Professional Documents

Culture Documents

Characterization of Water Treatment Sludges

Characterization of Water Treatment Sludges

Uploaded by

Geamby0 ratings0% found this document useful (0 votes)

15 views1 pageAlum sludges and other water treatment wastes are difficult to dewater through gravity thickening alone. They can be effectively dewatered using pressure filtration. The pressure filtration process involves conditioning the sludge with lime and fly ash, precoating the filters with diatomaceous earth or fly ash, continuously feeding conditioned sludge to the pressure filters to form a filter cake, and removing the consolidated cake for disposal once filtrate production stops. Alum sludges are specifically conditioned with 10-15% lime by weight or 100% fly ash by weight to aid in coagulation and dewatering.

Original Description:

.

Original Title

sludge

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAlum sludges and other water treatment wastes are difficult to dewater through gravity thickening alone. They can be effectively dewatered using pressure filtration. The pressure filtration process involves conditioning the sludge with lime and fly ash, precoating the filters with diatomaceous earth or fly ash, continuously feeding conditioned sludge to the pressure filters to form a filter cake, and removing the consolidated cake for disposal once filtrate production stops. Alum sludges are specifically conditioned with 10-15% lime by weight or 100% fly ash by weight to aid in coagulation and dewatering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageCharacterization of Water Treatment Sludges

Characterization of Water Treatment Sludges

Uploaded by

GeambyAlum sludges and other water treatment wastes are difficult to dewater through gravity thickening alone. They can be effectively dewatered using pressure filtration. The pressure filtration process involves conditioning the sludge with lime and fly ash, precoating the filters with diatomaceous earth or fly ash, continuously feeding conditioned sludge to the pressure filters to form a filter cake, and removing the consolidated cake for disposal once filtrate production stops. Alum sludges are specifically conditioned with 10-15% lime by weight or 100% fly ash by weight to aid in coagulation and dewatering.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Figure 1 Hypothetical relationship between the food - to - microorganism ratio and the

coefficient k in Equation 1.

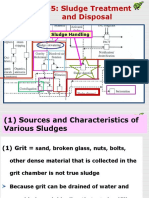

CHARACTERIZATION OF WATER TREATMENT SLUDGES

Water treatment plant wastes are suited to pressure filtration since they are often

difficult to dewater, particularly alum sludges and softening precipitates containing

magnesium hydroxide. Gravity-thickened alum wastes are conditioned by the addition

of lime slurry. A precoat of diatomaceous earth or fly ash is applied prior to each cycle,

and conditioned sludge is then fed continuously to the pressure filter until filtrate ceases

and the cake is consolidated under high pressure. A power pack holds the chambers as

the equalisation tank provides uniform pressure across the filter chambers as the cycle

begins. Prior to cake discharge, excess sludge in the inlet ports of the filter is removed

by air pressure to a core separation tank. Filtrate is measured through a weir tank and

recycled to the inlet of the water treatment plant. Cake is transported by truck to a

disposal site.

Alum sludges are conditioned using lime and/or fly ash. Lime dosage is in the range

10%-15% of the sludge solids. Ash from an incinerator, or fly ash from a power plant,

is applied at a much higher dosage, approximately 100% of dry sludge solids.

Polyelectrolytes may also be added to aid coagulation. Fly ash and diatomaceous earth

are used for precoating; the latter requires about 50.2 kg/m2 of filter area. Under

normal operation, cake density is 40%-50% solids and has a dense, dry, textured

appearance.

4 Module 9

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- ThickenersDocument4 pagesThickenersmacross086100% (1)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Digester Design2Document16 pagesDigester Design2Pragathees WaranNo ratings yet

- Residuals Processing and DisposalDocument30 pagesResiduals Processing and DisposalHeba YousifNo ratings yet

- The Advantages of Dissolved-Air Flotation For Water TreatmentDocument5 pagesThe Advantages of Dissolved-Air Flotation For Water TreatmentfeelsgdrivefeelsNo ratings yet

- Submitted by Natthu Shrirame: Under The Guidance ofDocument48 pagesSubmitted by Natthu Shrirame: Under The Guidance ofKamran Rana100% (2)

- Putus Asa FilterDocument20 pagesPutus Asa FilterLuthfi AinunNo ratings yet

- Sludge TreatmentDocument9 pagesSludge Treatmentrollrams100% (1)

- Design Fundamentals of Sedimentation Tanks KeertiDocument26 pagesDesign Fundamentals of Sedimentation Tanks KeertiMesfin DerbewNo ratings yet

- Road Dust Control With Calcium ChlorideDocument5 pagesRoad Dust Control With Calcium Chloridesschaffer345No ratings yet

- 5.4 ThickeningDocument2 pages5.4 ThickeningArgie AdduruNo ratings yet

- A New Approach For Particle Size ReductionDocument7 pagesA New Approach For Particle Size Reductioncsyena28225No ratings yet

- Redner RosaciaDocument5 pagesRedner RosaciaRedner S. RosaciaNo ratings yet

- Chapter 6Document17 pagesChapter 6Yohannes HabeshawiNo ratings yet

- High Concentration Slurry Density - Pem News LetterDocument4 pagesHigh Concentration Slurry Density - Pem News LetterGirish BhagchandaniNo ratings yet

- Chapter 2Document60 pagesChapter 2Solomon DesalegnNo ratings yet

- FI-465 Potash Ore ProcessingDocument7 pagesFI-465 Potash Ore ProcessingtrinhtrungNo ratings yet

