Professional Documents

Culture Documents

5 DG OH 17.5 (From Eng Salah 19 October)

Uploaded by

ايهاب العيسويOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 DG OH 17.5 (From Eng Salah 19 October)

Uploaded by

ايهاب العيسويCopyright:

Available Formats

OFFER

We would like to thank you for your enquiry and we hereinafter submit our best quote for the following supply :

N° 1 No. 1 KIT FOR

Structure ELECTRIC DOUBLE GIRDER BRIDGE CRANE in box beam

profile

Capacity 5t

Span 17500 mm

Featuring the technical characteristics and the specific terms of sale detailed in the following pages.

Sig.ra Squarzon Silvia and OMIS’s technical department are available for any further information you may require, in order to

guarantee that the selected crane is suitable for your specific needs.

While we wish to establish a mutually beneficial business relationship, we would like to convey our best regards,

OMIS Spa

TECHNICAL CHARACTERISTICS AND PRICES DESCRIPTION

No. 1 KIT FOR INDOOR USE

ELECTRIC DOUBLE GIRDER BRIDGE CRANE in box beam

Structure

profile

Capacity 5t

Span 17500 mm

Crane design group A5 according to FEM 1.001

Class of utilisation U4

Loading spectrum class Q3

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 1 di 8

Lifting unit mechanisms design group M5 according to FEM 1.001

Class of utilisation T4

Stress spectrum class L3

Travel mechanisms design group M5 according to FEM 1.001

Class of utilisation T4

Stress spectrum class L3

Lifting unit OMIS electrical wire rope hoist type OPE 312 4T 7N

Lift height 6,6 m

LIFTING SPEED

Main lifting speed 4 m/min

Slow lifting speed 1 m/min

Short-circuit rotor motor INVERTER 4 KW

LONG TRAVEL SPEED

Main long travel speed 40 m/min

Slow long travel speed 10 m/min

2 short-circuit rotor motors INVERTER 1,1 KW

CROSS TRAVEL SPEED

Main cross travel speed 20 m/min

Slow cross travel speed 5 m/min

Short-circuit rotor motor INVERTER 0,37 KW

Electrical system for 3-phase power supply 400 V - 50 Hz

Controlled through Pendant push -button station, voltage 110 V

Nominal power consumption 6,2 kW

Starting current consumption 35 A

Nominal current consumption 22 A

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 2 di 8

WORKING CONDITIONS DESCRIPTION

Working temperature min -10 °C / max +40 °C

With Inverter de -5 °C à max +40 °C

Relative humidity max 80%

Altitude Max 1000 m a.s.l.

Different climate conditions require special adaptations, which need to be agreed with the engineering department.

PAINTING with OMIS V01h cycle – TROLLEY DESCRIPTION

The cycle includes:

Mechanical brushing of the surfaces, degreasing with

Preparation of the surface to be painted

organic solvents and careful cleaning.

Electro-mechanical parts painting with ecological

Electro-mechanical parts painting

anticorrosive alkyl blue glaze RAL 5010 thickness 70-80 µm

Dry film total thickness 70 ÷ 80 µm.

In accordance with UNI EN ISO 12944-2, the environment is considered as C2 low, classification used for unheated buildings

where condensation may occur, e.g. depots, sport halls. Durability between 2 to 5 years.

Different climatic conditions from the ones indicated need special executions, which must be agreed with the authorised

technicians.

Lifting speed of the hoist by INVERTER

Two lifting speeds: main or slow speed. The slow one is adjustable from 20% to 100% of the main one.

Bridge and trolley speed by INVERTER

Two travel speed, main or slow. The slow one is adjustable from 15% to 100% of the main one.

The differential relay, which protects the crane electrical feeding power line, must have the following basic characteristics:

- Differential current, more or the same than 0.5

A; - Higher range of time intervention is 0.2

seconds.

Materials are loaded in our workshop on container/s supplied by the customer. (a126) Note: OMIS

loads max no. 2 container per day due to logistics needs.

