Professional Documents

Culture Documents

Astm c133 - Ccs & Mor

Astm c133 - Ccs & Mor

Uploaded by

Saragadam Dilsri0 ratings0% found this document useful (0 votes)

271 views5 pagesccs

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentccs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

271 views5 pagesAstm c133 - Ccs & Mor

Astm c133 - Ccs & Mor

Uploaded by

Saragadam Dilsriccs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

iA

iy Designation: C 133 - 91

Standard Test Methods for

Cold Crushing Strength and Modulus of Rupture of

Refractories*

‘Tis standard sed under the fed designation C138 the number immsttely folowing the designation inate the yea of

Bae Seoption or inte eae of rovion the year st eviion. A mumber in preathesesicats the yer of ast approval A

Sepeerp sin ( indater an edltoral change since the st evsion or reapeova

“This standards Bon approved fr use by eons ofthe Department of Defense. Consul the DoD Index of Specfeatins and

“Tun forte spect yar o awe which has ben adopted b the Departmen of Defense.

1. Seope

1.1 These test methods cover the determination of the

cold crushing strenath and the modulus of rupture (MOR) of

dried or fired refractory shapes of all types.

1.2 The test methods appear in the following sections:

Test Moho Sextions

Cold Crushing Stongt 408

Modus of Rupture ois

1.3 The values stated in inch-pound units are to be

regarded as the standard, The values given in parentheses are

for informatio only.

14 This standard does not purport 10 address all of the

safety problems, if any, associated with its use, It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior t0 use.

2. Referenced Documents

2.1 ASTM Standards:

‘C1054 Practice for Pressing and Drying Refractory Plastic

and Ramming Mix Specimens

E 4 Practices for Load Verification of Testing Machines?

3. Significance and Use

3.1 The cold strength of a refiactory material is an

indication of its suitability for use in refractory construction,

(it is not a measure of performance at elevated tempera-

tures.)

3.2 These test methods are for determining the room

‘temperature flexural strength in 3-point bending (cold mod-

ulus of rupture) or compressive strength (cold crushing

strength), of both, for all refractory products.

3.3. Considerable care must be used to compare the results

of different determinations of the cold crushing strength or

‘modulus of rupture. The specimen size and shape, the nature

‘of the specimen faces (that is, as-formed, sawed, or ground),

the orientation of those faces during testing, the loading

geometry, and the rate of load application, may all signifi-

‘eanily affect the numerical results obtained. Comparisons of

the results between different determinations should not be

"Thus tet mato are unde the jurisicion of ASTM Commitee C3 08

Refactouesond ac lhe ies cexponsility of Subeommitex CD80! on tens

‘havent eon approved July 13, 1991, Publsed October 1991. Originally

poblsed os C 123-37. Last previous esition C133~84.

2 dnl Bock of ASTI Standards, Vo 1501

anil Hook af ASTM Standards, Vol O31

two determinations. 4

3.4 The relative ratio of the largest grain size to the |

smallest specimen dimension may significantly affect the

numerical results. For example, smaller, cut specimens

containing large grains may present different results than the

bricks from which they were cut, Under no circumstances

should 6 by 1 by 1 in. (152 by 25 by 25 mm) specimens be

prepared and tested for materials containing grains with a

maximum grain dimension exceeding 0.25 in. (6.4 mm).

3.5 This test method is useful for research and develop-

ment, engineeting application and design, manufacturing

process control, and for developing purchasing specifica-

|

|

|

|

i

rate fone or more ofthese aati between he |

tions. |

COLD CRUSHING STRENGTH

4. Apparatus

4.1. Testing Machine—Any form of standard mechanical

or hydraulic compression testing machine conforming to the

requirements of Practices E 4 may be used.

Nore 1—For low strength mateials (such as insulating bricks or

castables), a sensitivity of 20 bt (67 KN) or less is sequited. The use of a

Inydravlie testing machine is als preferred over the mechanical type for

‘these materials.

