Professional Documents

Culture Documents

E44010.400 RB3

Uploaded by

Muhammad HanifullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E44010.400 RB3

Uploaded by

Muhammad HanifullahCopyright:

Available Formats

BACK

"In line" diaphragm seal,

with flanged connection MGS9/4

Diaphragm seals are designed to isolate the sensing element of pressure gauges, pressure switches and electronic pressure

transmitters from process liquids which may be corrosive, viscous, sedimentous and/or with a high temperature. The diaphragm

welded to the upper body and leak proof tested, ensure separation of filling fluid from process medium. Diaphragm faced position

permit an accurate and deeper cleaning. Process sizes are ASME/UNI/DIN flanged to suit application in chemical, petrochemical,

water treatment and paper industries.

4.400 - MGS9/4

Working pressure: from 0...15 to 0...600 psi (from 0...1to 0...40 Hastelloy B2 (cod. 1), Tantaluum (cod. B), Titanium (cod. 2),

bar). Nickel (cod. 7), AISI 316 st.st. PTFE** coated (cod. N), ASTM

Working temperature: -49...+302°F (-45°C...+150°C.) A182 gr. F51 (cod. S).

Accuracy*: (add to instrument accuracy) ±0,5% for direct Dimensions : DN 15...50 e PN 10...40 UNI-DIN step seal;

mounting; ± 1% for capillary mounting. 1/2"...2" class 150...600 RF as per ASME B16.5.

Instrument connection: AISI 316 st.st . UNI-DIN flanges finishing: type B1 (PN 2,5...40) = Ra 3,2...12,5

Diaphragm: AISI 316L st.st (cod. 4), Monel 400 (cod. 6), μm (cod. RF7); type B2 (PN 63...100) = Ra 0,8...3,2 μm (cod.

Hastelloy C276 (cod. 9), Hastelloy B2 (cod. 1), Tantaluum (cod. RF8).

B), Titanium (cod. 2), Nickel (cod. 7), AISI 316 L st.st. PTFE ASME flanges finishing: type RF = Ra 125...250 AARH (cod.

coated** (cod. 8), Incoloy 825 (cod. I), Inconel 600 (cod. J). RF3).

Flanged process connection: AISI 316 st.st. (cod. 4), AISI316 L Filling liquid: silicon oil.

st.st. (cod. 5), Monel 400 (cod. 6), Hastelloy C276 (cod. 9),

* at +68°F (20 °C) process temperature (or state when ordering) ** max. temperature 328°F (150 °C), with PTFE coating.

ASSEMBLING

All diaphragm seals are mounted on the instruments ad fixed by an aluminium protection label. For applications with capillary: shoul diaphragm

seal and instrument not be at the same level, instrument adjustment is required: max 36.37” (6 mt). (For use and installation, see data sheet ”4”)

D - Direct 9- Capillary AISI304 st.st., AISI304 st.st. armoured, 236” max (6 mt max)

T - Cooling extension 6- Capillary AISI316 st.st., AISI316 st.st. armoured, 236” max (6 mt max)

1 - Nude capillary AISI304, 236” max (6 mt max)

OPTIONS

B- Silicon liquid “B”for process fluid temperature from -4°F to +482°F (from -20°C to +250°C)

C - Silicon liquid “C” for process fluid temperature from +68°F to +644°F (from +20°C to +340°C)

E- Fluorinated liquid “E” for process fluid temperature from -76°F to +302°F (from -60°C +150°C)

R20 - Adaptor G 1/2 A M/F with filling screw

R21 - Adaptor G 1/2 A M x 1/4 - 18 NPT F with filling screw

C05 - Helium Test (1)

E30 - NACE version MR0103 (2) - MR0175 (ISO 15156) (3)

P04 - Die penetrant test (1)

(1) Available for some excutions pls. consult our technical dep. to check (2) With Monel 400 or Hastelloy C diaphragm only.

their feasibility. (3) Hastelloy C276 wetted parts

ISO 9001 : 2000

-1- Cert. no. 0433/3

"In line" diaphragm seal,

with flanged connection

MGS9/4

RB3 - 06/08

IN ORDER TO IMPROVE THEIR PRODUCTION, MESSRS. NUOVA FIMA RESERVE THE RIGHT TO THEMSELVES TO MAKE ALL THE MODIFICATIONS THAT THEY DEEM INDISPENSABLE AT ANY TIME. UPDATED DATA-SHEETS ARE AVAILABLE ON SITE: www.nuovafima.com

