Professional Documents

Culture Documents

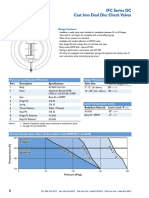

CAIR QR Series Spring Return Dead Man Handle Ball Valves

Uploaded by

nm shaikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAIR QR Series Spring Return Dead Man Handle Ball Valves

Uploaded by

nm shaikhCopyright:

Available Formats

“CAIR” has a Large Selection of Dead man Handle Ball Valves and

Self Closing Sampling Valves. Spring Return ( Quick Return ) Handle

Automatically Closes or Opens the Valve when Operator Releases

Handle. This Means the Operator Must Hold the Handle in the

Open Position for the Product to Flow. He can't Walk Away or the

Valve will Shut Off.

We have the Largest Selection of Dead man Handle Ball Valves

Available in India.

Let us Know your Application and we will Help you Find a Self

Closing Dead man Ball Valve to fit your Application.

Advantages:-

•Eliminates Spills, Leaks and Reporting to OSHA

•Prevents Overfilling of Day Tanks and Batch Tanks

•Improves Plant Safety

•Prevent Lost Product when Draining Water from Bottom of Propane and Butane Tanks

•Locking Handle Option for Security

•Fire Safe API607 Valve for Refineries, Chemicals and Hazardous Gas Applications

•Self Adjusting Packing Reduces Maintenance Cost

•Full Port Gives Faster Flow Rate than Most Competitive Valves

Up to 4" NPT, Socket Weld, Flange, Triclamp and other End Connections

Dead man Handle Ball Valve with Spring Return Handle

CAIR has the most rugged dead man ball valves with spring return handles on the internet. Our dead

man spring return ball valves are designed for everyday industrial use. We also offer Locking Handle

Option for our Spring Return Dead man Handle Ball Valves. Our valves are self closing.

Reasons to consider “CAIR’ QR Series Deadman Handle Ball Valves:

Ruggedness

We use the new industry standard ISO 5211 actuator mounting pad for our deadman spring return

handles. Our mounting pads are rugged, unlike the "weak panel mounting pad" used by our

competitors.

Our handles are made from heavy gauge stainless steel so they don't bend like competitors deadman

handle spring return ball valves.

Full Flow Full Port Design

Our dead man handle spring return ball valves are full port. Most competitors use standard port

valves or reduced port valves....so you need to hold the handle open longer with competitors valves.

Self Adjusting Packing

Most of our dead man handle ball valves use self adjusting packings with Belleville

washers. Competitors use thin Teflon packing and need to undo the handle for constant packing

readjustment. Our valves last longer and require less maintenance.

Options for Dead man Handle Ball Valves:

Fire Safe ball valves

Flanged ball valves

3 way ball valves

Steam Ball Valves

Sanitary Tri clamp Ball Valves

Brass, Carbon Steel and Alloy Ball Valves

High Temperature Ball Valves

High Pressure Valves

Locking Handle Option

Easy Turn Low Torque Ball Valve

Oval Handle Option

Applications include: Sampling, filling tanks, draining tanks, spill avoidance, butane tanks water

drain, propane tanks water drain, steam trap drain, chemical makeup, refueling, 55 gallon drum

dispensing, meat pipe plug cleanout, hose vent valve, oil tank load line drip pot valve, hose vent

valve, concrete mixer 3-way fill valve, slump control and more.