According to “SOLAS” international regulation, we inform that the box weighing will be carried out in our plants by means of

homologated weighing tool (method 1); after the container is loaded, OMIS will send to the shipper the VGM declaration.

Electromechanical parts packed in wooden crates suitable for marine transportation (a127)

CONDUCTOR SYSTEM SUPPLY

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 3 di 8

Line for crane feeding, blindotrolley type ATOLLO with the following characteristics:

Load 70 A

Working temperature range -30°: +60° C

Inflammability self-extinguishing

The electrical line is with support hangers and joint, feeder box and enclosure box.

OMIS supply of the electrical line terminates with the feeder box.

Cable and master switch are excluded from the supply. Line

length 150 m.

N. 1 current collector trolley, 35 A each, for ATOLLO conductor system supplied with shock absorbing turner arms.

Expansion joints for electrical feeding line(z0786).

Price/ meter 950 EGP

Rail 50mmx50mm / mt

Price/ meter 600 EGP

KIT description

• Electrical cabinet including sockets

• Pendant push button station inclusive of cable and connector

• Trolley Festoon cable inclusive of cable trolleys and connectors for electrical cabinet and hoist trolley

• Push button station Festoon cable inclusive of cable trolleys and connectors for electrical cabinet and push button

station

• LT limit switches including a 6 m cable

• LT motor cables

• Photoelectrical anti-collision devices with reflectors, a 6 m cable and accessories for installation purposes (only if

applicable)

• Electrical system wiring

• Completely wired hoist trolley / open barrel hoist trolley

• Painted trolley inclusive of anti-derail brackets and gearbox (disconnected)

• Unpainted End-Carriages and relevant gearboxes (disconnected)

• Track systems for push-button station and crab unit (omega channels or I-beam, bearings, couplings stops, etc.)

• Track system supports and relevant U channels (to be welded on the bridge beam) and bolting

• Packaging for electromechanical parts

• Bridge Beams construction Drawings

It is the buyer’s responsibility to undertake a state-of-the-art workmanship in order to assemble properly, paint, wire and test

OMIS kit together with the parts that he will manufacture.

Along with the crane supply, the standard OMIS digital documentation will be given:

Documentation and CE certificate, use and maintenance manual, installation instructions and electric schemes.

The supply will comply with the Community Directive 2006/42/EC and will marked with the CE symbol.

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 4 di 8

OMIS reserve the right to enhance the technical characteristics of the above described machinery in the design stage,

though in respect of the performance as described in this offer.

TOTAL AMOUNT OF

SUPPLY For Kit &

EGP 590.000,00

Girder Only

TERMS OF SALES DESCRIPTION PRICE

120 days from accounting and technical clearance (i.e. receipt of

LEAD TIME down payment and/or L/C, building measurements, etc.)

DELIVERY To Site – factory is Suez

VALIDITY 10 days

25% down payment in advance – 65% balance at notice of goods ready

PAYMENT for delivery 10% after inspection and test

PRICES VAT excluded

PACKAGING Included in the price if standard included

INSTALLATION Included

COMMISSIONING It is carried out in no-load conditions in our workshop before delivery. The

client must take care of commissioning as prescribed in the relevant

chapter in our “Installation, use and maintenance manual” delivered along

with the machine.

After commissioning, the client must fill out the “Crane Commissioning / Acceptance form”,

which has to be sent to the supplier.

Failure to carry out the commissioning of the crane after installation, for

reasons beyond OMIS responsibilities, shall in no way affect payment of

the supply.

WARRANTY OMIS guarantee to replace, for a period of 12 months from delivery, all parts that may

break down as a consequence of material or workmanship defects. Disassembly,

reassembly and shipment of these parts are at customer’s charge.

In case, at your charge:

- hours of travel of our technicians

- mileage reimbursement if destination is reached with our service van

- round-trip air tickets, if applicable

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 5 di 8

- local transportation of our technicians

- visas, if necessary

- board and lodging

- telescopic aerial work platform

- standard set of tools (spanners, screw drivers, etc...)

- shipments costs of material (both ways)

The replacement of the parts does not imply the renewal of the warranty period for the entire

machine, unless the entire machine is replaced.

