Professional Documents

Culture Documents

Ability Check Sheet Ravindra

Ability Check Sheet Ravindra

Uploaded by

ravindra191274Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ability Check Sheet Ravindra

Ability Check Sheet Ravindra

Uploaded by

ravindra191274Copyright:

Available Formats

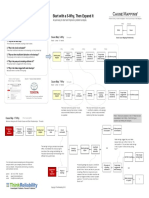

Ability check sheet: Leadership (development of staffs) 1/10

Plant: Section: Job title: Years of employment: Name: Missionary:

Do not know Know, but no experience Have experiences. Can instruct. Can make the system. Evaluation

Level 3 Level 4 Level 5

Sort No. Check point Purpose Level 1 Level 2

(TL) Initiate missionary (SL) Apprentice missionary (excellent SL) Missionary

Self Judge

Do not instruct Find out necessary

Instruct associates (OJT) Instruct associates about knowledge/skills at each work site

Formalize necessary tacit

1-1 Work instruction To hand down skills to associates associates acout working

following manuals.

feeling or knack work which and make a system for better understanding (feeling, 4

methods. is not indicated on manuals. training. knack).

Follow up the plans and

Development of skilled To develop associates (operators) Do not know what the Follow up the plans and

1-2

associates according to plans skilled associate is.

Just know (no experience). Make plans for the training.

deal with troubles.

instruct associates how to 2

deal with troubles.

Follow up the plans and

To raise the level of associates Do not know the contents of Know about it, but never Follow up the plans and

1-3 Education, qualifying plan

following training plans education and qualification. use.

Make plans for the training.

deal with troubles.

instruct associates how to 1

deal with troubles.

Do not have unified Make manuals to receive

To improve the work learning level of Follow the training, using

1-4 Training of new associates

new associates

Do not train new associates. Just know (no experience). instruction methods, but can

unified instruction cards.

new associates on each 1

Leadership instruct new associates. work site.

Instruct associates about

To have knowledge about Do not know about Know names of Know about roles and Know important points of

(Developmen 1-5 Knowledge about products

manufacturing products products. products(parts). functions of products. product quality.

important points of product 2

t of staffs) quality.

Principle of job site & actual To check actual things at the actual Know the meaning, but Find out causes at the Seek real causes and take

1-6

article work site and see the fact

Do not know the meaning.

never use. actual site. right action.

Make know-how manuals. 2

Know that information

Share necessary Make a system for

sharing is important Hold a morning meeting

1-7 Information sharing To communicate with people well Do not know the importance.

(Report, Inform, Consult, and share information.

information with related information sharing (e.g. 2

sections. morning meeting).

etc.).

To learn how to solve problems and Do not know about QC Know about it, but cannot Instruct associates how to

1-8 QC circle activity

importance of teamwork circle activity. conduct for real.

Be a leader of QC circle.

solve problems.

Make plans for activation. 2

Instruct associates Educate associates and

Do not know the Explain associates about Promote and fix 5S

1-9 5-S activity To understand basic works

meaning. each activity.

depending on each make training materials for

activity (e.g. 5S patrol) 2

situation. 5S.

Instruct associates about

Know visialized items and Implement the

1-10 Visualization To visualize the current situation Do not know. Know.

the purpose. visualization.

the importance of 2

visualization.

Promote specific

All associates participate in Make plans to improve

1-11

KAIZEN activities.

To make work sites active Do not know. Know. activities (e.g. Post-it

the participating rate.

Show specific activities. 2

activity).

Set individual targets

See individual targets Gain cooperations from

considering work sites'

1-12 Target control To achieve targets Do not know the targets. Know the targets.

targets and promote

and give associates related sections and 2

some advice. achieve targets.

activities.

Average 2.0

Comment (strong points) Comment (weak points)

1)Ability to make Work instruction 1)Never use the PDCA for development of associates

2)Know the name of the parts 2)Individual target on line never made

Ability check sheet: Quality 2/10

Plant: Section: Job title: Years of employment: Name: Missionary:

Do not know Know, but no experience Have experiences. Can instruct. Can make the system. Evaluation

Level 3 Level 4 Level 5

Sort No. Check point Purpose Level 1 Level 2

(TL) Initiate missionary (SL) Apprentice missionary (excellent SL) Missionary

Self Judge

Prepare check sheets which

Previous preparation for new To understand changing and important Find out problematic Review manuals and

2-1

products points of products

Do not know. Know, but no experience

points on the trial. maintain jigs.

check the workmanship 2

before L/O.

olumC

nS Stratify defects and Conduct

To seek out causes of defects and Make problem solving

2-2 Countermeasures for defects

conduct countermeasures Colum Do not know. Know. promote countermeasures

manuals. 3

nT countermeasures. involving related sections.

