Professional Documents

Culture Documents

Machine Safeguarding: Using The Quarter-Inch Rule: Safety and Health Resource Manual

Uploaded by

Ahmed ReguiegOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Safeguarding: Using The Quarter-Inch Rule: Safety and Health Resource Manual

Uploaded by

Ahmed ReguiegCopyright:

Available Formats

Michigan Municipal Workers’ Compensation Fund

Safety and Health Resource Manual

Machine Safeguarding: Using the Quarter-Inch

Rule

Protecting Employees from Point Of Operation & Mechanical Hazards

Where Hazards Occur

Any machine part, function, or process that might injure the operator or other workers must

have a safeguard. When the operation of a machine or accidental contact with it can injure

the operator or others in the vicinity, you must either control or eliminate the hazards.

There are three areas where mechanical hazards occur:

Point of Operation: The area on a machine where the employee performs work on the

material, such as cutting, boring, or forming of stock.

Power Transmission Apparatus: All mechanical systems that transmit energy to the

part of the machine performing the work. These components include flywheels, pulleys,

belts, connecting rods, couplings, cams, spindles, chains, and gears.

Other Moving Parts: All parts of the machine that move while the machine is working.

These can include reciprocating, rotating, and transverse moving parts, as well as feed

mechanisms and auxiliary parts of the machine.

Machinery hazards are as varied and complex as the types of equipment that you can find in

your operations. However, there is one rule you can apply to determine if the hazard has

adequate guarding. Mechanical hazards must have guarding unless you can reduce the

opening or access to the hazard to one-quarter inch or less.

The Quarter-Inch Rule

Under Part 24 Mechanical Power Presses, Part 23 Hydraulic Power Presses Part 26,

Metalworking Machinery, and Part 27, Woodworking Machinery one quarter inch or less is

the allowable opening that an MIOSHA inspector will accept when evaluating machinery

hazards. By definition, MIOSHA does not consider an opening of a quarter inch or less to be

a hazard.

Simply put, if the exposure to the operator at the point of operation is one-quarter inch or

less, you do not have to safeguard the exposure. Any opening greater than one-fourth inch

requires a safeguard.

According to MIOSHA Part 1, General Requirements R408.10034, Rule 34 (3)

“A point of operation guard or device shall be as prescribed in a specific standard, or in the

absence of a specific standard, shall be designed and constructed, when required, to prevent

the machine operator exposed to the hazard from having any part of his/her body in the

hazardous area during the operating cycle.”

If you need to know what measurements to use in the design of a guard for equipment, refer

to Table 1.

Machine Guarding: Using the Quarter-Inch Rule – 8-B-1

Michigan Municipal Workers’ Compensation Fund

Safety and Health Resource Manual

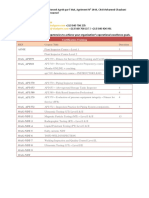

Table 1

Distance of opening from Maximum width of

point of operation hazard opening

(inches) (inches) Table 1 provides appropriate guidance that

applies to most machine safeguarding

1/2 to 1-1/2 1/4 exposures for the point of operation.

1-1/2 to 2-1/2 3/8 Whether the hazard is at the point of

2-1/2 to 3-1/2 1/2 operation or at a power transmission point,

you can usually use the one-fourth inch

3-1/2 to 5-1/2 5/8 rule as the standard to determine if the

5-1/2 to 6-1/2 3/4 hazard has proper guarding.

6-1/2 to 7-1/2 7/8

7-1/2 to 12-1/2 1-1/4

12-1/2 to 15-1/2 1-1/2

15-1/2 to 17-1/2 1-7/8

17-1/2 to 31-1/2 2-1/8

Requirements for Safeguards

Safeguards must meet the following general requirements:

The safeguard must prevent hands, arms, and any other part of a worker's body from

making contact with dangerous moving parts. A good safeguarding system eliminates

the possibility of the operator or another worker from placing parts of their bodies near

hazardous moving parts by reaching over, under, around or through the safeguarding

system.

Workers should not be able to easily remove or tamper with the safeguard. A safeguard

that a worker can easily make ineffective is no safeguard at all. Guards and safety

devices should be made of durable material that will withstand the conditions of normal

use. They must be firmly secured to the machine with a device that requires a “tool” to

remove.

The safeguard should assure that no objects can fall into moving parts. A small tool that

a worker drops or knocks into a cycling machine could easily become a projectile that

could strike and injure someone.