The manufacturer is thereby relieved of any obligation to pay any sort of compensation,

while the buyer waives any claim for expenses or damage even due to any machine

downtime.

Warranty does not include any parts accidentally damaged during transportation, goods

mishandling or wrong connection to the power supply, if such operations are at customer’s

charge.

Warranty does not include break downs due to lack of maintenance, improper use or

modifications carried out without our authorization. Parts subject to normal wear and tear

and to unforeseen weather elements are not included in the warranty either.

The warranty is subject to the correct execution of the maintenance operation as described

in the relevant Use and Maintenance manual delivered along with the machine.

The warranty will not be in force if the terms of payment are not abided by.

For all components supplied by third parties, the warranty in force is the warranty of these

suppliers.

Any legal disputes will be held in the Court of Vicenza.

AT CUSTOMER’S

CHARGE

1. checking the suitability of the required supporting structures (pillars or walls) according to the actions and reactions

connected with the use of the crane, as indicated in the attached drawing.

2. checking the suitability of the structure when the crane is installed together with an existing one.

3. installing and checking the suitability of the crane-ways and relative areas of manoeuvre (if not included in the supply).

4. checking the auxiliary and wall anchors and the crane-ways.

5. checking correct assembly of the crane-ways (where applicable).

6. checking the suitability and correct operation of the electrical system: power line, socket, distribution panel and

padlockable overload cut-out which must able to interrupt short circuit current (IEC 64-8 attachment D); checking the

phase, cross-section, power and length of the power cable and of the earthing system according to DPR 547 of 27/4/1955

and CEI - EN 60204-1 standards.

7. if a differential circuit breaker is used and an electronically-controlled operating system is installed on the crane, the

differential cut-out threshold I must not be less than 0.5 A.

8. the cross-section of the power cable is determined according to the following parameters:

- maximum current absorbed by the crane motors (indicated on the data plate attached to the electrical panel) -

line input voltage +/- 10% - length of power line

9. installing suitable signs, compliant with ISO 7000 standards, warning people that operations with a moving crane are

being performed.

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 6 di 8

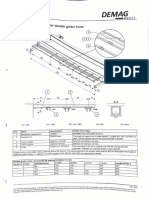

Pv = Max vertical Loads = 42 kN A= 140 mm F= 1150 mm

OMIS

Pv = Min. Vertical Loads = 14 kN B = 560 mm H= 340 mm

Transversal Load motions = 4,2 kN B1 = 1250 mm I = 3150 mm

Longitudinal Load motions = 6 C= 1180 mm L= 3650 mm

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 7 di 8

Height of lifting = 6,6 kN D= 1060 mm T= 360 mm

Span = 17500 mt. D1 = 1190 mm Ø= 100 mm All. prv.

TECHNICAL DATA AND DRAWING S REFER mm Loa d = 5 t hr =

SSQ2019338A

210 mm ENCE

OMIS S.p.a. _Offer SSQ2019338A _ 10/09/2019 ST Pag. 8 di 8

You might also like

- Gexol PDFDocument36 pagesGexol PDFJNo ratings yet

- CSIcodes PDFDocument5 pagesCSIcodes PDFksathsaraNo ratings yet

- Oracle eAMDocument92 pagesOracle eAMsri0403809235100% (2)

- Capital Costing 2015-16Document120 pagesCapital Costing 2015-16hazimraadNo ratings yet

- Caterpillar Cat Lift Trucks Spec Bb1766 DUNCAN FUND CENTRODocument14 pagesCaterpillar Cat Lift Trucks Spec Bb1766 DUNCAN FUND CENTROrichard cardenasNo ratings yet

- CARE Industries - InventoriesDocument57 pagesCARE Industries - Inventoriesmedidas012100% (1)

- Technology of Middle AgesDocument25 pagesTechnology of Middle AgesMarlon Joshua PacturanNo ratings yet

- Fibertech Exhibt E-1 Time WarnerDocument7 pagesFibertech Exhibt E-1 Time WarnerCarlosNo ratings yet

