain

lenge thicknesses. Above nominal size DN 600, flange thicknesses re

‘mein as they were, but the previous pressure/torperature ratings are

10 longer applicable (see E.11,

Notes to tables 12, 15, 16, 17, 18 and 19

1 For tolerances, see 2.7 and section 4

2 For facings, see 25, figure 7 and tables 5,6 and 7.

3. For spotfacing, s0e 26.

4 For reducing threaded, slip-on and weld neck Hanges, ae 2.4.4.2.

5 For threads in threaded flanges, see 2.4.3,

6

Blank flanges may be with or without hubs at the manufacturer's

option

7. For welding of unequal wall thicknesses, see the acceptable bevel

esigns in annex 8.

8 Dimensions for By correspond to the inside ameter ofthe pipe as

given in ANSI/ ASME 836.10 for Standard Wall pipe. The thickness of

‘Standarc Wallis the same as Schedule 40 in sizes DN 250 and smaller,

Tolerances in table 20 apaly

‘9. When PN 20 and PN 80 flanges are requited with fat face, ether

the fll thickness or the thicknass with the raised face ermaved may be

furnished. Users are rained tat removing the raised face will make

the length through the hub ron standaré. See 2.5.2,

10 The bore for a welding neck (type 11) or a socket weld (type 14)

flange should be specified by the purchaser if caquited to citer rom

the dimensions given in tables 12 and 15 10 19,

11. In respect of thveaded Nlanges, the outside diameters of ON 65,

DDN 125 and DN 160 pipes should be as shawn inthe following rable.

Dimensions in misimetes

Outside diameter

Rorirel aie shesded to threaded to

1507-1 ANSI’ ASME 8.20.1

Bi 73

125 1397 1413

180 65.1 | 163.3

12 Attention is drawn to 0.4 and annex F for ON 200 and above for

pipeline spoications,

13 The R, dimension only applies to DN 300 and above for tlangos

used in pipeline applications

14 Welding end giameters 4 given are for general application and not

for pipeline appications.

ISO 7005 PTX) 92 MM 4851903 0562337 TO? a

1SO 7005-1 : 1992 (E)

Section 4: Tolerances

Table 20 — Tolerances

Dimensions in mitimetes

Dimension LN Flange wpe | __Toleance Size renge

| 3 < ON 125

11,140,383 Ee DN 180 up to and incuding ON 300

Bore dameter ; -

coeen at > ON

F |< on 125,

ther than 1,141 a

nda

| DW 150 up to and including DN 600

Al (machined on

thickness < 18

18 < thickness < 50

both faces 3

“” thickness > 50

Flange thickness

Cue oa a

3 thiekness « 18

|

| A imacnines on os ee

trom foce ont ° Cee!

* thianess > 90

= ee SE

gra rough mab an "| DN 300 up wo and ncuding ON EDS]

[> oN 680

< ON 150

te amet of nc fa ont “ DN 200 up 0 and incuding ON 600

| 8 > DN 650

| 2 < ON 250

2 > ON 300

Facing diame i 1

a 7 at [at]

20, $0,110,180, nlc

Bola | oN eto

wf > ON GBD

Facing height E An ry tm. | aw

fi oe

Foca dares A a vos | < ONGDD

wy at a “a8 < OW 600

= AN 5, | ieew | tues teMos

3 le

‘sues

130 7006-1 : 1982 (E)

ISO 7005 PT*) 92 MMH 4851903 OSb2344 147 me

Table D.1 {continued

ome maeea

Original T a ae

Forging <6 DIN 17243, <6 1S0 2608.1 ~=1010 570

eee

eeea

coma

ais aa

Hewes

_ See alanis esa .

a = ce =

= Sea a oars eee liscees

Pe pea

res near

= ee ions re |e

1 = | ow 17290 - isosxea | _

ISO 7005 PTx) 92 MH 4851903 0562345 083 Mi

180 7006-1 : 1992 (E)

Table D.1 (continued)

DIN stool 180 stool

Grigina

Limiting Limiting 180 standard Service

Description | Group DIN standard "

thickness eee thickness temperature:

mm rm °c

Forging [own 7102

a0 WStE 255 e = 5

eet WtE 285 S = 2

ez - Wste 315 = &

a3 Ss WStE 355 - eI

Plate DIN 17102, 180 ow8-4

80 - WStE 255 = 2557N 5

eet - | wste 285 = Pain | S

oe Wee 315 - Pa1s TN =

7 283 Ss WStE 355 366 TN S

casting 960 = DIN T7246 = 150 «91 7

G-X2CMoV 121 coe

Forging <16 DIN T7175, © 180 3808-1 =

>16<%@ | x2CrMovI21 Fa

> 40 <0

casting 0=0 = = 7 150 4091 ~

as

Forging IN 17480 180 2608-1

= X2CrNi19 11 . Fee | -

X2 CrNIN 18 10 - = -

Paste DIN 17480 |

= x2 CiNI1911 - =

X2 CiNIN 18 10 = 150 90785 126 t0 850

| X2 Cri 18 10

Casting 110) a DIN 17446 = 150 961 =

| 6x6 oni 189 ca I

Forging = in 17440 . 180 2608-1 196 1 850

XS CIN 18 10 __| ew .