Do not know about the Grasp the tendency and

To prevent occurrence of defects, control charts (center point Calculate the control limit Take appropriate actions for Instruct associates about

2-3 Control chart

using control charts control, control limit line, line and Cpk.

troubles on the control deal with the matter

the control charts. 2

charts. beforehand.

etc.)

Check the accuracy at

Know about daily check

Make necessary check regular intervals Instruct associates about

2-4 Measuring tool control To assure accuracy of the tools Do not know. and accuracy assuring

manuals. (including requests ot gauge R&R. 3

Quality label.

other sections).

Make manuals receiving Make working manuals Show problematic points Make the know-how clear

2-5 Working manual To unify working procedures Do not make manuals.

advice. and instruct associates. on manuals. and teach skills. 3

Judge OK/NG of

Understand simple Assemble products Teach associates how to

2-6 Reading of product drawings To make products following drawings Do not know. products from the 2

0

drawings. seeing the drawing. read drawings.

drawings.

Explain changing points Check changing points Make a system that

2-7 Design change/ Process change To stratify new and old products Do not know. Know.

to associates. and judge OK/NG. prevents re-occurrence. 3

To share information each other by Use 5M1E changing Instruct how to deal with Make a system that

2-8 Control of 5M1E changing points

visualization

Do not know. Know.

control board. changing points. controls changing points. 2

To understand a definition and control Know the meanings of Know about the relevant Know the designated and

2-9 Critical control designated products

methods

Do not know the purpose. Know the purpose.

indications. products. releasing rule. 2

Do not know the control Deal with defects Suggest specific ideas for

2-10 POKAYOKE control To assure the accuracy

rule.

Know the control rule. Make check sheets.

appropriately. necessary POKAYOKE. 3

Show assurance items in Evaluate the level Promote assurance level-up

Do not know about SQA own section (reflect them

2-11 SQA (PQA) To raise the assurance level

(PQA).

Know about SQA (PQA). on manuals, instruct

(occurrence/non- activity (KAIZEN of 3

detection). POKAYOKE/work).

associates).

Average 2.5

Comment (strong points) Comment (weak points)

1) cannot assemble the product by drawing

1)Can use seven qc tools for resolving problems 2) Never made SQA matrix

2)can make working manual

Ability check sheet: Cost (workability) 3/10

Plant: Section: Job title: Years of employment: Name: Missionary:

Do not know Know, but no experience Have experiences. Can instruct. Can make the system. Evaluation

Level 3 Level 4 Level 5

Sort No. Check point Purpose Level 1 Level 2

(TL) Initiate missionary (SL) Apprentice missionary (excellent SL) Missionary

Self Judge

0

Analyse differences

Colum

nS

Colum

nT

Control the production Suggest KAIZEN ideas to

3-1 Man-hour decreasing activity To improve the workability Do not know. Know.

amount.

between the plan and

achieve targets. 3

performance.

Instruct associates about

Suggest problems for line Make one by one

3-2 One by one production To visualize problematic points Do not know. Know. one by one production

making. production process. 2

method.

Instruct associates about

To make workloads on associates

3-3 Efficiency of formation

equal

Do not know. Know (can calculate). Make element charts. Even out the elements. the practical method and 2

Cost training.

Promote KAIZEN from

Make three standard

3-4 Standard work To find out troubles Do not know. Know. Make standards.

sheets

the three standard 1

(Workability) sheets.

Explain the sort and Improve MUDA Instruct associates how

3-5 7 MUDA To continue KAIZEN activities Do not know. Know.

definition of each MUDA. specifically. to decrease MUDA. 2

Analyse downtime Suggest KAIZEN ideas to

3-6 Improvement of operation rati To improve the workability Do not know. Know. Calcurate operation ratio.

causes. achieve targets. 4

Explain average work Instruct associates about

3-7 Working speed To make working loads equal Do not know. Know the concept.

speed "100".

Check working speed.

working speed. 1

Know how to use the Instruct associates about

3-8 Standard man-hour To improve the workability Do not know. Know. Know the setting rule.

standard man-hour. the process control. 1

Know how to use Instruct associates about Promote KAIZEN using

3-9 Use of ANDON To find out and deal with troubles quickl Do not know. Know.