- 36777Document698 pages36777rapeterNo ratings yet

- Product 4Document2 pagesProduct 4Cristián Torres JaraNo ratings yet

- SWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhDocument21 pagesSWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhEmir MujićNo ratings yet

- 2013 Wright Specifications CatalogDocument189 pages2013 Wright Specifications CatalogcenicercNo ratings yet

- D475a 5eo PDFDocument209 pagesD475a 5eo PDFWill FrontNo ratings yet

- Overhead Crane CLPDocument5 pagesOverhead Crane CLPmarvin100% (1)

- Jsa For Air Flushin Amp Mech Cleaning of Pipes PDF FreeDocument17 pagesJsa For Air Flushin Amp Mech Cleaning of Pipes PDF FreeAbdullah FazilNo ratings yet

- Offshore StructuresDocument24 pagesOffshore StructuresSaaiyogeshNo ratings yet

- Gantrail Technical Datasheets Catalogue 0319Document76 pagesGantrail Technical Datasheets Catalogue 0319Nebojsa MomcilovicNo ratings yet

- SPACE 3000 Service Manual-GBDocument0 pagesSPACE 3000 Service Manual-GBAndrei Bleoju93% (14)

- BSI - Erection ManualDocument55 pagesBSI - Erection ManualRicardo Jesus Mallma CubasNo ratings yet

- Spare Part Catalogue For Hoist: SX50410100P55FEDOFDocument19 pagesSpare Part Catalogue For Hoist: SX50410100P55FEDOFjorgemegok1860No ratings yet

- IMIA WGP 09115 CCPP Combined Cycle Power PlantsFinal 1 PDFDocument44 pagesIMIA WGP 09115 CCPP Combined Cycle Power PlantsFinal 1 PDFBikash Kr. Agarwal100% (1)

- Rigging View Modular Overland ConveyorDocument84 pagesRigging View Modular Overland Conveyorrtyuibnm100% (2)

- Spare Parts List: Demag DH 200 Rope Hoist From 1.6.1997Document80 pagesSpare Parts List: Demag DH 200 Rope Hoist From 1.6.1997André PanezzaNo ratings yet

- Alignment of CouplingDocument24 pagesAlignment of Couplinger_sanjaypatelNo ratings yet

- Wire Rope Exchange June 2011Document72 pagesWire Rope Exchange June 2011Melissa HoodNo ratings yet

- Component Parts List: Demag Chain Hoist DKUN 10Document44 pagesComponent Parts List: Demag Chain Hoist DKUN 10Rafael LimónNo ratings yet

- GTS 2Document730 pagesGTS 2Aveek SenguptaNo ratings yet

- Application Guidelines: RF Belt Scale Application ManualDocument9 pagesApplication Guidelines: RF Belt Scale Application ManualBerada Otomasyon100% (1)

- GADocument72 pagesGABang OchimNo ratings yet

- CM Heavy-Duty Crane Hooks BrochureDocument12 pagesCM Heavy-Duty Crane Hooks BrochureMomchil Pekov100% (1)

- Variable Speed Electric Chain Hoist: Operating, Maintenance & Parts ManualDocument68 pagesVariable Speed Electric Chain Hoist: Operating, Maintenance & Parts ManualScottNo ratings yet

- ER2 Owners ManualDocument164 pagesER2 Owners ManualKito Canada100% (5)

- ABB Mine Hoist Systems FinalDocument4 pagesABB Mine Hoist Systems FinalGmyss UnoNo ratings yet

- Energy Storage Report 2024Document48 pagesEnergy Storage Report 2024EminNo ratings yet

- Adobe Scan 18 Jul 2021Document24 pagesAdobe Scan 18 Jul 2021Ismuliono INo ratings yet

- Quote: Thank You For Your Business!Document1 pageQuote: Thank You For Your Business!San DhuNo ratings yet

- Quotation 15: Quote To: Ensign SurveillanceDocument1 pageQuotation 15: Quote To: Ensign Surveillanceensign surveillance cctvNo ratings yet

