Professional Documents

Culture Documents

The Comparing of The Selected Temperature Sensors Compatible With The Arduino Platform

Uploaded by

abhe prasetyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Comparing of The Selected Temperature Sensors Compatible With The Arduino Platform

Uploaded by

abhe prasetyaCopyright:

Available Formats

Management Systems

in 2018, Volume 26, Issue 3, pp. 168-171

Production Engineering

Date of submission of the article to the Editor: 03/2018

Date of acceptance of the article by the Editor: 08/2018

DOI 10.1515/mspe-2018-0027

THE COMPARING OF THE SELECTED TEMPERATURE SENSORS COMPATIBLE

WITH THE ARDUINO PLATFORM

Emil ŠKULTÉTY, Elena PIVARČIOVÁ*, Ladislav KARRACH

Technical University in Zvolen

Abstract:

One of the most frequently measured quantity is temperature, which is also one of the most important physical

quantities. Temperature has influence on the almost all states and processes in the nature as well as in tech-

nique. A wide range of temperature sensors is currently available on the market. They use different measure-

ment principles and exist in many designs. According to the location of the sensing element in the measured

environment, they are divided into two main groups: contact and non-contact. Further, we can divide the

temperature sensors according to the physical principle on which they work. The article deals with the analysis

and comparison of selected Arduino-compatible contact temperature sensors. The temperature measurement

of machine functional nodes and its diagnostics are part of maintenance and engineering diagnostics. At pre-

sent, NC and CNC machine diagnostics are an important trend in machine condition monitoring and machine

status prediction to maintain production quality. Machine status monitoring allows reducing of machine ser-

vice costs as well as maintaining the high production quality.

Key words: temperature, sensor, measurement, Arduino

INTRODUCTION object and by early detection of physical changes and pro-

The temperature is one of the most important thermody- cesses [7]. At the same time, temperature is the most

namic properties which determine the state of matter and common malfunctioning factor in measuring physical and

is presented in many physical laws. There are very few chemical quantities, so it is often necessary to compen-

properties of substances that are not temperature de- sate its influence on the measurement of the requested

pendent [1]. quantity, which requires temperature measurement [4].

For a quantitative description of different thermal states, Sensors with different physical principles are used for

it is necessary to assign the numerical values to them and temperature measurement. According to the principle

so define a temperature scale. Two scales were standard- they use, we can divide them into resistive, thermoelec-

ized to measure the temperature: the Kelvin and the Cel- tric, semiconductor, monocrystalline, thermistors, dilata-

sius temperature scale [2]. tion, optical, chemical etc. Furthermore, they are divided

The current level of progress is influenced by advanced in- into contact and non-contact sensors, according to

formation technologies [3]. In automation technique, the whether or not they have contact with the measured en-

temperature belongs to the most monitored quantities in vironment. Despite the increasing importance of non-con-

production and also non-production processes and the tact measuring methods, industrial temperature is meas-

quality and production cost of many products and services ured by contact methods [8].

often depend on its accuracy [4]. For example, the accu-

rate measurement of the temperature in metallurgy is es- METHODOLOGY OF RESEARCH

sential mainly due to the high quality requirements for There are available many types of sensors and devices on

casting products. Quality can be achieved only by strict the market for temperature measurement. It is not easy

compliance to the technological regulations, where to select the most appropriate equipment from such a

knowledge of temperature and other physical and chemi- wide variety. [9]. The sensors, which we have chosen for

cal properties of the melt play a major role [5]. comparison, comply with following conditions: they can

High reliability of technical systems is a prerequisite for be connected to Arduino platform, for processing the in-

their efficient use and safety [6]. Reliability as one of the formation from the sensors it is not necessary to program

key features of the quality of each technical device is sub- complicated programs and they don’t need several other

ject to effective monitoring of the technical state of the components and ICs for correct functioning. For example,

the resistance temperature sensor Pt100, which is used in

Unauthentifiziert | Heruntergeladen 22.10.19 07:38 UTC

E. ŠKULTÉTY, E. PIVARČIOVÁ, L. KARRACH – The comparing of the selected temperature sensors… 169

various applications, needs Wheatstone bridge circuit for humidity sensor. The difference between these sensors is

evaluation. Temperature can be measured using deflec- in measurement range, accuracy and communication in-

tion or compensation method. terface. The basic parameters are shown in Table 3.

