Professional Documents

Culture Documents

Toughness of Old Mild Steel

Uploaded by

Arya Scout Bilspensam JambudCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toughness of Old Mild Steel

Uploaded by

Arya Scout Bilspensam JambudCopyright:

Available Formats

12th International Conference on Advances in Steel-Concrete Composite Structures (ASCCS 2018)

Universitat Politècnica de València, València, Spain, June 27-29, 2018

Doi: http://dx.doi.org/10.4995/ASCCS2018.2018.7029

Toughness of old mild steels

R. M. Stroetmanna*, L. Sieberb

a

Institute of Steel and Timber Construction, Technische Universität Dresden, Germany

b

Labor Konstruktiver Ingenieurbau, Hochschule für Technik und Wirtschaft Dresden, Germany

*corresponding author, e-mail address: richard.stroetmann@tu-dresden.de

Abstract

For the rehabilitation of steel structures from the 19th and the early 20th century the brit-

tle fracture behaviour is essential for the structural safety. The methods of the assessment

used in EN 1993-1-10 were predominantly developed for welded structures made of cur-

rent steel grades with more or less high toughness. The check by limitation of the plate

thickness (Table 2.1 in [1]) is not suitable for old mild steel structures with riveted and

bolted connections. Notch effects and residual stresses are quite different to those ones of

welded structures. The material properties of old mild steels are characterised by larger

scatters, particularly due to the inhomogeneous distribution of tramp elements and higher

contents of non-metallic inclusions. In this paper, experimental and analytical studies of

the brittle fracture behaviour of mild steels as well as aging effects of structural elements

with holes for riveted and bolted connections are presented (see also [2-4], [20]).

Keywords: Brittle fracture; old mild steel; riveted structures; fracture toughness; Master-

Curve; Sanz-correlation.

1. Introduction Nevertheless, in practice the limits for the

Charpy-energy according to EN 1993-1-10 are

Lots of steel structures dating from the 19th

often used to assess old steel structures. This

and early 20th century are still in use today

can lead to miscalculations of toughness re-

even if their expected lifetime has been signifi- quirements and unnecessary reinforcement

cantly exceeded. Steel structures constitute a measures or the preventive dismantling of the

large proportion of the existing buildings. Sto-

structures.

rey buildings, railway stations and industrial

plants from the 20th century play a particular It is already known from previous tests even

role. Due to heritage preservation aspects and at low temperatures, that old mild steels may

also for economic reasons, it is of significant have sufficient toughness to withstand brittle

importance to ensure the safe usage of these component failure. The assessment of the safety

buildings. against brittle fracture by using the results of

fracture-mechanical tests (C(T)-tests) for the

The analysis of the different reasons for

material toughness and the principals of fracture

damages and collapses of old steel structures

mechanics to determine the stress intensity at

shows, that besides the safety of the structural crack tips is not widespread. Up to now, it is

elements and connections against stability and limited to selected structures, in particular rail-

strength failure, the risk of brittle fracture plays

way and road bridges with cyclic traffic loads.

an important role (e. g. [5]). The procedure for

choosing steel grades to avoid brittle fracture

2. Steel grade selection in EN 1993-1-10

according to EN 1993-1-10 [1] is developed for

structures out of current steel grades in welded To evaluate the safety of steel structures

structures. The particular properties of old mild against brittle fracture, different complex and

steels made by the Thomas-, Bessemer- or Sie- meaningful methods have been developed,

mens-Martin-procedure were not reflected. In which are more or less closely related to the

addition, notch effects from holes for rivets and phenomenon of brittle fracture. The procedure

bolts in structures are significantly lower.

2018, Universitat Politècnica de València

659

Stroetmann R. M., Sieber L.