ANDON. the use of ANDON. ANDON. 1

Understand factors which

Assign associates

3-10 Plan for man-power To arrange associates without MUDA Do not know. Know. Calculate man-power. affect manpower

appropriately. 1

planning.

Average 1.8

Comment (strong points) Comment (weak points)

1) Hrly production report displayed at shop floor for finding gaps 1)One by one not followed on line

2)line balancing not done to equal the work load

3)No work as per process sheet/work instruction

4)Cycle time standard not available

Ability check sheet: Delivery 4/10

Plant: Section: Job title: Years of employment: Name: Missionary:

Do not know Know, but no experience Have experiences. Can instruct. Can make the system. Evaluation

Level 3 Level 4 Level 5

Sort No. Check point Purpose Level 1 Level 2

(TL) Initiate missionary (SL) Apprentice missionary (excellent SL) Missionary

Self Judge

Deal with abnormal Instruct associates about

To see production delay/ progress by Set target amount per

4-1 Production amount check shee

the hour

Do not know. Know.

hour.

phenomenon the practical method and 3

appropriately. traning.

Know about the sorts and Explain flow of products Make a flow chart of Instruct associates about

4-2 KANBAN To prevent over-production Do not know.

function of KANBAN. and information. products and information. the practical method. 1

Know about the first-in, Improve the first-in, first- Know about fill-up Implement fill-up

4-3 Stock control To promote first-in and first-out Do not know.

first-out system. out system. production system. production. 2

Delivery

Know about sorts of Suggest KAIZEN ideas Instruct associates about

4-4 Logistics To make transportation more effective Do not know.

transportation.

Make purchase lists.

for logistics. KAIZEN of logistics. 1

To know production delay/ progress on Control the delay and Deal with the changes of Make trouble shooting

4-5 Production progress control

the day

Do not know. Know.

progress. production amount. manuals. 3

Instruct associates about

4-6 Lead time To reduce detention time Do not know. Know. See the leadtime. Improve the lead time.

KAIZEN of lead time. 1

Average 1.8

Comment (strong point) Comment (weak points)

1)Hrly production amount monitored 1)Do not know kanban

2)Know the first in first out 2)Donot know the effective system of logistics

3)No data of lead time

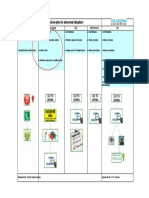

Ability check sheet: Safety 5/10

Plant:

Section: Job title: Years of employment: Name: Missionary:

Do not know Know, but no experience Have experiences. Can instruct. Can make the system. Evaluation

Level 3 Level 4 Level 5

Sort No. Check point Purpose Level 1 Level 2

(TL) Initiate missionary (SL) Apprentice missionary (excellent SL) Missionary

Self Judge

Instruct associates about Instruct associates about

Know about safety

5-1 Safety device To understand the sorts and fuctions Do not know.

devices at the work site.

the functions and check Check safety devices. the standard of safety 2

methods. devices (DAS).

Instruct associates about

5-2 3S activity To promote safe work Do not know. Know. Explain meanings of 3S.

3S activity.

Make a system to fix 3S. 2

Know about Heinrich's Suggest countermeasure Promote near-miss

5-3 Near-miss To make un-safe places clear Do not know. Know the word.

law. for near-miss. prevention activity. 3

Safety

Know about MSDS Instruct associates about

5-4 Handling of dangerous objectsTo keep the controlling condition Do not know. Know. Know the control rules.

system the control method. 1

Know about sorts and Indicate in the necessary

Understand the

5-5 Protective clothes To keep work safe Do not know.

importance.

roles of protective protective clothes for Make a system for fixing. 2

clothes. work.

Know about M/C safety

Make a system for safety

5-6 Safety check for new M/C To improve un-safe places Do not know. Know. standard (e.g. safety Check safety of M/C.

check. 2

gap).

Know about cooperative

Make manuals for

5-7 Safety work To prevent occurrence of troubles Do not know. Know. work and handling of

cooperative work.

Make a system for fixing. 2

heavy loads.

Make a system for boosting

Instruct associates about Deploy accident news to

5-8 Educational activity To boost awareness of safety Do not know. Know.

safety. other sections.

associates' awareness for 3

safety.

