Professional Documents

Culture Documents

Rock Bit Comparison Chart: Smith Smith

Uploaded by

HunterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rock Bit Comparison Chart: Smith Smith

Uploaded by

HunterCopyright:

Available Formats

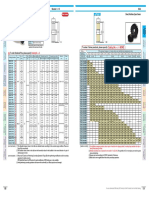

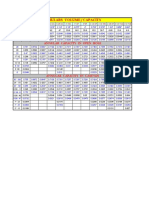

Rock Bit Comparison Chart

5. SEALED ROLLER BEARING 7. SEALED FRICTION BEARING SMITH TOOL BIT NOMENCLATURE

TCI GAUGE PROTECTED GAUGE PROTECTED

Series

Types

SMITH

Seal and Bearing Prefix Product Type Example

FORMATIONS HUGHES REED SECURITY SMITH HUGHES REED SECURITY D

S

Non-sealed (open) bearing

Single seal, roller bearing

Milled Tooth

Milled Tooth

DSJ

SDGH

F Single seal, friction bearing All F15

GS01, G02, GS03B, GTX-00, GX-00, T41, XT00-05, GFS01, GFS04 GT-00, MX-00, GT-03, TD41H, TD41, XS00-05, XL00-05, M Single seal, roller bearing motor bit All MSDGH

1 GS04B, G04 MAX-GT00, MX-00, EMS41H EBXT00-05

GTX-03, GX-03, MX-03

MX-03, GX-00, GX-03,

STR-03, H-03

TD41A EBXS00-05,

EBXL00-05

MF Single seal, friction bearing motor bit All MFDGH

Premium Product Type Prefix

GS05, GS05B, T42, XT06-09, GF05, GF05B, GFS05, STR-05C, HX-05C TD42H XS06-09, XL06-09,

2

FH FH™, single seal, friction bearing Insert FH23

EMS42H EBXT06-09 F05, MF05 EBXS06-09, GF Gemini™ twin seal, friction bearing All GF30

GS08 EBXL06-09 G Gemini™ twin seal, roller bearing All G18

Soft Formations/ GTX-09, MAXGT-09, T43, XT10-13, F10, F10B, F12, F12Y, GT-09, STR-09, SL43H, TD43, XS10-13, XL10-13,

XR Xplorer™, single seal, friction bearing Insert XR25

G10, GS10, GS10B

4 Low-Compressive XR+ Xplorer™ Expanded Milled Tooth XR+

Strength 3 MX-09, GTX-11, GX11, EMS43A, EBXT10-13

MX11 EMS43H

GF08B, GF10B, STX-09, H-09, HX-09, TD43A,

MX-09, GX-11, MX-11 TD43H, D43,

EBXS10-13,

EBXL10-13

GF10HB, GFS10B, HP43A, HP43H Milled Tooth Cutting Structures

GF12T,XR10T S Soft formation type Milled Tooth FDS

T Soft to medium formation type Milled Tooth DTJ

G15, G18, GS18, MAXGT-18, MX-18 T44, XT14-17, GT-18, STR-18, TD44, TD44H, XS14-17, XL14-17,

EMS44H, EBXT14-17

FH16, FH18, MF15T, STX-18, H-18, HX-18, TD44X, D44, EBXS14-17,

G Medium formation type Milled Tooth FDGH

V Medium to hard formation type Milled Tooth SVH

GS18B, 15JS

4 EMS44A XR15, XR15T, GF15, GX-18, MX-18 HP44H, EBXL14-17 S Self sharpening hard facing Milled Tooth MSDSSH

GF15B, GFS15, GFS15B HP44X H Heel inserts Milled Tooth SDSH

+ Premium Milled tooth cutting structure Milled Tooth FDS+

G20, GS20B, G25, GTX-20, MAXGT-20, T51, XT18-23, FH20, FH22, FH23, GT-20, STR-20, SL51H, TD51, XS18-23, XL18-23, Insert Cutting Structures