On the base of above mentioned conditions we have se-

lected the sensors LM35DZ, DS18B20 and AM2320, which Table 3

are often used in applications based on Arduino platform Parameters of the AM2320

e.g. meteo stations, temperature control in the flat or the Temperature measurement range –40-80°C

intelligent greenhouse. Accuracy ±0.5°C

The reference temperature was verified using a universal Resolution 0.1°C

measuring instrument, ALMEMO 2590-4AS. The first sen- Humidity measurement range 0-99.9%

sor in comparison is LM35DZ. It is semiconductor temper- Accuracy ±3%

ature sensor with analog output. The temperature meas- Resolution 0.1%

urement with this sensor can be more accurate than the Supply Voltage 3.1-5.5 V

Communication interface I2C

measurement with thermistors [10]. The LM35 device is

rated to operate over a −55°C to 150°C temperature

range. The important advantage against the other sensors The data from thermal sensors are processed with help of

is that, the analog output is directly proportional to tem- Arduino UNO R3. The Microcontroller ATmega 328P rep-

perature in °C [11]. The basic parameters are shown in Ta- resents the basic part of it and it works on 16 MHz fre-

ble 1. quency. The microcontroller board contain 6 analog pins

and 14 digital input/output pins of which 6 can be used as

Table 1 PWM outputs. It contains also power supply pins +5 V,

Parameters of the LM35DZ +3.3 V and 3 GND pins. Board is powered through USB or

Temperature-Voltage scale factor +10 mV/°C using AC-to-DC adapter 7–16 V.

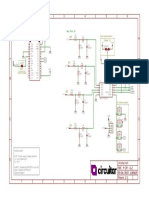

Measurement range –55-150°C The connection of sensors can be seen in Fig. 1. Sensor

Supply voltage 4-30 V LM35DZ has 3 pins. Pin Vcc is connected to pin +5 V, GND

Current drain 60 μA to ground and Vout to the analog input A0. For sensor

Self-heating 0.08°C DS18B20 was selected “parasite” mode. Pins Vcc and GND

Accuracy ±3/4°C of sensor are connected to ground pin of Arduino. Middle

Package TO – 92 pin DQ is connected to digital pin D4 and resistor 4k7 is

connected on one end to pin DQ of sensor and on other

The second sensor in comparing is DS18B20. This digital end to pin +5 V of Arduino. Sensor AM2320 has 4 pins. Pin

thermometer provides digital output and communicates Vcc is connected to pin +5 V and pin GND is connected to

over a 1-Wire bus that by definition requires only one data ground of Arduino. Pins SDA and SCL are connected to an-

line (and ground) for communication with a central micro- alog pins A4 and A5 of Arduino UNO, which are used for

processor. The DS18B20 has a unique 64-bit serial code, I2C communication on this programmable controller

which allows multiple DS18B20s to function on the same board. In wiring there is also included push-button with

1-Wire bus [12]. The analog-to-digital converter (ADC), 10 kΩ resistor. Button is connected to digital pin D5.

coupled to the temperature sensing unit, converts tem-

perature to 9-12 bit word. The measurement range of sen-

sor is from –55°C to 125°C [13]. In addition, sensor can

operate in normal or ”parasite” power supplying mode. It

means, that the DS18B20 can derive power directly from

the data line (“parasite power”), eliminating the need for

an external power supply. The basic parameters are

shown in Table 2.

Table 2

Parameters of the DS18B20

Operating Temperature Range –55-125°C

Fig. 1 Wiring scheme of sensors LM35DZ, DS18B20 and AM2320

Supply Voltage 3-5.5 V

Accuracy ±0.5°C

Programmable Resolution 9-12 bits The program for data reading from temperature sensors

Communication interface 1 – Wire was created in Arduino IDE 1.8.2. The program consists of

Pin-Package TO – 92 2 functions: function setup() and loop(). Function setup()

is executed once at program startup. In this function

The last one in comparing is sensor AM2320. This sensor speed of communication and pin setup is performed. Af-

contains beside thermometer also hygrometer. It com- ter function setup() is completed, the function loop() is ex-

municates via I2C interface. Temperature measurement ecuted in infinite loop. This function waits until push-but-

range is from –40°C to 80°C. The further similar sensors, ton is pressed. When push-button is pressed, ten values

which we can find in use, are sensors AM2302, DHT11,

DHT12. Those contain except a temperature sensor also a

Unauthentifiziert | Heruntergeladen 22.10.19 07:38 UTC

170 Management Systems in Production Engineering 2018, Volume 26, Issue 3

are read from temperature sensors. For efficient imple-

mentation of program there were used freely available li-

braries for sensors DS18B20 and AM2320.

