Professional Documents

Culture Documents

Advanced Heat Transfer Topics: Todd M. Lindrew, P.E. Bryan D. Evans, P.E

Uploaded by

Rahman AndreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Heat Transfer Topics: Todd M. Lindrew, P.E. Bryan D. Evans, P.E

Uploaded by

Rahman AndreCopyright:

Available Formats

Thermal & Process Sales, Inc. www.thermpro.

com

www.thermpro.com

Advanced Heat Transfer Topics

Todd M. Lindrew, P.E.

Bryan D. Evans, P.E.

Thermal & Process Sales, Inc.

www.thermpro.com

Advanced Heat Transfer Topics 1

Thermal & Process Sales, Inc. www.thermpro.com

Outline

Selection of Heat Exchanger

Technology

Estimating Heat Exchanger Sizing

Evaluating Heat Exchangers

www.thermpro.com

Types of Heat Exchangers

Shell & Tube

Double Pipe / Multi-Tube Hairpin

Plate & Frame

Spiral

Direct Steam Injection

Air Coolers / Coils

Waste Heat Recovery Units

Wet Surface Air Coolers

Electric Heaters

Fired Heaters

Tank / Reactor Coolers and Heaters

www.thermpro.com

Advanced Heat Transfer Topics 2

Thermal & Process Sales, Inc. www.thermpro.com

Heat Exchanger Type Selection

Factors which influence Decision

Temperature Cross

Approach Temperature

Design Pressure / Temperature

Cleanability

Size

Utility Availability

www.thermpro.com

Temperature Cross / Approach

5 Degree Approach / Temperature Cross

115

110

105

Temp., Deg.F

100

Product

95

10gpm Cooling Water

90

85

80

75

Inlet Outlet

www.thermpro.com

Advanced Heat Transfer Topics 3

Thermal & Process Sales, Inc. www.thermpro.com

Temperature Cross / Approach

Exchanger Type Cross? Approach?

Shell & Tube Single Pass or 5-10˚F

Multiple Units

Hairpin Yes 5-10˚F

Plate & Frame Yes 3-10˚F

Spiral Yes 5-10˚F

www.thermpro.com

Design Temperature / Pressure

Exchanger Type Temperature Pressure

Shell & Tube 1,200˚F 5-10,000 psi

Hairpin 1,200˚F 5-10,000 psi

Plate & Frame 250-350˚F 250 psi

Spiral 400˚F 400 psi

www.thermpro.com

Advanced Heat Transfer Topics 4

Thermal & Process Sales, Inc. www.thermpro.com

Cleanability

Exchanger Type Cleanable?

Shell & Tube Tubeside: Straight Tubes

Shellside: Removable Bundles

Hairpin Tubeside: Rod-Through Tubes

Shellside: Removable Bundles

Plate & Frame Gasketed Units Only

Spiral With Removable Covers

www.thermpro.com

Size

Exchanger Type Size

Shell & Tube Large

Hairpin Large

Plate & Frame Small

Spiral Medium

www.thermpro.com

Advanced Heat Transfer Topics 5

Thermal & Process Sales, Inc. www.thermpro.com

Utility Availability

Heating / Cooling Media Available?

Use One Of The Exchangers Shown Above

Heating / Cooling Media NOT Available?

Cooling

) Air Cooler, WSAC

) Cooling Tower or Chiller with Exchanger

Heating

) Fired Heater, Waste Heat Recovery, or Electric

Heater

www.thermpro.com

Single Fluid Exchangers

Temperature Approach

Exchanger Type Approach / Max Temp?

Air Cooler 20˚F to Dry Bulb

WSAC 10˚F to Wet Bulb

Electric Heat 1,200˚F Max Temp

Fired Heat 1,600˚F Max Temp

Waste Heat

www.thermpro.com

Advanced Heat Transfer Topics 6

Thermal & Process Sales, Inc. www.thermpro.com

Single Fluid Exchangers

Cleanability

Exchanger Type Cleanable?

Air Cooler Yes, with straight tubes

WSAC Yes, with straight tubes

Electric Heat Depends on Element Layout

Fired Heat By pigging in some units

Waste Heat No

www.thermpro.com

Single Fluid Exchangers

Size

Exchanger Type Size

Air Cooler Very Large

WSAC Very Large

Electric Heat Small

Fired Heat Very Large

Waste Heat Medium

www.thermpro.com

Advanced Heat Transfer Topics 7

Thermal & Process Sales, Inc. www.thermpro.com

Heat Exchanger Type Selection Tool

www.thermpro.com

Steps for Estimating the Size of a

Heat Exchanger:

Determine Heat Duty

Determine Type of Exchanger

Estimate Heat Transfer Coefficient

Calculate LMTD

Calculate Surface Area Required

Determine Approximate Size of

Exchanger

www.thermpro.com

Advanced Heat Transfer Topics 8

Thermal & Process Sales, Inc. www.thermpro.com

Determine Heat Duty

Q = m& c p ∆T (No phase change)

Q is the heat transferred (BTU/lb)

m & is the mass flowrate (lb/hr)

c p is the specific heat (BTU/lb°F)

∆T is the temperature change (°F)

Q = m& h fg (phase change only)

Q is the heat transferred (BTU/lb)

h is the latent heat (BTU/lb)

fg

www.thermpro.com

Heat & Mass Balance

One of the most common errors on

information submitted for us to

design is incorrect heat balance.

Heat transferred from the hot body

must equal that transferred to the

cold body!

m& hot c phot ∆Thot + m& hot h fg hot = m& cold c pcold ∆Tcold + m& cold h fg cold

www.thermpro.com

Advanced Heat Transfer Topics 9

Thermal & Process Sales, Inc. www.thermpro.com

Determine Type of Exchanger to

Use

Recall from earlier in this

presentation

Assume Shell & Tube

No Extended Surface

No Internal Enhancements

www.thermpro.com

Heat Transfer in Exchangers

Q = UA∆TLM

Q is the heat transferred (BTU/hr)

U is the Heat Transfer Coefficient

(BTU/hr ft °F)

A is the surface area (ft2)

∆TLM is the log mean temperature

difference (°F)

www.thermpro.com

Advanced Heat Transfer Topics 10

Thermal & Process Sales, Inc. www.thermpro.com

Log Mean Temperature Difference

Duty weighted average temperature

difference in the heat exchanger.

This is the thermal determination of

how well heat will transfer between

two bodies.

∆t 2 − ∆t1

LMTD =

∆t

ln 2

∆t1

∆t1 = T1 − t 2

∆t 2 = T2 − t1

www.thermpro.com

Corrected LMTD

LMTD calculation assumes counter-

current flow profile in the heat

exchanger.

Other (non counter-current)

configurations have specific LMTD

correction factors (F), which are

published in TEMA and GPH.

Corrected LMTD = MTD = LMTD × F

www.thermpro.com

Advanced Heat Transfer Topics 11

Thermal & Process Sales, Inc. www.thermpro.com

Overall Heat Transfer Coefficient, U

This is a mechanical determination

of how well heat will transfer

between two bodies.

1 1 1 2.3Do 1 1

log o + fouling ≈ + + fouling

D

= + +

U h Di ho 2k Di hi ho

i

Do

h is the coefficient of heat transfer

k is the thermal conductivity of the

tubes

Di / ois the tube ID / OD

www.thermpro.com

Fouling

Factor which increases the required

surface area to account for dirt, salt,

scale and other contaminant buildup

on the heat transfer surface area.