Fig. 1. Fracture mechanical basics for the safety assessment of brittle failure by EN 1993-1-10 [1, 6]

and background for the choice of steel grades given temperature (e. g. T27J). This requires a

according to EN 1993-1-10 are briefly suitable transformation, which takes place in

described as follows (see [6] and Fig. 1). two steps. On the one hand, the relationship

between the fracture toughness KJc and the

Based on a plate thickness-dependent initial

component temperature will be described by the

crack a0 (semi-elliptical surface crack from the

Wallin's "Master-Curve" (Fig. 1c). In a second

production, Fig. 1a), the design value of the

step, the ratio between the transition tempera-

crack depth ad will be determined after 500,000

ture T27J at the Charpy-test and the reference

load cycles. This value is associated with the

temperature T100, at which the median value of

period, in which a damaged component with an

the fracture toughness corresponds to 100

increasing crack can be safely used, even at

MPa√m (also called T0), will be determined by

extreme low temperatures (return period 50

using the modified Sanz-correlation (Fig. 1d).

years). Typical intervals for the fundamental

With this procedure it is possible to replace the

renewal of corrosion protection at bridges are

complex determination of the fracture

about one quarter of the life time, for which a

toughness KJc by simple notch impact tests.

calculated lump sum of two million load cycles

was assumed. Based on the maximum crack To simplify the assessment EN 1993-1-10

depth at the end of the observation period, the provides Table 2.1 [1]. It enables the

stress at the crack tip in form of the linear determination of the maximum permissible

elastic stress intensity factor KI in the product thicknesses of the intended steel grades

component will be determined as the reference depending on the reference temperature and the

for the impact. The increase of the stress at the applied stress for a defined exceptional

crack tip due to plastic zones can be considered combination of actions [1]. The table was

by the kR6 correction factor in the Failure developed for welded structures made out of

Assessment Diagram (FAD) of the R6 routine steel grades according to EN 10025 under

(Fig. 1b). defined boundary conditions.

The technical delivery conditions for

structural steels do not specify fracture

3. Investigations of old mild steels

toughnesses KJc, but minimum values of the

3.1. Specimens and their chemical content

Charpy-energy from notch impact tests at a

2018, Universitat Politècnica de València

660

Stroetmann R. M., Sieber L.

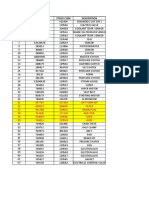

Table 1. Results of the chemical analysis

chemical content [%]

sample / section

C Mn Si P S N O

DT200 (I200) 0.03 0.27 0.001 0.049 0.029 0.0135 0.0110

DT260 (I260) 0.10 0.72 0.001 0.095 0.102 0.0250 0.0155

M31 (L120x13) 0.07 0.48 0.001 0.024 0.043 0.0115 0.0385

M56 (L110x12) 0.15 0.36 0.001 0.018 0.091 0.0080 0.0100

SGM21 (L80x8) 0.09 0.23 0.001 0.087 0.089 0.0210 0.0160

PA2 (L60x8) 0.07 0.67 0.001 0.103 0.079 0.0225 0.0150

DB_G1 (L100x65x11) 0.03 0.32 0.002 0.053 0.085 0.0250 0.0710

DB_G3 (L100x65x11) 0.04 0.41 0.001 0.060 0.084 0.0190 0.0570

Thomas-steel 0.05 0.46 0.009 0.051 0.044 0.0140 -

Siemens-Martin-steel 0.09 0.48 0.008 0.035 0.038 0.0050 -

It is already known from the investigation in positioned and cracks are expected. Fig. 2

[7, 8] that the chemical, metallurgical and me- shows the sulphur print of an angle section and

chanical characteristics of old structural steels the location of the test specimens.

may differ considerably. In order to capture a

large range of mild steels, material samples

from different structures and years of construc-

tion were chosen for these investigations. To

get more conservative results only material

samples from buildings were analysed, because

the steel quality of bridges was usually higher.

The results of the chemical analysis are con-

cluded and compared with the average concen-

trations of mild steels from typical production Sulphur print and positioning of test

procedures [7] in Table 1. The specimens in- specimens at sample SGM21 [19]

clude Thomas-steels with high contents of ni-

trogen (e. g. PA2) as well as Siemens-Martin- 3.2. Fracture toughness

steels (e. g. M3). For each analysed material

The fracture behaviour of structural steels

sample, the following test specimens were pro-

corresponds to a temperature-dependent transi-

duced:

tion of material toughness from the ductile (up-

6 cylindrical tensile specimens B5 (see DIN per shelf) to the brittle state (lower shelf). The

50125:2009), transition region is characterised by significant-

12 Charpy-impact-test specimens (see EN ly larger scatter than the upper and the lower

ISO 148-1:2011), shelf. The wide range of fracture toughness can

10 fracture mechanic specimens (compact be explained with the weakest-link-model [9].