In Fig. 2 there is block scheme of measuring workplace,

where we have tested accuracy of temperature sensors.

In experiment was used model of drying-plant at the de-

partment of institute. The model consists of a metal con-

struction that represents a model of a hot-air drying-plant

where temperature control is taking place. The spiral and

cooling fan are used as operational components. The con-

trol system is realized with help of programmable logic

controller (PLC) OMRON CP1L with touch panel [14]. Fig. 5 Course of the measured temperatures from the AM2320

Measurement was carried out by adjusting the tempera- sensor

ture from 25°C to 75°C stepwise, by step 5°C. At each step

10 measurements were made. The upper limit has been DISCUSSION

selected to prevent damage of the AM2320 sensor. The analyse of variance has shown, that sensors under-

rated the measured data. Sensor LM35DZ was the least

accurate. Using regression analysis for all sensors were as-

certained regression equations of linear regression mod-

els were ascertained relation between the real and meas-

ured temperature, which we obtained by sensors. We de-

termined the following parameters of regression equation

for sensor LM35DZ: a = 0.9725 and b = 1.177. In case of

sensor DS18B20 are parameters of regression equation: a

= 0.9985 and b = 0.1295. In case of sensor AM2320 the

Fig. 2 Block scheme of the measurement workplace parameters of regression equation were: a = 0.9956 and b

= 0.2327. The mathematical model of the sensors

RESULTS OF RESEARCH DS18B20 and AM2320 is closer to reality than in case of

The measured data were processed by Microsoft Excel sensor LM35DZ. The gradient of regression function of

2013. We analyzed the measured data and using the anal- sensors DS18B20 and AM2320 is closer to the value 1 and

ysis of variance we determined the basic statistical char- y-intercept constant is nearer to 0, than with sensor

acteristic. Then a regression analysis was performed. The LM35DZ.

results are shown in charts in Fig. 3-5. It is obvious from variance and regression analysis of the

measured data that sensors DS18B20 and AM2320 meas-

ure more accurate than sensor LM35DZ. For more precise

measurement the regular calibrating is necessary and also

using of further methods and approaches for increasing of

measurement accuracy.

Advantages of LM35DZ sensor are output voltage linearly-

proportional to the temperature and simple wiring. The

accuracy and speed of processing depends on the temper-

ature calculation formula in °C from the value we have got

from A/D converter. In case of DS18B20 sensor is the

measurement accuracy inversely proportional to the

time, which the sensor needs for A/D conversion. In com-

Fig. 3 Course of the measured temperatures from the LM35DZ parison to the LM35DZ sensor, the sensor communicates

sensor via the 1-Wire bus while supporting the “parasitic” mode.

The AM2320 sensor has a disadvantage of small measur-

ing range compared to the previous sensor. The ad-

vantage is that it contains, in addition to the thermometer

also a hygrometer and we can communicate with the I2C

bus. All examined sensors have their pros and cons. It is

up to the user, which of these sensors is the most suitable

for his application.

CONCLUSION

Temperature measuring and regulation is a dynamic field

of industrial automation. The sensors for temperature

measuring are produced in many sizes, shapes and preci-

Fig. 4 Course of the measured temperatures from the DS18B20 sions to fit requirements of specific tasks. Temperature

sensor

Unauthentifiziert | Heruntergeladen 22.10.19 07:38 UTC

E. ŠKULTÉTY, E. PIVARČIOVÁ, L. KARRACH – The comparing of the selected temperature sensors… 171

sensor must be periodically calibrated to provide accuracy 1 – Systémové pojetí automatizace. Brno: Computer

of measured data. The performance of individual parts of Press, 2012.

technological equipment could be optimised by calibrating [9] R. Strnad. “Měření teploty – porozumění vlastno-

with correct values of uncertainty and thereby make his op- stem měřicího přístroje”. Automa, vol. 15, no. 6, pp.

eration more effective [9]. 31-38, 2009.