- IPS Dissolving PulpDocument10 pagesIPS Dissolving PulpAditya ShrivastavaNo ratings yet

- Mod - 1 Fundamental of Cement Processing (Autosaved)Document67 pagesMod - 1 Fundamental of Cement Processing (Autosaved)Bambang Murtjahjanto50% (2)

- Cement IndustriesDocument29 pagesCement IndustriesHananNo ratings yet

- Contact Cell Info - Gen PDFDocument10 pagesContact Cell Info - Gen PDFsnarf273No ratings yet

- Sand Ballasted HRC For Treatment oDocument8 pagesSand Ballasted HRC For Treatment oibiza48No ratings yet

- 10 Chiariflocculazione EngDocument13 pages10 Chiariflocculazione EngAbdul BokhariNo ratings yet

- Pengolahan Fine CoalDocument2 pagesPengolahan Fine CoalMaura Dwi UtamiNo ratings yet

- SedimentationDocument6 pagesSedimentationgnino2No ratings yet

- Manufacturing & Industrial Processes With Plant Visit: Engr. Peter Clyde B. LamadridDocument23 pagesManufacturing & Industrial Processes With Plant Visit: Engr. Peter Clyde B. LamadridKristine Joy MataroNo ratings yet

- TreatDocument49 pagesTreatHussen MohammedNo ratings yet

- Chapter 7-5: Sludge Treatment and DisposalDocument36 pagesChapter 7-5: Sludge Treatment and DisposalSUWIPHA DAPHANo ratings yet

- The Consep AcaciaDocument7 pagesThe Consep AcaciaPrincess Ruwarashe Courteney MunyoroNo ratings yet

- Case 01Document19 pagesCase 01Rushanth ChandraboseNo ratings yet

- CETP ProcessDocument3 pagesCETP Processgsenv20r09No ratings yet

- Ce402 Ee Ii M6 P2 MeaDocument25 pagesCe402 Ee Ii M6 P2 MeaJesbin ECNo ratings yet

- Portland Cement Production Dry and Wet AssignemntDocument9 pagesPortland Cement Production Dry and Wet AssignemntPablo GomesNo ratings yet

- M13L17 Digester DesignDocument12 pagesM13L17 Digester DesignPragathees WaranNo ratings yet

- Sludge Treatment and DisposalDocument29 pagesSludge Treatment and DisposalKishin AbeloNo ratings yet

- 472 Actiflo WastewaterDocument4 pages472 Actiflo WastewaterLTE002No ratings yet

- MC ClariflowDocument9 pagesMC ClariflowLTE002No ratings yet

- Flocculants and Coagulants NALCO (LIT)Document6 pagesFlocculants and Coagulants NALCO (LIT)AlexisPereiraVásquezNo ratings yet

- 1 Sludge Treatment and Disposal-1Document27 pages1 Sludge Treatment and Disposal-1Liyana RaisNo ratings yet

- Crude Oil Desalting ProcessDocument24 pagesCrude Oil Desalting ProcessamirejazNo ratings yet

- Sludge Processing and Disposal: Characterization and Sources of Sludges From Wastewater TreatmentDocument62 pagesSludge Processing and Disposal: Characterization and Sources of Sludges From Wastewater TreatmentJohan Shane CarsidoNo ratings yet

- Concrete Technology Module 1Document32 pagesConcrete Technology Module 1shilpa Sara KurianNo ratings yet

- 1 PBDocument6 pages1 PBdante zegarraNo ratings yet

- Ce-311 Sludge ProcessingDocument21 pagesCe-311 Sludge ProcessingShubham BansalNo ratings yet

- GrowingDocument39 pagesGrowingMuzammil QamarNo ratings yet

- Leachate PresentationDocument21 pagesLeachate PresentationCarren MarquezNo ratings yet

- ZLD Evaparation Crystallization Plant in The Hydrometallurgical IndustryDocument6 pagesZLD Evaparation Crystallization Plant in The Hydrometallurgical Industrykosmc123No ratings yet

- Sludge DisposalDocument53 pagesSludge DisposalrushdiNo ratings yet

- Dairy Waste Water Treatment PlantDocument23 pagesDairy Waste Water Treatment PlantManu Jain87% (15)

- Liquid Cyclone Treatment of Weighted Muds: Paper NumberDocument8 pagesLiquid Cyclone Treatment of Weighted Muds: Paper NumberMoslemNo ratings yet

- Improve Contaminant Control in Ethylene Production: Hpimpact TechnologyDocument6 pagesImprove Contaminant Control in Ethylene Production: Hpimpact TechnologyVenkatesan DevendranNo ratings yet

- Case Study Whisky IndustryDocument4 pagesCase Study Whisky IndustryPaula MertensNo ratings yet

- Colloid SilDocument4 pagesColloid SiljnmanivannanmechNo ratings yet

- Coal Cleaning by Dense Medium Processes H.J. Ruff InprominDocument12 pagesCoal Cleaning by Dense Medium Processes H.J. Ruff InprominTsakalakis G. KonstantinosNo ratings yet

- M24L40Document7 pagesM24L40Andenet AshagrieNo ratings yet

- Vibrating ScreensDocument6 pagesVibrating Screensvarun_0512933No ratings yet

- Imp ZLD System Tamil NaduDocument4 pagesImp ZLD System Tamil Naduneeraj sharmaNo ratings yet