Can have a significant effect on

surface area:

Original U (without fouling)=150, U

(with 0.005 fouling)=85. This case

requires a unit which is 76% over-

surfaced based on clean unit.

www.thermpro.com

Advanced Heat Transfer Topics 12

Thermal & Process Sales, Inc. www.thermpro.com

Select Heat Transfer Coefficient

Approximate Overall Heat Transfer Coefficient U (Btu/hr-Ft^2-deg. F)

Hot Fluid Cold Fluid Overall U - S&T Overall U Plate Hot Fluid Cold Fluid Overall U - S&T Overall U Plate

Water Water 100-200 1200 Naptha Water 30-60

Light H.C. Water 50-100 200 Steam #2 Fuel Oil 40-70 100

Medium H.C. Water 30-70 140 Steam Butane (L) 50-150

Heavy H.C. Water 5-60 80 Steam Crude 10-25 50

Nat. Gas Water 5-35 Steam Sulfur Slurry 50-100

Methanol Water 100-200 Steam Methanol 100-400

Ammonia Water 100-200 500 Steam Ammonia 100-400

Hydrogen Water 10-60 Steam Light Organic 100-200 300

Oxygen Water 10-60 Steam Aqueous Soln.

Air Water 10-60 Less than 2 Cp 100-400 900

Glycol Water 30-150 1100 More than 2 Cp 75-250 500

Toluene Water 20-70 Steam Medium Organic 50-100

Sulfuric Acid Water 20-55 1000 Steam Gas 5-40

Nitrogen Water 10-60 Glycol H.C. Vapor 5-15 80

Diesel Fuel Water 50-110 800 Glycol Glycol 6-40 400

Sour Nat. Gas Water 25-60 Benzene Benzene 50-100

Lube Oil Water 10-25 600 Toluene Benzene 20-100

Carbon Dioxide Water 15-40 Brine Gas 20-75

Terpenes Water 10-25 Diesel Crude 20-60 100

Geraniol Water 10-25 Oil Fuel Gas 20-60 100

Steam #6 Fuel Oil 5-25 100 H.C. Vapor Crude 5-20

Steam Light H.C. 15-50 100 Ethanol Butane 50-100

Steam Gas 50-120 Sour Nat. Gas Sour Nat. Gas 25-100

Steam Nitrogen 50-120 Amine Amine 20-60 500

Steam 50% Caustic 7-20 90 15% DEA Crude 5-15 80

Fuel Oil Water 10-20 120 Butane Butane 30-60

Fuel Oil Oil 6-15 80 Aqueous Soln. Aqueous Soln. 200-450 1100

Gasoline Water 30-75 200 Heavy Organic Heavy Organic 10-35 100

Asphalt Water 10-20 Light Organic Light Organic 30-65 100

Kerosene Water 15-40 100 Slurry Slurry 5-30 80

Estimated Values are based on 4 ft/sec shellside and 6 ft/sec tubeside velocity

Light H.C. refers to fluids with 0.5 Cp viscosity or lower

Medium H.C. refers to fluids with 0.5 to 1.0 Cp viscosity

Heavy H.C. refers to fluids with above 1.0 Cp viscosity

www.thermpro.com

Solve for Area Required

Add additional area as required

Fouling

Process Variations

“Safety” Factor

www.thermpro.com

Advanced Heat Transfer Topics 13

Thermal & Process Sales, Inc. www.thermpro.com

Heat Exchanger Surface Area

Generally, the heat exchanger surface

area is calculated based on the outside

diameter of the tubes.

OD

A= ∗π ∗ L * n

12

A is measured in ft2

OD is measured in inches

L is measured in ft

n is the number of tubes

www.thermpro.com

Shell & Tube Configurations

Design Options

Straight Tube

U-Tube

Removable Bundle

Floating Tubesheet

Code Options

ASME Section VIII

TEMA B, C, or R

www.thermpro.com

Advanced Heat Transfer Topics 14

Thermal & Process Sales, Inc. www.thermpro.com

Shell & Tube Configurations

Tube Layout

Triangular

) More tubes

) Not cleanable on shellside

Square

) Less tubes

) Cleanable on shellside

www.thermpro.com

Given Area, Estimate Size:

Shell & Tube Surface Area, Sq. Ft.

Lengths (ft.)

Size (in.) # Tubes 6 10 16 20 24

8 34 40 67 107 134 160

10 64 75 126 201 251 302

12 102 120 200 320 401 481

14 126 148 247 396 495 594

16 178 210 350 559 699 839

18 236 278 463 741 927 1112

20 306 360 601 961 1202 1442

24 486 573 954 1527 1909 2290

30 794 935 1559 2494 3118 3742

36 1172 1381 2301 3682 4602 5523

48 2144 2526 4210 6736 8419 10103

Tube OD = 3/4"

Assumes Triangular Pitch - 15/16"

Assumes 4 Pass

www.thermpro.com

Advanced Heat Transfer Topics 15

Thermal & Process Sales, Inc. www.thermpro.com

Plate & Frame?

Same Process

Use Higher U value

Must use common plate sizes

On-Line sizing programs

www.phewizard.com

www.thermpro.com

Plate & Frame Surface Areas

Model Type Surface Area For Units With Specified Number of Plates (ft²)

50 Plates 100 Plates 150 Plates 200 Plates 250 Plates 300 Plates

APV - SR1 46 92

APV - SR2 94 187 281 374 468 561

APV - N35 188 375

APV - Q030 156 312 468 624 780 936

APV - R5* 280 560 840 1,120 1,400 1,680

APV - Q055 296 592 888 1,184 1,480 1,776

APV - Q080 442 883 1,325 1,766 2,208 2,649

APV - J060 282 564 846 1,128 1,410 1,692

APV - J092 450 900 1,350 1,800 2,250 2,700

APV - J107 534 1,067 1,601 2,134 2,668 3,201

APV - J185 996 1,991 2,987 3,982 4,978 5,973

APV - B063 339 678 1,017 1,356 1,695 2,034

APV - B110 592 1,184 1,776 2,368 2,960 3,552

APV - B134 721 1,442 2,163 2,884 3,605 4,326

APV - B158 850 1,700 2,550 3,400 4,250 5,100

APV - B205 1,103 2,206 3,309 4,412 5,515 6,618

APV - P190 1,025 2,050 3,075 4,100 5,125 6,150

APV - SR23PD 1,365 2,730 4,095 5,460 6,825 8,190

www.thermpro.com

Advanced Heat Transfer Topics 16

Thermal & Process Sales, Inc. www.thermpro.com

Plate & Frame Sizes

Standard Maximum

Model Type Connection Maximum Active Area Frame Length Plate

Dia. (in.) US GPM Per Plate ft² Width Height (Inches)** Capacity***

APV - SR1 1.5 125 0.92 10-5/16" 26-3/4" 33-7/8" 128

APV - SR2 2 200 1.87 13-7/8" 41-7/16" 51-1/2" 335

APV - N35 3 460 3.75 18-1/16" 53-3/16" 24-5/16" 139

APV - Q030 4 800 3.12 24-3/8" 49-5/16" 112-3/8" 319

APV - R5 4 800 5.6 21-7/8" 73-3/8" 234-3/8" 700

APV - Q055 4 800 5.92 24-3/8" 68-1/2" 112-3/8" 442

APV - Q080 4 800 8.83 24-3/8" 90-1/2" 112-3/8" 440

APV - J060 8 3100 5.64 34-7/8" 61-7/8" 150-11/16" 692

APV - J092 8 3100 9 34-7/8" 76-11/16" 150-11/16" 692

APV - J185 8 3100 19.91 35-1/16" 121-7/8" 150-11/16" 692

APV - B063 12 7000 6.78 38-15/16" 80-13/16" 168-1/8" 899

APV - B110 12 7000 11.84 38-15/16" 99-3/4" 167-1/8" 903

APV - B134 12 7000 14.42 38-15/16" 109-3/16" 165-15/16" 896

APV - B158 12 7000 17 38-15/16" 118-5/8" 164-3/4" 890

APV - B205 12 7000 22.06 38-15/16" 137-1/2" 163-3/4" 885

APV - P190 14 9600 20.5 179" 541

APV - SR23PD 16 11000 27.3 244" 730

** 150# ASME Frame Design as Basis

*** Based on Standard Plate Thickness

www.thermpro.com

Example: Amine Cross Exchanger

Given:

