Professional Documents

Culture Documents

Steel Grade: General Information

Steel Grade: General Information

Uploaded by

fimozukOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Grade: General Information

Steel Grade: General Information

Uploaded by

fimozukCopyright:

Available Formats

Material data sheet 41Cr4 +HH, 5155

Steel grade Last revised: Wed, 06 Mar 2019 14:06:55 GMT

41Cr4 All

General Information

41Cr4 is a steel for quenching and tempering recommended for components with strength requirements lower than the steel 42CrMo4. It is suitable

for induction surface hardening, min hardness 52 HRC. It through hardens in oil up to appr. 40 mm diameter.

For additional Heat Treatment Data, please visit the Heat Treatment Guide

Similar designations

41CrS4, SS2245, 530M40, 530H40, EN18, SCR440, 42C4, 1.7035, 1.7039

Chemical composition

Variant Cast Di C% Si % Mn % P% S% Cr %

Min 0.38 - 0.60 - 0.020 0.90

5515 CC 4.4

Max 0.45 0.40 0.90 0.025 0.035 1.20

Mechanical Properties

Dimension Yield strength min Tensile strength Elongation A5 Reduction of area Zmin Impact (ISO-V)

Variant Condition Format Hardness

[mm] [MPa] [MPa] [%] [%] strengthmin

Round

+A 20 < 160 - - - - < 241 HB -

bar

Round

5515 20 < 40 660* 900-1100 12 35 - 20 °C 35 J (long)

bar

+QT

Round

40.1 < 100 560* 800-950 14 40 - 20 °C 35 J (long)

bar

Rp0.2 * Reh, ** Rel

Transformation temperatures

Temperature °C

MS 320

AC1 735

AC3 790

Heat treatment recommendations

Treatment Condition Temperature cycle Cooling/quenching

Soft annealing +A 670- 710oC In air

Austenizing 830 - 860oC

Quench & Tempering +QT Water or oil

Tempering 540 - 680oC

60

55

50

Hardness [HRC]

45

40

35

30

25

10 20 30 40 50

Distance [mm]

41Cr(S)4 + HH max 41Cr(S)4 + HH min

Other properties (typical values)

Youngs module (GPa) Poisson´s ratio (-) Shear module (GPa) Density (kg/m3)

210 0.3 80 7800

Average CTE 20-300°C Specific heat capacity 50/100°C Thermal conductivity Ambient Electrical resistivityAmbient temperature

(µm/m°K) (J/kg°K) temperature (W/m°K) (µΩm)

12 460 - 480 40 - 45 0.20 - 0.25

Contact us

Would you like to know more about our offers? Don´t hesitate to contact us:

Via e-mail: info@ovako.com

Via telephone: +46 8 622 1300

For more detailed information please visit http://www.ovako.com/en/Contact-Ovako/

Disclaimer

The information in this document is for illustrative purposes only. The data and examples are only general recommendations and not a warranty or a guarantee.

The suitability of a product for a specific application can be confirmed only by Ovako once given the actual conditions.The purchaser of an Ovako product has

the responsibility to ascertain and control the applicability of the products before using them. Continuous development may necessitate changes in technical

data without notice. This document is only valid for Ovako material. Other material, covering the same international specifications, does not necessarily comply

with the properties presented in this document.

You might also like

- Project StartupDocument45 pagesProject StartupbvitalNo ratings yet

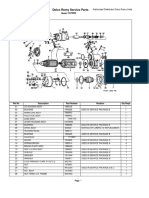

- Delco RemyDocument3 pagesDelco Remyboobalan_shriNo ratings yet

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan92% (12)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- 283057842 JIS G4053 2003 Low Alloyed Steels for Machine Structural Use 英文版 PDFDocument21 pages283057842 JIS G4053 2003 Low Alloyed Steels for Machine Structural Use 英文版 PDFDewi Lanjarsari Purnama Sastri100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Halliburton Packer ShoesDocument22 pagesHalliburton Packer ShoesTong Chaipanyakul100% (1)