The current trend in temperature sensors lies in wider use [10] S. Surya and S.S. Chauhan. “Water Level Indicator

of microelectronic technology e.g. in implementation of with Temperature Sensor”. IOSR Journal of Electrical

semiconductor temperature sensors on a single chip with and Electronics Engineering, vol. 10, no. 3, pp. 65-71,

analogue and digital circuits enabling the connection of 2015.

sensors to signal busses, in the development of new types [11] P.D. Patil and R.D. Patil. “Designing Multisensor Em-

of heat radiation detectors, in the integration of tempera- bedded System Using PSoC”. International Journal of

ture sensors into intelligent sensors for automatic correc- Current Advanced Research, vol. 8, no. 4, pp. 271-

tion of variations caused by temperature fluctuations [4]. 274, 2015.

Practical use of temperature measurement and tempera- [12] G. Gricius, D. Drungilas, A. Andziulis, D. Dzemydiene,

ture regulation is in manufacturing engineering in the field M. Voznak, M. Kurmis and S. Jakovlev. “Advanced

of maintenance and technical diagnostics. High demands Approach of Multiagent Based Buoy Communica-

on reliability and early fault diagnosis are placed on modern tion”. The Scientific World Journal, vol. 2015, 2015.

machining technology. Each CNC machine has a standard [13] H. Jing. “Design and Development of the Tempera-

operating diagnostics. The typical quantities, which are ture Detection System”. International Journal of

tracked, are engine winding temperatures and coolant Control and Automation, vol. 8, no. 2, pp. 409-416,

temperature. Measurement of temperature is important 2015.

for example in the diagnostics of electrical drives [15], con- [14] Ľ. Naščák and P. Koleda. “Regulácia teploty modelu

tact stress analysis [16], at determination of residual teplovzdušnej sušiarne programovateľným automa-

stresses [17], in vibration signals of machinery [18]. tom”. Acta facultatis technicae, vol. 1, pp. 127-133,

2014.

ACKNOWLEDGEMENTS [15] I.V. Abramov, A.I. Abramov, Z.R. Nikitin, E. Sosno-

This paper was prepared within the work on a research vich, P. Božek and V. Stollmann. “Diagnostics of Elec-

project KEGA 003TU Z-4/2016 “Research and education la- trical Drives”, in Proc. of International Conference on

boratory for robotics”, KEGA 001TU Z-4/2016 "Support Electrical Drives and Power Electronics, 2015, pp.

of Teaching for Heat and Mass Transfer in Technical Edu- 364-367.

cation" and VEGA 1/0086/18 “Researching Temperature [16] P. Frankovský, O. Ostertag, F. Trebuňa, E. Osterta-

Fields in a Set of Shaped Heat Transfer Surfaces”. gová and M. Kelemen. “Methodology of contact

stress analysis of gearwheel by means of experi-

REFERENCES mental photoelasticity”. Applied optics, vol. 55, no.

[1] M. Kreidl. Měření teploty – Senzory a měřící obvody. 18, pp. 4856-4864, 2016.

Praha: BEN – technická literatura, 2005. [17] K. Masláková, F. Trebuňa, P. Frankovský and

[2] P. Beneš, J. Chlebný, J. Král, J. Langer and M. Mar- M. Binda. ”Applications of the strain gauge – for de-

tinásková. Automatizace a automatizační technika 3 termination of residual stresses using ring-core

– Prostředky automatizační techniky. Brno: Compu- method”. Procedia Engineering, vol. 48, pp. 396-401,

ter Press, 2014. 2012.

[3] L. Chybowski, K. Gawdzińska and B. Wiśnicki. “Qual- [18] T. Stejskal, J. Kovac and S. Valencik. “Mechanism of

itative importance measures of systems components randomness in vibration signals of machinery”, in

– a new approach and its applications”. Manage- Proc. of International Conference on Industrial, Ser-

ment Systems in Production Engineering, vol. 24, no. vice and Humanoid Robotics, 2012, pp. 257-262.

4, pp. 237-246, 2016.

