Professional Documents

Culture Documents

Viscosity Measurement: June Edition

Uploaded by

Dea AbdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscosity Measurement: June Edition

Uploaded by

Dea AbdiCopyright:

Available Formats

JUNE 15, 1938 .

4NALYTICAL EDITION 297

ist in the corrosion tests in the circulation units previously It becomes necessary, therefore, in making the final evslua-

described. Any tendency to foaming should, therefore, mani- tion of a new antifreeze, to employ field tests in a wide variety

fest itself during these tests. Observations are made peri- of automobiles under various conditions of use. Accurate

odically for evidence of foaming. A solution which foams to comparative results cannot be obtained by road testa, it is

any serious extent will foam up into and out of the top of the true, because conditions cannot be controlled, but these tests

reflux condenser which is located on the top reservoir of the do occasionally reveal a fault in an antifreeze which did not

unit. manifest' itself in laboratory tests.

Field Tests Acknowledgrnen t

Sotwithstanding the care which is taken in making labora- Earlier forms of the corrosion-testing equipment described

tory tests, and the effort which is made to duplicate actual herewith were originally developed by the senior author at

conditions of use in a n automobile, it is difficult to simulate The Miner Laboratories in connect,ion m-it'h research fellow-

all conditions. This could probably be accomplished if all ships of the Association of American Soap and Glycerine

automobile cooling systems were constructed exactly alike. Producers, Inc.

Unfortunately, however, they all differ in some way, so that

if the investigator simulates one particular cooling system in Literature Cited

his laboratory tests, then his conditions of test and construc-

[lj Bengouyh, G. D., and May, R.. Engineer, 136,7710 (1923).

tion of equipment will not be wholly applicable to another. 12) Speller, F. N., "Corrosion: Causes and Prevention," 2nd ed..

Cooling systems of various makes of automobiles are likely p. 14, Xew Tork, McGraw-Hill Book Co., 1935.

to differ in one or more of the following characteristics: con- ( 3 ) Ihid., pp. 250-1.

structional design, materials of construction, ,metallic couples, RECEIVED March 28, 1938. Presented before t h e Division of Industrial and

rate of circulation, amount of aeration. and operating tem- Engineering Chemistry a t the 95th Meeting of the American Chemioal So-

perature. ciety, Dallas, Texas, April 18 t o 22, 1938.

Viscosity Measurement

R I . R. CANNON AND &I. R. FENSKE

School of Chemistry and Physics, The Pennsylvania State College, State College. Pa.

Viscosity and viscosity temperature coef- identical boiling points differ in viscosity by several hundred

ficients are valuable identifying properties per cent.

of pure compounds and petroleum frac- It is the purpose of this paper to describe briefly suitable

capillary-type viscometers for measuring viscosity in a simple

tions. This paper discusses the operating but precise manner. In addition, the sources of error and

characteristics of simple modified Ostwald their magnitude will be discussed, together with means of ren-

viscometers that are suitable for covering a dering these negligible.

wide range of viscosity with accuracy. The Figure 1 is a n illustration of a n accurate routine viscometer,

particularly designed for petroleum fractions, which is now in

important sources of error in capillar>- extensive use in the petroleum industry both in this country

viscometers are analyzed briefly and equa- and abroad. A complete description and operating technic

tions for computing the necessary correc- have been recently published by the American Society for

tions are given. Comparisons are made Testing Materials (1).

with other types of capillary viscometers The extra bulb on the capillary side of the instrument is for the

which show that the modified Ostwald is purpose of incorporating an accurate loading device as an integral

part of the viscometer. A glass bridge joins the two legs of the

equal in accuracy to any now- available. viscometer as shown; in addition heavy-walled glass is used

throughout, so that the instrument is not fragile. Practically

any size of working capillary can be used in the viscometer, so

that very viscous fluids such as heavy lubricating oils c m be

F OR many years viscosity and viscosity-temperature co-

efficients of petroleum fractions have been regarded as

important physical constants. The work of hlikeska (8) and

tested quickly and accurately. For example, a series of four

such instruments of different capillary bores will conveniently

cover a viscosity range of 2 t o 1000 centistokes: The instrument

of smallest bore would be for a range of 2 to 10 centistokes, the

Wiggins (13) on organic compounds shows these properties next for 6 to 40 centistokes, the next for 30 to 200 centistokes, and

to be valuable identifying characteristics that will doubtless the fourth for 150 to 1000 centistokes. Because of the low cost

find greater application in future work. Since viscosity is and ease of construction, it is possible to obtain viscometers with

bores most convenient for the particular viscosity range in question.

intimately associated with structure, constitution, symmetry, Six cubic centimeters of liquid are required for a test. The over-

polarity, saturation, and molecular size, it may be employed all length of the instrument is approximately 25 cm. Six or more

as a means of analysis. For example, the data of Wiggins (13) will readily fit into a small constant-temperature bat.h.

show the viscosity of diallyl, the diolefinic derivative of hex-

ane, to be 1.5 per cent less than hexane at 0" C. and toluene Operation of Modified Ostwald Viscometer

differs from methylcyclohexane in viscosity by more than 20 The viscometer is loaded at room temperature by holding it in

per cent a t 0' C. Many high-boiling petroleum fractions of an inverted vertical position with the capillary side submerged