1 2JS MX-20, GX-20, EMS51A, EBXT18-23

GTX-22, GX-22, MX-22 EMS51H

MF20T, MFS20T, STX-20, H-20, HX-20,

GX-20, MX-20, GX-22,

TD51A, TD51H,

TD51X, D51,

EBXS18-23,

EBXL18-23

S Shamal™ design

00-99 Insert bit digits (00 Softest - 99 Hardest)

Insert

Insert

GFS10

FH50

XR20T, Xr25, GF20, HP51, HP51A,

MX-22, GX-23

GFS20B HP51H, HP51X Cutting Structure and Feature Suffix

A Air application bit Insert F47A

GTX-20C, T52, XT24-27, FH26, FH28, F27, F27I, GT-20C, GT-28, H-28, TD52, TD52A, XS24-27, XL24-27, B Binary carbide gauge Insert GFS10B

Soft to Medium-Hard

2 G26B MAX-GT20CG, GX-23, EMS52H EBXT24-27 F27IY, GF26, XR20Y, HX-28, GX-20C,

TD52H, TD52I,

TD52X, HP52,

EBX24-27, BD

C

Binary diamond gauge

Center jet

Insert

All

GS03BD

F10C

MX28G F20Y, XR20TY GX-28, MX-20C, MX-28 EBXL24-27

5 Formations/ HP52X D SRT diamond gauge Insert XR30D

DD Fully diamond enhanced cutting structure Insert MF37DD

Low-Compressive FH30, FH32, F30T,

SL53, SL53A,

T53, XT28-33, STR-30, STX-30, XS28-33, XL28-33, G Super-D Gun cone coating Insert F12YG

Strength G30, 3JS TD53, TD53A,

3 GX-30, MX-30H, EMS53, EBXT28-33 EBXS28-33, H Heavy set gauge design Insert F37H

FS30T, MF30T, XR30, GT-30, STX-35, GX-30, TD53B, TD53H,

I Inclined chisel on gauge Insert F27I

MAX-GT30 EMS53A, XR32, GF30B, GFS30B H-30, HX-30, MX-30, D53, HP53, EBXL28-33 L Lug Pads pressed with tungsten carbide inserts All FH45L

ETS53A HP53A, HP53H,

XL-30A JA53

LD Lug pads pressed with diamond inserts All MF15LD

N Nominal gauge diameter All GF05N

FH35, F37, F37Y, F37HY, GT-30C, STR-30C, STR- OD Diamond heel (50%) All F57OD

GTX-30C, GX-30, XT34-39, TD54A, XS34-39, XL34-39,

4 MAX-GT30CG, GX35, T54 EBXT34-39 MF37, XR30TY, XR30Y,

35C, STX-30C, HR-38C,

HR-30C, HR-35, GX-30C, TD54X, TD54 EBXS34-39,

OD1

PS

Diamond heel (100%)

SRT tungsten carbide legback protection

All

All

XR25OD1

FH28PS

HR-38CH XR30YA GX-35, MX-35C EBXL34-39 PD SRT diamond legback protection All F37PD

R Upper and Lower tungsten carbide legback protection All GS18R

FH40, FH45, F40, GF40H, RD Upper and Lower diamond legback protection All F50RD

STR-40, HR-40, HR-44, SL61, SL61A, XS40-45, XL40-45,

1 XT40-45, SD Shaped diamond gauge and 50% Diamond heel Insert G25SD

G40, G40Y, G40HY, GF40YB, XR38, XR40, STX-40, MX-40, MX-44 TD61, TD61A, EBXS40-45, SD1 Shaped diamond gauge and 100% Diamond heel Insert MF20SD1

ETS61A EBXT40-45

F47A, F47Y, GF47Y HP61A, HP61H EBXL40-45 T Trucut carbide gauge Insert XR20T

4JS TD Trucut diamond gauge inserts Insert XR32TD

SL62, SL62A, XS46-51, XL46-51, U Unconventional cutting structure/feature All GS18U

STR-40C, STR-44C,

Medium-Hard GT-40C, MX-44C EMS62 XT46-51, FH43Y, FH50, F47H, STX-44C, HR-40C, SL62X, TD62, V V-Flo hydraulics All FH35V