•Locking devices

Hook

Lock Barred plate

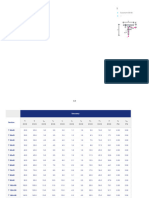

•SPRING RETURN HANDLE DIMENSIONS & BILL OF MATERIALS

Size A B D d1 d2 E F G H L M

1/2" 1.46 0.35 0.43 0.24 0.24 2.60 1.42 1.65 0.35 2.22 5.12

3/8" 1.46 0.35 0.49 0.24 0.24 2.60 1.42 1.65 0.35 2.22 5.12

1/2" 1.46 0.35 0.59 0.24 0.24 2.60 1.42 1.65 0.35 2.32 5.12

3/4" 1.57 0.43 0.79 0.24 0.24 2.72 1.42 1.65 0.35 2.83 5.12

1" 1.89 0.55 0.98 0.24 0.28 3.15 1.65 1.97 0.43 3.13 6.30

1-1/4" 2.11 0.55 1.26 0.24 0.28 3.35 1.65 1.97 0.43 3.78 6.30

1-1/2" 2.50 0.71 1.50 0.28 - 3.86 1.97 - 0.55 4.11 8.07

2" 2.83 0.71 1.97 0.28 - 4.17 1.97 - 0.55 4.86 8.07

Part No. Description Material

1 Handle Head CF8

2 Anchor CF8M

3 Anchor Screw SS 316

4 Spring Rod SS 316

5 Spring SS 301

6 Handle Extension SS 304

7 Sleeve PVC

8 Washer SS 304

9 Hex Nut SS 304

10 Socket Head Screw SS 304

CAIR QR Series Spring Return Dead Man Handle

With Flanged Ball Valve

Face-to-Face - ANSI B16.10

Working Pressure: 275 psi

Temperature Range: -20°F ~ 400°F

Available in Stainless or Carbon Steel

Body & flange cap are investment cast

Self adjusting stem packing

Blow-out proof stem design

ISO 5211 direct mounting pad

100% air tested under water at 80 psi

Flange Dimensions (Class 150)

Size A B E L H K M F G d1 d2 D Bolt Hole t g f

C h n

1/2" 0.59 1.89 0.43 4.25 0.35 3.15 5.12 1.42 1.65 0.24 0.24 3.50 2.38 0.63 0.20 0.45 1.38 0.06

3/4" 0.79 2.09 0.43 4.61 0.35 3.15 5.12 1.42 1.65 0.24 0.24 3.86 2.76 0.63 0.20 0.45 1.69 0.06

1" 0.98 2.32 0.55 5.00 0.43 3.54 6.50 1.65 1.97 0.24 0.28 4.25 3.13 0.63 0.20 0.45 2.01 0.06

1-1/4" 1.26 2.80 0.55 5.51 0.43 4.02 6.50 1.65 1.97 0.24 0.28 4.61 3.50 0.63 0.20 0.50 2.52 0.06

1-1/2" 1.50 2.99 0.71 6.50 0.55 4.33 8.07 1.97 2.76 0.28 0.36 5.00 3.88 0.63 0.20 0.56 2.87 0.06

2" 1.97 3.35 0.71 7.01 0.55 4.72 8.07 1.97 2.76 0.28 0.36 5.98 4.74 0.75 0.20 0.63 3.62 0.06

ISO 9001 : 2015 Certified Company www.cairindia.com

You might also like

- Check Valve Parker Serie CDocument4 pagesCheck Valve Parker Serie CRamiro EspinozaNo ratings yet

- Leading Latin American manufacturer of cryogenic valves and pumpsDocument50 pagesLeading Latin American manufacturer of cryogenic valves and pumpsAlvaro Antonio Cristobal AtencioNo ratings yet

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Document11 pagesPDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18No ratings yet

- Catálogo Válvulas de Mariposa Sanitarias.Document1 pageCatálogo Válvulas de Mariposa Sanitarias.Sixto MuñozNo ratings yet

- Proven technology for individual valve solutions worldwideDocument16 pagesProven technology for individual valve solutions worldwideApresia KiranaNo ratings yet

- Essential Valve GuideDocument36 pagesEssential Valve GuidetvwrightchwNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- Manual ValvesDocument20 pagesManual ValvesLuis Enrique Barreto GarciaNo ratings yet

- Catalogo - Productos - ValvulaAceroRoscadaOptimizado TRIVECADocument3 pagesCatalogo - Productos - ValvulaAceroRoscadaOptimizado TRIVECAUrielNo ratings yet