298 INDUSTRIAL AKD ENGINEERISG CHEMISTRY VOL. 10, NO. 6

in the liquid under test. Suction is then applied to the other routine type (Figure l),first, because no kinetic energy correc-

arm of the instrument and both small bulbs on the capillary arm tions are encountered in products of 2 centistokes or more in

are filled with oil. The liquid is brought into the working cap-

illary to the etched mark; hence, the total charging volume is these instruments if properly used, and secondly, because pe-

that held by the two bulbs plus that held by the capillary ex- troleum fractions do not differ sufficiently in surface tension to

t'ending to the open end of the instrument. After filling, the become a n appreciable source of error. It will be shown later

viscometer is revolved to its normal vertical position and placed that a large difference in surface tension will necessitate only

in the constant-temperature bath. The liquid will drain into the

lovier reservoiy during the time required for it to attain the bath a small correction.

temperature. When this temperature is reached, the efflux time This second viscometer has a n over-all length of approxi-

is obtained by drawing the liquid up to the mark beheen the mately 30 cm. and requires a 2,5-cc. charge. The efflux bulb

bulbs and measuring the time required for the meniscus to pass has a volume of 1.0 cc. It is recommended for viscosities

from the mark bet,ween the bulbs to the mark below the lower

bulb on the capillary. The viscosity of the fluid is then obtained ranging from 0.3 to 5 centistokes. It can be used for more

by multiplying the efflux time in seconds by the viscometer con- viscous liquids, but the type shown as Figure 1 is more con-

stant. The evaluation of the viscometer constant is discussed venient for the higher viscosity range.

later. The only function of the upper bulb on the capillary arm A semimicroviscometer (Figure 3) has an over-all length of

is to serve as an accurate loading device in conjunction with thc

end capillary and efflux bulb. Laboratory experiments show approximately 30 cm. and requires a total charge of 0.25 cc.

that the instrument and liquid contents will reach a bath tem- It can be made with practically any desired capillary bore to

perature of 37.78" C. (100" F.) in about 4 minutes and a tem- cover a range of 0.5 to 800 centistokes. The efflux volume is

perature of 98.8 C. (210' F.) in approximately 10 minutes.

O

approximately 0.15 cc. and the efflux capillary and lower re+

ervoir capillary are of the same diameter to eliminate surface

tension corrections. Although the over-all length of these

instruments is 30 cm., the length submerged in the bath is ap-

proximately 20 cm., so that a constant-temperature bath that

is 20 cm. deep is suitable.

Magnitude and Source of Errors

Loading errors arise from the fact that the driving fluid head

is dependent upon the amount of liquid in the instrument.

Thus, if too much liquid is charged to the instrument, the level

in the lower reservoir is too high and driving head is reduced

GLASS by that amount. The expression for loading errors is:

STRENGTHENIN

BRIDGE 100 Y

;( error in loading = -

K P H

d i e r e v is the loading error, r is the working radius of the

lolver reservoir, and H is the driving liquid head.

LINE ETCHED

As a specific example of the magnitude of this error, consider a

routine type of viscometer (Figure 1). In these instruments H

is approximately 10 cm., T is 1.5 em., and a working capillary of

0.1-cm. diameter will be considered. If, when loading, the

operator misses the etched mark on the capillary by 0.1 cm.,

then Y will be 0.00079 cc. and the percentage error 0.001 per cent.

To make an error of 0.1 per cent it would be necessary for the

operator to miss the etched mark on the capillary by 12 em. The

viscometers shown as Figures 2 and 3 are more sensitive to loading

errors, but the error is readily maintained below 0.1 per cent.

The validity of this loading error equation was proved by weigh-

ing into several viscometers a known excess of test liquid and

checking the results obtained with those predicted by the equa-

tion. Checks were also made by withdrawing known amounts,

so that a deficient quantity of liquid was in the instrument. In

\ all cases the experimental results agreed with those predicted by

the equation.

Kinetic energy corrections are primarily due to contraction

and expansion losses at the entrance and exit of the capillary.

It is customary (2) to include the kinetic energy correction in

Poiseuille's equation as follows:

1. ROUTIXE

FIGURE FOR PETRO-

VISCOMETER

LEUM PRODUCTS

Dimensions in mm.

where K V = kinematic viscosity in stokes

w = viscosity in poises

A viscometer more suitable for nonviscous liquids is illus- p = density in grams per cc.

trated by Figure 2. This instrument differs from Figure 1 in g = gravitational constant in cm. per see. per sec.

several respects. The efflux volume and working capillary H = fluid head in cm.

r = radius of capillary in cm.

are considerably smaller and the diameters of the efflux bulb t = efflux time in seconds

and the lower reservoir (actually part of the larger arm) are L = capillary length in cm.

the same. These changes were made to reduce kinetic energy V = efflux volume in cc.

and surface tension corrections, but are not incorporated in the m = kinetic energy coefficient

JUNE 15, 1938 ANALYTICAL EDITION 299

The second term on the right side of this equation is the capillary so that kinetic energy corrections may be maintained

kinetic energy correction. In a properly designed instrument below 0.2 per cent. This was verified by testing water a t two

this term should be very small compared with the first term on different temperatures in each of two viscometers with capil-

the same side of the equation. The percentage error or cor- laries of different size.

rection is more important than the absolute figure. The ex-

pression for the percentage correction can be obtained by

dividing the kinetic energy term by the main term and multi-

plying by 100.