Average 2.1

Comment (strong points) Comment (weak points)

1)Know about heinrich law 1)No explanation given for meaning of 3S

2)Training provided for awareness of safety 2)Do not know the handling of dangerous objects

You might also like

- Global vs. Differentiated Models & Real and Ideal Self ConceptsDocument21 pagesGlobal vs. Differentiated Models & Real and Ideal Self ConceptsChristian Alegado66% (38)

- WCM Temple - Environtment PillarDocument2 pagesWCM Temple - Environtment PillarIswandi100% (2)

- ROBO TRAINING PowerPoint PresentationDocument56 pagesROBO TRAINING PowerPoint Presentationravindra191274No ratings yet

- KEY Adverbs - Types, Formation, Comparison PDFDocument3 pagesKEY Adverbs - Types, Formation, Comparison PDFEdward Castle50% (4)

- MEG-PRG-NISSAN-001-100 Rev 001-Automatic Inspection Machine PDFDocument18 pagesMEG-PRG-NISSAN-001-100 Rev 001-Automatic Inspection Machine PDFMerced HernandezNo ratings yet

- FMEA Facilitator Thought-Starter QuestionsDocument5 pagesFMEA Facilitator Thought-Starter QuestionsvikeshmNo ratings yet

- Colour Composition PDFDocument16 pagesColour Composition PDFCATIA V5 TutorialNo ratings yet

- Psychology Essay - Social LoafingDocument3 pagesPsychology Essay - Social LoafingRuhisha EeshaNo ratings yet

- Meat-Eating and Human EvolutionDocument383 pagesMeat-Eating and Human EvolutionAdrian100% (4)

- Kaizen - Esp02 221B4 DamperDocument4 pagesKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)No ratings yet

- Qad Wi - MPPLDocument22 pagesQad Wi - MPPLKaran Malhi100% (1)

- Final Report TPM PartDocument16 pagesFinal Report TPM PartNikita AwasthiNo ratings yet

- Kobetsu Kaizen: Maintenance ManagementDocument34 pagesKobetsu Kaizen: Maintenance ManagementMohammed Rushnaiwala100% (1)

- Process Check Hot ShopDocument12 pagesProcess Check Hot ShopSumeet RatheeNo ratings yet

- 01.SOP - Center BezelDocument2 pages01.SOP - Center BezelRS MANIKANDANNo ratings yet

- JH - Fugai Sheet of T1Document8 pagesJH - Fugai Sheet of T1Anonymous vcadX45TD7No ratings yet

- 5j GM1927 84 Drill Deep Worksheet 12 Oct 04Document2 pages5j GM1927 84 Drill Deep Worksheet 12 Oct 04jesusmemNo ratings yet

- Standard Work CombinationDocument1 pageStandard Work Combinationlam nguyenNo ratings yet

- 4 M Change LatestDocument8 pages4 M Change LatestVikas KashyapNo ratings yet

- Operator History Card 07.10.2020 SKILL EVALUATION JOINNING TIMEDocument96 pagesOperator History Card 07.10.2020 SKILL EVALUATION JOINNING TIMEPrakash kumarTripathiNo ratings yet

- Butterworth Feedmill SDN BHD: Toolbox Meeting RecordsDocument1 pageButterworth Feedmill SDN BHD: Toolbox Meeting RecordsNurul NatashaNo ratings yet

- 5 Why WeldingRobot ToyotaDocument1 page5 Why WeldingRobot ToyotaMickloSoberanNo ratings yet

- Variation and DefectsDocument16 pagesVariation and DefectssushmaxNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Defect MonitoringDocument18 pagesDefect MonitoringSanjayNo ratings yet

- Potential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Document4 pagesPotential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Mukesh YadavNo ratings yet

- Standard Reaction Plan To Abnormal Situation: Restart ProcessDocument1 pageStandard Reaction Plan To Abnormal Situation: Restart ProcessDeepak kumarNo ratings yet

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Document5 pagesFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Danistergladwin100% (1)

- FRM-WS-11 DWM Check Sheet (Weld SHP)Document2 pagesFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalNo ratings yet

- Equipment Name Theme Division TPM Pillar Pilllar Step Basic Work Minor Classification Classification No: Major ClassificationDocument1 pageEquipment Name Theme Division TPM Pillar Pilllar Step Basic Work Minor Classification Classification No: Major ClassificationGiö GdlNo ratings yet

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush Narang100% (1)

- SPC II EditionDocument63 pagesSPC II Editionshariq warsiNo ratings yet

- Multi SkillDocument6 pagesMulti SkillK.s. RameshNo ratings yet

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardDocument6 pagesChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsNo ratings yet