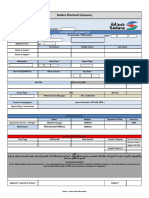

42 Spherical Bearing Block—The plane surface of the

spherical bearing block (see Fig. 1) shall have an area which |

is equal to of greater than the cross-section of the test

specimen. |

5. Test Specimehs

5.1 Brick and Shapes (bulk density greater than 100 Ib/jt3|

(1.60 z/em))—The test specimens shall be 2-in. (S1-mm))

‘cubes or cylinders, 2 in. (51 mm) in diameter by 2 in. (51

mm) high. ‘The height should be parallel to the originall

direction of pressing of the brick or shape. In the case of}

Special shapes, only one specimen shall be cut from a single)

shape and as many of the original surfaces as possible shall be;

preserved, In. preparing specimens from irregular or large

‘refractory shapes, any method involving the use ‘of abrasives,

such as a high-speed abrasion wheel, core drill, or rubbing

bed, that will produce a specimen with approximately plane

and parallel sides without weakening the structure of the,

specimen may be used, '

5.2 Insulating Brick or Shapes (typical bulk density of 100

Ibi? (1.60 g/em'), or greater than 45 % total porasity, of

‘both)—The test specimens shall be 4/2 by 4/2 by 21 or 3 in.

(114 by 114 by 64 or 76 mm), each taken from a different

46

qh c 133

Ploten of

Testing Mochine

terial —L ah

Splyricel— pcs bs ohereal

Genter of Bedding Materia!

Sphercd Surfoce where required)

|_—Test Specimen

jedding Material

FIG. 1 Recommended Design for Crushing Test Assembly,

Including Bearing Block

brick. It is permissible to prepare these specimens from the

half-brick resulting from the modulus of rupture test (see

Sections 10 to 15). The test surfaces shall be approximately

parallel planes.

5.3, Gasabe Rgfactorier—The tet specimens sal be 2

by 2 by 2-in, (51/by 51 by 51-mm) cubes or cylinders 2 in.

(1 mm) in diameter by 2 in, (51 mm) high, prepared by

casting or gunning. It is permissible to prepare one specimen

from cach 9 by 2 by 2-in. (230 by 51 by Sl-mm) bar after the

modulus of rupture test (see Sections 10 to 15). The loaded

surfaces shall be approximately parallel planes. All samples

must be dried at 220 to 230°F (105 to 110°C) for 18 h

(overnight). Upon removal from the oven, allow the sample

to coo! naturally until coo! to the touch. Complete testing

within 24 h of removal from the drying oven,

6. Procedure

6.1 At least five specimens from an equivalent number of

refractory shapes compose & sample.

Nore 2-—For celatively weak specimens

insulating

prcerec,

62 Brick and Shapes—Place a cellulose fiber wall board

(for example, Masonite!) 0.25 in. (6.4 mm) in thickness and

extending 0.5 in. (12.7 mm) or more beyond the edges of the

loaded faces of the specimen, Apply the load parallel to the

direction in which the brick was originally pressed.

63 Regular and High Strength Castables—Place a cellu-

lose fiver wall board 0.25 in. (6.4 mm) in thickness and

extending 0,5 in. (12,7 mm) or more beyond the edges of the

loaded faces of the specimen. Apply the load on the 2 by

2in, (51 by Si-mm) or 2-in. (SI-mm) diameter face and

perpendicular to the depth of the specimen as originally cast

or gunned.

6.4 Insulating Brick or Shapes—Apply the load directly to

the 4% by difin. (11d by 114mm) surface of the test

sp

insutating castables or

febricks, a minimum sample size of ten specimens is

en,

6.85 Insulating Castables (iypical bulk density of 100 tb/ft?

* Masonite has ben found saisactory for this purpose

a

(1.60 g/om?), o greater than 45 % total poresity, or both) —

Apply the load directly to the 2 by 2-in. (SI by St-mm) face

‘and perpendicular to the depth of the specimen as originally

cast or gunned,

6.6 Use the bearing block on top of the test specimen, and

position it so that the center of the sphere is in alignment

with the vertical axis of the specimen (see Fig. 1). Keep the

spherical bearing block thoroughly lubricated to ensure

accurate adjustment which may be made by hand under a

small initial load for each specimen,

Nore 3—The spherical bearing block may not be necessary on test,

machines having mechanical linkages which ensure that the stress

applied is colinese wit the ais ofthe specimen.