A safeguard defeats its own purpose if it creates a hazard of its own such as a shear

point, a jagged edge, or an unfinished surface that can cause a laceration. The edges of

guards, for instance, should have rolled edges or be bolted in such a way that they

eliminate sharp edges.

Any safeguard that impedes a worker from performing the job quickly and comfortably

might soon be overridden or disregarded. Proper safeguarding can actually enhance

efficiency since it can relieve the worker's apprehensions about injury.

Machine Guarding: Using the Quarter-Inch Rule – 8-B-2

Michigan Municipal Workers’ Compensation Fund

Safety and Health Resource Manual

Safeguarding should allow for minor equipment adjustments and lubrication when

possible. Locating adjustment controls, control devices and lubrication lines outside the

area requiring guarding will reduce the need for the operator or maintenance worker to

enter the hazardous area. It will also reduce the need to remove the guard. If workers

remove guards, they may not replace them.

Although Part 24, Mechanical Power Presses is the major source of information in this

document, other MIOSHA standards use similar applications of the principle when discussing

means of protecting workers from machinery hazards. MIOSHA requires that tongue guards

for abrasive wheels be one-quarter inch from the grinding wheel. A rigid guard for the in-

running nip of a printing press should be set one-quarter inch from the surface of the rotating

cylinder. The stroke for equipment cutting sheet metal or chopping light gauge scrap is

frequently set to a maximum opening of one-quarter inch.

Press break safeguarding applies a variation of the quarter inch rule by using the "two hand

down and step through" technique. The operator places his or her hands on the two hand

control buttons which bring the knife (sized for the operation) of the press brake down to

within one quarter inch of the work piece. The operator then steps on the foot control to

bring the knife into contact with the work piece, keeping the hands free to support other steps

of the operation.

Consider Engineering to Reduce Exposure

You can avoid the need to use safeguards by engineering the system to keep exposures

to an opening one-quarter inch or less. This can have several advantages:

You do not have to fabricate or purchase guards; you are not investing time or

money.

If guards are unnecessary, maintenance staff does not have to worry about replacing

guards following maintenance work.

You minimize potentially serious injury to operators from machinery hazards because

of substantial engineering control.

Summary

A citation from MIOSHA for failure to properly guard machinery or equipment can be

costly, depending on the number of pieces of equipment and the number of exposed

operators. Violations of the requirements for proper guarding, including the quarter inch

rule, always receive a rating of “serious” for the point of operation.

You should take time to inspect your machinery for compliance with MIOSHA’s guarding

requirements. In addition you should ask the following questions:

1. Do you use standardized guidance (Table 1) to determine if all hard guards have

been properly fabricated, set, or adjusted for the point of operation?

Machine Guarding: Using the Quarter-Inch Rule – 8-B-3

Michigan Municipal Workers’ Compensation Fund

Safety and Health Resource Manual

2. Do your written procedures for maintaining or servicing equipment include the

removal and replacement of safeguards? Remember that MIOSHA requires

lockout/tagout if safeguards are defeated or removed.

3. Do you train your operator before they start work with you and thereafter on a

scheduled basis in what constitutes good safeguarding practices? Does the training

familiarize them with their equipment safeguards, enable them to recognize if the

equipment is in good condition before operating, and teach appropriate procedures

and how to report deficiencies? Do you document all training?

4. Do you perform and document self-audits of your safeguard practices for both

operator and maintenance groups on a periodic basis? Quarterly self-audits are

typical.

Even if you cannot adjust your production methods to apply the one-quarter inch rule, a

supportable "yes" to each of the four questions indicates an operations management

system that will enhance loss control.

References

MIOSHA General Industry Standards

1. Part 1, General Rules, R408.10034

2. Part 7, Guards for Power Transmission

3. Part 23, Hydraulic Power Presses

4. Part 24, Mechanical Power Presses

5. Part 26, Metalworking Machinery

6. Part 27, Woodworking Machinery

Machine Guarding: Using the Quarter-Inch Rule – 8-B-4

You might also like

- Machine Safeguarding 101Document12 pagesMachine Safeguarding 101ashok nakumNo ratings yet

- Machinery and Machine GuardingDocument13 pagesMachinery and Machine GuardingRanganayaki Tirumale Srinivasa Rangachar0% (1)