- Skill Matrix: 1 - Basic Trg. AcquiredDocument4 pagesSkill Matrix: 1 - Basic Trg. AcquiredDinesh KumarNo ratings yet

- Kaizen Road MapDocument13 pagesKaizen Road MapSudhakar Mars ConsultantsNo ratings yet

- 3.10.5 Shop Floor (Gemba) Examples of Walk Around and Dialogue ActivitiesDocument12 pages3.10.5 Shop Floor (Gemba) Examples of Walk Around and Dialogue ActivitieskearnjNo ratings yet

- Process: Process Control Chart Chart No'Document1 pageProcess: Process Control Chart Chart No'AngelikaNo ratings yet

- JH - Why-Why Training ModuleDocument24 pagesJH - Why-Why Training Moduleshariq warsiNo ratings yet

- Setup & Inprocess Inspection Report CaseDocument19 pagesSetup & Inprocess Inspection Report CaseMURALIDHRANo ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- Layered Process Audit Checklist (LPA)Document5 pagesLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONo ratings yet

- First Time Quality: SAP Course #: 62006505Document65 pagesFirst Time Quality: SAP Course #: 62006505MickloSoberanNo ratings yet

- BrainstormingDocument1 pageBrainstormingUng Kok AikNo ratings yet

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- 5A CAPA Best Practices (I) (MQ1)Document24 pages5A CAPA Best Practices (I) (MQ1)Chris GloverNo ratings yet

- Defect Matrix AutosavedDocument23 pagesDefect Matrix AutosavedVikas KashyapNo ratings yet

- Sae J4000Document6 pagesSae J4000Jorge Montforte0% (1)

- Autonomous Maintenance WebinarDocument37 pagesAutonomous Maintenance WebinarMadhavaKrishnaNo ratings yet

- SKILL MATRIX StaffDocument3 pagesSKILL MATRIX StaffMAHIPAL baseraNo ratings yet

- Breakdown Hrs FormatDocument3 pagesBreakdown Hrs FormatnishantNo ratings yet

- Formato 8DDocument2 pagesFormato 8DALEJANDRONo ratings yet

- Corporate Training AS 63Document32 pagesCorporate Training AS 63Anonymous 7yN43wjlNo ratings yet

- MTPDocument10 pagesMTPmurilocabriniNo ratings yet

- Bgl-Fm-Qa-10a Daily Rework RecordDocument1 pageBgl-Fm-Qa-10a Daily Rework RecordMohit SinghNo ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- Competence Format ExampleDocument10 pagesCompetence Format ExampleAbraham GutierrezNo ratings yet

- 4M Change Management PresentationDocument42 pages4M Change Management PresentationSARAI MARINNo ratings yet

- Process Flow Chart (PFC) : Write Down The Opposite of Product Characteristics As in PFCDocument4 pagesProcess Flow Chart (PFC) : Write Down The Opposite of Product Characteristics As in PFCakav123No ratings yet

- 3c Red Tag TemplateDocument1 page3c Red Tag TemplatehiteshcparmarNo ratings yet

- Bolded Text Indicates New To ISO 9001:2015 and IATF 16949:2016Document21 pagesBolded Text Indicates New To ISO 9001:2015 and IATF 16949:2016Ankur Dhir100% (1)

- Standard Operating ProcedureDocument4 pagesStandard Operating ProcedureJana VinayaNo ratings yet

- Why-Why AnalysisDocument20 pagesWhy-Why AnalysisVijay K SharmaNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- LHPL-FMT-09 Break Down Hrs Monitoring Chart MTTR & MTBFDocument6 pagesLHPL-FMT-09 Break Down Hrs Monitoring Chart MTTR & MTBFDevendra SinghNo ratings yet

- Activities To Be Implemented After Monozukuri Training Phase-IIIDocument1 pageActivities To Be Implemented After Monozukuri Training Phase-IIIravindra191274No ratings yet

- Development of Displaying 20 Basic Quality Rules at The Work Area and Recital Declaration To Abide - '03 Activity - Basic Rule Recital ActivityDocument23 pagesDevelopment of Displaying 20 Basic Quality Rules at The Work Area and Recital Declaration To Abide - '03 Activity - Basic Rule Recital Activityravindra1912740% (1)

- Customer Code Request Form Customer Code Request FormDocument1 pageCustomer Code Request Form Customer Code Request Formravindra191274No ratings yet

- Abnormality Item SheetDocument4 pagesAbnormality Item Sheetravindra191274No ratings yet