Amine Flow rate 21,000 lb/hr

Lean Amine in at 250°F out at 160°F

Rich Amine in at 86 °F

Lean Amine Cp = 0.93 (BTU/lb°F)

Rich Amine Cp = 0.83 (BTU/lb°F)

www.thermpro.com

Advanced Heat Transfer Topics 17

Thermal & Process Sales, Inc. www.thermpro.com

Step 1: Determine Heat Duty

Q = m& c p ∆T (No phase change)

Q is the heat transferred (BTU/lb)

) Solve for Q

m& is the mass flowrate (lb/hr)

) 21,000 lb/hr

c p is the specific heat (BTU/lb°F)

) (Lean) 0.93

∆T is the temperature change (°F)

) 250°F -160°F = 90°F

Q = 1,558,200 Btu/hr

www.thermpro.com

Step 2: Balance Heat & Mass

m& hot c phot ∆Thot + m& hot h fg hot = m& cold c pcold ∆Tcold + m& cold h fg cold

No phase change

Mass flow rate is the same on both

sides

Solve for Temp. Change to

determine Rich Amine Outlet Temp.

www.thermpro.com

Advanced Heat Transfer Topics 18

Thermal & Process Sales, Inc. www.thermpro.com

Step 3: Calculate LMTD

T1-t2 = 250 - 166.3

T2-t1 = 160 – 86.0

LMTD = 78.8

∆t 2 − ∆t1

LMTD =

∆t

ln 2

∆t1

∆t1 = T1 − t 2

∆t 2 = T2 − t1

www.thermpro.com

Step 4: Select U

Approximate Overall Heat Transfer Coefficient U (Btu/hr-Ft^2-deg. F)

Hot Fluid Cold Fluid Overall U - S&T Overall U Plate Hot Fluid Cold Fluid Overall U - S&T Overall U Plate

Water Water 100-200 1200 Naptha Water 30-60

Light H.C. Water 50-100 200 Steam #2 Fuel Oil 40-70 100

Medium H.C. Water 30-70 140 Steam Butane (L) 50-150

Heavy H.C. Water 5-60 80 Steam Crude 10-25 50

Nat. Gas Water 5-35 Steam Sulfur Slurry 50-100

Methanol Water 100-200 Steam Methanol 100-400

Ammonia Water 100-200 500 Steam Ammonia 100-400

Hydrogen Water 10-60 Steam Light Organic 100-200 300

Oxygen Water 10-60 Steam Aqueous Soln.

Air Water 10-60 Less than 2 Cp 100-400 900

Glycol Water 30-150 1100 More than 2 Cp 75-250 500

Toluene Water 20-70 Steam Medium Organic 50-100

Sulfuric Acid Water 20-55 1000 Steam Gas 5-40

Nitrogen Water 10-60 Glycol H.C. Vapor 5-15 80

Diesel Fuel Water 50-110 800 Glycol Glycol 6-40 400

Sour Nat. Gas Water 25-60 Benzene Benzene 50-100

Lube Oil Water 10-25 600 Toluene Benzene 20-100

Carbon Dioxide Water 15-40 Brine Gas 20-75

Terpenes Water 10-25 Diesel Crude 20-60 100

Geraniol Water 10-25 Oil Fuel Gas 20-60 100

Steam #6 Fuel Oil 5-25 100 H.C. Vapor Crude 5-20

Steam Light H.C. 15-50 100 Ethanol Butane 50-100

Steam Gas 50-120 Sour Nat. Gas Sour Nat. Gas 25-100

Steam Nitrogen 50-120 Amine Amine 20-60 500

Steam 50% Caustic 7-20 90 15% DEA Crude 5-15 80

Fuel Oil Water 10-20 120 Butane Butane 30-60

Fuel Oil Oil 6-15 80 Aqueous Soln. Aqueous Soln. 200-450 1100

Gasoline Water 30-75 200 Heavy Organic Heavy Organic 10-35 100

Asphalt Water 10-20 Light Organic Light Organic 30-65 100

Kerosene Water 15-40 100 Slurry Slurry 5-30 80

Estimated Values are based on 4 ft/sec shellside and 6 ft/sec tubeside velocity

Light H.C. refers to fluids with 0.5 Cp viscosity or lower

Medium H.C. refers to fluids with 0.5 to 1.0 Cp viscosity

Heavy H.C. refers to fluids with above 1.0 Cp viscosity

www.thermpro.com

Advanced Heat Transfer Topics 19

Thermal & Process Sales, Inc. www.thermpro.com

Step 5: Calculate Area Required

Q = UA∆TLM

Q is the heat transferred (BTU/hr)

) 1,568,700 Btu/hr

U is Heat Trans Coef. (BTU/hr ft °F)

) 30 (BTU/hr ft °F)

A is the surface area (ft2)

) Solve for area!

∆T is the LMTD (°F)

LM

) 78.8 °F

Area Required is 1000 ft2

www.thermpro.com

Step 6: Estimate Size

Surface Area, Sq. Ft.

Lengths (ft.)

Size (in.) # Tubes 6 10 16 20 24

8 34 40 67 107 134 160

10 64 75 126 201 251 302

12 102 120 200 320 401 481

14 126 148 247 396 495 594

16 178 210 350 559 699 839

18 236 278 463 741 927 1112

20 306 360 601 961 1202 1442

24 486 573 954 1527 1909 2290

30 794 935 1559 2494 3118 3742

36 1172 1381 2301 3682 4602 5523

48 2144 2526 4210 6736 8419 10103

Tube OD = 3/4"

Assumes Triangular Pitch - 15/16"

Assumes 4 Pass

www.thermpro.com

Advanced Heat Transfer Topics 20

Thermal & Process Sales, Inc. www.thermpro.com

Verify Size

Selected size for this example is 20-

240

Could also use 24-192 or 30-120

These are intended to be estimates

only!