tension specimens, see ASTM E1820-13). The weakness of a ligament at the crack front

(weakest link of a chain) is decisive for the

Before starting sample preparation sulphur toughness of a sample. At these weak points

prints were made to make core segregations micro-cracks will form, which extend in an

visible. The specimens were positioned in the unstable manner and thus initiate failure. The

areas of segregations. Due to the increased reason for the wide scatter range is the stochas-

amount of impurity the lowest material tough- tic distribution of the weaknesses of the micro-

ness could be expected in these parts of the structure in the ligament. The closer there is the

cross sections. All test specimens of one type weak point to the crack front, the lower is the

were positioned behind each other in longitudi- fracture toughness. The probability increases

nal direction of the sections to make sure, that with the width of the crack. For that reason, the

the tested series have approximately the same toughness against brittle fracture of a thicker

material properties. Furthermore, the notches of sample is lower than that of a thinner one. At

the Charpy-specimens and the fatigue cracks of the same time, the scatter of the material tough-

the C(T)-specimens were located in areas of the ness is lower. This will be captured with the

cross sections, where rivet holes are usually Weibull distribution of the Master-Curve-

2018, Universitat Politècnica de València

661

Stroetmann R. M., Sieber L.

concept ([10, 11]) in the brittle-ductile transi- below the curve for 2 % failure probability.

tion region. For the probability of failure Pf a However, it can be seen that (except the sample

three-parametric distribution is common in PA2) the fracture toughness of the mild steels is

which two parameters are predefined. The also described sufficiently precise by the

shape parameter m is 4, the threshold parameter standard Master-Curve according to ASTM

Kmin restricts the lower bound of the fractural E1921. Based on experimental data and the

toughness of ferritic steels to 20 MPa√m. multimodal evaluation the reference tempe-

rature T0 of -30 °C as well as a characteristic

K K m value of the fracture toughness (5 %-fractile)

Pf 1 exp Jc min

(1)

K 0 K min are obtained with

1T,5% 25.9 29.7 exp0.0186 T 30

K JcMM (3)

The scale parameter K0 will be determined

from the values of fracture toughness KJc for

unstable failure. The values KJc are assigned to 3.3. Previous investigations

a normalised toughness-temperature-curve. The Since the 1980th, fracture mechanical inves-

Master-Curve describes the dependency of the tigations of old structural steels have been per-

median fracture toughness of 1T-samples from formed in order to evaluate the brittle fracture

the temperature. safety of bridge structures. The results were

published e. g. in [14–16] and were used in

K Jc( med ) 30 70 exp0.019 T T0 (2)

various concepts to determine the brittle frac-

The test standard ASTM E1921 is valid for ture resistance of riveted structures. Some of the

macroscopic homogenous material. The multi- research results have also been published on an

modal Master-Curve-approach by [12] allows international level (e. g. [17, 18]). While the

the analysis of data sets which consist of origin of the steels was mostly given, the test

several subsets, e. g. records of different procedure and standards, the dimensions of the

batches or non-homogeneous material. Hence specimens and also partly the test temperatures

this method is suitable for the evaluation of were only insufficiently recorded.

different mild steel samples. However, it is The fracture toughnesses and the conditions

much more complex than the standard method for their determination are only stated in [15].

according to ASTM E1921 [13]. The results While the sample thickness varies between 7

from the analysis of the old mild steels related and 12.5 mm, the tests were carried out accord-

to the standard Master-Curve of ASTM E1921 ing to ASTM E813-89 [19] on 0.5T-C(T)-

are also shown in Fig. 3. samples. The data of the analysed structural

bridge steels are well described with a few ex-

ceptions with the multimodal Master-curve

(Fig. 4). However, it is remarkable that with

increasing temperature the fracture toughness

KJc seems to drop in the average. Reasons for

this may be given in the way of evaluation and

interpretation of the test results. Depending on

the fracture behaviour of the specimen, a dis-

tinction between brittle failure and initiation of

ductile crack growth was made.