6.7 For dense refractories with sufficient strength to re-

quire greater than about 3 min per test, initial loading to

‘one-half of the anticipated failure load may be accomplished

at any convenient rate exceeding the specified rate. Subse-

quently, each specimen shall be crushed with a compressive

load applied at the standard rates specified in Table 1. The

rates shall not vary by more than +10 % of the specified rate

for the type of refractory being tested.

6.8 When using a mechanical testing machine, keep the

balance beam in a constantly floating position,

6.9 Specimens are loaded, as specified, to failure, Failure

is defined as the collapse of the specimen (failure to support

the load), or the reduction of the specimen height to 90 % of

its original value. The maximum applied load is recorded.

7. Calculation

7.1 Calculate the cold crushing strength using Eq 1:

WIA 0

where:

'S = cold crushing strength, Ibf/in.? (MPa),

‘otal maximum load indicated by the testing machine,

Ibf (N), and

A =average of the areas of the top and bottom of the

specimen perpendicular to the line of application of the

load, in? (mm),

8. Report.

8.1 Report the following:

8.1.1 Designation of the materials tested (that is, manu

facturer, brand, desctiption, lot number, etc.);

8.1.2 Specimen configuration, including size, shape, loce-

tion in the original brick or shape, the character of the faces

{that is, cut, drilled, as-pressed, as-cast, ctc.), and the

specimen orientation during testing;

8.1.3 Pretreatment, if any, given to the test piooes (for

example, curing, firing, coking, etc.);

8.1.4 Number of specimens in a sample;

8.1.5 Individual specimen dimensions, the maximum ap-

plied load, and the calculated cold crushing strength for each

specimen (see 7.1);

8.1.6 Mean modulus of rupture and standard deviation,

for each sample.

9. Precision and Bias

9.1 Precision—The precision of this test method is cur-

rently being investigated.

9.2 Bias—No justifiable statement can be made on the

TT

h c 133

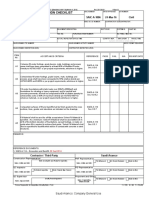

TABLE 1_ Standard Leading Rates for Cold Cushing Strength

‘rare Rae

ee im. trmy esos ended cain? SAE ace nat oeamnatea

Fete Tipe Seno secon tty nes ERIN camino

eet Refractory Srick and Shapes

SODAS Sane ow azme —_axaKE axe 7 T7398 08 aa

cat, So gixsixsy erent ‘ia ora 3

(ociosregis ohh sega cases dana xs Sram St te Seo? fase

ae rod oss orranmec retest) (hdres x51) carmen) _Gaehy ita a3 0m

sig hates

‘Dowie ad anions, eiSRMa exdexDEe —asxas "aS = co cr

rey obo Gieenaee Gabetin gaan ® 6) 03)

(rete id, need pistcorcanmes —“tsxaseseo "yan ys aa & io ta

seiner) qiexnex79 ciety sass & 2) 03

garner END 2 & i bee

gixsixey, xen ay a ean 3

Sconce et Saami = Se & {oer See

Gidanoie = 5) Glew) oer ® (80) 3)

“nee pose, adhg a a constant ste al a preferable o Gonstant stn

“For dense reractry Dick and shapas raquing mee tran @3-nin lest talon, specimens my be loaded to on

coment ae exceeding that specie.

These sizes ae prelered for insuatrg frebrcks,

‘2 These paces may bs oul om broken halves of NOR specinens.

‘These sizes ae profered for mst casttes,

bias of the test method for measuring the cold crushing

strength of reftactories, because the value of cold crushing

strength can be defined only in terms of a test method.

MODULUS OF RUPTURE.

10. Apparatus

10.1 Testing Machine—Any form of standard mechanical

or hydraulic compression testing machine conforming to the

requirements of Practices E 4 may be used.