- Tools Req MachineDocument7 pagesTools Req MachineAnonymous bbJlkgQNo ratings yet

- Safe Use of Power-Operated Cross-Cut Saws: HSE Information SheetDocument7 pagesSafe Use of Power-Operated Cross-Cut Saws: HSE Information SheetCamilo CubidesNo ratings yet

- Bosh Machine Safety 2Document9 pagesBosh Machine Safety 2Rovic VistaNo ratings yet

- Material HseDocument6 pagesMaterial HseOsmar JrNo ratings yet

- Are Your Press Brakes SafeDocument2 pagesAre Your Press Brakes Saferaj kumarNo ratings yet

- Tools Req MachineDocument7 pagesTools Req MachineTemp WorkNo ratings yet

- Reporting 70 75Document33 pagesReporting 70 75Patrick Joseph BugayNo ratings yet

- Industrial Safety Regulations for Machinery GuardingDocument4 pagesIndustrial Safety Regulations for Machinery GuardingMohamed AbdinNo ratings yet

- Machine and Equipment Guarding: Group 5Document29 pagesMachine and Equipment Guarding: Group 5Ronald James DiazNo ratings yet

- Safety in Chemical Process PlantsDocument5 pagesSafety in Chemical Process PlantsSrinivasan .MNo ratings yet

- OSHA machine guarding standards summaryDocument6 pagesOSHA machine guarding standards summaryMBAHNo ratings yet

- Machine Safeguarding Hazards and SolutionsDocument43 pagesMachine Safeguarding Hazards and Solutionsfaizijust4uNo ratings yet

- Safety ManualDocument25 pagesSafety ManualbeeNo ratings yet

- MCN 401 Ise Module 4-1Document122 pagesMCN 401 Ise Module 4-1Sheena ShajiNo ratings yet

- MCN 401 Ise Module 4-1Document97 pagesMCN 401 Ise Module 4-1taapseveniaavaniNo ratings yet

- Eis 28Document4 pagesEis 28Ab AUNo ratings yet

- Handbook On Guarding and Operation of MachineryDocument65 pagesHandbook On Guarding and Operation of MachineryNebosh IGCNo ratings yet

- Pis18-Safety Requirements For Using Hand-Fed Platen (Die-Cutting) MachinesDocument7 pagesPis18-Safety Requirements For Using Hand-Fed Platen (Die-Cutting) MachinesYassin SajidNo ratings yet

- WSH Guidelines On Safe Use of MachineryDocument72 pagesWSH Guidelines On Safe Use of MachinerySofias TrendyNo ratings yet

- Physical Hazards of MachineryDocument3 pagesPhysical Hazards of MachineryNamitaNo ratings yet

- Stretch Wrap Machine and Automation Safety GuidelinesDocument5 pagesStretch Wrap Machine and Automation Safety GuidelinesAndrei MarinNo ratings yet

- Selected Info CE DirectiveDocument4 pagesSelected Info CE Directivejohn paulNo ratings yet

- Machinery Guarding HandbookDocument65 pagesMachinery Guarding HandbookSubimal DasNo ratings yet

- Machine Guarding - Barry BlodgettDocument66 pagesMachine Guarding - Barry BlodgettmanimeczNo ratings yet

- Group 12 Machine SafetyDocument21 pagesGroup 12 Machine SafetydorojajobertNo ratings yet

- Electrical Connector Servicing & Cleaning Instructions For Large Mining Truck ApplicationsDocument22 pagesElectrical Connector Servicing & Cleaning Instructions For Large Mining Truck ApplicationsAdolfo MarínNo ratings yet

- Machine Guarding BasicsDocument30 pagesMachine Guarding BasicsAjay meena Ajay meenaNo ratings yet

- Machine Guarding Safety RequirementsDocument31 pagesMachine Guarding Safety Requirementsm_alodat6144No ratings yet

- Machine Guarding PrinciplesDocument5 pagesMachine Guarding Principlesliveconnectionz282No ratings yet

- Machinery Guarding For PUWER White Paper 2021 Ed3Document11 pagesMachinery Guarding For PUWER White Paper 2021 Ed3whtez0neNo ratings yet

- Machine Safety Guide for OSH OfficersDocument19 pagesMachine Safety Guide for OSH OfficersGing FreecsNo ratings yet