2 EBXT46-51 F47HY, XR40Y, XR40YA, TD62A, HP62, EBXS46-51, W Softer than standard insert grades Insert XR15W

6 Formations/

High-Compressive XR50, F50, GF45Y

XL-40A, HR-44C,

GX-44C, MX-40C

HP62A, HP62H,

JA62

EBXL46-51 Y

3

Conical cutting structure

2-7/8” connection (not Sii default size 2-3/8")

Insert

All

F59Y

XR30-3

Strength 6 6-5/8” connection (not Sii default size 7-5/8”) All XR+6

MX-55 XT52-58 F57, F57Y, STR-50, STX-50, SL63, TD63, XS52-58, XL52-58, 7 7-5/8” connection (not Sii default size 8-5/8”) All XR+7

M57

3 F50YA, XR50Y HR-50, HR-55, MX-50, HP63 EBXS52-58,

MX-55 EBXL52-58

HR-60, HR-66, HR-68, TD64, TD64H,

XT61-69 F59Y, F59HY, F67Y, XS61-69,

4 MF67Y, XR65Y

STX-60, MX-66, MX-68,

STX-66, XL-50A

HP64, HP64H EBXS61-69

1 XT71-75 XS71-75, EBXS71-75

Hard, Semi-Abrasive F68Y, XR68Y, XS77-81,

7 and Abrasive 3 XT77-81

XR68HY, XR70Y

STR-70, STX-70,

HR-70

SL73, HP73

EBXS77-81

Formations

4 XT83-89 XR75Y TD74, HP74 XS83-89, EBXS83-89

Extremely Hard

1 XT91-93 F80Y, XR80Y

HR-80, HR-88, STX-80,

STX-88, STR-90, MX-88

TD81, HP81 XS91-93, EBXS91-93

8 and Abrasive

Formations

2 XT95-97 F85Y HR-89

H-90, HR-99, STX-90, STX- SL83, TD83,

XS95-97, EBXS95-97

3 XT99 F90Y, XR90Y 99, STR-90, HR-95, MX-99 HP83

XS99, EBXS99

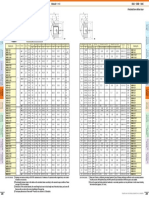

Rock Bit Comparison Chart

1. STANDARD 4. SEALED 5. SEALED ROLLER BEARING 6. SEALED 7. SEALED FRICTION BEARING

MILLED TOOTH ROLLER BEARING ROLLER BEARING GAUGE PROTECTED FRICTION BEARING GAUGE PROTECTED

Series

FORMATIONS Types SMITH HUGHES REED SECURITY SMITH HUGHES REED SECURITY SMITH HUGHES REED SECURITY SMITH HUGHES REED SECURITY SMITH HUGHES REED SECURITY

DSJ R1 Y11 XN1 SDS GTX-1 XR+ GTX-G1 T11 XT1 FDS HP11 XS1 XR+ GT-1 TC10 XSC1

MAX-GT1 EMS11G EBXT1 MX-1 TC11 XLC1

1 MSDSH MX-1 ETS11G FDS+ STR-1 SL11 EBXS1

MSDSSH STX-1 TD11 EBXSC1

D11 EBXLC1

Soft SDSH

1 Formations/

Low-

Compressive 2 DTJ FDT HP12 SL12, HP12

Strength

MGGH+ GTX-G3 T13 HP13G XS3

XT3 HP13 MFDGH

3 DGJ R3 Y13 XN3 GTX-3 GGH+ MAX-GT3 EMS13G EBXT3

FDGH

D13 XL3

MSDGH MX-3 ETS13G

Med. to Med.-Hard SVH, ATJ-4 GFVH, ATJ-G4 HP21G XS4, XL3

Formations/ 1 XN4

MSVH

XT4

FVH

2 High-

Compressive

2 OFM DR5

Strength 3

1 XN5

3

Hard, Semi-

Abrasive

2 OFH R7

Formations 3

4 ATJ-G8

IADC DULL BIT GRADING

Cutting Structure Bearings/ Other Dull Reason

Inner Outer Dull Char. Location Seals Gauge Char. Pulled

Inner Cutting Structure (1) (All Inner Rows) 1 2 3 4 5 6 7 8

(For fixed cutter bits, use the inner 2/3 of the bit radius)