Many factors may alter size or

improve design

Heat exchanger rating engineers

should be consulted

www.thermpro.com

Plate & Frame Surface Areas

Model Type Surface Area For Units With Specified Number of Plates (ft²)

50 Plates 100 Plates 150 Plates 200 Plates 250 Plates 300 Plates

APV - SR1 46 92

APV - SR2 94 187 281 374 468 561

APV - N35 188 375

APV - Q030 156 312 468 624 780 936

APV - R5* 280 560 840 1,120 1,400 1,680

APV - Q055 296 592 888 1,184 1,480 1,776

APV - Q080 442 883 1,325 1,766 2,208 2,649

APV - J060 282 564 846 1,128 1,410 1,692

APV - J092 450 900 1,350 1,800 2,250 2,700

APV - J107 534 1,067 1,601 2,134 2,668 3,201

APV - J185 996 1,991 2,987 3,982 4,978 5,973

APV - B063 339 678 1,017 1,356 1,695 2,034

APV - B110 592 1,184 1,776 2,368 2,960 3,552

APV - B134 721 1,442 2,163 2,884 3,605 4,326

APV - B158 850 1,700 2,550 3,400 4,250 5,100

APV - B205 1,103 2,206 3,309 4,412 5,515 6,618

APV - P190 1,025 2,050 3,075 4,100 5,125 6,150

APV - SR23PD 1,365 2,730 4,095 5,460 6,825 8,190

www.thermpro.com

Advanced Heat Transfer Topics 21

Thermal & Process Sales, Inc. www.thermpro.com

Verify Size - PHE

Selected model for this example is

Q055 w/200 plates

Could also use J107 w/100+ plates

These are intended to be estimates

only!

Design is flexible w/ number of

plates

Heat exchanger rating engineers

should be consulted

www.thermpro.com

Consider Pressure Drop

Beyond the scope of this

presentation

Is the process or equipment

particularly sensitive to pressure

drop?

What type of pump is used?

What is the downstream pressure?

Is the viscosity in range? Does it

change?

www.thermpro.com

Advanced Heat Transfer Topics 22

Thermal & Process Sales, Inc. www.thermpro.com

“Black Magic”

Some heat exchanger designs make

several common mistakes:

High “U” values

Low fouling factors

Incorrect viscosities

Incorrect MTD

www.thermpro.com

Heat Exchanger Comparison

Typical Differences in Heat Exchanger

Design

Surface Area

Heat Exchanged / Duty

Mean Temperature Difference (MTD)

Heat Transfer Coefficient (U)

www.thermpro.com

Advanced Heat Transfer Topics 23

Thermal & Process Sales, Inc. www.thermpro.com

THERMAL & PROCESS SALES, INC.

WWW.THERMPRO.COM

HEAT EXCHANGER SPECIFICATION SHEET

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

Surface Area

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

•Heat Exchanged (Q) 8

9

10

FLUID ALLOCATION

FLUID NAME

FLUID QUANTITY, TOTAL lb/hr

IN SHELL SIDE

Boiler Feedwater

928,000

OUT IN TUBE SIDE

Condensate Blowdown

224,700

OUT

11 VAPOR (IN / OUT) lb/hr

•Heat Transfer Rate (U) 12

13

14

LIQUID

STEAM

WATER

lb/hr

lb/hr

lb/hr 928,000 928,000 224,700 224,700

15 NONCONDENSABLE lb/hr

•Mean Temperature

16 TEMPERATURE (IN / OUT) F 178.3 259 589.1 243.9

17 SPECIFIC GRAVITY / DENSITY lb/ft^3 60.71 58.66 43.23 59.29

18 VISCOSITY cP 0.3497 0.2208 0.08246 0.2395

Difference (MTD) 19

20

21

MOLECULAR WEIGHT, VAPOR

MOLECULAR WEIGHT, CONDENSABLE

SPECIFIC HEAT BTU/lb*F 1 1.016 1.446 1.008

22 THERMAL CONDUCTIVITY BTU/ft*hr*F 0.3885 0.3961 0.3064 0.3979

23 LATENT HEAT BTU/lb

24 INLET PRESSURE psi 490 1,415

25 VELOCITY ft/sec 5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

28 HEAT EXCHANGED 75,400,000 BTU/hr MTD CORRECTED 122.2 F

29 TRANSFER RATE, SERVICE 182.4 BTU/ft^2*ft*hr CLEAN

30 CONSTRUCTION OF ONE SHELL SKETCH

Q

31 SHELL SIDE TUBE SIDE

32 DESIGN / TEST PRESSURE psig 500 / 1,540 /

A=

33 DESIGN TEMPERATURE / MDMT F 300 / 32 650 / 32

34 NO. PASSES PER SHELL 1 6

35 CORROSION ALLOWANCE in 1/16 1/16

36 CONNECTIONS IN 14" - 300 # RF 8" - 900 # RTJ

U * MTD

37 SIZE & OUT 14" - 300 # RF 8" - 900 # RTJ

38 RATING INTERMEDIATE

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

44 FLOATING HEAD COVER IMPINGEMENT PROTECTION

45 BAFFLES - CROSS CS TYPE horiz - seg % CUT SPACING C/C INLET in

46 BAFFLES - LONG SEAL TYPE

47 BYPASS SEAL ARRANGEMENT TUBE - TUBESHEET JOINT

48 EXPANSION JOINT TYPE

49 GASKET SHELL TUBE FLOATING HEAD

50 CODE REQUIREMENTS ASME SECTION VIII, Div 1 TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

Heat

THERMAL & PROCESS SALES, INC.

WWW.THERMPRO.COM

HEAT EXCHANGER SPECIFICATION SHEET

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

Exchanged

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

8 FLUID ALLOCATION IN SHELL SIDE OUT IN TUBE SIDE OUT

9 FLUID NAME Boiler Feedwater Condensate Blowdown

10 FLUID QUANTITY, TOTAL lb/hr 928,000 224,700

•Flowrate ( m& ) 11

12

13

14

VAPOR (IN / OUT)

LIQUID

STEAM

WATER

lb/hr

lb/hr

lb/hr

lb/hr 928,000 928,000 224,700 224,700

•Specific Heat ( c )

15 NONCONDENSABLE lb/hr

16 TEMPERATURE (IN / OUT) F 178.3 259 589.1 243.9

p 17

18

SPECIFIC GRAVITY / DENSITY

VISCOSITY

lb/ft^3

cP

60.71

0.3497

58.66

0.2208

43.23

0.08246

59.29

0.2395

∆T )

19 MOLECULAR WEIGHT, VAPOR

•Temperature Difference ( 20

21

MOLECULAR WEIGHT, CONDENSABLE

SPECIFIC HEAT BTU/lb*F 1 1.016 1.446 1.008

22 THERMAL CONDUCTIVITY BTU/ft*hr*F 0.3885 0.3961 0.3064 0.3979

h fg)

23 LATENT HEAT BTU/lb

•Latent Heat ( 24

25

INLET PRESSURE

VELOCITY

psi

ft/sec

490 1,415

5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

28 HEAT EXCHANGED 75,400,000 BTU/hr MTD CORRECTED 122.2 F

29 TRANSFER RATE, SERVICE 182.4 BTU/ft^2*ft*hr CLEAN

30 CONSTRUCTION OF ONE SHELL SKETCH

31 SHELL SIDE TUBE SIDE

32 DESIGN / TEST PRESSURE psig 500 / 1,540 /

Q = m& * c p * ∆T + m& * h fg

33 DESIGN TEMPERATURE / MDMT F 300 / 32 650 / 32

34 NO. PASSES PER SHELL 1 6

35 CORROSION ALLOWANCE in 1/16 1/16

36 CONNECTIONS IN 14" - 300 # RF 8" - 900 # RTJ

37 SIZE & OUT 14" - 300 # RF 8" - 900 # RTJ

38 RATING INTERMEDIATE

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

44 FLOATING HEAD COVER IMPINGEMENT PROTECTION

45 BAFFLES - CROSS CS TYPE horiz - seg % CUT SPACING C/C INLET in

46 BAFFLES - LONG SEAL TYPE

47 BYPASS SEAL ARRANGEMENT TUBE - TUBESHEET JOINT

48 EXPANSION JOINT TYPE

49 GASKET SHELL TUBE FLOATING HEAD

50 CODE REQUIREMENTS ASME SECTION VIII, Div 1 TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

Advanced Heat Transfer Topics 24

Thermal & Process Sales, Inc. www.thermpro.com

Mean

THERMAL & PROCESS SALES, INC.