- Safety at Injection Moulding MachinesDocument4 pagesSafety at Injection Moulding Machinesasparagas2013No ratings yet

- Eis7-Safe Use of 3 Roll Bending MachinesDocument3 pagesEis7-Safe Use of 3 Roll Bending MachinesYassin SajidNo ratings yet

- Safety Instructions for Packaging MachineDocument12 pagesSafety Instructions for Packaging MachineKarina García VivancoNo ratings yet

- Rog-Hse-Pro-015, Procedure For Machine GuardingDocument3 pagesRog-Hse-Pro-015, Procedure For Machine GuardingvladNo ratings yet

- Machine Guarding Program Rev 2Document18 pagesMachine Guarding Program Rev 2gauti0102No ratings yet

- Machine Guarding Methods and Safety StandardsDocument8 pagesMachine Guarding Methods and Safety StandardsEvan Charl MoraledaNo ratings yet

- Machine Safety EssentialsDocument7 pagesMachine Safety EssentialsHurty James DayonNo ratings yet

- Mechanical Hazards and Machine SafeguardingDocument19 pagesMechanical Hazards and Machine Safeguardingm_alodat6144No ratings yet

- TB PpressDocument1 pageTB Ppresssoheil ghanbariNo ratings yet

- Safety at Compression Moulding MachinesDocument4 pagesSafety at Compression Moulding MachinesAlexander Alexander100% (1)

- Machine Guarding 2022 - R2Document14 pagesMachine Guarding 2022 - R2D PandeyNo ratings yet

- Mechanical Hazards and Common Mechanical InjuriesDocument4 pagesMechanical Hazards and Common Mechanical Injuriesabegail capistranoNo ratings yet

- Machine Guarding: 29 CFR 1910.211 To 1910.219Document45 pagesMachine Guarding: 29 CFR 1910.211 To 1910.219Kim Lien TrinhNo ratings yet

- Safety Precautions and Practices in Operation and MaintenanceDocument8 pagesSafety Precautions and Practices in Operation and MaintenanceQwe AsdfNo ratings yet

- SafetyMgt Handouts Topic9Document7 pagesSafetyMgt Handouts Topic9ALyzha Mae LacuestaNo ratings yet

- PAES 101. 2000 - Technical Means For Ensuring Safety - GeneralDocument17 pagesPAES 101. 2000 - Technical Means For Ensuring Safety - Generalshii anihsNo ratings yet

- METPOL-A Instruction ManualDocument45 pagesMETPOL-A Instruction ManualIvy LiNo ratings yet

- Lathe usage room 207 safety proceduresDocument13 pagesLathe usage room 207 safety proceduresPinto CarlosNo ratings yet

- GC2 Element4 AnswersDocument5 pagesGC2 Element4 AnswersekkyagungNo ratings yet

- Arquivo em InglesDocument92 pagesArquivo em InglesLeonardo Almeida RamosNo ratings yet

- Microsoft PowerPoint - Mechanical Hazards Jan07Document44 pagesMicrosoft PowerPoint - Mechanical Hazards Jan07Bhalvindrakumar MaranNo ratings yet

- Someks Manual GL1000 CompleteOperatorsManual enDocument135 pagesSomeks Manual GL1000 CompleteOperatorsManual endmitriy.astakhovNo ratings yet

- American Risk AssessmentDocument5 pagesAmerican Risk AssessmentKleber BonamimNo ratings yet

- Day 2 Machine SafetyDocument26 pagesDay 2 Machine Safetymike camsNo ratings yet

- Work Safety Alert Trapped by Moving Parts of A Concrete Batching Plant 1. Date of Accident: October 2015Document3 pagesWork Safety Alert Trapped by Moving Parts of A Concrete Batching Plant 1. Date of Accident: October 2015morisNo ratings yet

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- Welding SafetyDocument42 pagesWelding SafetycfcshakerNo ratings yet

- The 8th Habit FINALDocument13 pagesThe 8th Habit FINALdnyanesh00967% (3)

- APIs Trainings HMDDocument1 pageAPIs Trainings HMDAhmed ReguiegNo ratings yet

- APIs Trainings HMDDocument1 pageAPIs Trainings HMDAhmed ReguiegNo ratings yet

- Four Role Leadership Stephen CoveyDocument7 pagesFour Role Leadership Stephen CoveyAhmed ReguiegNo ratings yet