;i2

-100

T0

BORE 2.5

L

Kinetic energy correction in per cent = GLASS

STRENGTHENINC

BRIDGE

The velocity in the capillary is given by U. From this

expression it is obvious that kinetic energy corrections ~vill

increase as the square of the velocity in the capillary. 0 ETCHED

LINES

GLASS

STRENGTHENN

BRIDGE

T

1

s

1

BORE 1.5

BOTH BULBS

CAPACITY

= LOCC.

ETCHED

,LINES

BORE 2.5

1-

BORE RANGE

0.3 to 2.0

FIGURE3. MICROVISCOMETEB

Dimensions in mm.

The kinetic energy term needs special attention only when

designing instruments for nonviscous liquids (2 centistokes or

less). I n viscometers designed for moreviscousliquids thecap-

illary is large enough to make this correction negligible. Since

the value of m is not accurately known, it is not safe to allow

the kinetic energy correction to become appreciable and at-

tempt to apply this correction to the results. There is no assur-

ance that m is a constant for a given instrument; it may vary

with the velocity of the liquid in the capillary in addition to the

shape of the capillary openings. It is a simple matter to con-

struct a viscometer with dimensions such that the calculated

kinetic energy correction is less than 0.2 per cent for liquids as

FOR NONVISCOUS

FIGURE2. VISCOMETER low as 0.5 centistoke in viscosity. The viscometer shown as

FLUIDS Figure 2 differs in its dimensions from that shown as Figure 1,

Dimensions in mm. mainly for the purpose of eliminating kinetic energy correc-

tions. These corrections are not encountered in the first

viscometer, since it is designed to cover a range of viscosity

For most types of viscometers the correct value of m is not from 2 centistokes upward. The microviscorneters are free

known, but it is probably intimately associated with the shape from kinetic energy corrections if the dimensions are properly

of the entrance and exit of the capillary. Values of m = 0 to selected. It is obvious that the efflux volume and capillary

m = 1.12 have been reported (2). I n all the instruments dis- diameter should be made small in order to reduce the kinetic

cussed here the capillary openings are gradually tapered to energy correction. It is also reduced by increasing the driving

give a trumpet-shaped opening. Bingham and Thompson fluid head-i. e., the distance between the efflux bulb and the

(3) report a value of m = 0.56 for such openings. Granted that lower reservoir.

this value may not apply to other capillaries of similar construc- As the fluid stream emerges from the capillary, it has a tend-

tion, nevertheless it is probably of the proper magnitude and ency to retain the shape of the capillary for a finite distance

may be used t o calculate the permissible velocity range in a into the fluid medium. This apparent increase in capillary

300 INDUSTRIAL AND ENGINEERING CHEMISTRY VOL. 10, NO. 6

length, known as the Couette correction, is a function of the which is placed in the open arm of the viscometer. An ex-

capillary radius. It is included in the viscometer constant perienced operator can load and align the viscometer in the

established by calibration. bath in less than one minute. The viscometer of Figure 1

Drainage errors arise from the fact that all liquids do not has the efflux bulb and lower reservoir directly in line for

drain from a surface with equal ease; hence, the measured eliminating alignment errors. This modification has not

efflux volume for one fluid may be different than for another. been incorporated in the other two viscometers, because they

In a series of experiments performed to measure drainage er- are longer and readily adjusted to the vertical position. The

rors (4) it was shown that these are of negligible magnitude. vertical alignment of bulbs was originated by Gruneisen (2).

In addition t o the possible effect on efflux volume, Fitzsimons The viscometer constant will vary with the temperature,

(6) pointed out that drainage will affect the liquid head. but the magnitude of the change is small and readily com-

The experimental drainage measurements indicate that this puted. This correction arises because of the change of spe-

effect will never change the liquid head by 0.01 per cent in cific volume with temperature. Thus, if the viscometer is

viscometers of the type described here. loaded a t 25" C. and then used a t some higher temperature,

If there is a considerable difference between the surface say 100" C., a correction should be applied. The ther-

tension of the calibrating fluids and the fluids subsequently mal coefficients of cubical expansion of most hydrocarbons do

tested, an error due to capillarity will arise. Although the not differ sufficiently to necessitate an individual correction

familiar capillary-rise equation will not hold rigidly for tubes for each type of compcund. It is therefore possible to give

of large diameter, it may be employed to determine the mag- simply the viscometer constant a t two different tempera-

nitude of this error. It can be readily shown that the change tures, and for other temperatures one can interpolate or

in effective driving head due to surface tension difference is ap- extrapolate. Mathematically the viscometer constant a t a

proximated by the following equation: second temperature may be readily computed from the known

constant a t some other temperature by the following equation :