If the specimen completely failed brittle

without macroscopic visible cracks on the frac-

ture surface, the determined fracture toughness

Assessment of all test series according to was named Jc (Index c means “critical”). The

ASTM E1921 and the multimodal ap- equivalent KJc-values are shown in Fig. 4. If the

proach

cleavage fracture was initiated by a ductile and

on the fracture surface visible crack, the frac-

As expected, the fracture toughness of the

ture toughness was named with Ji (toughness

inhomogeneous samples are better represented

when initiating ductile crack growth). The

by the multimodal Master-curve. Only two (2,4

applied experimental procedure during the

%) of the totally determined 83 KJc-1T-values are

current investigations at TU Dresden also

2018, Universitat Politècnica de València

662

Stroetmann R. M., Sieber L.

quantifies the fracture toughness due to brittle Table 2. Results of the chemical analysis from spec-

failure according to ASTM E1921. However, imens out of Siemens-Martin-steels

the code permits a low level of ductile crack

Sample / Chemical content [%]

growth up to a crack elongation of

Section C Mn Si P S N

0.05 W a0 1mm (4) B1 (L80x8) 0.07 0.35 0.000 0.029 0.028 0.0047

were W is the width of the specimen and a0 the B2 (Pl 13) 0.14 0.42 0.007 0.038 0.044 0.0057

length of the initial crack. The fracture tough- B3 (Pl 13) 0.09 0.42 0.202 0.018 0.027 0.0053

ness is limited to the maximum measurement B4 (Pl 11) 0.19 0.41 0.011 0.065 0.030 0.0074

capacity KJc(limit) depending on the specimen and Thomas-St. 0.05 0.46 0.009 0.051 0.044 0.0140

the yield strength of the material [13]. Since the S-M-Steel 0.09 0.48 0.008 0.035 0.038 0.0050

degree of ductile crack growth is not

documented in [15], Fig. 4 does not contain Ji- Two material samples in Table 1 and Fig. 3,

values in this comparison. which are designated as M31 and M56, may

also be identified as Siemens-Martin-steels. The

evaluation of the fracture toughness together

with the three rimming mild steels B1, B2 and

B4 according to ASTM E1921 leads to a

reference temperature T0 of -45 °C (Fig. 5).

This is about 15 K lower than the value of the

mild steels according chapter 3.2. The

characteristic value of the fracture toughness is

obtained for the Siemens-Martin-steels as

K Jc1T ,5% 25.2 36.6 exp0.019 T 45 (5)

Comparison of the fracture toughness

values from [15] with results of the

Master-Curve analysis in [20]

3.4. Dependency from the production process

To compare the fracture toughness of mainly

Thomas-steels described in 3.1. and 3.2. with

those once of higher quality, further investi-

gations were carried out (see [20]). Additional

material samples of welded structures from

1937 were considered. The results of the

chemical analyses are shown in Table 2. All Evaluation of all test series of Siemens-

four samples are identified as Siemens-Martin- Martin-steels acc. to ASTM E1921 [3,

20].

steels. Since specimen B3 contains a silicon

ratio of 0.2 % it is a killed steel.

3.5. Correlation of the material toughness

Similar to the investigations described Since the dermination of the fracture

before, extensive tests for analysing the toughness is sometimes not possible or too

material toughness according the Master-Curve- expensive, many research projects were carried

concept were carried out. As expected, the out to derive correlations to other material

transition temperature T27J of the Charpy- properties. Most of the research was focused on

energy as well as the reference temperature T0 the estimation of KJc from the Charpy-impact-

of the C(T)-tests are significantly lower for the energy KV2. Some of the correlations are

killed steel than for the other plate samples. In explained, evaluated and critically discussed in

general, the analysed Siemens-Martin-steels [21, 22]. In general these relationships are

have significantly lower reference temperatures based on empirical data and only valid for

than the Thomas-steels. certain types and states of materials.

2018, Universitat Politècnica de València

663

Stroetmann R. M., Sieber L.

For the mild steels of Table 1, the T0 [24]. The modified type in Eq. (8) is part of

recommended estimation of the fracture the steel grade selection by EN 1993-1-10. The

toughness from the results of the Charpy-test comparison of the analysed mild steels with

according to the SINTAP-guidelines [23] was current steel grades shows that the correlation

checked. The lower threshold value of the

fracture toughness Kmat in a brittle material state T0 T27 J 18C 2 with 13C (8)

was determined by Eq. (6). is not correct for old mild steels (Fig. 6). For

0.25 comparable reference temperatures T0 of the

25

K mat 12 KV2 20 20 (6) fracture toughness, the transition region of the

B Charpy-impact test is at significant higher

B is the given thickness of the specimen related temperatures.

to 25 mm.