WWW.THERMPRO.COM

HEAT EXCHANGER SPECIFICATION SHEET

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

Temperature

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

8 FLUID ALLOCATION IN SHELL SIDE OUT IN TUBE SIDE OUT

9 FLUID NAME Boiler Feedwater Condensate Blowdown

Difference

10 FLUID QUANTITY, TOTAL lb/hr 928,000 224,700

11 VAPOR (IN / OUT) lb/hr

12 LIQUID lb/hr

13 STEAM lb/hr

14 WATER lb/hr 928,000 928,000 224,700 224,700

15 NONCONDENSABLE lb/hr

16 TEMPERATURE (IN / OUT) F 178.3 259 589.1 243.9

•Temperatures In / Out 17

18

SPECIFIC GRAVITY / DENSITY

VISCOSITY

lb/ft^3

cP

60.71

0.3497

58.66

0.2208

43.23

0.08246

59.29

0.2395

19 MOLECULAR WEIGHT, VAPOR

20 MOLECULAR WEIGHT, CONDENSABLE

21 SPECIFIC HEAT BTU/lb*F 1 1.016 1.446 1.008

22 THERMAL CONDUCTIVITY BTU/ft*hr*F 0.3885 0.3961 0.3064 0.3979

23 LATENT HEAT BTU/lb

24 INLET PRESSURE psi 490 1,415

25 VELOCITY ft/sec 5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

28 HEAT EXCHANGED 75,400,000 BTU/hr MTD CORRECTED 122.2 F

29 TRANSFER RATE, SERVICE 182.4 BTU/ft^2*ft*hr CLEAN

30 CONSTRUCTION OF ONE SHELL SKETCH

31 SHELL SIDE TUBE SIDE

32 DESIGN / TEST PRESSURE psig 500 / 1,540 /

33 DESIGN TEMPERATURE / MDMT F 300 / 32 650 / 32

34 NO. PASSES PER SHELL 1 6

35 CORROSION ALLOWANCE in 1/16 1/16

∆t 2 − ∆t1 36 CONNECTIONS IN 14" - 300 # RF 8" - 900 # RTJ

LMTD =

37 SIZE & OUT 14" - 300 # RF 8" - 900 # RTJ

38 RATING INTERMEDIATE

∆t

ln 2

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

∆ t 41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

1

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

44 FLOATING HEAD COVER IMPINGEMENT PROTECTION

45 BAFFLES - CROSS CS TYPE horiz - seg % CUT SPACING C/C INLET in

∆t1 = T1 − t 2 46

47

48

BAFFLES - LONG

BYPASS SEAL ARRANGEMENT

EXPANSION JOINT

SEAL TYPE

TUBE - TUBESHEET JOINT

TYPE

49 GASKET SHELL TUBE FLOATING HEAD

∆t 2 = T2 − t1

50 CODE REQUIREMENTS ASME SECTION VIII, Div 1 TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

THERMAL & PROCESS SALES, INC.

WWW.THERMPRO.COM

HEAT EXCHANGER SPECIFICATION SHEET

Heat Transfer

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

Coefficient

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

8 FLUID ALLOCATION IN SHELL SIDE OUT IN TUBE SIDE OUT

9 FLUID NAME Boiler Feedwater Condensate Blowdown

10 FLUID QUANTITY, TOTAL lb/hr 928,000 224,700

11 VAPOR (IN / OUT) lb/hr

12 LIQUID lb/hr

•Process Factors 13

14

STEAM

WATER

lb/hr

lb/hr 928,000 928,000 224,700 224,700

15 NONCONDENSABLE lb/hr

16 TEMPERATURE (IN / OUT) F 178.3 259 589.1 243.9

•Flowrate 17

18

19

SPECIFIC GRAVITY / DENSITY

VISCOSITY

MOLECULAR WEIGHT, VAPOR

lb/ft^3

cP

60.71

0.3497

58.66

0.2208

43.23

0.08246

59.29

0.2395

20 MOLECULAR WEIGHT, CONDENSABLE

•Specific Heat 21

22

23

SPECIFIC HEAT

THERMAL CONDUCTIVITY

LATENT HEAT

BTU/lb*F

BTU/ft*hr*F

BTU/lb

1

0.3885

1.016

0.3961

1.446

0.3064

1.008

0.3979

24 INLET PRESSURE psi 490 1,415

•Viscosity 25 VELOCITY ft/sec 5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

28 HEAT EXCHANGED 75,400,000 BTU/hr MTD CORRECTED 122.2 F

•Thermal Conductivity

29 TRANSFER RATE, SERVICE 182.4 BTU/ft^2*ft*hr CLEAN

30 CONSTRUCTION OF ONE SHELL SKETCH

31 SHELL SIDE TUBE SIDE

32 DESIGN / TEST PRESSURE psig 500 / 1,540 /

33 DESIGN TEMPERATURE / MDMT F 300 / 32 650 / 32

34 NO. PASSES PER SHELL 1 6

35 CORROSION ALLOWANCE in 1/16 1/16

36 CONNECTIONS IN 14" - 300 # RF 8" - 900 # RTJ

37 SIZE & OUT 14" - 300 # RF 8" - 900 # RTJ

38 RATING INTERMEDIATE

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

44 FLOATING HEAD COVER IMPINGEMENT PROTECTION

45 BAFFLES - CROSS CS TYPE horiz - seg % CUT SPACING C/C INLET in

46 BAFFLES - LONG SEAL TYPE

47 BYPASS SEAL ARRANGEMENT TUBE - TUBESHEET JOINT

48 EXPANSION JOINT TYPE

49 GASKET SHELL TUBE FLOATING HEAD

50 CODE REQUIREMENTS ASME SECTION VIII, Div 1 TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

Advanced Heat Transfer Topics 25

Thermal & Process Sales, Inc. www.thermpro.com

Heat Transfer

THERMAL & PROCESS SALES, INC.