- 42 CR Mo 4Document4 pages42 CR Mo 4Alin ChehadeNo ratings yet

- Fire ResistanceDocument5 pagesFire Resistancermaffireschool100% (1)

- MBN 10317 1 2006 07 PDFDocument17 pagesMBN 10317 1 2006 07 PDFDewi Lanjarsari Purnama SastriNo ratings yet

- MBN 31030 2015 03 PDFDocument6 pagesMBN 31030 2015 03 PDFDewi Lanjarsari Purnama SastriNo ratings yet

- Cost Savings Through Intelligent Robotization For The 21 CenturyDocument8 pagesCost Savings Through Intelligent Robotization For The 21 CenturySanta Kim100% (1)

- Career Engineering UnisaDocument41 pagesCareer Engineering Unisaabubakr fingerNo ratings yet

- Functional Safety Data SheetDocument18 pagesFunctional Safety Data SheetFederico FranchinoNo ratings yet

- 41 CR 4Document3 pages41 CR 4AHMED FATHINo ratings yet

- 41 CR 4Document5 pages41 CR 4Bouraoui AlaeddineNo ratings yet

- 30crnimo8: Steel GradeDocument2 pages30crnimo8: Steel GradewemersonsrNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General Informationabu asiyahNo ratings yet

- 16 MN CR 5Document2 pages16 MN CR 5bd54No ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- 42crmo4: Steel GradeDocument3 pages42crmo4: Steel GradeMada TetoNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetNaveen HlNo ratings yet

- 20160323011855-41Cr4 - 41CrS4 PDFDocument1 page20160323011855-41Cr4 - 41CrS4 PDFMarius ZenoagaNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetjon perez diezNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4Matthew HaleNo ratings yet

- 34 CR Mo 4Document1 page34 CR Mo 4^passwordNo ratings yet

- S355JRDocument3 pagesS355JRYasmeen HaiderNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- 56 Si 7Document2 pages56 Si 7Bhuvanesh ShanmugamNo ratings yet

- 2083X40Cr14Document1 page2083X40Cr14D K NaskarNo ratings yet

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- C55Document3 pagesC55kishpchakraNo ratings yet

- 20 MN VS6Document2 pages20 MN VS6billNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetZakaria ChaoufiNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetHDNo ratings yet

- 61 Si CR 7Document2 pages61 Si CR 7RaduIonNo ratings yet

- 40crmov4-6: Steel GradeDocument3 pages40crmov4-6: Steel GradeMahsaNo ratings yet

- 48CrMoNi4 10Document4 pages48CrMoNi4 10FernandoiNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- 38 MN VS6Document3 pages38 MN VS6Jaison JacobNo ratings yet

- 630 (17-4) Precipitation Hardening Stainless Steel BarDocument4 pages630 (17-4) Precipitation Hardening Stainless Steel Barehudingram6535No ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- Quality 40nicrmov16 Ku: Lucefin GroupDocument1 pageQuality 40nicrmov16 Ku: Lucefin Groupkbwoniu123No ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetShaswat HECNo ratings yet

- S355JRDocument3 pagesS355JRaabco.purchaseNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4InaamNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- 20160323010627-C45E (Ck45) - C45R (Cm45) PDFDocument2 pages20160323010627-C45E (Ck45) - C45R (Cm45) PDFNikolat84No ratings yet

- 52crmov4: Steel GradeDocument2 pages52crmov4: Steel GradeHEMANTNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeemregnesNo ratings yet

- 21crmov5-7: Steel GradeDocument1 page21crmov5-7: Steel GradeEdward PongracNo ratings yet

- 42crmo4: Steel GradeDocument3 pages42crmo4: Steel GradeCarlos LopezNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetMahammad ShehattaNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Daphne Magplus AM 30: Lubricant Product InformationDocument2 pagesDaphne Magplus AM 30: Lubricant Product InformationDewi Lanjarsari Purnama SastriNo ratings yet

- Metric Washers - Form ADocument2 pagesMetric Washers - Form ADewi Lanjarsari Purnama SastriNo ratings yet