where AH change in effective driving head

=

T] working radius of efflux bulb

=

T~ = working radius of lower reservoir

ST1 = surface tension of calibrating fluid

where CT? = viscometer constant at temperature TD

ST, = surface tension of test fluid C T ~= viscometer constant at temperature T ,

dl = density of calibrating fluid V B = total volume of liquid in viscometer at temperature

d2 = density of test fluid T2

VI = total volume of liquid in viscometer at temperature

Hence, if an instrument of the type presented as Figure 1 TI

H = driving liquid head, approximately equal t o dis-

were calibrated with water a t a temperature where the surface tance between centers of efflux bulb and lower

tension is 70 dynes per centimeter and then used on oils whose reservoir

surface tension is 30 dynes per centimeter, the change in effec- d = working diameter of lower reservoir

tive head would be approximately 0.7 mm. Since the driving

head is 10 cm., the percentage error introduced by neglecting

This correction may be eliminated entirely by preheating

the surface tension correction is 0.7 per cent. However, it is

the sample and the instrument to test temperature before

a simple matter to make this correction accurately or to Cali-

loading However, it is of such small magnitude and deter-

brate the instruments by means of viscosity standards which

mined so readily that it is advisable simply to load the instru-

have been standardized in master instruments especially con- ment a t room temperature. Calibrated viscometers have the

structed to maintain all errors negligible ( 5 ) . It is evident

constant specified a t two temperatures, so that the user may

that surface tension changes produce a very small effect, €or

readily interpolate or extrapolate. The above correction

in the case considered a change of over 200 per cent in surface amounts to only 0.5 per cent for a 60' C. change in tempera-

tension necessitated a correction of only 0.7 per cent. The ture for lubricating oils and gasoline fractions in the viscome-

viscometers presented as Figures 2 and 3 are free from surface ters of Figure 1. It is obvious that this correction, due to

tension corrections because in the latter instrument the efflux

temperature, is very similar to loading errors discussed earlier.

and lower reservoir tubing are of the same diameter and in the

The error caused by expansion of Pyrex glass over the tem-

instrument shown in Figure 2 practically all the efflux time is

perature range 0" to 200" C. has a negligible effect on the

measured when the menisci of both the upper and lower levels viscometer constant. Consequently, if the glass should show

are in tubes of equal diameter. a hysteresis effect no appreciable error will be introduced.

It is necessary to align the viscometer in the bath in an ex- X variation in the gravitational constant from the place of

act vertical position, so that the full available driving fluid calibration to the place of usage will necessitate a simple

head is utilized. If the center of the efflux bulb is joined to

correction which is made by multiplying the constant of the

the center of the lower reservoir by an imaginary line which viscometer by the ratio of g a t the point in question to g at the

makes an angle of A degrees with the vertical, and if this point of calibration. As the value of g does not change by

should be moved dA degrees, then the resultant fractional more than 0.1 per cent throughout the United States, this cor-

change in the fluid head will be given by the expression: rection is of secondary importance.

1 -

cos (A+ dA) Dark fluids will readily absorb radiant heat energy from

solar or unshielded light sources. Consequently a dark fluid

cos A

under test may be several tenths of a degree higher in tem-

For this to be a minimum, angle A should be zero. In perature than the bath medium in which i t is immersed. Since

othe,r words, the upper efflux bulb and the lower reservoir a slight change in temperature causes an appreciable change in

should lie in the same vertical planes. With this type of con- viscosity of most fluids, it is important that lights employed

struction the viscometer must be tilted 2.5" from the vertical in the immediate vicinity of the bath be shielded. Table I

to introduce an error of 0.1 per cent. A deviation of 2" is contains data which show the magnitude of this radiant en-

readily detected by visual inspection, but for safety the vis- ergy effect. I n most practical cases lights employed for good

cometer may be aligned vertically with the aid of a small visibility in constant-temperature baths are not more than

plumb bob made from silk thread and a small piece of lead, 25 watts and are placed in the rear, so that their distance from

JUNE 15, 1938 LNALYTICAL EDITIOh 301

the working area of the bath is greater than 10 cm. (4 inches). For accurate results it is necessary to employ sensitive

I n most installations their effect mill be small, but if proper and reliable auxiliary equipment. Descriptions of satisfac-

care is not exercised the error so introduced may be of conse- tory units have been published ( 5 ) .

quence.

Comparison with Other Viscometers

TABLE1. MAGNITUDE O F TEhIPERlTURE IXCREiSE I S LIQUIDS Various other modifications of the Ostwald instrument are

CAUSED BY RADIASTENERGY FROM USSHIELDED LIGHTBULBS advocated by some investigators. Ubbelohde's (12) sus-

Distance

of Bulb

pended-level type of instrument differs from the type de-

Surface Temp. scribed here only in eliminating loading errors and reducing

from Temp. of Dif-

Type of 110- Bath of Water fer- surface tension errors I n the design presented here such

Liquid Color Voit Light Bulb Surface Liquid Bath ence errors are of negligible magnitude; hence either type of in-

Cm. C. ' C. C. strument, will yield results of equal accuracy. Zeitfuchs (14)

Lube oil A.S.T.M. 100-watt frosted 1.25 38.41 37.78 0.63 has recently described another modification of the Ostwald

KO. 7 5.00 38 19 37.78 0.41

10.00 38.07 37.78 0.29 instrument.which also reduces loading errors and undoubtedly

-la-watt

_ frosted 1.25 38.06 37.78 0.28 will yield accurate results. Slight modifications of the Ubbe-

5.00 37.92 37.78 0.14

10.00 37.89 37.78 0.11 lohde type have been described by Fitzsiinons (6) and by

50-watt frosted 1.25 37.86 37.78 0.08 Payne and Miller (9).