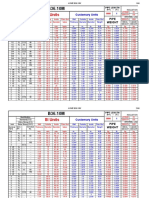

UNI-DIN STANDARDS

dimensions : mm

DN PN-bar Code D E c b a d g h s L F Ranges (2)

15 10...40 OK0 15 95 65 45 40 28 2 17 19 16,5 14 2,5...40

20 10...40 PK0 20 105 75 58 40 28 2 17 19 16,5 14 2,5...40

25 10...40 QK0 25 115 85 68 50 38 2 17 19 24,5 14 1...40

40 10...40 SK0 40 150 110 88 50 38 3 16 19 24,5 18 1...40

50 10...40 TK0 50 165 125 102 50 38 3 17 20 23,5 18 1...40

(1) N° holes .

(2) bar ranges, for instruments with dial size ≥ 4” (100mm).

ASME STANDARDS

dimensions : inches

DN Class Code D E c b a d g h s L N (1) F Ranges (3)

1/2" 150 4AA 0.59” 3.5” 2.37” 1.37” 1.18” 1.02” 0.06” 0.66” 0.72” 0.64” 4 0.62” 100...290 (4)

1/2" 300 4BA 0.59” 3.74” 2.62” 1.37” 1.18” 1.02” 0.06” 0.66” 0.72” 0.64” 4 0.62” 100...580

1/2" 600 4DA 0.59” 3.74” 2.62” 1.37” 1.18” 1.02” 0.25” 0.66” 0.95” 0.64” 4 0.62” 100...580

3/4" 150 5AA 0.78” 3.87” 2.74” 1.68” 1.57” 1.10” 0.06” 0.66” 0.72” 0.64” 4 0.62” 60...290

3/4" 300 5BA 0.78” 4.62” 3.24” 1.68” 1.57” 1.10” 0.06” 0.66” 0.72” 0.64” 4 0.74” 60...580

3/4" 600 5DA 0.78” 4.62” 3.24” 1.68” 1.57” 1.10” 0.25” 0.66” 0.95” 0.64” 4 0.74” 60...580

1" 150 6AA 0.98” 4.25” 3.12” 2” 1.57” 1.10” 0.06” 0.7” 0.76” 0.64” 4 0.62” 60...290

1" 300 6BA 0.98” 4.88” 3.5” 2” 1.96” 1.49” 0.06” 0.7” 0.76” 0.96” 4 0.74” 15...580

1" 600 6DA 0.98” 4.88” 3.5” 2” 1.96” 1.49” 0.25” 0.7” 0.96” 0.96” 4 0.74” 15...580

1"1/2 150 AAA 1.57” 5” 3.87” 2.87” 1.96” 1.49” 0.06” 0.7” 0.76” 0.96” 4 0.62” 15...290

1"1/2 300 ABA 1.57” 6.12” 4.5” 2.87” 1.96” 1.49” 0.06” 0.80” 0.86” 0.86” 4 0.86” 15...580

1"1/2 600 ADA 1.57” 6.12” 4.5” 2.87” 1.96” 1.49” 0.25” 0.88” 1.14” 0.59” 4 0.86” 15...580

2" 150 BAA 1.96” 6” 4.74” 3.62” 1.96” 1.49” 0.06” 0.74” 0.80” 0.92” 4 0.74” 15...290

2" 300 BBA 1.96” 6.49” 5” 3.62” 1.96” 1.49” 0.06” 0.88” 0.94” 0.78” 8 0.74” 15...580

2" 600 BDA 1.96” 6.49” 5” 3.62” 1.96” 1.49” 0.25” 1.04” 1.25” 0.47” 8 0,74” 15...580

(1) N° holes . (3) psi ranges, for instruments with dial size ≥ 4” (100mm).

(2) bar ranges, for instruments with dial size ≥ 4” (100mm). (4) not available, when PTFE coated.