WWW.THERMPRO.COM

HEAT EXCHANGER SPECIFICATION SHEET

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

Coefficient

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

8 FLUID ALLOCATION IN SHELL SIDE OUT IN TUBE SIDE OUT

9 FLUID NAME Boiler Feedwater Condensate Blowdown

10 FLUID QUANTITY, TOTAL lb/hr 928,000 224,700

•Mechanical Factors (Tubeside)

11 VAPOR (IN / OUT) lb/hr

12 LIQUID lb/hr

13 STEAM lb/hr

14 WATER lb/hr 928,000 928,000 224,700 224,700

•Tube Count

15 NONCONDENSABLE lb/hr

16 TEMPERATURE (IN / OUT) F 178.3 259 589.1 243.9

17 SPECIFIC GRAVITY / DENSITY lb/ft^3 60.71 58.66 43.23 59.29

18 VISCOSITY cP 0.3497 0.2208 0.08246 0.2395

19 MOLECULAR WEIGHT, VAPOR

•Number of Passes (tube) 20

21

MOLECULAR WEIGHT, CONDENSABLE

SPECIFIC HEAT BTU/lb*F 1 1.016 1.446 1.008

22 THERMAL CONDUCTIVITY BTU/ft*hr*F 0.3885 0.3961 0.3064 0.3979

23 LATENT HEAT BTU/lb

•Tube Diameter 24

25

INLET PRESSURE

VELOCITY

psi

ft/sec

490 1,415

5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

•Internal Enhancements 28

29

HEAT EXCHANGED

TRANSFER RATE, SERVICE

75,400,000 BTU/hr

182.4 BTU/ft^2*ft*hr

MTD CORRECTED

CLEAN

122.2 F

30 CONSTRUCTION OF ONE SHELL SKETCH

31 SHELL SIDE TUBE SIDE

32 DESIGN / TEST PRESSURE psig 500 / 1,540 /

33 DESIGN TEMPERATURE / MDMT F 300 / 32 650 / 32

34 NO. PASSES PER SHELL 1 6

35 CORROSION ALLOWANCE in 1/16 1/16

36 CONNECTIONS IN 14" - 300 # RF 8" - 900 # RTJ

37 SIZE & OUT 14" - 300 # RF 8" - 900 # RTJ

38 RATING INTERMEDIATE

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

44 FLOATING HEAD COVER IMPINGEMENT PROTECTION

45 BAFFLES - CROSS CS TYPE horiz - seg % CUT SPACING C/C INLET in

46 BAFFLES - LONG SEAL TYPE

47 BYPASS SEAL ARRANGEMENT TUBE - TUBESHEET JOINT

48 EXPANSION JOINT TYPE

49 GASKET SHELL TUBE FLOATING HEAD

50 CODE REQUIREMENTS ASME SECTION VIII, Div 1 TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

Heat Transfer

THERMAL & PROCESS SALES, INC.

WWW.THERMPRO.COM

HEAT EXCHANGER SPECIFICATION SHEET

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

Coefficient

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

8 FLUID ALLOCATION IN SHELL SIDE OUT IN TUBE SIDE OUT

9 FLUID NAME Boiler Feedwater Condensate Blowdown

10 FLUID QUANTITY, TOTAL lb/hr 928,000 224,700

•Mechanical Factors (Shellside)

11 VAPOR (IN / OUT) lb/hr

12 LIQUID lb/hr

13 STEAM lb/hr

14 WATER lb/hr 928,000 928,000 224,700 224,700

•Tube Count

15 NONCONDENSABLE lb/hr

16 TEMPERATURE (IN / OUT) F 178.3 259 589.1 243.9

17 SPECIFIC GRAVITY / DENSITY lb/ft^3 60.71 58.66 43.23 59.29

18 VISCOSITY cP 0.3497 0.2208 0.08246 0.2395

19 MOLECULAR WEIGHT, VAPOR

•Tube Diameter 20

21

MOLECULAR WEIGHT, CONDENSABLE

SPECIFIC HEAT BTU/lb*F 1 1.016 1.446 1.008

22 THERMAL CONDUCTIVITY BTU/ft*hr*F 0.3885 0.3961 0.3064 0.3979

23 LATENT HEAT BTU/lb

•Tube Pitch / Layout 24

25

INLET PRESSURE

VELOCITY

psi

ft/sec

490 1,415

5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

•External Enhancements 28

29

HEAT EXCHANGED

TRANSFER RATE, SERVICE

75,400,000 BTU/hr

182.4 BTU/ft^2*ft*hr

MTD CORRECTED

CLEAN

122.2 F

30 CONSTRUCTION OF ONE SHELL SKETCH

31 SHELL SIDE TUBE SIDE

•Shell Diameter 32

33

34

DESIGN / TEST PRESSURE

DESIGN TEMPERATURE / MDMT

NO. PASSES PER SHELL

psig

F

500 /

300 / 32

1

1,540 /

650 / 32

6

35 CORROSION ALLOWANCE in 1/16 1/16

•Number of Passes (shell) 36

37

38

CONNECTIONS

SIZE &

RATING

IN

OUT

INTERMEDIATE

14" - 300 # RF

14" - 300 # RF

8" - 900 # RTJ

8" - 900 # RTJ

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

•Baffle Type

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

•Baffle Cut 44

45

46

FLOATING HEAD COVER

BAFFLES - CROSS CS TYPE

BAFFLES - LONG

horiz - seg % CUT

IMPINGEMENT PROTECTION

SEAL TYPE

SPACING C/C INLET in

47 BYPASS SEAL ARRANGEMENT TUBE - TUBESHEET JOINT

•Baffle Spacing 48

49

50

EXPANSION JOINT

GASKET SHELL

CODE REQUIREMENTS

TUBE

ASME SECTION VIII, Div 1

TYPE

FLOATING HEAD

TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

Advanced Heat Transfer Topics 26

Thermal & Process Sales, Inc. www.thermpro.com

Heat Transfer

THERMAL & PROCESS SALES, INC.

HEAT EXCHANGER SPECIFICATION SHEET

WWW.THERMPRO.COM

1 CUSTOMER Thermal & Process Sales JOB / REFERENCE NO.

2 PROPOSAL NO. REV

3 PLANT LOCATION ITEM NO

Coefficient

4 SERVICE OF UNIT BFW Preheater DATE 1/20/2006

5 SIZE 31-288 TYPE CEU ORIENTATION horizontal CONNECTED IN series

6 SQ. FT. SURF. / UNIT 3384 SHELLS / UNIT 1 SQ. FT. SURF. / SHELL 3384

7 PERFORMANCE OF ONE UNIT

8 FLUID ALLOCATION IN SHELL SIDE OUT IN TUBE SIDE OUT

9 FLUID NAME Boiler Feedwater Condensate Blowdown

10 FLUID QUANTITY, TOTAL lb/hr 928,000 224,700

•Other Factors 11

12

VAPOR (IN / OUT)

LIQUID

lb/hr

lb/hr

13 STEAM lb/hr

14 WATER lb/hr 928,000 928,000 224,700 224,700

•Shell and Tube sides switched? 15

16

NONCONDENSABLE

TEMPERATURE (IN / OUT)