5.00 37.84 37.78 0.06

10.00 37.81 37.78 0.03 The semimicroviscometer described here is simpler than

Lube oil A.S.T.M. 100-watt frosted 1.25 38.36 37.78 0.58 the falling-sphere type described by Schneider and i\IcCon-

KO.2.5 LOO 38.13 37.78 0 35 riel1 (11) and is more convenient than the type described by

10.00 38.02 37.78 0.24

75-watt frosted 1.25 38.04 37.78 0.26 Levin (7') ivhere surface tension is employed as the driving

5.00 37.94 37.78 0.16 force.

10.00 37.89 37.78 0.11

The viscometer recently described by Raaschou (10) is also

50-watt hosted 1.25 37.86 37.78 0.08

5.00 37.84 37.78 0.06 a modification of the Ostwald tube and again the main purpose

10.00 37.82 37.78 0.04 is to reduce loading errors. This is accomplished by adjust-

Water .,. 100-watt frosted 1.25 37.83 37.78 0.05 ing the liquid level by visual inspection of the meniscus in a

5.00 37.80 37.78 0.02

10.00 37.79 37.78 0.01 tube of large diameter (17.5 mm.). It is difficult to make

75-katt frosted 1.25 37.80 37.78 0.02 such an adjustment to better than 0.5 mm. An error of this

5.00 37.79 37.78 0.01

10.00 37.78 37.7s 0.00 magnitude would change the driving fluid head by the same

T h e constant-temperature bath was of 36-liter capacity and was filled with amount and introduce a percentage error of 0.5 per cent

water. T h e walls were of Pyrex glass approximately 0.6 cm. thick. T h e (since the total head is approximately 100 mm.). For most

Pyrex teat tube containing t h e sample w&s 5 om. from the inner bath surface,

practical purposes such an error is of little consequence.

Raaschou uses a value of 1.0074 centistokes as the viscosity

The data of Table I were obtained a t 37.23" C. (100" F.) of water a t 20" C., whereas a value of 1.0068 centistokes has

because it is a standard test temperature in the petroleum been recommended by the American Society for Testing

industry. The measurements were made by placing the Materials as the standard for viscosit,y work. While this

fluid under test in a Pyrex test tube and then immersing it difference is slight, it has been included in this report to cover

in a constant-temperature water bath automatically con- completely the many factors involved.

trolled a t 100" F. to within *0.05" F. Temperature meas- It appears, then, that there are available a number of

urements were made by very sensitive Bureau of Standards capillary-type viscometers which will yield accurate results.

calibrated thermometers. I n the experiments where water The prospective user can be guided in his choice by such fac-

was tested, the radiant heat was probably picked up by the tors as cost, simplicity of design and operation, etc.

thermometer bulb rather than by the mater. The magnitude The reproducibility of results with the modified Ostwald

of the actual errors in viscosity caused in this way depend viscometers described in this paper is *0.2 per cent,. The

upon the viscosity temperature coefficient of the fluid a t the accuracy of the results depends upon the accuracy with which

test temperature. Many heavy oils change in viscosity the absolute viscosity of water is known a t 20" C., since water

by 0.2 per cent with a temperature change of 0.1" F. in is used as the ultimate reference basis. This error is prob-

the vicinity of 100" F. At lower temperature levels the ably in the neighborhood of *0.5 per cent. However, rela-

effect would be more pronounced because viscosity tempera- tive viscosities are very accurate and if the reference basis is

ture coefficient increases with decreasing temperature level. clearly defined little confusion will exist and reported values

of viscosities may be readily compared.

Calibration of Viscometers Literature Cited

A nearly ideal reference basis for viscosity work is pure (1) Am. SOC.Testing Materials, "Standards on Petroleum Products

mater. Instruments which are designed t o cover a viscosity and Lubricants," 1936.

range in the neighborhood of water can be calibrated directly (2) Barr, G., "Monograph of Viscometry," London, Oxford Uni-

against water. When an instrument is designed t o cover a versity Press, 1931.

(3) Bingham. E . C., and Thompson, R. T., J. Rheol., 1, 418 (1930).

range far removed from water, such as that found in lubri- (4) Cannon, hf. R., and Fenske, M. R., Oil Gas J.,33, 52 (1935).

cating oils, direct calibration is not possible. However, (5) Ibid., 34, 46 (1938).

water may be retained as the reference basis by standardizing (6) Fitesimons, 0.. ISD. ESG. CHEni., Anal. Ed.. 7, 346 (1935).

a series of oils in suitable master instruments and then em- (7) Levin, H., Ibzd., 9, 147 (1937).