[4] J. Šturcel. Snímače a prevodníky. Bratislava: Vyda-

vateľstvo STU, 2002. Ing. Emil Škultéty

[5] P. Koleda, P. Koleda and S. Grúbel. “Analysis of tem- Assoc. Prof. Elena Pivarčiová, PhD.

peratures in the mould area during the process of Ing. Ladislav Karrach

engine cylinder heads casting”. Acta facultatis tech- Technical University in Zvolen

nicae, vol. 1, pp. 31-40, 2016. Faculty of Environmental and Manufacturing Technology

[6] S. Gierej. “Big data in the industry – overview of se- Department of Manufacturing and Automation Technology

lected issues”. Management Systems in Production Študentská 26, 960 53 Zvolen, Slovakia

Engineering, vol. 25, no. 4, pp. 251-254, 2017. e-mail: xskultetye@tuzvo.sk

[7] M. Kreidl and R. Šmíd. Technická diagnostika – Sen- pivarciova@tuzvo.sk (corresponding author)

zory, metody, analýza signálu. Praha: BEN – tech- karrach@zoznam.sk

nická literatura, 2006.

[8] P. Beneš, J. Janeček, J. Král, G. Künzel, B. Lacko, J. Se-

merád, P. Souček, L. Šmejkal, R. Voráček, L. Maixner

and B. Šulc. Automatizace a automatizační technika

Unauthentifiziert | Heruntergeladen 22.10.19 07:38 UTC

You might also like

- KJHTDocument15 pagesKJHTEngr Nayyer Nayyab MalikNo ratings yet

- Sensors 18 03445 PDFDocument23 pagesSensors 18 03445 PDFadfasfdafssafNo ratings yet

- Temperature Measurement of Dynamic ObjectDocument5 pagesTemperature Measurement of Dynamic Objectbelvinthomas8095No ratings yet

- Temperature Controller for Order-sorting Interference FiltersDocument22 pagesTemperature Controller for Order-sorting Interference FiltersMicu Adrian DanutNo ratings yet

- University of Engineering and Technology, TaxilaDocument20 pagesUniversity of Engineering and Technology, TaxilaAbdul RehmanNo ratings yet

- IJAEA Jan 2011 I 21Document6 pagesIJAEA Jan 2011 I 21Jitendra Singh MeenaNo ratings yet

- Noncontact-Body-Temperature-Measurement: Poster SessionDocument10 pagesNoncontact-Body-Temperature-Measurement: Poster SessionThanh Tin DangNo ratings yet

- CAT CP 1 (T) Calibration of RTDDocument4 pagesCAT CP 1 (T) Calibration of RTDAmar Singh100% (1)

- AIOT Assignment - Leo FrankDocument11 pagesAIOT Assignment - Leo FrankLeo FrankNo ratings yet

- Control & Instrumentation-1Document123 pagesControl & Instrumentation-1Ashish Vashisth100% (8)

- A Micocotroller Based Digital Thermometer With Timer DigithermoDocument10 pagesA Micocotroller Based Digital Thermometer With Timer DigithermoKarthik MohanNo ratings yet

- Industrial Temperature Controller GuideDocument17 pagesIndustrial Temperature Controller GuidePooja GNo ratings yet

- SynopsisDocument6 pagesSynopsisPooja GNo ratings yet

- Design AND Implementation OF A Digital Thermometer With ClockDocument10 pagesDesign AND Implementation OF A Digital Thermometer With ClockMuhammad Raza RafiqNo ratings yet

- AN3031Document18 pagesAN3031mfani12345No ratings yet

- RakeshDocument16 pagesRakeshchandhuNo ratings yet

- Microcontroller Based Real Time Weather Monitoring Device With GSMDocument5 pagesMicrocontroller Based Real Time Weather Monitoring Device With GSMshankiyaNo ratings yet

- RakeshDocument15 pagesRakeshchandhuNo ratings yet

- Group MechatronicsDocument13 pagesGroup MechatronicsSiddhi BambNo ratings yet

- Low-Cost Weather MonitoringDocument8 pagesLow-Cost Weather MonitoringRohit PatilNo ratings yet

- Implementation of A Broad Range Smart Temperature Measurement System Using An Auto-Selecting Multi-Sensor Core in LabviewDocument5 pagesImplementation of A Broad Range Smart Temperature Measurement System Using An Auto-Selecting Multi-Sensor Core in LabviewPonnalagu R NNo ratings yet

- Lab Manual 2022Document23 pagesLab Manual 2022Ashutosh ShuklaNo ratings yet

- An Engineer's Guide To Temperature Sensing: Temperature Sensor Design Challenges and SolutionsDocument59 pagesAn Engineer's Guide To Temperature Sensing: Temperature Sensor Design Challenges and SolutionsBrent De MesaNo ratings yet