lb/hr

F 178.3 259 589.1 243.9

17 SPECIFIC GRAVITY / DENSITY lb/ft^3 60.71 58.66 43.23 59.29

18 VISCOSITY cP 0.3497 0.2208 0.08246 0.2395

•Fluid Velocities 19

20

21

MOLECULAR WEIGHT, VAPOR

MOLECULAR WEIGHT, CONDENSABLE

SPECIFIC HEAT BTU/lb*F 1 1.016 1.446 1.008

22 THERMAL CONDUCTIVITY BTU/ft*hr*F 0.3885 0.3961 0.3064 0.3979

•Pressure Drop

23 LATENT HEAT BTU/lb

24 INLET PRESSURE psi 490 1,415

25 VELOCITY ft/sec 5

26 PRESSURE DROP, ALLOW / CALC. psi 10 / 10 10 / 8.5

•Fouling Factors

27 FOULING RESISTANCE (MIN) hr*ft^2*f/BTU 0.001 0.002

28 HEAT EXCHANGED 75,400,000 BTU/hr MTD CORRECTED 122.2 F

29 TRANSFER RATE, SERVICE 182.4 BTU/ft^2*ft*hr CLEAN

30 CONSTRUCTION OF ONE SHELL SKETCH

31 SHELL SIDE TUBE SIDE

•Materials of Construction (tubes) 32

33

DESIGN / TEST PRESSURE

DESIGN TEMPERATURE / MDMT

psig

F

500 /

300 / 32

1,540 /

650 / 32

34 NO. PASSES PER SHELL 1 6

35 CORROSION ALLOWANCE in 1/16 1/16

36 CONNECTIONS IN 14" - 300 # RF 8" - 900 # RTJ

37 SIZE & OUT 14" - 300 # RF 8" - 900 # RTJ

38 RATING INTERMEDIATE

39 TUBE NO. 350 U OD 3/4 in THK 16 BWG LENGTH 24 ft PITCH 15/16 in

40 TUBE TYPE Bare MATERIAL ASTM A789 Gr S32205 LAYOUT ▲ ◄ ■ ♦

41 SHELL SA-516-70 ID 30.75 in OD 32 in SHELL COVER SA-516-70 (INTEG / REMOV)

42 BONNET / CHANNEL SA-516-70 CHANNEL COVER SA-516-70

43 TUBESHEET - STATIONARY SA-516-70 w/ 2205 weld overlay TUBESHEET - FLOATING

44 FLOATING HEAD COVER IMPINGEMENT PROTECTION

45 BAFFLES - CROSS CS TYPE horiz - seg % CUT SPACING C/C INLET in

46 BAFFLES - LONG SEAL TYPE

47 BYPASS SEAL ARRANGEMENT TUBE - TUBESHEET JOINT

48 EXPANSION JOINT TYPE

49 GASKET SHELL TUBE FLOATING HEAD

50 CODE REQUIREMENTS ASME SECTION VIII, Div 1 TEMA CLASS R

51 REMARK

52

53

www.thermpro.com

Credits

Kern, Process Heat Transfer

TEMA Standard

www.thermpro.com

Advanced Heat Transfer Topics 27

Thermal & Process Sales, Inc. www.thermpro.com

www.thermpro.com

Advanced Heat Transfer Topics 28

You might also like

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Troublshooting For PET PreformDocument5 pagesTroublshooting For PET PreformSteven Cheng75% (4)

- Plate Heat ExchangerDocument12 pagesPlate Heat ExchangerEngSafwanQadous100% (1)

- Andritz Separation Fluid Bed Dryer en DataDocument16 pagesAndritz Separation Fluid Bed Dryer en DataElias AyanaNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Coker Heater Design - The Heart of The Coking ProcessDocument45 pagesCoker Heater Design - The Heart of The Coking ProcessVigneswaran SNo ratings yet

- Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesMethod Statement For Domestic Water Piping Installation UG & AGBelal AlrwadiehNo ratings yet

- D RP Heat Transfer Fluid: OwthermDocument24 pagesD RP Heat Transfer Fluid: Owthermhmudassir_1No ratings yet

- Lecture - 1 - Thermal Equipment Design - IntroductionDocument14 pagesLecture - 1 - Thermal Equipment Design - IntroductionAbed Baayoun100% (2)

- A' Level Inorganic Chemistry: by Mukanda S.MDocument51 pagesA' Level Inorganic Chemistry: by Mukanda S.MTeejay Makazhu100% (4)

- Thermax LTD - CHPCDocument33 pagesThermax LTD - CHPCmohamad100% (1)

- 06 Legacy A2 Unit 6Document9 pages06 Legacy A2 Unit 6Azsumcute0% (1)

- 3 - Rivers and Lakes Their Distribution Origins and FormsDocument28 pages3 - Rivers and Lakes Their Distribution Origins and FormsDenisse GrandaNo ratings yet

- Caloritech Immersion HeatersDocument44 pagesCaloritech Immersion HeatersanaNo ratings yet

- Flange Immersion Heater: FeaturesDocument1 pageFlange Immersion Heater: FeaturesRidwan Haque DolonNo ratings yet

- English Version Catalogue-2013-02-1Document27 pagesEnglish Version Catalogue-2013-02-1Arunee SombatjindaNo ratings yet

- Ttsicatalog PDFDocument8 pagesTtsicatalog PDFMd. Osman AliNo ratings yet

- Paratherm HR: Heat Transfer FluidDocument2 pagesParatherm HR: Heat Transfer FluidshyamNo ratings yet

- ThermalDocument15 pagesThermalJulián MoranNo ratings yet

- Calefactores de Alternador Hotwatt PDFDocument176 pagesCalefactores de Alternador Hotwatt PDFTomislav SimunovicNo ratings yet

- Catalogo Caldera Aceite Termico FT-C FultonDocument16 pagesCatalogo Caldera Aceite Termico FT-C FultonELTIPAZONo ratings yet

- Ayvaz Steam Traps BookDocument79 pagesAyvaz Steam Traps BookgideonolinyoNo ratings yet

- 811072SequenceofOperationmanualwithcoverRev AenDocument100 pages811072SequenceofOperationmanualwithcoverRev Aenrio23.mbNo ratings yet

- Globaltherm M Product Information SheetDocument4 pagesGlobaltherm M Product Information SheetMalek MahmoudNo ratings yet

- TK Brochure Industrial CubicUnit Coolers ESEC ENG 04Document12 pagesTK Brochure Industrial CubicUnit Coolers ESEC ENG 04Alex AndersNo ratings yet

- K050 DMDocument1 pageK050 DMvitor4santos_6No ratings yet

- 12 Peter Baen ThermonDocument31 pages12 Peter Baen ThermonHafeez AhmadNo ratings yet

- Product SummaryDocument1 pageProduct SummarychinitnNo ratings yet

- Tempsens: Thermal and Cable SolutionsDocument31 pagesTempsens: Thermal and Cable Solutionssajid vermaNo ratings yet

- OPTITEMP TRA-TW59 - KROHNE GroupDocument3 pagesOPTITEMP TRA-TW59 - KROHNE GroupalicardozoNo ratings yet

- Heaters Film and BulkDocument24 pagesHeaters Film and BulkMelissa RamirezNo ratings yet

- HTRI Membership ApplicationDocument2 pagesHTRI Membership ApplicationManoj ManivasagamNo ratings yet

- High Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicsDocument12 pagesHigh Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicscivicbladeNo ratings yet

- TPR Temperature Switch: Series TPR High Accuracy Nema 4X & Ip 65 UL, CSA and CE Approved Compact, Economical DesignDocument4 pagesTPR Temperature Switch: Series TPR High Accuracy Nema 4X & Ip 65 UL, CSA and CE Approved Compact, Economical DesignargaNo ratings yet

- Holtech Marine (Heating Solutions) BROUCHER FOR HEATING SYSTEMDocument2 pagesHoltech Marine (Heating Solutions) BROUCHER FOR HEATING SYSTEMsyed WajihNo ratings yet

- Skin Effect Heating System: Chromalox ConfidentialDocument9 pagesSkin Effect Heating System: Chromalox ConfidentialMarco SilvaNo ratings yet

- RjyhetrsgdfzDocument1 pageRjyhetrsgdfzMohamed SelimNo ratings yet

- TMP0001 ThermaSeam BrochureDocument4 pagesTMP0001 ThermaSeam BrochureniyasNo ratings yet

- Evaluating Heat Exchanger Performance ResearchDocument9 pagesEvaluating Heat Exchanger Performance ResearchMohamed RagabNo ratings yet