- Valvulas Triveca PDFDocument9 pagesValvulas Triveca PDFABRIL MILLANNo ratings yet

- GUIA PARA Tasas de InterésDocument9 pagesGUIA PARA Tasas de InterésjuliodbNo ratings yet

- Itap - PRV EuropaDocument16 pagesItap - PRV EuropaRajkishorNo ratings yet

- Hydroflex Catalogue - 2018-PDF FOR TEXTDocument12 pagesHydroflex Catalogue - 2018-PDF FOR TEXTdhaktodesatyajitNo ratings yet

- Sakti Suria CatalogueDocument112 pagesSakti Suria CatalogueChoon Wei WongNo ratings yet

- Pigging Valve Brochure Argus ValvesDocument7 pagesPigging Valve Brochure Argus ValvesIsares PodkohNo ratings yet

- (New) E-Flex Viet Nam Catalogue 2021Document10 pages(New) E-Flex Viet Nam Catalogue 2021Trung Trinh BaoNo ratings yet

- Series 3 & 4 U BonnetedDocument9 pagesSeries 3 & 4 U BonnetedBaskaran RathinamNo ratings yet

- Brass Ball Valve (BBV) V0816Document1 pageBrass Ball Valve (BBV) V0816Saiful Islam SagorNo ratings yet

- Copper Pipe.unifLOWDocument8 pagesCopper Pipe.unifLOWdesignNo ratings yet

- Style 257Document5 pagesStyle 257Ummes AhmedNo ratings yet

- Class 800 Steel Check ValvesDocument2 pagesClass 800 Steel Check Valvesnnaemeka omekeNo ratings yet

- Hydraulic SAE FlangesDocument18 pagesHydraulic SAE Flangesmjpadia_131980No ratings yet

- E44010.400 RB3Document2 pagesE44010.400 RB3Muhammad HanifullahNo ratings yet

- De Va: Series D65/D69Document2 pagesDe Va: Series D65/D69AZMATNo ratings yet

- Basics of Piping EngineeringDocument43 pagesBasics of Piping EngineeringAyushNo ratings yet

- FlowCon AHU-Wafer Tech Note PDFDocument4 pagesFlowCon AHU-Wafer Tech Note PDFViệt Đặng XuânNo ratings yet

- ABZ ValveDocument8 pagesABZ ValveJavierfox98No ratings yet

- Mining’s Final Knife Gate Valve SolutionDocument6 pagesMining’s Final Knife Gate Valve SolutionDaniel SanNo ratings yet

- Specifications Ball ValvesDocument4 pagesSpecifications Ball ValvesANo ratings yet

- Valves & Fittings Equivalent LengthsDocument5 pagesValves & Fittings Equivalent LengthsCzarSASNo ratings yet

- ANSI:ASME B16.9 Buttweld Long Stub End Manufacturer, Fittings Long Stub End Supplier, Butt Weld LongDocument12 pagesANSI:ASME B16.9 Buttweld Long Stub End Manufacturer, Fittings Long Stub End Supplier, Butt Weld LongCarlos MoscosoNo ratings yet

- Liv BFV Di DFM 001Document1 pageLiv BFV Di DFM 001romel tilakNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- KVS Diaphragm Valves Technical SpecificationsDocument8 pagesKVS Diaphragm Valves Technical SpecificationsThinh Chu100% (1)

- GWC Valve International Threaded & Socketweld Ball ValveDocument16 pagesGWC Valve International Threaded & Socketweld Ball ValveGWC Valve InternationalNo ratings yet

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- For Cylinder Size Dia 57mm X 55mm StrokeDocument4 pagesFor Cylinder Size Dia 57mm X 55mm StrokesrdNo ratings yet

- GLT Small ValvesDocument5 pagesGLT Small ValvesAristo MNo ratings yet

- Protect equipment and processes with a compact line strainerDocument3 pagesProtect equipment and processes with a compact line strainersanthoshkrishnaNo ratings yet