(8) hlikeska, L. A., ISD. ESG. C H E W , 28, 970 (1936).

ploying these oils as calibration standards. This procedure (9) Payne, E. H., and hliller, C. C., Ibid., Anal. Ed., 8, 300 (1936).

has been explained in detail elsewhere (6). As many oils are (10) Raaschou, P. E., Zbid.. 10, 35 (1938).

unstable and increase in viscosity with age as much as 2.0 (11) Schneider, H. F., and McConnell, T. 8., Ibid., 8, 28 (1936).

per cent per year, it is advisable to check the viscosity of (12) Lbbelohde, L., I b i d . , 9, 85 (1937).

(13) Kggins, W. R., J.Inst. Petroleum Tech., 22, 305 (1936).

standardized oils from time to time. Solvent-treated or (14) Zeitfuchs, E. H., E a t [ . Petroleum News, 29, 68 (1937).

aluminum chloride-desludged oils of high viscosity index are

the most stable and some vary only 0.2 per cent per year. RECEIVED

February 8, 1938.

You might also like

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- A Large Spinning-Band Fractionating ColumnDocument4 pagesA Large Spinning-Band Fractionating ColumnNestor Armando Marin SolanoNo ratings yet

- Viscosity PDFDocument2 pagesViscosity PDFNindy Dellia PutriNo ratings yet

- Experimental Investigation and Modelling of Sulzer I-Ring HydraulicsDocument6 pagesExperimental Investigation and Modelling of Sulzer I-Ring HydraulicsAreli CervantesNo ratings yet

- Computers & Chemical Engineering: S.M.C.P. Pedrosa, J.R. NunhezDocument7 pagesComputers & Chemical Engineering: S.M.C.P. Pedrosa, J.R. NunhezMamoon ShahidNo ratings yet

- Viscosity of Asphalts by Vacuum Capillary Viscometer: Standard Test Method ForDocument8 pagesViscosity of Asphalts by Vacuum Capillary Viscometer: Standard Test Method ForMohamed Maamoun T.No ratings yet

- PET 527 ViscosityDocument18 pagesPET 527 ViscosityToluNo ratings yet

- Design and Analysis of Rockets Engine InjectorsDocument4 pagesDesign and Analysis of Rockets Engine InjectorsMarianela AriasNo ratings yet

- 1953 - A Comparative Study On The Rate of Mixing in Stirred TanksDocument8 pages1953 - A Comparative Study On The Rate of Mixing in Stirred Tankszainul fikriNo ratings yet

- Fields 1252 WoodheadDocument14 pagesFields 1252 Woodheadlatifa boussaliaNo ratings yet

- Kinetics of The Dehydrogenation of Ethanol ToDocument6 pagesKinetics of The Dehydrogenation of Ethanol ToReyes Lopez EstebanNo ratings yet

- Power Consumption in Shaking Flasks I Buchs 2000Document5 pagesPower Consumption in Shaking Flasks I Buchs 2000Diego Chicaíza FinleyNo ratings yet

- Safe Design and Operation of Fluidized-Bed Reactors: Choice Between Reactor ModelsDocument22 pagesSafe Design and Operation of Fluidized-Bed Reactors: Choice Between Reactor ModelsKarenRosioMoreiraCruzNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- Particles and Moisture Effect On Dielectric Strength of Transformer Oil PDFDocument6 pagesParticles and Moisture Effect On Dielectric Strength of Transformer Oil PDFalumnopitagorasNo ratings yet

- Fluids Lab Manual 1Document6 pagesFluids Lab Manual 1اسامة نعمة جبارNo ratings yet

- Conventional MeasurementDocument10 pagesConventional MeasurementAna MoraNo ratings yet

- RheometerDocument7 pagesRheometerAl Alawi PanggabeanNo ratings yet

- Mini DSTDocument0 pagesMini DSTNagaraju JallaNo ratings yet

- SPE 149858 Modeling Inflow Performance Relation - Qasem Et Al.Document12 pagesSPE 149858 Modeling Inflow Performance Relation - Qasem Et Al.Isaac MuñozNo ratings yet

- V64 N02 1978 - Viscosity IIDocument24 pagesV64 N02 1978 - Viscosity IIopurataNo ratings yet

- Astm E96 1995Document10 pagesAstm E96 1995Kasra GolbanNo ratings yet

- Paper (Vol. 40, No. 5, October, 2022, Pp. 1258-1264)Document7 pagesPaper (Vol. 40, No. 5, October, 2022, Pp. 1258-1264)Banipal yaqobNo ratings yet

- Crepe Papers & Crepe-Paper Cables (Camilli, G. 1954)Document6 pagesCrepe Papers & Crepe-Paper Cables (Camilli, G. 1954)Platon ApergisNo ratings yet

- Microstructure and Properties of AC HVAF Sprayed Ni60WC Composite Coating 2009 Journal of Alloys and CompoundsDocument5 pagesMicrostructure and Properties of AC HVAF Sprayed Ni60WC Composite Coating 2009 Journal of Alloys and CompoundsastronotusNo ratings yet

- OTC-26450-MS Application of Artificial Intelligence For Water Coning Problem in Hydraulically Fractured Tight Oil ReservoirsDocument22 pagesOTC-26450-MS Application of Artificial Intelligence For Water Coning Problem in Hydraulically Fractured Tight Oil ReservoirsAbbas AlkhudafiNo ratings yet