- Tolerancing: Interpreting, Specifying, Manufacturing & Measuring Various Dimensional TolerancesDocument45 pagesTolerancing: Interpreting, Specifying, Manufacturing & Measuring Various Dimensional Tolerancesravindra191274No ratings yet

- Robot Handelling TrainingDocument11 pagesRobot Handelling Trainingravindra191274No ratings yet

- 2.05.form Tolerances35Document35 pages2.05.form Tolerances35ravindra191274No ratings yet

- LPDCDocument34 pagesLPDCravindra191274No ratings yet

- Type of InclusionDocument58 pagesType of Inclusionravindra191274No ratings yet

- Defect Type in EnglishDocument9 pagesDefect Type in Englishravindra191274No ratings yet

- UBE 3.shot Hyd. Curcuit DiagramDocument3 pagesUBE 3.shot Hyd. Curcuit Diagramravindra191274No ratings yet

- The Theory of The Pressure Die Casting of Aluminium Alloys: Dilip Panjikar Consultant, PuneDocument27 pagesThe Theory of The Pressure Die Casting of Aluminium Alloys: Dilip Panjikar Consultant, Puneravindra191274No ratings yet

- Pdev Long Quiz 1Document3 pagesPdev Long Quiz 1Mark Allen Secondes67% (3)

- The Small Voice of HistoryDocument4 pagesThe Small Voice of Historyorient84100% (1)

- Sigmund FreudDocument2 pagesSigmund FreudHaifa KanapiaNo ratings yet

- Mahadasha of JupiterDocument6 pagesMahadasha of JupiterHarsh AroraNo ratings yet

- The Vienna School Beyond ViennaDocument3 pagesThe Vienna School Beyond ViennapedronijuancruzNo ratings yet

- Errant DaughterDocument193 pagesErrant DaughterPrat83% (23)

- Nature of LanguageDocument7 pagesNature of LanguageBerkah Hasudungan NasutionNo ratings yet

- Blooms Taxonomy Action Verbs PDFDocument1 pageBlooms Taxonomy Action Verbs PDFcalelohuNo ratings yet

- Scoring Rubrics For Cut-Out Picture On Connectors CSSDocument2 pagesScoring Rubrics For Cut-Out Picture On Connectors CSSVincent Librea100% (1)

- Research in Music Education RiME 2019Document4 pagesResearch in Music Education RiME 2019sound hourNo ratings yet

- Essence and Language: The Rupture in Merleau-Ponty's PhilosophyDocument9 pagesEssence and Language: The Rupture in Merleau-Ponty's PhilosophyJeffrey BussoliniNo ratings yet

- Developing Multiple Talents - SAMPLEDocument15 pagesDeveloping Multiple Talents - SAMPLEDouglas EbyNo ratings yet

- Bruce Lipton InterviewDocument28 pagesBruce Lipton InterviewDr Ron100% (2)

- Psychology Final Project PDFDocument12 pagesPsychology Final Project PDFapi-447026013No ratings yet

- Nominal: Research Section of The Introduction ModuleDocument2 pagesNominal: Research Section of The Introduction ModuleJustin CebrianNo ratings yet

- Article Response CHD 216Document1 pageArticle Response CHD 216api-252378804No ratings yet

- Displacing CastrationDocument27 pagesDisplacing Castrationamiller1987No ratings yet

- Remember The Titans MGT4020 Organization PDFDocument11 pagesRemember The Titans MGT4020 Organization PDFAnonymous OP6R1ZS0% (1)

- Critical Theory and Society-PPT-20Document20 pagesCritical Theory and Society-PPT-20Keith KnightNo ratings yet

- Mindanao State University General Santos City Graduate School ProgramDocument1 pageMindanao State University General Santos City Graduate School ProgramDee Phoi SunNo ratings yet

- Secure Base ChecklistDocument15 pagesSecure Base ChecklistSaul PsiqNo ratings yet

- Easy Logic Questions and Answers Tagalog: Read/DownloadDocument2 pagesEasy Logic Questions and Answers Tagalog: Read/DownloadErwin Condino100% (1)

- TM TEMPLATES With Guide 2019Document91 pagesTM TEMPLATES With Guide 2019Hershey EspañolNo ratings yet

- Evolution of OBDocument2 pagesEvolution of OBshanika100% (6)

- The Importance of Philippine HistoryDocument2 pagesThe Importance of Philippine HistoryMary Ann AntenorNo ratings yet