- 1,000 Psi Full Port 3-Piece Ball Valve: DPV® Fig. 3F133SDocument1 page1,000 Psi Full Port 3-Piece Ball Valve: DPV® Fig. 3F133SPradipta DwiNo ratings yet

- ANSI Flanges Guide for Pipe SizesDocument20 pagesANSI Flanges Guide for Pipe Sizesthe alchemistNo ratings yet

- FF 65 45 GdsDocument1 pageFF 65 45 Gdsadewunmi olufemiNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Nibco Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageNibco Wafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- Spring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)Document4 pagesSpring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)cmpuckNo ratings yet

- PVC ValveDocument28 pagesPVC ValveVincent Ferrer NironNo ratings yet

- I.1.12 BallVlv-1000WOG-SS316-3Way-BSPT - Continuous-1Document1 pageI.1.12 BallVlv-1000WOG-SS316-3Way-BSPT - Continuous-1Mochamad Rizal Armajaya YudhaNo ratings yet

- FlangesDocument114 pagesFlangesBoriche DivitisNo ratings yet

- Din Reactors CEDocument3 pagesDin Reactors CEvallamreddyNo ratings yet

- I.1.8 BallVlv-1000WOG-SS304, SS316&WCB-2Bd-BSPTDocument1 pageI.1.8 BallVlv-1000WOG-SS304, SS316&WCB-2Bd-BSPTTajul fakhriNo ratings yet

- Kompact Series: Flanged / Wafer Full Bore Ball ValveDocument4 pagesKompact Series: Flanged / Wafer Full Bore Ball ValveJuan CisnerosNo ratings yet

- Swing Check Valve Dimensions and MaterialsDocument1 pageSwing Check Valve Dimensions and MaterialsTou SvnkNo ratings yet

- Series dc125Document2 pagesSeries dc125Daniel FigueroaNo ratings yet

- Eliminador de Ar para Liquidos Pae10 275Document2 pagesEliminador de Ar para Liquidos Pae10 275Keronlline GomesNo ratings yet

- Hydraulic Pressure Control Valves - OOVAL - Product CatalogDocument16 pagesHydraulic Pressure Control Valves - OOVAL - Product CatalogIsrael Exporter100% (2)

- Fivalco Cvg01 ChequeDocument3 pagesFivalco Cvg01 ChequeSergio HoyosNo ratings yet

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationFrom EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationRating: 4.5 out of 5 stars4.5/5 (21)

- Upvc 3 Way Ball ValveDocument3 pagesUpvc 3 Way Ball Valvenm shaikhNo ratings yet

- Upvc Butterfly ValveDocument1 pageUpvc Butterfly Valvenm shaikhNo ratings yet

- Upvc ValvesDocument3 pagesUpvc Valvesnm shaikhNo ratings yet

- Chemical Compatibility PDFDocument6 pagesChemical Compatibility PDFSuresh Kumar MittapalliNo ratings yet

- Aircraft Load Analysis and Sizing ReportDocument62 pagesAircraft Load Analysis and Sizing ReportRizqy AgungNo ratings yet

- M16AR Installation Instructions 1.0Document2 pagesM16AR Installation Instructions 1.0sandyNo ratings yet

- Part Iii Amendments/Supplements To en 13445 EN 13445-1 GENERAL 1.2 Add To This ClauseDocument8 pagesPart Iii Amendments/Supplements To en 13445 EN 13445-1 GENERAL 1.2 Add To This ClauseDhakshina KNo ratings yet

- Control Valve Dx28 Solar III 20287132gDocument58 pagesControl Valve Dx28 Solar III 20287132gAlejandro Mayr100% (1)

- Valve Actuators C13Document5 pagesValve Actuators C13Jose F Rivera Morales100% (3)

- Altis MV2 (11.12.03)Document1 pageAltis MV2 (11.12.03)D Wahyu BawonoNo ratings yet