4. Structures with punched holes

The minimum Charpy-impact energy of the

mild steel specimens from Table 1 is 4.5 J, the The risk of brittle fracture of riveted and

related fracture toughness Kmat according Eq. bolted steel structures is affected by influences

(6) is 25.5 MPa√m. This lower threshold value from the material, construction and production

is below all crack toughnesses KJc-1T of the methods of the structural elements. The high

analysed mild steels and thereby provides a nitrogen concentration of converter steels

conservative estimation. The fracture toughness (Bessemer and Thomas procedure) in

in the lower transition region of the toughness- combination with plastic deformation leads to

temperature-curve can be estimated for a certain ageing and brittleness.

failure probability Pf as a function of the tempe- The risk of brittle fracture increases

rature T and the transition temperature T27J by significantly due to strain ageing, particularly in

Eq. (7). the region of plastic deformations. Such strain

K mat 20 11 77 exp0.019 T T27 J 3 ageing effects can occur due to cold

0.25 (7) deformations, e. g. in the peripheral areas of

0.25

25 1 punched holes. At the beginning of the 20th

ln

B 1 P century punched holes at cyclic loaded steel

f

structures were only allowed in secondary

This approach is also applicable for old mild structural components. In contrast, the rivet

steels but leads to very conservative values of holes for joints in steel structures of the 19th

the toughness for the steels of Table 1. century were always punched.

The notch effect of holes causes stress

concentrations, which have to be compensated

by local plastifications. If local yielding due to

embrittlement is only insufficiently possible,

brittle fracture, starting from cracks at the

punched holes, may occur (see e. g. [5]).

To examine the influence of punching on the

brittleness in the region of the holes, metallo-

graphic investigations and measurements of

Vickers hardnesses were carried out in [4]. In

the microsections (Fig. 7) there are visible the

typical areas of penetration and plastic

deformations in moving direction of the

Toughness of the examined mild steels

and modern structural steels compared punching tool. The direction of the stretched

to the modified SANZ-correlation [3, ferrite grains is pronounced in the middle and

20]. the exit part of the hole. Similar texture

conditions were documented at all punched

The relationship between Charpy-impact edges. The micrographs illustrated that the

energy and fracture toughness, which is very visually deformed zones of the grain texture

often used in steel engineering, is the have a maximum width of 1.5 mm. In the

correlation of transition temperatures T27J and examinations in [25] the strain hardening effect

2018, Universitat Politècnica de València

664

Stroetmann R. M., Sieber L.

at the punched holes was alredy quantified by 5. Summary and Outlook

Vickers hardness measurements. However, the

This paper presents examinations of the

research was done with current steel grades

fracture toughness of old mild steels, the

without any significant tendency of strain

correlation between the results of Charpy- and

ageing.

C(T)-tests as well as effects of strain ageing at

punched holes of riveted structures. An

essentiel part is the extensive material analysis

carried out to identify the fracture toughness in

the brittle-ductile transition zone using the

Master-Curve concept. The evaluation confirms

that different material grades can be defined

depending on the manufacturing process. To

assess the influence of punching holes in com-

bination with high contents of nitrogen,

Micrographs at the punched edge of a microstructure examinations and hardness

hole after micro etching in alcoholic measurements were carried out.

HNO3-solution [20].

Based on the analysed material toughness of

old mild steels a procedure for the assessment

of brittle fracture of riveted structural elements

was derived for typical structural details within

a fracture mechanical safety analysis in [20,

26]. Related to the width of the hardened zone

from punched holes, a crack with a straight

front and a depth of 3 mm may be assumed at

the most stressed hole edges of predominantly

statically loaded structures. Equations for stress

intensity factor approaches from the relevant

literature can be used to determine the

toughness requirements for components with

rivet holes. Based on fracture mechanical finite-

element-calculations a modification of these

Hardness of all examined samples, hard-

approaches was carried out for the joints of

ness values in relation to the unaffected

base material [20] angle profiles in [20, 26]. The assessment

procedure was transferred to a semi-

Analogous to [25], hardness measurements probabilistic verification concept by using

by Vickers (HV0,2 according to EN ISO 6507) statistic methods to consider the variation of

on sections of old mild steels with punched strength and toughness values of old mild steels

holes were carried out in [4]. The results are after verification by component tests.