”HOW TO ORDER” SEQUENCE

Section / Model / Connection / Diaphragm / Process / Flange / Instrument / Assembling / Options

material material connection finishing connection

4 400 4, 5, 6 4, 6, 9 OK0..TK0 RF3...RF8 41F - G 1/2 F D, T B, C, E

9, 1, B 1, B, 2 4AA...BDA 1, 9, 6 R20, R21

2, 7, N, S 7, 8, I, J

NUOVA FIMA S.p.A. - www.nuovafima.com

-2- P.O. BOX 58 - VIA C. BATTISTI 59 - 28045 INVORIO (NO) ITALY

TEL. +39 0322 253200 - FAX +39 0322 253232

You might also like

- MK 608 BPMDocument9 pagesMK 608 BPMrogelgerardo643No ratings yet

- Nmfguk PDFDocument7 pagesNmfguk PDFBruno RochaNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Din en 853 2Sn / Sae 100R2AtDocument1 pageDin en 853 2Sn / Sae 100R2Atafrizal ardityawanNo ratings yet

- Rhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Document3 pagesRhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Yerson JuarezNo ratings yet

- Check Valve Parker Serie CDocument4 pagesCheck Valve Parker Serie CRamiro EspinozaNo ratings yet

- Fv-Cat-322-0316 Htaf PDFDocument2 pagesFv-Cat-322-0316 Htaf PDFTaylor RamirezNo ratings yet

- Metric Conversion ChartDocument2 pagesMetric Conversion ChartSafwan SahriNo ratings yet

- Fusion Series 322 Threaded Ball ValveDocument2 pagesFusion Series 322 Threaded Ball ValveOceanexNo ratings yet

- Jacketed Piping CalculationDocument9 pagesJacketed Piping CalculationKamran Shaikh0% (1)

- AMF601NTV1 1 9 A4 en PDFDocument4 pagesAMF601NTV1 1 9 A4 en PDFtruongNo ratings yet

- KVF-B16.48 Spectacle Blind BrochureDocument26 pagesKVF-B16.48 Spectacle Blind Brochurepmech consultantNo ratings yet

- Coturi F SuduraDocument7 pagesCoturi F SudurastroiebogdanNo ratings yet

- Spir Star 2013Document259 pagesSpir Star 2013Ahmadreza AminianNo ratings yet

- FlowCon SM DN50-250 Tech Note PDFDocument7 pagesFlowCon SM DN50-250 Tech Note PDFViệt Đặng XuânNo ratings yet

- CPVC pipes and fittings standardsDocument3 pagesCPVC pipes and fittings standardsAsif S KhanNo ratings yet

- Anaconda Multiflex Conduit: TYPE SLI-316Document3 pagesAnaconda Multiflex Conduit: TYPE SLI-316Arnab DebNo ratings yet

- Balflex Din en 853 2Sn / Sae 100R2AtDocument1 pageBalflex Din en 853 2Sn / Sae 100R2AtJuan Alberto Mendoza VegaNo ratings yet

- Mark 96C Series: Sanitary Pressure Regulators (1/2"-1")Document5 pagesMark 96C Series: Sanitary Pressure Regulators (1/2"-1")Danel GonzalezNo ratings yet

- Bolt EqualentsDocument1 pageBolt EqualentsvkturkiNo ratings yet

- Amal Cast Arrester CatalogueDocument8 pagesAmal Cast Arrester CatalogueTifano KhristiyantoNo ratings yet

- Alia AMF600 Sanitary FlowmeterDocument3 pagesAlia AMF600 Sanitary FlowmeterRexCrazyMindNo ratings yet

- 2642 Ni 71350002Document56 pages2642 Ni 71350002ToudNo ratings yet

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Document11 pagesPDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18No ratings yet

- Model SS-8 Stainless Steel Flexible Coupling Spec SheetDocument3 pagesModel SS-8 Stainless Steel Flexible Coupling Spec SheetCoutinho AcnNo ratings yet

- 44 - Ing - 1319115187 5199Document1 page44 - Ing - 1319115187 5199Luis Matamala MoNo ratings yet

- Folleto 75Document4 pagesFolleto 75ricardoNo ratings yet

- Victualic CouplingDocument6 pagesVictualic CouplingjigneshdalwadiNo ratings yet

- MSM-Series (PICV)Document11 pagesMSM-Series (PICV)FareethAbdullahNo ratings yet

- RC5 Data Sheet TV606 @enDocument2 pagesRC5 Data Sheet TV606 @ensenthilrsenthilNo ratings yet

- 2 SN PDFDocument1 page2 SN PDFJulio César Párraga CurielNo ratings yet

- Vacuum Suction CupsDocument50 pagesVacuum Suction CupsAshok Kamath100% (1)