- Control of Boiler Operation Using PLC - SCADADocument9 pagesControl of Boiler Operation Using PLC - SCADARoshan RaiNo ratings yet

- Irjet V7i5176Document3 pagesIrjet V7i5176sagarvivek kothapalliNo ratings yet

- Comparing Temperature Sensors Using an Embedded SystemDocument8 pagesComparing Temperature Sensors Using an Embedded SystemPG ElectronicsNo ratings yet

- Temperature Control and Data Acquisition Method For Factory Using LabviewDocument14 pagesTemperature Control and Data Acquisition Method For Factory Using LabviewIAEME PublicationNo ratings yet

- Automated Greenhouse Monitoring and Control System PDFDocument9 pagesAutomated Greenhouse Monitoring and Control System PDFSaiKrishna100% (2)

- I Jcs It 2012030324Document4 pagesI Jcs It 2012030324Muntasir AnwarNo ratings yet

- 5.2.6 Semiconductor Temperature Sensors - DSPEDocument3 pages5.2.6 Semiconductor Temperature Sensors - DSPEH HNo ratings yet

- Arduino Based Digital ThermometerDocument3 pagesArduino Based Digital ThermometerVanjelyn Roque50% (2)

- Department of Computer Science & EngineeringDocument10 pagesDepartment of Computer Science & EngineeringC191235 Sadia IslamNo ratings yet

- Act 4 InstrumentationDocument4 pagesAct 4 InstrumentationErvin MedranoNo ratings yet

- Jet Irc 006196Document6 pagesJet Irc 006196Issa BakariNo ratings yet

- Temperature and Humidity Sensor: IM Lab ProjectDocument4 pagesTemperature and Humidity Sensor: IM Lab ProjectFasih KhanNo ratings yet

- 1.ourside - Vip.automatic Temperature Control and Alert System Simulation and design.2207ELX019Document9 pages1.ourside - Vip.automatic Temperature Control and Alert System Simulation and design.2207ELX019ssNo ratings yet

- Process Instrumentation PrinciplesDocument66 pagesProcess Instrumentation PrinciplesnizamuddinNo ratings yet

- TemperatureDocument6 pagesTemperatureAngah SyafiqNo ratings yet

- Calibrating HVAC Control SystemsDocument5 pagesCalibrating HVAC Control SystemsThuan Vo ThanhNo ratings yet

- Computer Controlled Heat Conduction Unit, With SCADA and PID ControlDocument15 pagesComputer Controlled Heat Conduction Unit, With SCADA and PID Controlmohamadreza1368No ratings yet

- Temperature ControlDocument9 pagesTemperature ControlMauricio López NúñezNo ratings yet

- Digital Thermometer PDFDocument7 pagesDigital Thermometer PDFchessgeneralNo ratings yet

- Conformity Assessment in Infrared Ear Thermometer CalibrationDocument11 pagesConformity Assessment in Infrared Ear Thermometer CalibrationIJAR JOURNALNo ratings yet

- Control Systems For Heating, Ventilating Air Conditioning Systems: PredictionDocument4 pagesControl Systems For Heating, Ventilating Air Conditioning Systems: Predictioncool coolNo ratings yet

- Monitoring The Sht75 Relative Humidity Sensor Using An Atmel Family MicrocontrollerDocument12 pagesMonitoring The Sht75 Relative Humidity Sensor Using An Atmel Family MicrocontrollerZoran ConstantinescuNo ratings yet

- Sensor and TransducerDocument7 pagesSensor and TransducerjuniNo ratings yet

- Design and Simulation of Fan Speed ControlDocument5 pagesDesign and Simulation of Fan Speed ControlAro YeeNo ratings yet

- Automatic Temperature Control in Furnace Using PLCDocument19 pagesAutomatic Temperature Control in Furnace Using PLCAhammedali Ch0% (1)

- Digital Thermometer Using Arduino: Mini Project Report ONDocument5 pagesDigital Thermometer Using Arduino: Mini Project Report ONNeha PintoNo ratings yet

- Unit7-Piping Instruments1Document9 pagesUnit7-Piping Instruments1Marcel BaliñoNo ratings yet

