Professional Documents

Culture Documents

Fuel Level Monitoring in Internal Combustion Engines: Synopsis

Fuel Level Monitoring in Internal Combustion Engines: Synopsis

Uploaded by

GOWRRAJU ANILOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Level Monitoring in Internal Combustion Engines: Synopsis

Fuel Level Monitoring in Internal Combustion Engines: Synopsis

Uploaded by

GOWRRAJU ANILCopyright:

Available Formats

FUEL LEVEL MONITORING IN INTERNAL COMBUSTION ENGINES

SYNOPSIS

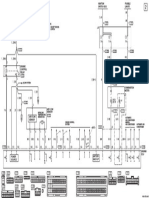

Now a day, Machines are widely controlled by automation. To meet the need of

exploding population economic and effective control of machines is necessary. The

main theme of our project is used to “Monitoring the Fuel Level in IC Engine Tank in

Industrial”. By using the pump operation the fuel is filled.

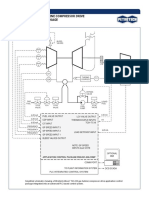

According to the data given to the microcontroller, An AC/DC motor is used for

pumping the fuel when fuel level becomes low in tank, when fuel attain maximum

level automatically pump will switch off. Many double contact relays are used to drive

the DC motors such that the output of the microcontroller is given to the relays. The

main advantage of our project is to monitor the fuel level monitoring as well as filling

system, and avoid fuel wastage

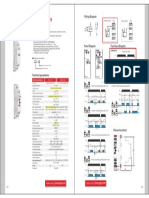

Fuel Level Monitoring In IC Engines

LEVEL -1 CONTROLLER

KIT

LEVEL -2

LEVEL -1

TANK LEVEL -3

POWER TO

PUMP

OUT LET TO

TANK

INLET OF

TANK PUMP

Advantages:

1) Accurate level of the fuel is measured.

2) Fuel level is indicated for every specified level.

3) Unskilled labour also finds fuel level in the engine.

Disadvantages:

1) It should be used in stationary engines only & not applicable in

moving engines.

You might also like

- FAULT CODE 2215 (ISB/QSB Automotive, Industrial, or Marine Application) - Fuel Pump Delivery Pressure - Data Valid But Below Normal Operating Range - Moderately Severe LevelDocument19 pagesFAULT CODE 2215 (ISB/QSB Automotive, Industrial, or Marine Application) - Fuel Pump Delivery Pressure - Data Valid But Below Normal Operating Range - Moderately Severe Levelcrash2804No ratings yet

- AIRCRAFT FUEL SYSTEM-Indication and Warning SystemsDocument67 pagesAIRCRAFT FUEL SYSTEM-Indication and Warning SystemsAidlin Safea100% (1)

- Bomba de Alta Presion Denso HP2 PDFDocument4 pagesBomba de Alta Presion Denso HP2 PDFDiegoD'AmbrosioNo ratings yet

- b737cl FuelDocument10 pagesb737cl FuelAnonymous lXk7jPMNo ratings yet

- Bold Face Gulfstream GiiDocument12 pagesBold Face Gulfstream GiixxgsmqdqrbNo ratings yet

- McDonnell Douglas DC 10 40 Fuel SystemDocument9 pagesMcDonnell Douglas DC 10 40 Fuel SystemAlly GuiaoNo ratings yet

- Hybrid Vehicle ControlDocument600 pagesHybrid Vehicle ControlMirceaNo ratings yet

- EMBRAER 135/145: For Training Purposes OnlyDocument31 pagesEMBRAER 135/145: For Training Purposes OnlyIludiran KolaNo ratings yet

- Doosan Retrofit ServiceDocument99 pagesDoosan Retrofit Servicestopless_dalian685No ratings yet

- 737-800-Yakit SysDocument16 pages737-800-Yakit Sysakkayags18100% (1)

- ERJ190POWERPLANTSYSTEMDocument27 pagesERJ190POWERPLANTSYSTEMArnaldo DiasNo ratings yet

- Alpha LubricatorDocument22 pagesAlpha LubricatorarvanitakiscNo ratings yet

- HHT Parameter (Finished) 0227Document10 pagesHHT Parameter (Finished) 0227Rachmad Maulana Ramadhan83% (6)

- Electrical System: Customer Support DepartmentDocument49 pagesElectrical System: Customer Support DepartmentVanHieu LuyenNo ratings yet

- C5-DTC P0463 Fuel Level Sensor Circuit High VoltageDocument7 pagesC5-DTC P0463 Fuel Level Sensor Circuit High Voltage100a100aNo ratings yet

- Digital Fuel Indicator Cum Study of Effeciency Increaser-Exhaust Gas InputDocument4 pagesDigital Fuel Indicator Cum Study of Effeciency Increaser-Exhaust Gas InputJyotishk MalviyaNo ratings yet

- Digital Fuel Level Indicator: SynopsisDocument3 pagesDigital Fuel Level Indicator: SynopsisSahil GaudeNo ratings yet

- DCP011 Automatic Fuel Reserve Indication SystemDocument3 pagesDCP011 Automatic Fuel Reserve Indication SystemANAND KRISHNANNo ratings yet

- Bomba de Alta Presion Denso HP2 PDFDocument4 pagesBomba de Alta Presion Denso HP2 PDFDiegoD'AmbrosioNo ratings yet

- AUTOMATION OF SERIES TANK LEVEL CONTROL USING PLC AND HMI Ijariie10774Document6 pagesAUTOMATION OF SERIES TANK LEVEL CONTROL USING PLC AND HMI Ijariie10774Mengistu BirukeNo ratings yet