- 3-Phase Locomotive OverviewDocument38 pages3-Phase Locomotive OverviewDevarshi Gaur100% (3)

- Machinery Operating Manual TransferDocument249 pagesMachinery Operating Manual TransferEmin Alim100% (3)

- Building Technologies: HVAC ProductsDocument7 pagesBuilding Technologies: HVAC Productsshivv230No ratings yet

- MLA PresentationDocument8 pagesMLA PresentationPaijo TejoNo ratings yet

- PHA and What-If Checklist Questions: AppendixDocument18 pagesPHA and What-If Checklist Questions: Appendixrachit singhNo ratings yet

- 2lec3&4 With Assignment 2 Reinf Conc 412Document42 pages2lec3&4 With Assignment 2 Reinf Conc 412Emmanuel MwabaNo ratings yet

- Pitch Angle Control For Variable Speed Wind TurbinesDocument6 pagesPitch Angle Control For Variable Speed Wind TurbinesNandan ModaniNo ratings yet

- FEDR15180 - Discharge Nozzle 180º FEDRxx180 - Rv04Document3 pagesFEDR15180 - Discharge Nozzle 180º FEDRxx180 - Rv04EMMA VIDALNo ratings yet

- AMERICAN Pipe Manual Linings and Coatings 5 24 21Document15 pagesAMERICAN Pipe Manual Linings and Coatings 5 24 21Ludi D. LunarNo ratings yet

- SVP3000 Alphaplus Smart Valve PositionerDocument8 pagesSVP3000 Alphaplus Smart Valve Positioner鄭元豪No ratings yet

- Engine Monitors For General Aviation Piston Engines Condition MonitoringDocument6 pagesEngine Monitors For General Aviation Piston Engines Condition MonitoringShanker PandeyNo ratings yet

- Comments On Io List & P&I Diagram: Motor Feeder SignalsDocument4 pagesComments On Io List & P&I Diagram: Motor Feeder SignalsNaveen NagisettiNo ratings yet

- Specification Sheet: Pour Point of Crude Oils - Procedure BDocument3 pagesSpecification Sheet: Pour Point of Crude Oils - Procedure BMiguelNo ratings yet

- Service and Maintenance of Engine TAD1355GEDocument90 pagesService and Maintenance of Engine TAD1355GEЕвгений АрабаджиNo ratings yet

- Voith Montage PDFDocument168 pagesVoith Montage PDFWafa GharbiNo ratings yet

- Chapter III Propulsion Systems Thrust and Performance ParametersDocument29 pagesChapter III Propulsion Systems Thrust and Performance ParametersshmyeNo ratings yet

- 50121-6-1 Eastern Pak PDFDocument1 page50121-6-1 Eastern Pak PDFJohn MaNo ratings yet

- Mahle TL SB En-SpreadDocument8 pagesMahle TL SB En-SpreadVictor BalasNo ratings yet

- T, 1-2 Ipe, 1-2 Hem, 1-2 Heb, 1-2 HeaDocument46 pagesT, 1-2 Ipe, 1-2 Hem, 1-2 Heb, 1-2 HeaCédric ConreuxNo ratings yet

- Catalyst Handling Services for BST RefineriesDocument3 pagesCatalyst Handling Services for BST RefineriesIqbal Safirul BarqiNo ratings yet

- MEBS6006 Environmental Services I Psychrometric AnalysisDocument52 pagesMEBS6006 Environmental Services I Psychrometric Analysisahtin618100% (2)

- Unit 1 Physics NotesDocument69 pagesUnit 1 Physics Notesdilexsan100% (1)

- RPM Tech LM220 Brochure 01 2020 en SourcewellDocument4 pagesRPM Tech LM220 Brochure 01 2020 en SourcewellPhil B.No ratings yet

- Caterpillar 966d Wheel Loader Service Manual SN 35s PDFDocument7 pagesCaterpillar 966d Wheel Loader Service Manual SN 35s PDFyudi0% (2)