Piao = IN T7440 = 150 928-5 196 to 550

X5CrNi 189 X5CiNi 189

casting 1280 : DIN 17445 = 7180 «00r =

6X5 CNN 188 | ow

Forsing IN 17440 180 26081 [196 to 550

X6.CrNiTi 18 10 Fs

Paste IN 17480 180 28041 |

= X6 CrNINb 1810 - Fo -

180 9328.5

= X6 CANT 18 10 = X6.CrNITI18 10) 196 10 850

s X6 CNIND 18 10 = X6-CrNiNd 18.10 =

Casing 1360) IN 17445, 1504991

- GX 3 CMON = csr =

17138

fue este

Forging = [ow 17440 : 180 28041 | 6010 550

1380 X2.CeNMo 8

W192

1981 -

Plate in 17440 150 99785

1360 = 2 CANMo = | x2cevimo = 60 10 880

wi32 rar

1381 x2 CiNiMoN X2.CrNIMoN,

pu

ISO 7005 PT#) 92 MM 4852903 O56234b TIT mt

130 7006-1 : 1992 (E)

Table D.1 (concluded

Oise 150 sed

Original 7

Liming Lining | 160 standara

Description. Group w DIN standard 1g

nein, | emgage | tec | Ate

cara va ona Soa

ox écrit - co poe

Sete = es -

Forging - DIN 17440 = | #0 2604-1 Teo 10 560

xB crumo me |

free

Pia =P oi ra = wesaes feo

xBonthe |e cao 112

fee

cone Ta Tain rs se er

xs cmon Cros

bo

Forging DIN 17440 10 26087 | ~~

- 6 Cn ve | tors

17122 |

- 210 CrNi 18 10 - | -

Plate DIN 17440 180 93285, | dt

26 CrNIMoTi X6CrNiMoTi |

tree We

| toca | xenon

tei nr

coo ia eae so see

enemas 4 we

foe Tie sew sows)

is ONS! ms :

B20 |

- xo] we -

1) The upper imiting valve indicates that prolonged use above the given temperature sat recommended

NOTE — The mechanical properties given in the standards refered to should be regarded es the minimum velues for which the

ressure/ temperature ratings given in annex E are vali

ISO 27005 PT) 92 MM 4851903 0562347 956 mm

1SO 7006-1 : 1992 (E)

Table D.2 — Reference standards for materials used for PN 20, PN 50, PN 110, PN 150, PN 260 and PN 420 flanges,

a 180 garded] imitng tickness | Remarks

1Al Casting ASTM A216 Tua 1S0 4991 - 0.2

wes cas ~ 54 | |

Forona 1s0 28041

ASTI At05 ne r2

Fora asta Ao a iso aot

tr re

Foe ASTI Aa is0 8083 < a

B ae y2Ni14GI

e leat

Ta | Gosina AST Re fF 50 r = :

toa at

ae asta Aa iso 982 1

A na raz0 |< 100

° ea Prats 30

ASTM ASS sso sea

& va | tanita <0 i

STM ASI6

& in

Tae | Foran Asma iso me ry ;

tn I 2

Plate ASTM A515: 1S0 9328-2 |

@ ir nase <0 ee

ASTM ASI6 rts Sece

® aa rio Socio [ns

vas | Cosine ASTM AT pe) 0 = re

wet 1 c28H

ASTM A325, bo»

ter

ASTI AT ne some ea

fr

Pie atta aloe =e a

2 as | temos

3 ea

ISO 7005 PT*) 92 MM 4851903 0562348 892 mm

1S0 7005-1 : 1992 (E)

Table D.2 (continued)

Tiara ‘Ati speafonion | gomana | BO standard | Geng mone | momen

group: and grade Remarks and grade eae | oe

Ta | ean awa . = =

wee ja

wes a 7

Ferore STW Ate 2 - = -

re

Rae ror ° =

C

ad one aati 7 [soar = 7

wos can !