Nore 4—Propely-aibrated portable apparatus may be used.

10.2 Bearing Surfaces, that shall have a radius of curva~

ture of % in. (16 mm) or be cylindrical pieces 1¥-in,

(32-mm) in diameter. For 6 by 1 by I-in. (152 by 25 by

25-mm) specimens, the radius of curvature shall be 9s in. (5

mm) or cylindrical pieces % in. (10 mm) in diameter. Ail

such bearing surfaces shall be straight and of a length at least

equal to the width of the test specimen. The supporting

members for the lower bearing surfaces shall be constructed

so as to provide a means for the alignment of the bearing

surfaces with the under surface of the test specimen because

the test brick may have a longitudinal twist. Apparatus of the

design shown in Fig. 2is recommended, although other types

may be used, provided they conform to these requirements.

A satisfactory alternative design is shown in Fig, 3

11, Test Specimens

U.1 Brick and Shapes (bull density greater than 100

logfe? (1.60 g/em-)—The preferred test specimens shall be

standard 9 by 4¥2 by 2¥4 or 3-in, (228 by 114 by 64 or

‘T6-tam) bricks, or specimens of equivalent size ground or cut

from refractory shapes. In the case of special shapes, only one

specimen shall be cut from a single shape. As many original

surfaces as possible shall be preserved. Where brick sizes are

impossible or impracticable, alternative specimen sizes of 9

by 2 by 2in, (228 by 51 by 51 mm) or 6 by I by 1 in, (152 by

25 by 25 mm) may be prepared. In preparing specimens

from irregular or larger shapes, any method involving the use

of abrasives, such as a high-speed abrasion wheel or rubbing

48

"ale sing,

ofthe snicpated Fracture strength at any

bed, that will produce a specimen with approximately plane

and parallel sides without weakening the structure may be

used.

112 Insulating Brick or Shapes (typical bulk density of

100 tbff? (1.60 g/em’), or total porosity greater than 43 %,

or both) —The test specimens shall be whole brick measuring

9 by 4¥ by 2s or 3 in. (228 by 114 by 64 or 76 mm), of

specimens of equivalent size cut from larger shapes. '

11.3 Castable Reffactories—The test specimens shall be 9 |

bby 2 by 2-in, (228 by 51 by 51-mm) bars prepazed by casting |

or gunning The top and bottom, and the side faces, |

respectively, shall be approximately parallel planes. Ali |

samples must be dried at 220 to 230°F (105 to 110°C) for 18 |

h (overnight). Upon removal from the oven, allow the |

sample to cool naturally until cool to the touch. Complete |

testing within 24 h of removal from the drying oven,

12. Procedure

12.1 At least five specimens from an equivalent number |

of refractory shapes compose a sample,

Nore $—For relatively weak specimens like insulating refractories, @

‘minimum sample size often specimens is preferred,

12.2 Place a test specimen flat on the bearing cylinders

with a span as specified in Table 2 and with the load applied

at mid-span. Whenever possible, use an original, unbranded

surface ofa brick or shape as the tension face, that i, the face

in contact with the two bottom. bearing’ cylinders. For

castable pieces, the depth dimension of the specimen as

originally cast or gunned is horizontal; that is, the top surface

of the casting or gunned sample becomes a side of the

properly-oriented test specimen,

12.3 Bach specimen shall be broken at mid-span in

Aexure with a loading applied according to the standard

loading rates given in Table 2. For high strength materials

requiring longer than about 3 min to perform a test, initial

loading to one-half of the anticipated failure load may be

accomplished at any convenient rate exceeding the specified

rate. Subsequently, the specimens should be loaded at the

Donal

FS cote Roled Ste!

cub

Li

Wate

Transverse Brick Testing Apporctus

Nore—the dimensions appear nF, 2 aa ences. See table bobow fr metic aque,

ete Ecuvaients

%e 5 1 8

w 6 2 s

% 10 3 %

% 8 4 12

a 16 ae Me

moe is 5 7

is 25 7 178

1M 32 308

FIG. 2 Recommended Design of Bearing Cylinders for Modulus of Rupture Test

standard rate specified in Table 2, The rates shall not vary

more than +10% from the stated rate for the type of

refractory being tested. The maximum applied load is

recorded.