Gauge (6)

Outer Cutting Structure (2) (Gauge Row Only) Measure to nearest

(For fixed cutter bits, use the outer 1/3 of the bit radius) 1/16 of an inch

I - In Gauge Reason Pulled or Run Terminated (8)

1 - 1/16” Out of Gauge BHA - Change Bottom-Hole Assembly

In columns 1 and 2 a linear scale from 0 to 8 is used to Dull Characteristics (3) Location (4) 2 - 2/16” Out of Gauge

describe the condition of the cutting structure according to the DMF - Downhole Motor Failure

(Use only cutting structure related codes) 4 - 4/16” Out of Gauge DTF - Downhole Tool Failure

following: Roller Cone

*BC - Broken Cone OC - Off Center Wear N - Nose Row DSF - Drillstring Failure

Steel Tooth Bits BF - Bond Failure PB - Pinched Bit M - Middle Row Other Dull Characteristics (7) DST - Drill Stem Test

A measure of lost tooth height due to abrasion and/or damage BT - Broken Teeth/Cutters PN - Plugged Nozzle/Flow G - Gauge Row Refer to column 3 codes DP - Drill Plug

0 - No Loss of Tooth Height BU - Balled Up Bit Passage A - All Rows CM - Condition Mud

8 - Total Loss of Tooth Height *CC - Cracked Cone RG - Rounded Gauge Cone # CP - Core Point

Inner Bits *CD - Coned Dragged RO - Ring Out 1 2 3 Bearings / Seals (5) FM - Formation Change

A measure of total cutting structure reduction due to lost, worn CI - Cone Interference SD - Shirttail Damage Fixed Cutter Non-Sealed Bearings HP - Hole Problems

and/or broken inserts CR - Cored SS - Self Sharpening Wear C - Cone A linear scale estimating bearing LIH - Left in Hole

0 - No Lost, Worn and/or Broken Inserts CT - Chipped Teeth/Cutters TR - Tracking N - Nose life used HR - Hours on Bit

8 - All Inserts Lost, Worn and/or Broken ER - Erosion WO - Washed Out Bit T - Taper 0 - No Life Used LOG - Run Logs

Fixed Cutter Bits FC - Flat Crested Wear WT - Worn Teeth/Cutters S - Shoulder 8 - All Life Used, i.e., no PP - Pump Pressure

A measure of lost, worn and/or broken cutting structure HC - Heat Checking NO - No Dull G - Gauge bearing life remaining PR - Penetration Rates

0 - No Lost, Worn and/or Broken Cutting Structure JD - Junk Damage Characteristics A - All Areas Sealed Bearings RIG - Rig Repair

8 - All of Cutting Structure Lost, Worn and/or Broken *LC - Lost Cone * Show cone number(s) under E - Seals Effective TD - Total Depth/Casing Depth

LN - Lost Nozzle location (4) F - Seals Failed TW - Twist Off

LT - Lost Teeth/Cutters N - Not Able to Grade TQ - Torque

X - Fixed Cutter Bit WC - Weather Conditions

(Bearingless)

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Lecture 7 (Types of Welding)Document22 pagesLecture 7 (Types of Welding)Syed Ahmed RazaNo ratings yet

- KMC HydraulicDocument1 pageKMC HydraulicHunterNo ratings yet

- U-4100 Instruction Manual PDFDocument98 pagesU-4100 Instruction Manual PDFVương AnhNo ratings yet

- Evaluation of Thin Beds PDFDocument26 pagesEvaluation of Thin Beds PDFMustapha BouregaaNo ratings yet

- Section 300 Dimensions and CapacitiesDocument26 pagesSection 300 Dimensions and CapacitiesHunterNo ratings yet