- 2018 An Oscillating Cup Viscometer Based On Shvidkovskiy Algorithm For Molten MetalsDocument6 pages2018 An Oscillating Cup Viscometer Based On Shvidkovskiy Algorithm For Molten MetalsLai JacobNo ratings yet

- The Physical Properties of Pressure Sensitive Rubber CompositesDocument7 pagesThe Physical Properties of Pressure Sensitive Rubber CompositesRonald Lucas Silva Lefundes OliveiraNo ratings yet

- Assessment of Asphalt Binder Viscosities With A New ApproachDocument9 pagesAssessment of Asphalt Binder Viscosities With A New ApproachAhmed MostafaNo ratings yet

- The Wet Sp&ning of Secondary Cellulose Acetate: Solution Rheology and Filament SpinnabilityDocument11 pagesThe Wet Sp&ning of Secondary Cellulose Acetate: Solution Rheology and Filament Spinnabilityapi-3733260No ratings yet

- Droplet Entrainment From A Shear-Driven Liquid Wall Film in Inclined Ducts: Experimental Study and Correlation ComparisonDocument7 pagesDroplet Entrainment From A Shear-Driven Liquid Wall Film in Inclined Ducts: Experimental Study and Correlation ComparisonD DNo ratings yet

- Abigail Exp2Document15 pagesAbigail Exp2ToluNo ratings yet

- 2006 AIChEJ ARK Flow RegimesDocument19 pages2006 AIChEJ ARK Flow RegimesGopal KasatNo ratings yet

- Glass Blend ShoutingDocument7 pagesGlass Blend Shoutingkaveh-bahiraeeNo ratings yet

- Densida y ViscosidadDocument6 pagesDensida y ViscosidadGuillermo OrozcoNo ratings yet

- PT08-Comparatorts and Reference Panels PDFDocument29 pagesPT08-Comparatorts and Reference Panels PDFravindra_jivaniNo ratings yet

- A1 Experiment No 03Document6 pagesA1 Experiment No 03Azmain IktedarNo ratings yet

- About: Chromatography For Process ControlDocument2 pagesAbout: Chromatography For Process ControlMira Lucis CaelumNo ratings yet

- MATC122Document22 pagesMATC122Mohsen GolmohammadiNo ratings yet

- AIAA-2000-0858 PaperDocument12 pagesAIAA-2000-0858 PaperksvvijNo ratings yet

- Lab Manual - PRPCDocument45 pagesLab Manual - PRPCKaushal BaldhaNo ratings yet

- Ijmqe 180001Document8 pagesIjmqe 180001Tan TranNo ratings yet

- Pergamon 0892-6875 (00) 00003-0: Minerals EngineeringDocument10 pagesPergamon 0892-6875 (00) 00003-0: Minerals EngineeringRafaelNo ratings yet

- Concrete Rainfall StudyDocument8 pagesConcrete Rainfall Studyiker88No ratings yet

- The Influence of Viscosity On Centrifugal Pump Performance - 199 - 1Document16 pagesThe Influence of Viscosity On Centrifugal Pump Performance - 199 - 1poyopoankNo ratings yet

- Numerical Modelling of Hydrodynamics and Gas Dispersion in An Autoclave - Appa Et Al 2013-1Document9 pagesNumerical Modelling of Hydrodynamics and Gas Dispersion in An Autoclave - Appa Et Al 2013-1ninaNo ratings yet

- Propiedades Viscolesticas Brea Matriz AglutinanteDocument6 pagesPropiedades Viscolesticas Brea Matriz Aglutinantejuliomotta247682No ratings yet

- Is 4031 Part 6 - Compressive StrengthDocument6 pagesIs 4031 Part 6 - Compressive Strengthbhustlero0o75% (4)

- Smoke PointDocument16 pagesSmoke PointSuhaib IqbalNo ratings yet

- On The Viscosity of Energol 320Document12 pagesOn The Viscosity of Energol 320Charlie HanniganNo ratings yet

- Lozano, A., Influence of Liquid Properties On Ultrasonic AtomizationDocument8 pagesLozano, A., Influence of Liquid Properties On Ultrasonic AtomizationphutonsNo ratings yet

- CFD Analysis of Turbulence Non-Homogeneity in Mixing Vessels, A Two-Compartment ModelDocument18 pagesCFD Analysis of Turbulence Non-Homogeneity in Mixing Vessels, A Two-Compartment ModelRodrigo MirandaNo ratings yet

- Advanced Process Design in High Volume Kneader Reactors Using Multiple Feed Ports To Avoid Crust Forming Foaming and Low Heat TransferDocument10 pagesAdvanced Process Design in High Volume Kneader Reactors Using Multiple Feed Ports To Avoid Crust Forming Foaming and Low Heat TransferRaja WajahatNo ratings yet

- Tranformer Oil Sampling MethodsDocument68 pagesTranformer Oil Sampling MethodsMohammed NouzalNo ratings yet

- ASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Document8 pagesASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Sudip MukhopadhyayNo ratings yet

- Laboratory AssignmentsDocument44 pagesLaboratory AssignmentsPewdiepaw RockNo ratings yet

