Professional Documents

Culture Documents

Cti

Uploaded by

Imthiyaz H0 ratings0% found this document useful (0 votes)

42 views5 pagesExchanger re-tubing technology

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentExchanger re-tubing technology

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views5 pagesCti

Uploaded by

Imthiyaz HExchanger re-tubing technology

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

re

k

UND EU ST Lob es

CONDENSER & HEAT EXCHANGER

RESTORATION SYSTEMS

www.cti-ind.com

CTI SHIELD/SEALS ™

‘The CTI Shield/Seal™ is a thin-walled metallic tube insert made of highly durable alloys, from copper-based

alloys to stainless steels to nickel-based alloys. They also include alloys for high-temperature service.

STOP THROWING YOUR MONEY DOWN THE TUBES!

The Shield/Seal™, besides repaiing tube-end

erosionicorrosion, will restore tube-to-tubesheot

hole integrity, permit proper mechanical tube

cleaning and in many cases restore leaking, plugged

tubes to full operation. “Shields” meet the strict

regulations ofthe nuclear power industry and the

United States Navy

‘Once expanded ~ either mechanically, hydraulically

or a hybrid of the two — the Shields then become

integral with the parent tubes. Because material and

installation are only a fraction of the cost, this

restoration technique saves precious repair dollars

versus retubing or bundle replacement. The thin-wall

construction, expansion and I.D. chamfer eliminate

the possibility of end-step erosion which has been

historically associated with other tube inserts.

Why replace the entire ube when only the first few inches need repair?

APPLICATIONS: 1A

Tube-end erosion 90/10 CuNi Monel

Stress Corrosion Cracking 70/30 CuNi Incoloy/Inconel

Crevice corrosion 300/400 series Hastelloy

Localized pitting & AL-6XN ‘Nickel 200

‘Ammonia grooving stainless stee! Titanium

Improper tube expansion Duplex 2205 Zirconium

Weakened tube-to-tubesheet joints plus many more!

‘Our track record speaks for itself. Since 1976, CTI has installed over 6 milion Shields throughout the world.

From condensers to air coolers to HP feedwater heaters, CT! has the answers that will SAVE YOU MONEY.

CTI FULL LENGTH TUBE LINERS ™

For those units that suffer from

full-length erosion/corrosion, pitting

and/or an overage of plugged tubes.

The CTI Full Length Tube Liner™ may

be a cost-effective solution to keep

your exchanger running at maximum

¢ capacity. “Liners” (thin-walled tubes)

are hydraulically expanded into existing

tubes, resulting in a full restoration.

TUBE CLEANING TUBE INSPECTION

* 3-ball micrometer

* Boroscopic

* Video fibreoptic

* Tube removal

* Cleaning services

* Cleaning brushes

* Cleaning kits

and accessories

COATINGS

RETUBING

In-situ or in 100% solids

our fully equipped polymeric

workshop epoxy

INTRODUCTION

CTI Industries is a service company that

specializes in the restoration of condensers

and_ heat exchangers.

CTI has been of service to the electric utility,

commercial marine, U.S. Navy, petroleum

refining, chemicals/petrochemicals production,

desalination, paper mill and fertilizer industries

in over 45 countries throughout the world.

Paco eit

In 1976, CTI developed a tube repair

technique that today is recognized as the

most widely used cost-effective system

in the world. The thin-walled tube insert —

the CTI SHIELD/SEAL™ — propelled our

success in offering cost-effective solu-

tions for equipment life extension.

The information herein describes our

turnkey “restoration systems”, which also

include Full Length Tube Liners™, inspec-

tions, retubing, coatings and cleaning.

CTI-NEW SOLUTIONS TO OLD PROBLEMS.

Don’t take our word for it......

“The first condenser which was sleeved was intended to be a short term five (5) year fix. These same

tubes are still in service after 22 years with no problems”

Bill Stroman

San Diego Gas & Electric

*...Il took four weeks to install all the inserts (Shield/Seals”) compared with an estimated 240 weeks to

partially retube 120 units. The cost comparison for partial retubing of the exchangers versus the actual

cost for using inserts was dramatic.”

Dave Kaiser

The Arabian Sun

(ARAMCO)

“After several years of technical research and numerous market surveys we have established that there

are only two means by which to repair condenser tubes reliably. The first method is to replace the tubes.

The alternate method of Shield/Seal"tepair has proven to be the most effective and technologically

sound means of not only repairing, but also significantly extending the service life of condensers.”

HEADQUARTERS

CTI Industries, Inc.

283 Indian River Road

Orange, CT 06477 USA

Phone: 203-795-0070

Fax: 203-795-7061

Email: ctius@cti-ind.com

Website: www.cti-ind.com

EUROPE/ASIA

CTI (G.B) Limited

4 Honister Dr.

Kendal, Cumbria LA9-7PD, UK

Phone: 44-1539-738-040

Fax: 44-1539-738-202

Email: kcox@cti-ind.com

J.J. D'Amato, Commanding Officer

NAVSURFLANT

United States Navy

USA WEST

CTI Industries, Inc.

2412 Torrejon Place

Carlsbad, CA 92009

Phone: 760-632-9117

Fax: 760-632-7691

Email: tquinn @cti-ind.com

MIDDLE EAST/AFRICA

CTI Gulf LLC

P.O. Box 62298

Dubai, UAE

Phone: 971-4-324-1296

Fax: 971-4-324-1869

Email: ctigulf @emirates.net.ae

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Flexitallic Flexpro Brochure 11-30-2017Document8 pagesFlexitallic Flexpro Brochure 11-30-2017Imthiyaz HNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- High Temperature Effects On Vessel IntegrityDocument33 pagesHigh Temperature Effects On Vessel IntegrityImthiyaz H100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

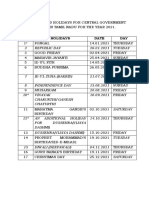

- SL - NO. Holidays Date DAYDocument2 pagesSL - NO. Holidays Date DAYImthiyaz HNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Skirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignDocument15 pagesSkirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignImthiyaz HNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)