- Stud Bolt SpecificationDocument8 pagesStud Bolt SpecificationsantoshblonkarNo ratings yet

- Din en 853 2 SN: Wire Braid Hydraulic Hose Meets EN 853 2 SN, SAE 100R2 and ISO 1436 2SNR2Document1 pageDin en 853 2 SN: Wire Braid Hydraulic Hose Meets EN 853 2 SN, SAE 100R2 and ISO 1436 2SNR2Zoran JankovNo ratings yet

- Ozone PartsDocument19 pagesOzone PartsEliasDraNo ratings yet

- 6 Conical Spring WashersDocument4 pages6 Conical Spring Washersbcsf01No ratings yet

- JazeeraDocument38 pagesJazeeraaegon1510No ratings yet

- IPS S.S. - Grooved Couplings (17.03)Document4 pagesIPS S.S. - Grooved Couplings (17.03)SureshNo ratings yet

- Itap - PRV EuropaDocument16 pagesItap - PRV EuropaRajkishorNo ratings yet

- 15 - Ing - 1288377409.2 - SAE R14 - MangueraDocument2 pages15 - Ing - 1288377409.2 - SAE R14 - MangueraJaimeEnriquePadillaPobleteNo ratings yet

- Protect equipment and processes with a compact line strainerDocument3 pagesProtect equipment and processes with a compact line strainersanthoshkrishnaNo ratings yet

- Nuova Fima MGS18 - 100150mmDocument2 pagesNuova Fima MGS18 - 100150mmPaweł HejmowskiNo ratings yet

- Diameter / Decimal / Metric Chart For Small DiametersDocument2 pagesDiameter / Decimal / Metric Chart For Small DiametershansNo ratings yet

- BS 4825 Ferrule Clamp DimensionsDocument1 pageBS 4825 Ferrule Clamp DimensionssergioNo ratings yet

- FERRULE Clamp BS 4825 Dimensions Rev.2Document1 pageFERRULE Clamp BS 4825 Dimensions Rev.2Gigin PlusNo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- Standard Bolt Specs and Torque ValuesDocument85 pagesStandard Bolt Specs and Torque Valuescpgmotors83% (6)

- ValvoRobica__Raccordi-ASMEDocument18 pagesValvoRobica__Raccordi-ASMEPaolo AndreettaNo ratings yet

- Uniflow Copper Tubes TDSDocument7 pagesUniflow Copper Tubes TDSFilorNo ratings yet

- Filettature Tiranti ASTM-A193Document25 pagesFilettature Tiranti ASTM-A193markoredsNo ratings yet

- Omani steel pipe manufacturer historyDocument36 pagesOmani steel pipe manufacturer historykarthickNo ratings yet

- Socitec Wirerope Iso Load Deflection PDFDocument0 pagesSocitec Wirerope Iso Load Deflection PDFraju3685No ratings yet

- Sanitary Pressure Gauges: DS 2.5", 4" (63-100mm)Document2 pagesSanitary Pressure Gauges: DS 2.5", 4" (63-100mm)esmail aliNo ratings yet

- Leading Latin American manufacturer of cryogenic valves and pumpsDocument50 pagesLeading Latin American manufacturer of cryogenic valves and pumpsAlvaro Antonio Cristobal AtencioNo ratings yet

- Alia AVF250 Variable Area FlowmeterDocument4 pagesAlia AVF250 Variable Area FlowmeterRexCrazyMindNo ratings yet

- FPJ 320 Series: Explosion Proof Cum Weatherproof Junction BoxesDocument2 pagesFPJ 320 Series: Explosion Proof Cum Weatherproof Junction BoxestejassidhpuraNo ratings yet

- DS100 7 Eng Mut2200elDocument16 pagesDS100 7 Eng Mut2200elAhmed IsmailNo ratings yet

- PipeDocument44 pagesPipesudokuNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Quotation Price - Differential Pump Versi 1Document3 pagesQuotation Price - Differential Pump Versi 1Muhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 004 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 004 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 004 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 004 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Inv. 005 - KLY Pemkab Banyuwangi PDFDocument1 pageInv. 005 - KLY Pemkab Banyuwangi PDFMuhammad HanifullahNo ratings yet

- Tennis Court Constructions GuideDocument30 pagesTennis Court Constructions Guidetalent1968100% (1)