- Catalog Ankor TeploenergoDocument24 pagesCatalog Ankor TeploenergoADIPESHNo ratings yet

- 172.4 206.4 Ton Ultra Air Cooled Semi Hermetic Chiller V 4.0 MexicoDocument4 pages172.4 206.4 Ton Ultra Air Cooled Semi Hermetic Chiller V 4.0 MexicoEdison EspinalNo ratings yet

- jThomsonPPT PDFDocument5 pagesjThomsonPPT PDFThaHir MuhammedNo ratings yet

- HYDAC Comoso CombiCoolersforMobileDocument4 pagesHYDAC Comoso CombiCoolersforMobileMilad RahimiNo ratings yet

- HTT 45 CableDocument1 pageHTT 45 CableKoel DeyNo ratings yet

- Brochure en T Rex Transformer Oil Coolers Onan OnafDocument6 pagesBrochure en T Rex Transformer Oil Coolers Onan Onafnaczelny_naczelnikNo ratings yet

- Globaltherm Omnipure Product Information SheetDocument4 pagesGlobaltherm Omnipure Product Information SheetMalek MahmoudNo ratings yet

- Stainless Steels For High Service Temperatures: Outokumpu Therma RangeDocument12 pagesStainless Steels For High Service Temperatures: Outokumpu Therma RangeAngel MendozaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument30 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- MaterialData - 14076 HDS H13Document2 pagesMaterialData - 14076 HDS H13Amol KulkarniNo ratings yet

- Paratherm MR BulletinDocument1 pageParatherm MR Bulletinkman548No ratings yet

- DMCDocument7 pagesDMCFares NasserNo ratings yet

- Jacketed Reactor Vessel PDFDocument1 pageJacketed Reactor Vessel PDFSH1961No ratings yet

- Air Cooled Semi Hermetic ChillerDocument2 pagesAir Cooled Semi Hermetic ChillerEduardo Ramirez TinocoNo ratings yet

- Benefits of Extruded Heat Sinks: Plate Fin Heat Sinks Cross Cut Heat SinksDocument17 pagesBenefits of Extruded Heat Sinks: Plate Fin Heat Sinks Cross Cut Heat SinksFebri AndriyudaNo ratings yet

- Heat Transfer & Clean Water Solutions: Alila Uluwatu BaliDocument2 pagesHeat Transfer & Clean Water Solutions: Alila Uluwatu BaliMartin TjoaNo ratings yet

- HT Cast: Product DescriptionDocument2 pagesHT Cast: Product DescriptionanassNo ratings yet

- Ht-Cast EngDocument2 pagesHt-Cast EnganassNo ratings yet

- Heat Exchangers Ver A 2018Document19 pagesHeat Exchangers Ver A 2018Hemant SolankiNo ratings yet

- MechanicalDocument478 pagesMechanicalMelele MuNo ratings yet

- 120 - 154.8 Toneladas Ultra Semi Hermetico EcochillersDocument10 pages120 - 154.8 Toneladas Ultra Semi Hermetico EcochillersRudy TorrezNo ratings yet

- Santeco Technologies Heatpump CatalogDocument24 pagesSanteco Technologies Heatpump CatalogMichael Ver SantecoNo ratings yet

- Armstrong Plate and FramesDocument6 pagesArmstrong Plate and FramesbenNo ratings yet

- Optitemp Tca-Ts53 - Krohne GroupDocument3 pagesOptitemp Tca-Ts53 - Krohne GroupalicardozoNo ratings yet

- Drying of Woody Biomass. Process Engineering - GEA Barr-RosinDocument21 pagesDrying of Woody Biomass. Process Engineering - GEA Barr-RosinvhendrayawanNo ratings yet

- About Us Expertise Services Design Tips Design Tools Testimonials Our Team Contact UsDocument4 pagesAbout Us Expertise Services Design Tips Design Tools Testimonials Our Team Contact UssyahrilcalliNo ratings yet

- BAWASA Orientation (081104)Document20 pagesBAWASA Orientation (081104)JERRY T. LICAYANNo ratings yet

- River Training Manual Final Wecs 2020-06-15 (F)Document190 pagesRiver Training Manual Final Wecs 2020-06-15 (F)sandeshNo ratings yet

- Trai He HSG 6 7 8 9Document11 pagesTrai He HSG 6 7 8 9HieuNo ratings yet

- Hoja de Seguridad 242Document6 pagesHoja de Seguridad 242Gabo TellezNo ratings yet

- Sustainable and Resilient UWIDocument20 pagesSustainable and Resilient UWIvenu4u498No ratings yet

- Goal 6: Clean Water and SanitationDocument3 pagesGoal 6: Clean Water and SanitationNazakat HussainNo ratings yet

- Water Supply and DistributionDocument65 pagesWater Supply and DistributionchinNo ratings yet

- Marala HeadworksDocument4 pagesMarala HeadworksJahangir ImtiazNo ratings yet

- WL1 and AF1 Virginia Form P-378 Product BulletinDocument2 pagesWL1 and AF1 Virginia Form P-378 Product BulletinTwisty OliverNo ratings yet

- Prelim Exam EssayDocument1 pagePrelim Exam EssayKeanu PeraltaNo ratings yet

- Fyp Technical Paper - Nurul Syafiqah Rosli - kh17033Document9 pagesFyp Technical Paper - Nurul Syafiqah Rosli - kh17033anis amiraNo ratings yet

- Regional Studies in Marine ScienceDocument11 pagesRegional Studies in Marine ScienceBOUCHNANNo ratings yet

- Week 1 - Modules 1-3: Earth As The Only Habitable PlanetDocument25 pagesWeek 1 - Modules 1-3: Earth As The Only Habitable PlanetDon't mind meNo ratings yet

- Sts Study Guide Hatag Nyag Answer UgmaDocument18 pagesSts Study Guide Hatag Nyag Answer UgmaTribunalo, Aliana R.No ratings yet

- GeneratorDocument9 pagesGeneratorSooraj Surendran SugathaNo ratings yet

- ANH 8 - Huong Dan On Tap Giua Ki 2 - Nam Hoc 23-24Document6 pagesANH 8 - Huong Dan On Tap Giua Ki 2 - Nam Hoc 23-24Lê Na Nguyễn ThịNo ratings yet

- Hydrographic and Tunnel SurveyingDocument21 pagesHydrographic and Tunnel Surveyingzain Ishaq100% (1)

- EDS For FPSC (Pakmcqs)Document352 pagesEDS For FPSC (Pakmcqs)Muhammad IlyasNo ratings yet

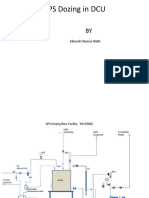

- APS Dosing New Facility1Document8 pagesAPS Dosing New Facility1Abhishek PandeyNo ratings yet

- Phu GiaDocument7 pagesPhu Giaquoctho1905No ratings yet

- Applied Catalysis B: EnvironmentalDocument9 pagesApplied Catalysis B: EnvironmentalElson OliveiraNo ratings yet

- Dispersants and Their Effects On Hydratable AluminaDocument7 pagesDispersants and Their Effects On Hydratable AluminaKerem BNo ratings yet

- Characteristics of Earth That Are Necessary To Support LifeDocument1 pageCharacteristics of Earth That Are Necessary To Support LifeBenedict De Los ReyesNo ratings yet

- Factory Act 1948Document27 pagesFactory Act 1948priya singhNo ratings yet