- WorkBook - CalculationsDocument30 pagesWorkBook - CalculationsHunterNo ratings yet

- Brochure OTR Komatsu 2016Document7 pagesBrochure OTR Komatsu 2016Avaa AmgaaNo ratings yet

- Resources Mechanical Flowserve Pusher P50Document2 pagesResources Mechanical Flowserve Pusher P50Suresh Kumar MittapalliNo ratings yet

- Chapter4 (Drilling String Design)Document13 pagesChapter4 (Drilling String Design)Kalpana Venugopal100% (6)

- Rock Bit Comparison Chart: Smith SmithDocument2 pagesRock Bit Comparison Chart: Smith Smithmohamed karamNo ratings yet

- Dokumen - Tips Rock Bit Comparison ChartDocument2 pagesDokumen - Tips Rock Bit Comparison Chartعلی محمودیNo ratings yet

- Bit Selection DataDocument2 pagesBit Selection DatajalalNo ratings yet

- BPW VB-axles Specs. EngDocument4 pagesBPW VB-axles Specs. EngakangucaiNo ratings yet

- Wind Aftermarket Brochure NADocument8 pagesWind Aftermarket Brochure NASalem IereebiNo ratings yet

- FP - Engineering700 - Spare PartsDocument1 pageFP - Engineering700 - Spare PartsDaniel LagosNo ratings yet

- AaaaaDocument24 pagesAaaaaLathif SeswitoNo ratings yet

- UCPXDocument1 pageUCPXdAvId rObLeSNo ratings yet

- SSR Steel Ring Gears (Spur Gears)Document1 pageSSR Steel Ring Gears (Spur Gears)dindo_waeNo ratings yet

- Telescopic CylinderDocument2 pagesTelescopic CylinderReference mapiyeNo ratings yet

- E1224b PDFDocument3 pagesE1224b PDFMai Thế ToanNo ratings yet

- 2019 34 Grip Damper Shaft AssembliesDocument1 page2019 34 Grip Damper Shaft AssembliesKrzysztof PiątekNo ratings yet

- Alpine12D2+4 SubwooferDocument1 pageAlpine12D2+4 Subwoofersoundman2No ratings yet

- MC Cylinder Accessories Clevis Brackets Pins Rod EyesDocument1 pageMC Cylinder Accessories Clevis Brackets Pins Rod EyesCAT CYLINDERNo ratings yet

- EV-Disc BR PADS-2132K PDFDocument1 pageEV-Disc BR PADS-2132K PDFSpeedyGonsalesNo ratings yet

- Tal Wsa PNG Iso 1afl062502 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1afl062502 - 00 - A01 - 00landeopauloNo ratings yet

- Gear SsaDocument4 pagesGear Ssa3DSNo ratings yet

- Mr. Arlone M. Aquino Proposed Three (3) Storey Renovation With Roofdeck, 3 Units ResidencesDocument1 pageMr. Arlone M. Aquino Proposed Three (3) Storey Renovation With Roofdeck, 3 Units ResidencesRenmaster ConstructionNo ratings yet

- Spherical Rod End and Sleeve Bearings NMBDocument93 pagesSpherical Rod End and Sleeve Bearings NMBdesignNo ratings yet

- Fixture Components: MS SA Implant - Narrow Ridge MS SA Implant - Denture MS Implant - Provisional Ms KitDocument8 pagesFixture Components: MS SA Implant - Narrow Ridge MS SA Implant - Denture MS Implant - Provisional Ms KitSung Soon ChangNo ratings yet

- Fy 1Document6 pagesFy 1Arie Akhmad FaizalNo ratings yet

- Dhembezor Konik PDFDocument1 pageDhembezor Konik PDFShahadin QajaniNo ratings yet

- Ground Zerol Miter Gears: SMZG SMZGDocument1 pageGround Zerol Miter Gears: SMZG SMZGShahadin QajaniNo ratings yet