- Garcia-Villalba Froehlich Rodi JEGT 07Document10 pagesGarcia-Villalba Froehlich Rodi JEGT 07Gabriel FeresNo ratings yet

- Experiment 2Document13 pagesExperiment 2ToluNo ratings yet

- Iso 649 1 1981Document9 pagesIso 649 1 1981Armando DomínguezNo ratings yet

- Ebook Electric Circuits 10Th Edition Nilsson Solutions Manual Full Chapter PDFDocument68 pagesEbook Electric Circuits 10Th Edition Nilsson Solutions Manual Full Chapter PDFalexandercampbelldkcnzafgtw100% (10)

- AdvThermo PS01 2013 SolnDocument14 pagesAdvThermo PS01 2013 SolnPraveen P JoseNo ratings yet

- Determine Specific Air Capacity Using Air Conditioning UnitDocument13 pagesDetermine Specific Air Capacity Using Air Conditioning UnitTan Xing YanNo ratings yet

- Linear Slot DiffuserDocument15 pagesLinear Slot DiffuserhyderabadNo ratings yet

- 3865 PDFDocument7 pages3865 PDFANANDNo ratings yet

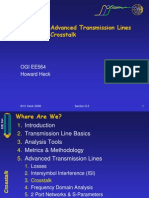

- Module 5: Advanced Transmission Lines Topic 3: Crosstalk: OGI EE564 Howard HeckDocument35 pagesModule 5: Advanced Transmission Lines Topic 3: Crosstalk: OGI EE564 Howard HeckVivek ShrivastavaNo ratings yet

- TASK 01:: Name: Syed Tanzeel Ur Rehman ROLL NO: 2020-BSCS-037 Sec: ADocument8 pagesTASK 01:: Name: Syed Tanzeel Ur Rehman ROLL NO: 2020-BSCS-037 Sec: ASahil JagdeshNo ratings yet

- Heatpro: Heat Pump Replacement PartsDocument6 pagesHeatpro: Heat Pump Replacement PartsDavid TerronNo ratings yet

- Manual Eb30Document80 pagesManual Eb30Ignacio Quispe MaytaNo ratings yet

- Manual Mass Combi UltraDocument32 pagesManual Mass Combi UltraAlvaro beltran reinosoNo ratings yet

- Electroneumatica BasicaDocument270 pagesElectroneumatica BasicaReinaldo CorderoNo ratings yet

- Relative Motion in One Dimension 1D and 2DDocument16 pagesRelative Motion in One Dimension 1D and 2DChristine RomanillosNo ratings yet

- Pelton Turbine: Experiment - 5Document8 pagesPelton Turbine: Experiment - 5gebremariam birkieNo ratings yet

- Past Papers IGCSE 2022 32Document8 pagesPast Papers IGCSE 2022 32David ThydetNo ratings yet

- FM Transmitter LR1Document46 pagesFM Transmitter LR1edna sisayNo ratings yet

- Assignment 1 - Fluid StaticsDocument3 pagesAssignment 1 - Fluid StaticsaarijNo ratings yet

- Power System Analysis Lecture NotesDocument134 pagesPower System Analysis Lecture NotesHyma GelliNo ratings yet

- Magnetic Effects of Electric CurrentDocument14 pagesMagnetic Effects of Electric CurrentREHANNo ratings yet

- Isa-Plan // Precision Resistors: SMV-PW // Size 4723Document3 pagesIsa-Plan // Precision Resistors: SMV-PW // Size 4723AliNo ratings yet

- Lab Report 5Document9 pagesLab Report 5Kazi Ershadul IslamNo ratings yet

- Prepaid Energy Meter Block DiagramDocument5 pagesPrepaid Energy Meter Block DiagramchawlamiteshNo ratings yet

- Kinematic Viscosity (Astm D-445) : Lube Expert Prepared By: Approved By: Page-1of1Document1 pageKinematic Viscosity (Astm D-445) : Lube Expert Prepared By: Approved By: Page-1of1ShunmuganathanNo ratings yet

- 2016 FINAL - SRAC - R410A - 60Hz - CO-HP - 19012016 - V8, FINALDocument55 pages2016 FINAL - SRAC - R410A - 60Hz - CO-HP - 19012016 - V8, FINALShaikhMazharAhmed100% (1)

- BUILDING UTILITIES 2 Building HVAC SystemsDocument142 pagesBUILDING UTILITIES 2 Building HVAC Systemsjona serranoNo ratings yet

- Data Sheet For SINAMICS Power Module PM240-2: Article No.: 6SL3210-1PE21-1UL0Document2 pagesData Sheet For SINAMICS Power Module PM240-2: Article No.: 6SL3210-1PE21-1UL0DejanNo ratings yet

- Stamford As440 Voltage RegulatorDocument4 pagesStamford As440 Voltage Regulatorabuzer1981100% (1)

- CH 5Document46 pagesCH 5Chala1989No ratings yet

- Quiz1 Key PDFDocument2 pagesQuiz1 Key PDFJosef CatiggayNo ratings yet

- Gree Electric Air ConditionersDocument6 pagesGree Electric Air ConditionersElvio MNo ratings yet