- Guide Tech Potences EngDocument42 pagesGuide Tech Potences EngflasnicugNo ratings yet

- 2008 May Transtank Estimators GuideDocument27 pages2008 May Transtank Estimators GuideNevTNo ratings yet

- Es 14 403 20Document28 pagesEs 14 403 20malawanyNo ratings yet

- Yale - Hoist - Global - King - 5 - To - 15 - Ton - Manual V2 PDFDocument56 pagesYale - Hoist - Global - King - 5 - To - 15 - Ton - Manual V2 PDFJulValdiNo ratings yet

- Kalmar DCG180-330 Forklift Brochure EN-USDocument11 pagesKalmar DCG180-330 Forklift Brochure EN-USPercy Flores Morales0% (1)

- Sansui Digital Weighbridge DetailsDocument11 pagesSansui Digital Weighbridge DetailsShreepad ChandolkarNo ratings yet

- Weighbridge Formats PDFDocument16 pagesWeighbridge Formats PDFEdhz AmbalesNo ratings yet

- Gearless Drives For Medium-Power Belt Conveyors: MotionDocument6 pagesGearless Drives For Medium-Power Belt Conveyors: MotionchalogdNo ratings yet

- KAT7100-0002-E Product Overview Motor Driven ReelsDocument28 pagesKAT7100-0002-E Product Overview Motor Driven ReelsAleksas StoknaNo ratings yet

- Weidmuller - Connectpower DCDC Converter Flyer - LIT1605 - v4 PDFDocument2 pagesWeidmuller - Connectpower DCDC Converter Flyer - LIT1605 - v4 PDFeuqehtbNo ratings yet

- Catalogo Hadef Product OverviewDocument47 pagesCatalogo Hadef Product OverviewPedro MoralesNo ratings yet

- Winch Gearboxes GPT-W enDocument16 pagesWinch Gearboxes GPT-W enPaulNo ratings yet

- BUDGIT Electric Hoists and Trolley BrochureDocument16 pagesBUDGIT Electric Hoists and Trolley BrochureJogi Oscar SinagaNo ratings yet

- Winch Machine Power Operated PDFDocument2 pagesWinch Machine Power Operated PDFSujoy BanikNo ratings yet

- Compact and Fast The New Demag DR Rope Hoist: More Efficiency For Cranes With Capacities Up To 10 TDocument12 pagesCompact and Fast The New Demag DR Rope Hoist: More Efficiency For Cranes With Capacities Up To 10 Tadijuniarko100% (1)

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- Hz30477 Machu Picchu Smt2022 - LiftDocument2 pagesHz30477 Machu Picchu Smt2022 - LiftAbel Valderrama PerezNo ratings yet

- Price List 2022Document172 pagesPrice List 2022Ravindra SinghNo ratings yet

- Price Format 'A' (Main Equipment) For Wagon Tippler, Crushing and Conveying Plant Package For NTPC Vindhyachal STPP Stage III (2 X500 MW)Document4 pagesPrice Format 'A' (Main Equipment) For Wagon Tippler, Crushing and Conveying Plant Package For NTPC Vindhyachal STPP Stage III (2 X500 MW)istyloankurNo ratings yet

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLONo ratings yet

- BDA40804 Integrated Engineering Design: Proposal: Portable 20 Litre Bottle Automatic Cleaning MachineDocument5 pagesBDA40804 Integrated Engineering Design: Proposal: Portable 20 Litre Bottle Automatic Cleaning MachineRaffiq RosliNo ratings yet

- MORS Relais Brochure-Railway-Relays-V1-4 PDFDocument190 pagesMORS Relais Brochure-Railway-Relays-V1-4 PDFclementNo ratings yet

- Field Service ReportDocument1 pageField Service Reportpurnama dewiNo ratings yet

- Access BrochureDocument39 pagesAccess BrochureAdriel NardoNo ratings yet

- Auma MaticDocument60 pagesAuma Maticapi-3727411No ratings yet

- Hoist DataDocument21 pagesHoist DataVictor OleasNo ratings yet

- Automatic Material Handling With Conveyor Modular From Impel Intralogistics - Rajkot (Gujarat) IndiaDocument23 pagesAutomatic Material Handling With Conveyor Modular From Impel Intralogistics - Rajkot (Gujarat) IndiaImpel IntralogisticsNo ratings yet