Fore STW Ae = -

mH : |

a i |

oo ast 57 . : =

nee |

TAI0 Casting ASTM A217 | n 10 4991 | ”

wos cata

| astwage ~~~» | 18026087 = 3

faa 7 [Be | :

oo AST AS > | isosme2 S08 3

pow ‘Bem 1072

vais] canis STW AST ——Yisoaer ro

cs | can 7

| rer 1s0 0047 p= =

= _ |e |

re Es | |

aa | min asa | | oat oT

cia | coon ! |

Forora AST Ai = =F

Fo |

mi | Cana AST A wa

cre cre TF

oe He fo

Fora ‘sTw aise "so 2681 — =

rat 2

ra = ;

a TT Aa ‘sommes = -

mee - | xsomiss

en 3

wa Cove STW a woah

cra - | -

cro | cence : :

co = :

cr = :

== ror veo

m6 |e -

raion Lt dee =

Plate ASTM A240 180 9328-5 |

316 = | xs eine 1792 |

an ’ : =

210k =| reat 2 =

ISO 7005 PT#) 92 MMH 4852903 O5b2349 729

1SO 7005-1 : 1992 (E)

Table D.2 (concluded)

Material viption | ASTM specification | pemars | 190 standard See rastey aaa

waver! T Descript M specication | Remark 50 standard |” Limiting thickness | Remarks

2A3_| Foran "ASTM A182 180 26047 |

ek » | rs pee

rate nd =

Puae “ASTM A260 | 180 93285 ~

sot Fy | Sezcine 10 - *

a6 & | x2emino 172 2 7

x2ciiMo 1713 | ‘

tae | Forcing ASTM ATEE 150 2806:

Fat » | 2

aie eo

Paw ASTM AzaD| iso se

a a» | xecmvti 810 >

son X7CmNiTi 1810

zs | Fora ASTM Ava 150 20081

7 > | #0 . 2

rua ! rs 2

ra liaaea - -

rage : = =

Paw ASTM Az isos

x7 > | xe citinw 1810 . | 2

am X7 Crib 1810 *

348 a - = |

38H 2 - | =

ze | Covina STW AST

cH | -

ono | - :

Paw ASTM AZO = [so aa8s =

09s Hie

Tay | casing ASTM AISI = ~ = =

cx

Foaina ASTM Aig? | woase : °

F310 | ee

Paw ASTM AZO | woes = |»

308 15 |

1 Farmasbie bat nat ecornded Tor prolonged use above about 45°C

2) Not tobe used over 540°C

3) Nott be used over 245°.

4) Notto be used over 455°C

5) Purmasible but nt recommended fo prolonged use above about 455 °C

6) Nott be used ove 505°C

1 Not to be weed over 580°C

8) Permissible but not commended for prolonged use above about 880 °C

8) Not to be used over 425°C.

101_Forsenico temperature 585 °C and above, shout be used only when assurance is provided thet ain sz isnt fier han ASTM No 6

ISO 7005 PT#) 92 M™ 4852903 0562350 440 mm

ISO 7006-1 : 1992 (E)

Table D.3 — Materials applicable to tables 12, 15, 16 and 17 covering PN 20, PN 50, PN 110

‘and PN 180 flanges types 05 and 11 in the size range DN 300 and larger

for pipeline applications’!

Yea point Tensile svonons_ | Minin slepgton

identification number " ‘of 50,8 mm

ert Nien *

TA 70 a0 2

4.8290 20 410 20

40.318 a5. 10 20

44.390 = 490 20

Am 25 0 2

4.a.360 360 40 2

3.8385 285 470 20

Aas “15, 20 2»

44.460 “0 50 18

A485 435, 0 8

1 See ao 04

D.5 Reference documents

180 630 : 1980, Structural steels.

(SO 2604-1 : 1975, Steel products for pressure purposes —

Quality requirements — Part 1: Forgings.

180 3755

purposes.

1981, Cast carbon steels for general engineering

1S0 4965 : 1983, Heat-resisting steels and alloys.

180 4991 : —0, Stee! castings for pressure purposes.

1S0 9928-1 : 1981, Steel plates and strips for pressure purposes

= Technical detvery conditions ~ Part 1: General requirements.

180 98282 : 1981, Stee! plates and strips for pressure purposes

= Technical delivery conditions — Part 2: Unaloyed and tow-

alloyed steels with specified room temperature and elevated

temperature properties.

180 9828-3 : 1981, Stee/ plates and strips for pressure purposes

= Technical delivery conditions — Part 3: Nickel-afoyed stools,

with spectied low temperature properties.

'SO 99284 : 1991, Stee! plates and stips for pressure purposes

= Technical delivery conditions — Part 4: Weidable fine grain

‘steals with high proof stress supplied in the normalized or

‘quenched and tempered condition.

1S0 9328-5 : 1991, Stee! plates and strips for pressure purposes

= Technical defvery conditions — Pert §: Austenitic steels.

ASTM A 106/A105M-87a, Specification for Forgings, Carbon

‘Steet, for Piping Components.

11 To be published,

ASTM A 182/A182M-88, Specification for Forged or Rolled

Alloy-Stee! Pipe Flanges, Forged Fittings, and Valves and Parts

for High: Temperature Service.

ASTM A. 203/A203M-82(1988), Specification for Pressure

Vessel Pates, Alloy Steel, Nickel

ASTM A 204/A204M-88, Specification for Pressure Vessel

Plates, Alloy Steel, Molybdenum.

ASTM A 216/A216M-84b, Specification for Stee! Castings,

Carbon Suitable for Fusion Welding for High-Temperature

Service.