- R0 - Col Fot - MR - Sameer - 17.10.2023Document1 pageR0 - Col Fot - MR - Sameer - 17.10.2023Shaikh ImranNo ratings yet

- A2-Floor Plan, ElevationsDocument1 pageA2-Floor Plan, ElevationsRonnel John CruzNo ratings yet

- STANDARD DETAILS GEN - ModelDocument1 pageSTANDARD DETAILS GEN - ModelAteeq RahmanNo ratings yet

- Sigma Lenses ChartDocument4 pagesSigma Lenses ChartAlex MilarNo ratings yet

- Hilti Mft-Fox VT Pub 5201456 000Document1 pageHilti Mft-Fox VT Pub 5201456 000Meka MekarnikasNo ratings yet

- Flow Solutions Division: Durametallic SealsDocument2 pagesFlow Solutions Division: Durametallic SealshukNo ratings yet

- SERIE 80M20 - 2C: Wing Style ComponentsDocument8 pagesSERIE 80M20 - 2C: Wing Style ComponentsflytorahulNo ratings yet

- WCB 232.20.0844 Swing Circle Gear Roller and Ball Turntable Slewing Ring BearingDocument1 pageWCB 232.20.0844 Swing Circle Gear Roller and Ball Turntable Slewing Ring BearingWCB BEARINGNo ratings yet

- SHIMANO SLX Front DerailleurDocument1 pageSHIMANO SLX Front DerailleurDani ArandaNo ratings yet

- 4 Nos. Rafter Bracing Reqd. Marked As Gr3-Rbr2: Bill of MaterialsDocument1 page4 Nos. Rafter Bracing Reqd. Marked As Gr3-Rbr2: Bill of MaterialsVikram DalalNo ratings yet

- Bearing MS 51961-35Document2 pagesBearing MS 51961-35Moutaz IsmailNo ratings yet

- Standard Sprockets Standard Sprockets / Double Sprockets: 60B Series 80B Series 40SD, 50SD SeriesDocument1 pageStandard Sprockets Standard Sprockets / Double Sprockets: 60B Series 80B Series 40SD, 50SD SeriesTomi KazuoNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- Sma SMB SMCDocument1 pageSma SMB SMCKen MaglinteNo ratings yet

- Corrosion Resistant Series Pillow Block Units: B S A B SDocument2 pagesCorrosion Resistant Series Pillow Block Units: B S A B SAkmalNo ratings yet

- Data Expansion Joint (Bellows)Document3 pagesData Expansion Joint (Bellows)Sreesanth SaruvilNo ratings yet

- Side View Elevation: Detail - ADocument1 pageSide View Elevation: Detail - AShabbir AliNo ratings yet

- 200-345-65182 Wbhd-Dt-Xxx-All Scheduled Maintenance ManualDocument10 pages200-345-65182 Wbhd-Dt-Xxx-All Scheduled Maintenance ManualMiki 40No ratings yet

- Brake System: Modification NoticeDocument3 pagesBrake System: Modification NoticeJorge Luis Gonzalez ValdiviaNo ratings yet

- Lit Mag Cyclone DataDocument2 pagesLit Mag Cyclone DataMajdi BelguithNo ratings yet

- Ground Spur Gears: Made To OrderDocument9 pagesGround Spur Gears: Made To OrderJohn Fake Last NameNo ratings yet

- TH180Document2 pagesTH180Leonard AntelizNo ratings yet

- Suzuki TS 125 ER PDFDocument2 pagesSuzuki TS 125 ER PDFAlliNo ratings yet

- 7-12-0004 Rev7 (Skirt Base Details)Document1 page7-12-0004 Rev7 (Skirt Base Details)sumit kumarNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- PART 8 SealtechDocument42 pagesPART 8 SealtechjorgebarrocasNo ratings yet

- Seal Assemblies Web FPRDocument3 pagesSeal Assemblies Web FPRVictor Flores ResendizNo ratings yet

- NSK FreeDocument3 pagesNSK FreeSachin NambiarNo ratings yet

- Mecha Lock - MisumiDocument1 pageMecha Lock - MisumiDuong NguyenNo ratings yet

- P055azor 03RG00 0001 54Document1 pageP055azor 03RG00 0001 54alhad.maNo ratings yet