- World's most energy efficient temperature sensor datasheetDocument7 pagesWorld's most energy efficient temperature sensor datasheetRachel RowlandNo ratings yet

- Control Loops IntroDocument4 pagesControl Loops IntroJohnNo ratings yet

- Royal University of Dhaka: Assignment OnDocument11 pagesRoyal University of Dhaka: Assignment OnAbid AhmedNo ratings yet

- Thermocouple Measurement DeviceDocument3 pagesThermocouple Measurement DeviceylmalaverNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Copeland Scroll Compressors Specifications AC Models Only PDFDocument32 pagesCopeland Scroll Compressors Specifications AC Models Only PDFabhe prasetyaNo ratings yet

- Accreditation Criteria FarmDocument5 pagesAccreditation Criteria Farmabhe prasetyaNo ratings yet

- Japanese Quail As A Laboratory Animal Model: Janet Baer, DVM, Rusty Lansford, PHD and Kimberly Cheng, PHDDocument24 pagesJapanese Quail As A Laboratory Animal Model: Janet Baer, DVM, Rusty Lansford, PHD and Kimberly Cheng, PHDabhe prasetyaNo ratings yet

- VentilationDocument9 pagesVentilationabhe prasetyaNo ratings yet

- WDC PDFDocument84 pagesWDC PDFabhe prasetyaNo ratings yet

- Qty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: DateDocument12 pagesQty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: Dateabhe prasetyaNo ratings yet

- Copeland Hermetic QR 2003 PDFDocument41 pagesCopeland Hermetic QR 2003 PDFabhe prasetyaNo ratings yet

- Fault Zone Analysis RotorDocument8 pagesFault Zone Analysis Rotorabhe prasetyaNo ratings yet

- Questions & Answers Handbook For in Small and Medium-Scale Poultry HatcheriesDocument92 pagesQuestions & Answers Handbook For in Small and Medium-Scale Poultry Hatcheriesabhe prasetyaNo ratings yet

- Thermo-Hygrometer-Air Quality: Data SheetDocument4 pagesThermo-Hygrometer-Air Quality: Data Sheetabhe prasetyaNo ratings yet

- Inline pump technical specificationDocument10 pagesInline pump technical specificationabhe prasetyaNo ratings yet

- Grundfos - CR 5 3 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 3 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Hatchery Practice: InternationalDocument40 pagesHatchery Practice: Internationalabhe prasetyaNo ratings yet

- CR, Cri, CRN: Installation and Operating InstructionsDocument78 pagesCR, Cri, CRN: Installation and Operating Instructionsahmed abdohNo ratings yet

- Qty. Description CR 4-100 A-A-A-AUUE: Company Name: Created By: Phone: DateDocument10 pagesQty. Description CR 4-100 A-A-A-AUUE: Company Name: Created By: Phone: Dateabhe prasetyaNo ratings yet

- FTang - Portable HD110 - 10 11 17 PDFDocument2 pagesFTang - Portable HD110 - 10 11 17 PDFabhe prasetyaNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- BST Bme280 DS002Document55 pagesBST Bme280 DS002abhe prasetyaNo ratings yet

- S-Line Incubator System for Single and Multi-Stage HatchingDocument5 pagesS-Line Incubator System for Single and Multi-Stage Hatchingabhe prasetyaNo ratings yet

- Effects of Egg Position in Artificial Incubation of Japanese Quail Eggs (Coturnix Japonica)Document5 pagesEffects of Egg Position in Artificial Incubation of Japanese Quail Eggs (Coturnix Japonica)abhe prasetyaNo ratings yet

- Electronic Controller With 2 Intervention PointsDocument28 pagesElectronic Controller With 2 Intervention Pointsabhe prasetyaNo ratings yet

- ADC 4-20 v1.2 EN PDFDocument1 pageADC 4-20 v1.2 EN PDFabhe prasetyaNo ratings yet

- Poultrysci86 1372Document8 pagesPoultrysci86 1372abhe prasetyaNo ratings yet

- PN RangeDocument12 pagesPN Rangeabhe prasetyaNo ratings yet

- S7300 Fail-Safe Modules eDocument236 pagesS7300 Fail-Safe Modules eBhayu alfianNo ratings yet

- Data Process Control 1653086088Document17 pagesData Process Control 1653086088Luzgardo MejíaNo ratings yet