- AAAC ConductorsDocument14 pagesAAAC ConductorsDipanku GoswamiNo ratings yet

- CRSI-PILECAP (Full Version)Document228 pagesCRSI-PILECAP (Full Version)xhq08No ratings yet

- Aerospace Standard: Hose Assembly, Polytetrafluoroethylene, Metallic Reinforced, 3000 Psi, 400 °F, Heavyweight, HydraulicDocument5 pagesAerospace Standard: Hose Assembly, Polytetrafluoroethylene, Metallic Reinforced, 3000 Psi, 400 °F, Heavyweight, HydraulicRangaNo ratings yet

- REXWAY PVC Coated Rigid Metal Conduit Catalogue (PVC Coated)Document7 pagesREXWAY PVC Coated Rigid Metal Conduit Catalogue (PVC Coated)Jeson Etorma0% (1)

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- Use of Brick Dust and Fly Ash As A Soil Stabilizer: November 2019Document5 pagesUse of Brick Dust and Fly Ash As A Soil Stabilizer: November 2019alibuxjatoiNo ratings yet

- Rubber Isolator 1921Document10 pagesRubber Isolator 1921Mario Daniel MLNo ratings yet

- Structure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Document37 pagesStructure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Divya Varshney100% (1)

- 02 Sistema de CR New HollandDocument23 pages02 Sistema de CR New HollandEloy100% (1)

- 093 Sinadumparan Ivatan House TypesDocument2 pages093 Sinadumparan Ivatan House TypesRoxanne NasingaoNo ratings yet

- Ejemplo AASHTO-PCI Bulb-Tee, BT-72, Single Span With Composite Deck. Designed in Accordance With AASHTO LRFD Specifications.Document47 pagesEjemplo AASHTO-PCI Bulb-Tee, BT-72, Single Span With Composite Deck. Designed in Accordance With AASHTO LRFD Specifications.Hermann PankowNo ratings yet

- Manual TenarisDocument28 pagesManual TenarisCamilo Moreno100% (1)

- API PLAN 23 COOLINGDocument3 pagesAPI PLAN 23 COOLINGsapu11jagat5855No ratings yet

- Bim NRMDocument18 pagesBim NRMenglishlearnercaNo ratings yet

- Behaviour of Skew Footings Resting On Clayey and Sandy SoilDocument10 pagesBehaviour of Skew Footings Resting On Clayey and Sandy SoilShahzad AnwarNo ratings yet

- Timor-Leste Industrial Development Survey Final ReportDocument164 pagesTimor-Leste Industrial Development Survey Final ReportOlga Putri SholichaNo ratings yet

- MANGUITO ETA 17 0081 - AssessmentDocument23 pagesMANGUITO ETA 17 0081 - AssessmentJavier Gómez CorreaNo ratings yet

- Initial Environmental Exam for Green Energy CorridorDocument72 pagesInitial Environmental Exam for Green Energy CorridorPravin HireNo ratings yet

- Shell Structures PDFDocument21 pagesShell Structures PDFDivya VarshneyNo ratings yet

- Install Geocell GuidelinesDocument3 pagesInstall Geocell GuidelinesDaniel MartinezNo ratings yet

- Greek Architecture StructuresDocument5 pagesGreek Architecture StructuresJan WickNo ratings yet

- DIN 16963-05 GeneralDocument9 pagesDIN 16963-05 GeneralFelipe BarrientosNo ratings yet

- Proximity Sensing and Warning Technology For Heavy Construction Equipment OperationDocument10 pagesProximity Sensing and Warning Technology For Heavy Construction Equipment OperationAnand ReddyNo ratings yet

- CCR & Simulator Room DesignDocument27 pagesCCR & Simulator Room DesignapsNo ratings yet

- NICMAR Distance Education Details PDFDocument13 pagesNICMAR Distance Education Details PDFShashank RajaNo ratings yet

- Progress Monitoring SheetDocument50 pagesProgress Monitoring Sheeterjuniorsanjip100% (1)

- Cooling Tower Fundamentals PDFDocument27 pagesCooling Tower Fundamentals PDFDarshan Raghunath100% (3)

- Logic ValveDocument3 pagesLogic ValveaungaungoomanualNo ratings yet

- Sec 1H (4HL1)Document11 pagesSec 1H (4HL1)Susilo purwanggiNo ratings yet