- 3463c enDocument85 pages3463c enberkahharianNo ratings yet

- BNS Cam SwitchesDocument36 pagesBNS Cam Switchess_barriosNo ratings yet

- 1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceDocument11 pages1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceIstiQamahh MuhamadNo ratings yet

- Tech 123Document78 pagesTech 123unnikrishnanNo ratings yet

- DC Pro Chain Hoist Tech DataDocument24 pagesDC Pro Chain Hoist Tech DataIvan BaracNo ratings yet

- Apollo 10 TDocument60 pagesApollo 10 TXavyer MoralesNo ratings yet

- Caddy Mig C200i: Portable MIG/MAG Welding Unit With Built-In Wire Feeder For Ø200 MM SpoolsDocument2 pagesCaddy Mig C200i: Portable MIG/MAG Welding Unit With Built-In Wire Feeder For Ø200 MM SpoolsDjordjeNo ratings yet

- Alwasy Step Ahead in TechnologyDocument4 pagesAlwasy Step Ahead in TechnologyDxFxNo ratings yet

- 24 - 1 Core LT XLPE CableDocument9 pages24 - 1 Core LT XLPE CabledrravijainNo ratings yet

- ZCC1300 0712Document10 pagesZCC1300 0712SabahNo ratings yet

- SWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Document8 pagesSWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Md Shahbaz AlamNo ratings yet

- Igo50 Self Erecting Tower Cranes Product Guide - Compass EquipmentDocument16 pagesIgo50 Self Erecting Tower Cranes Product Guide - Compass EquipmentCompass equipmentNo ratings yet

- TSA 005 Rev 0 General LiftingDocument5 pagesTSA 005 Rev 0 General LiftingMusadiq HussainNo ratings yet

- SP Palu Utama Rev. 1 PDFDocument4 pagesSP Palu Utama Rev. 1 PDFArifNo ratings yet

- Accident Report - Cargo Gear FailureDocument19 pagesAccident Report - Cargo Gear FailureSanto IskandarNo ratings yet

- 60019-PLN-H020000-HS-000008 (4) - Lifting Operations Management PlanDocument18 pages60019-PLN-H020000-HS-000008 (4) - Lifting Operations Management PlanbesongNo ratings yet

- Probst Handling Equipment Catálogo - Geral - CompletoDocument240 pagesProbst Handling Equipment Catálogo - Geral - CompletoManuel AlejandroNo ratings yet

- TV 20 2013 1 59 64 PDFDocument6 pagesTV 20 2013 1 59 64 PDFEduardo Caldas da RochaNo ratings yet

- Company Profile PDFDocument9 pagesCompany Profile PDFSamir WalunjNo ratings yet

- Vessel PortfolioDocument19 pagesVessel PortfolioJina DevNo ratings yet

- Re08026 2008-09 PDFDocument6 pagesRe08026 2008-09 PDFbrunosamaeianNo ratings yet

- Internship Master Thesis: MSC of General Management (Fet) 2020-2021Document43 pagesInternship Master Thesis: MSC of General Management (Fet) 2020-2021AhmadNo ratings yet

- Liftman IndiaDocument12 pagesLiftman IndiaChandrashekhar NehateNo ratings yet

- Sample Co. Profile - Crane - SupplierDocument17 pagesSample Co. Profile - Crane - Suppliermyke_0101No ratings yet

- Hyundai R210-7 Specifications Machine - Market192327 PDFDocument11 pagesHyundai R210-7 Specifications Machine - Market192327 PDFAldhi BrajamustiNo ratings yet

- M & M H D 32474: Technical Procurement Specification Achinery Aterial Andling Epartment Project NoDocument57 pagesM & M H D 32474: Technical Procurement Specification Achinery Aterial Andling Epartment Project Nocandra trisilawatiNo ratings yet