- Training On RCM at Jakarta by Marcus EvansDocument4 pagesTraining On RCM at Jakarta by Marcus EvansJigarDhabaliaNo ratings yet

- Materi TIS11Document87 pagesMateri TIS11Firly FebrianNo ratings yet

- Opticline C200 C1000 EN 10026497 03 2009Document16 pagesOpticline C200 C1000 EN 10026497 03 2009Amit KumarNo ratings yet

- 06 Session PlanDocument9 pages06 Session Planjoy visitacionNo ratings yet

- Jicable19 67 VLF FinalDocument6 pagesJicable19 67 VLF FinalLucho RufoNo ratings yet

- 2008 Aprilia 750 Dorsoduro (Workshop Manual)Document305 pages2008 Aprilia 750 Dorsoduro (Workshop Manual)alexander ortizNo ratings yet

- Advance Numerical Mechanical SimulationDocument259 pagesAdvance Numerical Mechanical SimulationSankit SinghNo ratings yet

- User's ManualDocument25 pagesUser's ManualwulanluvspinkNo ratings yet

- Fan Failure Cause AnalysisDocument144 pagesFan Failure Cause AnalysisNarayanan Kharthi100% (1)

- Data Bug On Open Source For Predictive ArticulatesDocument16 pagesData Bug On Open Source For Predictive ArticulatesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Microwave Synthesis SolutionsDocument12 pagesMicrowave Synthesis SolutionsbekkuNo ratings yet

- Analysis of Reliability Parameters of Conveyor Bel PDFDocument7 pagesAnalysis of Reliability Parameters of Conveyor Bel PDFAndrewNo ratings yet

- Application of Genetic Algorithm For Reliability Allocation in Nuclear Power PlantsDocument10 pagesApplication of Genetic Algorithm For Reliability Allocation in Nuclear Power PlantsEric ChienNo ratings yet

- Assessing The Cost Effectiveness of NDE Methods in Civil StructuresDocument10 pagesAssessing The Cost Effectiveness of NDE Methods in Civil StructuresmyronhechtNo ratings yet

- Tent Steps To Avoid Unnecesary Plant ShutdownsDocument44 pagesTent Steps To Avoid Unnecesary Plant Shutdownsclnieto49No ratings yet

- BBSR Traffic Signal RFP - FinalDocument273 pagesBBSR Traffic Signal RFP - FinaladilNo ratings yet

- ADMS Guide - 2 11.2015 PDFDocument33 pagesADMS Guide - 2 11.2015 PDFBharat RajNo ratings yet

- Newsletter - More Flexibility and Lower CostsDocument16 pagesNewsletter - More Flexibility and Lower CostsGabriel FerreiraNo ratings yet

- IEEE 67-1995 O&M Turbine GeneratorsDocument46 pagesIEEE 67-1995 O&M Turbine GeneratorsVICTOR JOSE VILORIANo ratings yet

- Volvo EC200D Crawler Excavator Fuel Efficient ReliableDocument16 pagesVolvo EC200D Crawler Excavator Fuel Efficient ReliableRidho PangestuNo ratings yet

- ABB Review NR 4 2013Document84 pagesABB Review NR 4 2013sorin1gunnerNo ratings yet

- Software Reliability Engineering More Reliable Software Faster and Cheaper 2nd EditionDocument634 pagesSoftware Reliability Engineering More Reliable Software Faster and Cheaper 2nd EditionNachiyar Nandhini100% (2)

- Start: Application of The Poisson DistributionDocument4 pagesStart: Application of The Poisson DistributionArchit VermaNo ratings yet

- Process Solutions: Solution For Specialty Chemical SitesDocument7 pagesProcess Solutions: Solution For Specialty Chemical SitestyaskartikaNo ratings yet

- Icmed 9001Document20 pagesIcmed 9001Ankur DhirNo ratings yet

- Sustainable Energy, Grids and NetworksDocument8 pagesSustainable Energy, Grids and NetworksРоман БуйнийNo ratings yet

- ME6012-Maintenance-Engineering 2 MarksDocument14 pagesME6012-Maintenance-Engineering 2 MarksAravind SelvaNo ratings yet

- Lighting: ScopeDocument14 pagesLighting: Scopemichael100% (3)

- LEED Green Associate - HandbookDocument25 pagesLEED Green Associate - HandbookkatageriguruNo ratings yet