- ML11223A379Document21 pagesML11223A379Muhammad ImranNo ratings yet

- Level Control Relay: Wiring DiagramDocument1 pageLevel Control Relay: Wiring DiagramRamius HamdaniNo ratings yet

- Section3 Mecatro sytemS6OA00801ZE03Document54 pagesSection3 Mecatro sytemS6OA00801ZE03Ichalcorey Rock OnNo ratings yet

- CRJ 200 Ata70Document12 pagesCRJ 200 Ata70romixrayzenNo ratings yet

- Allison 501 KB CompressorDocument3 pagesAllison 501 KB CompressortaghiNo ratings yet

- Rolls Royce Avon MKDocument3 pagesRolls Royce Avon MKfrdnNo ratings yet

- Figure 1: in Shop FloorDocument2 pagesFigure 1: in Shop Floorlingesh1892No ratings yet

- Panel For Control and Protection of Irrigation Motor PumpsetDocument8 pagesPanel For Control and Protection of Irrigation Motor PumpsetmorusNo ratings yet

- Section 5 Mechatronics SystemDocument4 pagesSection 5 Mechatronics Systemdeniden2013No ratings yet

- PerformanceDocument116 pagesPerformancetumbNo ratings yet

- Hawker 00XPC-Master Warning SystemDocument14 pagesHawker 00XPC-Master Warning SystemJose LaraNo ratings yet

- CW Pump House Log BookDocument10 pagesCW Pump House Log BookmkoelrealNo ratings yet

- TYPE - CIM-137/4G ( - CIM-137/4GW (: Control Units For Irrigation Motor Pumps and Pump Water Pressure ControlDocument20 pagesTYPE - CIM-137/4G ( - CIM-137/4GW (: Control Units For Irrigation Motor Pumps and Pump Water Pressure ControlТони ИлиевNo ratings yet

- QRH2 ch85-1Document12 pagesQRH2 ch85-1nashNo ratings yet

- OIL Pump Controllers: Simplex - DuplexDocument2 pagesOIL Pump Controllers: Simplex - DuplexAhmedNo ratings yet

- Wa0010.Document1 pageWa0010.Rafael rezende dos santosNo ratings yet

- Fuel Transfer Pump System: 8.1. Circuit FunctionsDocument5 pagesFuel Transfer Pump System: 8.1. Circuit FunctionsAram MorenoNo ratings yet

- System Description Section 20: 737 Flight Crew Operations ManualDocument5 pagesSystem Description Section 20: 737 Flight Crew Operations ManualWilliam XavierNo ratings yet

- Level ControlDocument36 pagesLevel ControlWogayehuGizawNo ratings yet

- Engine Control System Engine Control System Multiport Fuel Injection (MFI) SystemDocument34 pagesEngine Control System Engine Control System Multiport Fuel Injection (MFI) SystemAlex RonNo ratings yet

- 5-1. Mechatronics System PDFDocument75 pages5-1. Mechatronics System PDFAleixandre Gomez VasquezNo ratings yet

- B737CL HydraulicsDocument14 pagesB737CL HydraulicsMonica Nishizaki HernándezNo ratings yet

- SM 93Document159 pagesSM 93jhon greigNo ratings yet

- Atmel 9189 Drivers ATA6843 ATA6844 DatasheetDocument27 pagesAtmel 9189 Drivers ATA6843 ATA6844 Datasheet134 Manav SinghNo ratings yet

- 01-Inlet Pump StationDocument24 pages01-Inlet Pump Stationmohaamed aliNo ratings yet

- Optional Lincoln Lubricator: GeneralDocument3 pagesOptional Lincoln Lubricator: Generalferdy ramosNo ratings yet

- Cielo Euro IIIDocument603 pagesCielo Euro IIIb btb100% (1)

- Adv Feeder Vision Relay ChartDocument2 pagesAdv Feeder Vision Relay ChartshiyasNo ratings yet

- Fusible Link Ignition Switch (Ig1) Fusible Link: Note Except Euro5B EURO5bDocument1 pageFusible Link Ignition Switch (Ig1) Fusible Link: Note Except Euro5B EURO5bElisio MarquesNo ratings yet

- Perkins Electronically Controlled Engine: Preliminary Updated July 2002 - Jeff PulferDocument9 pagesPerkins Electronically Controlled Engine: Preliminary Updated July 2002 - Jeff PulferFarid RezigNo ratings yet

- FD120 Display MD05805151K MN DSPL FD120Document1 pageFD120 Display MD05805151K MN DSPL FD120Yilber TarazonaNo ratings yet

- Group 14 Engine Control System: 1. Cpu Controller MountingDocument4 pagesGroup 14 Engine Control System: 1. Cpu Controller Mountinghamdi galipNo ratings yet

- 5-1. Mechatronics SystemDocument73 pages5-1. Mechatronics SystemJuan David Ospina RincónNo ratings yet

- Periodical Service Form Unit Model: Komatsu HM 400Document3 pagesPeriodical Service Form Unit Model: Komatsu HM 400lilikNo ratings yet

- Monitor r55 - 9Document36 pagesMonitor r55 - 9MaiChiVuNo ratings yet

- Hvac 1Document1 pageHvac 1nam nguyenNo ratings yet

- Group 14 Monitoring System (Cluster Type 1)Document36 pagesGroup 14 Monitoring System (Cluster Type 1)Andrei 26No ratings yet