12.4 When using a mechanical testing machine, keep the

balance beam in a constantly floating position.

13, Cateulation

13.1 Calculate the modulus of rupture using Eq 2:

MOR = 3PL/2@ a

where:

MOR = modulus of rupture, lbffin? (MPa),

P ‘maximum applied at rupture, Ibf (N),

L —_ = span between supports, in. (mm),

b breadth or width of specimen, in. (mm), and

d= depth of specimen, in. (mm),

14, Report

14.1. Report the following:

_ 14.1.1 Designation of the materials tested (that is, mamu-

facturer, brand, description, lot number, etc.),

14.1.2 Specimen configuration, including size, location

the original brick or shape, the character of the faces (that is,

cat, ground, as-pressed, as-cast, etc.), the specimen orienta.

tion during testing, and the load spat

14.13 Pretreatment, if any, given to the test pieces (for

example, curing, fring, coking, etc;

14.1.4 Number of specimens in a sample;

49

Pioten of

Festng Machine

ER x

on

eg

a

LAE

Nore-—The mensions epoeamg Fg. $ ae ees, Se tabla neides

with le. 2 for metic eauaent

FIG. 3 Alternative Design of Bearing Cylinders for Modulus of

‘Rupture Test

14.1.5 Individual specimen dimensions, the maximum

applied load, the location of the fracture plane, and the

calculated modulus of rupture for each specimen (soc 13.1);

14.1.6 Mean modulus of rupture and standard des

for each sample.

15. Precision and Bias

15.1 Precision—The precision of this test method is

currently being investigated.

15.2 Bias—No justifiable statement can be made on the

bias of the test method for measuring the modulus of rupture

of refractories, because the value of the modulus of rupture

can be defined only in terms of a test method,

EE qb c 133

TABLE 2 Standard Loading Ratos for Modulus of Rupture

‘Sees Fale,

Specimen Sum, CoH8 S850. oan amy RSE Loaing Rate, San Rate *

fata Tp2 ie ‘ey Seamer) IRE ny _tin

Terao Brok and Shoes

Sica me Pte Sxdsuosr 45x28 7 "308 i O05

exes) iaxen or © ese 03)

(ectdes ogdecertigratengh cases 9x 45x98 45x 7 1305 is Sas

Srdtrad piste ertammadrotacotes) — @2BX 18x78) (4x78) ot ® 220 3)

oxaxee, axa 7 1808 ‘ar bas

qaaxsixsy —@ixsn oie, ®. ay 69

oxtxt tie 3 105 ‘24 bag

(vs2% 25525) (25x25 zn 8. 076 3)

rst Ratios

SOO pr aDgiorh, SR Me SxaBx?E®4sxas 7 rr 6s 005

ors, o bot eaxnaxey — (tex 6h are @ 25) 03

(rales deed inves psteorramnes “9 xAsx3 5x8 Ss {ere aos

‘ereroes) eae sex79 Cie T5 9) ® (40) 63)

Dx2x2e axe 7 & ‘1 bas

wearers) ies) 0, ® i) 3)

“Finer posi, bading a a constant ates rat pofraie to conta sta ate aig,

‘ Prford ees fr brioc andchapos. Roqued ses forfrebks,

praerrd sz for a eastates.

‘The American Society for Testing and Materials takes no poean respecting the vlyof any patent ahs asserted in connection

‘win any Rem mentaned inthis stondard Users of he standard rs expressly advised tat determination of to vay of any such

portland the ik ef iingomert of ech its, are etry st ovn reppomey.