- Safety AlertDocument1 pageSafety AlertAhmed ReguiegNo ratings yet

- Overhead Crane Safety and Inspection RequirementsDocument69 pagesOverhead Crane Safety and Inspection RequirementsAhmed ReguiegNo ratings yet

- Iso 10816 3Document6 pagesIso 10816 3Ahmed ReguiegNo ratings yet

- Inglés C2 Corrector Septiembre 2021Document11 pagesInglés C2 Corrector Septiembre 2021CRISTINA MARTINEZ SANCHEZNo ratings yet

- Business Plan ForbesDocument4 pagesBusiness Plan ForbesMoiz AhmedNo ratings yet

- Ch3 Profiles, Password Policies, Privileges, and RolesDocument79 pagesCh3 Profiles, Password Policies, Privileges, and Rolesahlam alzhraniNo ratings yet

- Power Solutions GuideDocument60 pagesPower Solutions Guidetheodoiq100% (1)

- Violence ADocument236 pagesViolence AEndry AbidinNo ratings yet

- Boiler Commissioning Procedure1Document62 pagesBoiler Commissioning Procedure1Okeyman100% (1)

- Amphenol PV Cable AssembliesDocument1 pageAmphenol PV Cable AssembliesLeonardo CoelhoNo ratings yet

- Cortes Constitutional Foundations of Privacy in Emerging Trends in LawDocument3 pagesCortes Constitutional Foundations of Privacy in Emerging Trends in LawAce Reblora IINo ratings yet

- Impact of Organizational Culture On Employee Motivation WithDocument11 pagesImpact of Organizational Culture On Employee Motivation WithMohammad ElabedNo ratings yet

- Forms6i 10GDocument42 pagesForms6i 10GRolando OcañaNo ratings yet

- Project Report ON: "Brand Preference of Onida Colour TV in Coastal OrissaDocument66 pagesProject Report ON: "Brand Preference of Onida Colour TV in Coastal OrissaApurba KhanduriNo ratings yet

- Swiss Ephemeris Table of Houses for Southern HemisphereDocument121 pagesSwiss Ephemeris Table of Houses for Southern HemisphereAnonymous 5S91GvOgNo ratings yet

- SA-10/20 User ManualDocument31 pagesSA-10/20 User ManualJorgeLuis Anaya NúñezNo ratings yet

- 1 Introduction To Electrical DrivesDocument45 pages1 Introduction To Electrical DrivesSetya Ardhi67% (3)

- Guide Spec DX Air Outdoor Condensing Unit 2 2017Document5 pagesGuide Spec DX Air Outdoor Condensing Unit 2 2017JamesNo ratings yet

- Token Economics BookDocument81 pagesToken Economics BookNara E Aí100% (3)

- Copier CoDocument9 pagesCopier CoHun Yao ChongNo ratings yet

- This Study Resource Was: Advanced Accounting Ifrs 15Document6 pagesThis Study Resource Was: Advanced Accounting Ifrs 15YukiNo ratings yet

- 5442 - FVRDocument100 pages5442 - FVRKrishna Chaitanya DeepalaNo ratings yet

- Missing Dovetail RfiDocument1 pageMissing Dovetail RfiPurushotam TapariyaNo ratings yet

- 2019Document164 pages2019Nguyễn Sơn CaNo ratings yet

- Excel calendarDocument28 pagesExcel calendarThanh LêNo ratings yet

- 1978 Damage - To Rock Tunnels From Earthquake ShakingDocument18 pages1978 Damage - To Rock Tunnels From Earthquake Shakingofelix505100% (1)

- IPUMS CPS Exercise 2 For RDocument7 pagesIPUMS CPS Exercise 2 For RKateO838No ratings yet

- SCL 3711Document2 pagesSCL 3711MikeNo ratings yet

- Tekla - DocumentDocument2,005 pagesTekla - DocumentTranタオNo ratings yet

- Baranda v. GustiloDocument2 pagesBaranda v. GustiloRiena MaeNo ratings yet

- 802 11 Qos OverviewDocument38 pages802 11 Qos Overviewswapnil tiwariNo ratings yet

- DSP Lect 11 Iir DesignDocument50 pagesDSP Lect 11 Iir DesignSayyeda UmbereenNo ratings yet

- University of The Cordilleras Process CostingDocument5 pagesUniversity of The Cordilleras Process CostingJane PadillaNo ratings yet