- SprocketDocument1 pageSprocketkoenNo ratings yet

- Jikov-Carburetor PartsDocument23 pagesJikov-Carburetor PartsToniNo ratings yet

- Technical Specifications Manual: Titanium (DCSP) Aluminium (Achf)Document1 pageTechnical Specifications Manual: Titanium (DCSP) Aluminium (Achf)anon-878904No ratings yet

- Ps 0412 0612obh WDocument1 pagePs 0412 0612obh WHunterNo ratings yet

- Drilling Engineering (1) : M. Moarefian Azad University - Marvdasht Campus Fall 2006Document19 pagesDrilling Engineering (1) : M. Moarefian Azad University - Marvdasht Campus Fall 2006HunterNo ratings yet

- Rotary Drilling ProcessDocument22 pagesRotary Drilling ProcessHunterNo ratings yet

- Ps 0412 0600obh WDocument1 pagePs 0412 0600obh WHunterNo ratings yet

- Certificate Iso 1774Document1 pageCertificate Iso 1774HunterNo ratings yet

- 1.3 Housting and Power SystemsDocument10 pages1.3 Housting and Power SystemsHunterNo ratings yet

- Section 900 Carbon Dioxide and NitrogenDocument20 pagesSection 900 Carbon Dioxide and NitrogenHunterNo ratings yet

- Section 700 Physical Properties of Cement SlurriesDocument68 pagesSection 700 Physical Properties of Cement SlurriesHunterNo ratings yet

- Underbalanced Drilling (UBD) : Lesson 1Document39 pagesUnderbalanced Drilling (UBD) : Lesson 1HunterNo ratings yet

- Common Metric ConversionDocument1 pageCommon Metric ConversionHunterNo ratings yet

- Section 800 FracturingDocument24 pagesSection 800 FracturingHunterNo ratings yet

- Section 500 Annular Volume Between Casing and Casing or Open HoleDocument92 pagesSection 500 Annular Volume Between Casing and Casing or Open HoleHunterNo ratings yet

- Contact List: Geographical Areas and GeomarketsDocument2 pagesContact List: Geographical Areas and GeomarketsHunterNo ratings yet

- M-I Drilling Fluids Material Safety Data Sheet: Pipelax WDocument4 pagesM-I Drilling Fluids Material Safety Data Sheet: Pipelax WHunterNo ratings yet

- Safety Data Sheet Idfilm 220 X: 1. Identification of The Substance/Preparation and The CompanyDocument4 pagesSafety Data Sheet Idfilm 220 X: 1. Identification of The Substance/Preparation and The CompanyHunterNo ratings yet

- Section 200 Pipe DataDocument26 pagesSection 200 Pipe DataHunterNo ratings yet

- Safety Data Sheet Idlube XL: 1. Identification of The Substance/Preparation and The CompanyDocument4 pagesSafety Data Sheet Idlube XL: 1. Identification of The Substance/Preparation and The CompanyHunterNo ratings yet

- Input Parameters Mud Weight: Cuttings Slip Velocity Annular VelocityDocument4 pagesInput Parameters Mud Weight: Cuttings Slip Velocity Annular VelocityHunterNo ratings yet

- Volume & CapacityDocument2 pagesVolume & CapacityHunterNo ratings yet

- M-I Drilling Fluids: Material Safety Data Sheet Ep Lube 1. Identification of The Product and The CompanyDocument4 pagesM-I Drilling Fluids: Material Safety Data Sheet Ep Lube 1. Identification of The Product and The CompanyHunter0% (1)

- KCL Glycol Blending FormulaDocument1 pageKCL Glycol Blending FormulaHunterNo ratings yet

- Pit Volume CalculatorDocument24 pagesPit Volume CalculatorHunterNo ratings yet

- Product Generic Name SGDocument7 pagesProduct Generic Name SGHunterNo ratings yet