“hie standard subject wit at any tne bythe responsi tehaeal conti and rst be reviewed every ve years and

rnotrevisee, her reeporoved or wshraun. Your comments are ad ee or revision ois lac or for adn etandarcs

fra shou be addressed to ASTI Headauares. Your coniments wil recave cart censicraon a! a meting ofthe reponse

{eshntal committee, hich you may attend you fe! ht your comments have nt reeled fa herng you shoul malo your

iowa known fo th ASTM Commntes on Standard, 1076 Race St, Pladephia, PA 19168.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Refractory Method Statement of Refractory Liquid Burn PitDocument22 pagesRefractory Method Statement of Refractory Liquid Burn PitSaragadam Dilsri100% (4)

- B.Tech CertificateDocument1 pageB.Tech CertificateSaragadam DilsriNo ratings yet

- Tools List - VedantaDocument7 pagesTools List - VedantaSaragadam DilsriNo ratings yet

- 54gene Mobile Laboratory 10 Nike Art Gallery RD, Ikate, LagosDocument1 page54gene Mobile Laboratory 10 Nike Art Gallery RD, Ikate, LagosSaragadam DilsriNo ratings yet

- Proceeding O019: Innovative Solutions For Rotary Clinker Kiln RefractoryDocument4 pagesProceeding O019: Innovative Solutions For Rotary Clinker Kiln RefractorySaragadam DilsriNo ratings yet

- Dna Diagnostic Laboratory No 2 Ajayi Crowther Street Asokoro, AbujaDocument1 pageDna Diagnostic Laboratory No 2 Ajayi Crowther Street Asokoro, AbujaSaragadam DilsriNo ratings yet

- (LAPTOP MANUAL) SAP Concur User DocumentationDocument35 pages(LAPTOP MANUAL) SAP Concur User DocumentationSaragadam DilsriNo ratings yet

- SADARA ID Card Request Form-001Document1 pageSADARA ID Card Request Form-001Saragadam DilsriNo ratings yet

- Erosion Refractory CastableDocument1 pageErosion Refractory CastableSaragadam DilsriNo ratings yet

- Degree Provisional (B.Tech) CertificateDocument1 pageDegree Provisional (B.Tech) CertificateSaragadam DilsriNo ratings yet

- Medical Laboratory Report: MR S.DileepDocument1 pageMedical Laboratory Report: MR S.DileepSaragadam DilsriNo ratings yet

- Quotation: Att: Ronaldo Dela Roma GarciaDocument2 pagesQuotation: Att: Ronaldo Dela Roma GarciaSaragadam DilsriNo ratings yet

- Covid Report 1Document1 pageCovid Report 1Saragadam DilsriNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Saragadam DilsriNo ratings yet

- Shotcreting Rev DSGDocument11 pagesShotcreting Rev DSGSaragadam DilsriNo ratings yet

- App Note Ceramics - Us PDFDocument2 pagesApp Note Ceramics - Us PDFSaragadam DilsriNo ratings yet

- Cement Test Methods High AluminaDocument22 pagesCement Test Methods High AluminaSaragadam DilsriNo ratings yet

- Daily Progress Report of NGL: Faisal S. Al-Naimi EstDocument1 pageDaily Progress Report of NGL: Faisal S. Al-Naimi EstSaragadam DilsriNo ratings yet

- BT 003196166 TicketDocument3 pagesBT 003196166 TicketSaragadam DilsriNo ratings yet

- Fused and Sintered AluminaDocument7 pagesFused and Sintered AluminaSaragadam DilsriNo ratings yet

- EAF Refractory Performance at Pacific SteelDocument11 pagesEAF Refractory Performance at Pacific SteelSaragadam DilsriNo ratings yet

- Daily Progress Report of NGL: Faisal S. Al-Naimi EstDocument1 pageDaily Progress Report of NGL: Faisal S. Al-Naimi EstSaragadam DilsriNo ratings yet

- Cement PurityDocument75 pagesCement PuritySaragadam DilsriNo ratings yet

- Fugro Test ResultsDocument5 pagesFugro Test ResultsSaragadam DilsriNo ratings yet

- Refractory Brick Data SheetsDocument5 pagesRefractory Brick Data SheetsSaragadam DilsriNo ratings yet

- Data Sheet Sair Set PDFDocument2 pagesData Sheet Sair Set PDFSaragadam DilsriNo ratings yet