- American Honda's Vehicle Data Privacy Practices: Fundamentals of The Privacy PrinciplesDocument27 pagesAmerican Honda's Vehicle Data Privacy Practices: Fundamentals of The Privacy PrinciplesDewi Lanjarsari Purnama SastriNo ratings yet

- Metric Washers - Form ADocument2 pagesMetric Washers - Form ADewi Lanjarsari Purnama SastriNo ratings yet

- Honda Extended Guarantee Brief Details of Plan: EligibilityDocument7 pagesHonda Extended Guarantee Brief Details of Plan: EligibilityDewi Lanjarsari Purnama SastriNo ratings yet

- Inspection StikerDocument1 pageInspection StikerDewi Lanjarsari Purnama SastriNo ratings yet

- Inspection Report APM Armada Suspension: Dimensio Nal ApparanceDocument1 pageInspection Report APM Armada Suspension: Dimensio Nal ApparanceDewi Lanjarsari Purnama SastriNo ratings yet

- United States Patent (10) Patent No.: US 8.458,168 B2Document20 pagesUnited States Patent (10) Patent No.: US 8.458,168 B2sonurehalNo ratings yet

- Pump GreaseDocument46 pagesPump GreaseFco JavierNo ratings yet

- Case Study ESSS - Milestone 04 Data ModelingDocument10 pagesCase Study ESSS - Milestone 04 Data ModelingsNo ratings yet

- Angularity NumberDocument5 pagesAngularity NumberSolankiNo ratings yet

- Vxworks Vs RTLinuxDocument5 pagesVxworks Vs RTLinuxNithin RamakrishnaNo ratings yet

- Water Towers Using GTSTRUDLDocument1 pageWater Towers Using GTSTRUDLKelly WhiteNo ratings yet

- Fig. Coi00-01a1 Cooling System (Radiator) (#C62001-)Document3 pagesFig. Coi00-01a1 Cooling System (Radiator) (#C62001-)ChimanNo ratings yet

- Behem X SlayrDocument28 pagesBehem X SlayrtarunNo ratings yet

- Ijsrp p3178 PDFDocument11 pagesIjsrp p3178 PDFJeannot MpianaNo ratings yet

- Quadcopter PDFDocument6 pagesQuadcopter PDFOla Fonda100% (1)

- Power i-MIG 200 Quick Adjustment Guide : Steel Steel SteelDocument1 pagePower i-MIG 200 Quick Adjustment Guide : Steel Steel SteelThương LêNo ratings yet

- SSI Letter of Support 2-22-2016Document2 pagesSSI Letter of Support 2-22-2016tbncmichaelNo ratings yet

- Trabajo 212066 21 TC1Document20 pagesTrabajo 212066 21 TC1yeye cardonaNo ratings yet

- 5G Radio Access TechnologyDocument50 pages5G Radio Access TechnologyshibinpsNo ratings yet

- B302 BteqDocument30 pagesB302 BteqranusofiNo ratings yet

- 01 - Bavaria CO2 FiresearchDocument3 pages01 - Bavaria CO2 FiresearchDaryl Gomez Timatim100% (1)

- Charli D'amelio - Google SearchDocument1 pageCharli D'amelio - Google SearchRosalinda LappayNo ratings yet

- 85GDocument4 pages85GBeny StephenNo ratings yet

- ReleaseNotes VISSIM 11.00-12 ENGDocument20 pagesReleaseNotes VISSIM 11.00-12 ENGgongleeNo ratings yet

- Supreme Student Government: Data SheetDocument2 pagesSupreme Student Government: Data SheetJhonric M. LugtuNo ratings yet

- Ecsecuritybased-Safety Auto Brake System For Hill Station Vehicle Using Mems Sensor.Document3 pagesEcsecuritybased-Safety Auto Brake System For Hill Station Vehicle Using Mems Sensor.kanchan bone100% (1)

- DSMB10 VL PDFDocument2 pagesDSMB10 VL PDFJason GuerreroNo ratings yet