- Material Conc.Document2 pagesMaterial Conc.HunterNo ratings yet

- Length H.D P.Od P.Id AV CAP Disp HWDP HV AvbftDocument1 pageLength H.D P.Od P.Id AV CAP Disp HWDP HV AvbftHunterNo ratings yet

- Bit Hydraullics CalculationsDocument5 pagesBit Hydraullics CalculationsHunterNo ratings yet

- Hydraulic Calculations: Data Input Data OutputDocument1 pageHydraulic Calculations: Data Input Data OutputHunterNo ratings yet

- Math 112 Module 9 Time RatesDocument16 pagesMath 112 Module 9 Time Ratespangcheat pubgNo ratings yet

- Marc Reibert Legged RobotsDocument16 pagesMarc Reibert Legged RobotsChris LatanNo ratings yet

- Y6 HL Summer Block 1 Properties of Shape 2020Document9 pagesY6 HL Summer Block 1 Properties of Shape 2020eddie zhouNo ratings yet

- PDF-produkte Neu-VACUREMA Inline 2013 09 enDocument9 pagesPDF-produkte Neu-VACUREMA Inline 2013 09 endangkhuyenmai0% (1)

- Installation Manual: Ref. 1108 Soft: V01.0xDocument694 pagesInstallation Manual: Ref. 1108 Soft: V01.0xAnonymous m6yoprE9zNo ratings yet

- Amido de Taro PDFDocument8 pagesAmido de Taro PDFAryane OliveiraNo ratings yet

- Snuffler 1301Document8 pagesSnuffler 1301schwa1234No ratings yet

- Dis Coupling - Misumi 1Document1 pageDis Coupling - Misumi 1SenthilNo ratings yet

- TDS-100M Manual Ece 1Document25 pagesTDS-100M Manual Ece 1Oana CristinaNo ratings yet

- ELJODocument3 pagesELJOElvira CuestaNo ratings yet

- ASTM D 790 - 17 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating MaterialsDocument1 pageASTM D 790 - 17 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating MaterialsGustavoNo ratings yet

- What Is COFDM: The Modulation Scheme That DAB Uses IsDocument18 pagesWhat Is COFDM: The Modulation Scheme That DAB Uses Ishafsakhan21No ratings yet

- A219 245 B019 4015 3813 ServiceDocument373 pagesA219 245 B019 4015 3813 ServiceCaroline Daniel100% (1)

- ZVS Full BridgeDocument20 pagesZVS Full Bridgejameschall1No ratings yet

- Is 10162Document16 pagesIs 10162Amit TodiNo ratings yet

- Kollmorgen AKM Servomotor Selection Guide S4W ItalyDocument52 pagesKollmorgen AKM Servomotor Selection Guide S4W Italyjaime198819No ratings yet

- ResumeDocument3 pagesResumeRavi RajNo ratings yet

- Penrose BrochureDocument39 pagesPenrose BrochureRonnie TanNo ratings yet

- Discrete Mathematics: Logic and ProofsDocument71 pagesDiscrete Mathematics: Logic and ProofsanzoromanNo ratings yet

- Magnetism Part 1Document8 pagesMagnetism Part 1AnonymousNo ratings yet

- Analytical Method PDFDocument85 pagesAnalytical Method PDFiaderzNo ratings yet

- N4 Electrotechnics Augustus 2019Document8 pagesN4 Electrotechnics Augustus 2019Petro Susan BarnardNo ratings yet

- Design and Plantwide Control of N-Butyl Acrylate Production ProcessDocument17 pagesDesign and Plantwide Control of N-Butyl Acrylate Production Processhamidrezaee008No ratings yet

- Technical CatalogueDocument320 pagesTechnical Cataloguevellas_jeg50% (2)

- Geotechnical Engineering 3-4 Virtual Class 2021Document67 pagesGeotechnical Engineering 3-4 Virtual Class 2021Naigell Solomon100% (1)

- Basohli Cable Stayed Bridge - IndiaDocument7 pagesBasohli Cable Stayed Bridge - IndiajnshreyNo ratings yet