shown in Fig. 8. The measured values refer to

the hardness of the unaffected base materials Acknowledgements

(HVBM), which is in the range between 130 and The presented material examinations were

180 HV0.2. In the peripheral zone of the holes mainly carried out within the research project

the hardness values increases up to 2.5-times. “Assessment of the risk of brittle fracture at

These values already point out an increasing punched steel structures further development

tendency of cold cracking, but they are still of analytical methods” [4] and were supported

below the permissible hardness value by funding from the research initiative “Zukunft

380 HV 10 according to EN 1090-2. As already Bau des BBSR” (AZ: II 3-F20-12-1-054). The

shown in the investigations in [11], the authors sincerely thank them for their support.

influence of punching is noticeable within an

edge distance of about 3 mm. The hardened References

zone is wider than the area, in which deformed

grain texture occurs. [1] EN 1993-1-10: Eurocode 3 − Design of steel

structures - Part 1-10: Material toughness and

through-thickness properties. CEN European

2018, Universitat Politècnica de València

665

Stroetmann R. M., Sieber L.

Committee for Standardization, May 2005. In- Ferritic Steels in the Transition Range. United

corporating Corrigenda December 2005 and States; 2013.

March 2009. [14] Hensen W. Grundlagen für die Beurteilung der

[2] Sieber L, Stroetmann R. Assessment of old Weiterverwendung alter Stahlbrücken. Doctoral

mild steel structures related to brittle fracture. thesis. RWTH Aachen; 1992.

Proceedings of EUROSTEEL Conference [15] Langenberg P. Bruchmechanische Sicher-

2017, Copenhagen, Denmark. Publisher: Verlag heitsanalyse anrissgefährdeter Bauteile im

Ernst & Sohn, Berlin. Stahlbau. Doctoral thesis. RWTH Aachen.

[3] Sieber L, Stroetmann R. Zum Sprödbruch alter Shaker Verlag; 1996.

Baustähle. Stahlbau 85, 2016, Heft 12, S. 853- [16] Stötzel G. Verfahren zur Beurteilung der

861 and Stahlbau 85 ,2017, Heft 8, S. 682-693. Sicherheit bei Weiterverwendung alter

Verlag Ernst & Sohn, Berlin. Stahlbrücken. Doctoral thesis. RWTH Aachen.

[4] Stroetmann R, Sieber L, Viehrig HW, Houska Shaker Verlag; 1998.

M, Vetter B, Schubert V. Beurteilung der Sprö- [17] National Cooperative Highway Research Pro-

dbruchgefährdung gelochter Stahltragwerke − gram Report: Fatigue and Fracture Evaluation

Weiterentwicklung der Analysemethoden. For- for Rating Riveted Bridges. Report 302. Wash-

schungsinitiative Zukunft Bau, Aktenzeichen: ington D.C.: National Research Council; 1987.

II 3- F20-12-1-054. Stuttgart. Fraunhofer-IRB-

[18] Moreno J, Valiente A. J-integral determination

Verlag 2015.

in riveted beams of a structural old steel by es-

[5] Klinger C, Mehdianpour M, Klingbeil D, timation methods. Fatigue & Fracture of Engi-

Bettge D, Häcker R, Baer W. Failure analysis neering Materials and Structures 2007; 30: 712-

on collapsed towers of overhead electrical lines 722.

in the region Münsterland (Germany) 2005.

[19] ASTM E813: Standard Test Method for JIC, A

Engineering Failure Analysis Journal

Measure of Fracture Toughness. United States;

2011;18:1873-1883.

1989.

[6] Sedlacek G et al. Commentary and Worked

[20] Sieber L. Beurteilung der Sprödbruch-

Examples to EN1993-1-10 “Material toughness

gefährdung gelochter Stahltragwerke aus

and through thickness properties”. JRC–report;

Flussstahl. Doctoral Thesis at the Institute of

2008.

Steel and Timber Construction, Technische

[7] Reiche A. Zustandsbewertung von metallischen Universität Dresden; 2016.

Tragwerkskomponenten. Stuttgart. Fraunhofer-

[21] Phaal R, Macdonald KA. Critical examination

IRB-Verlag; 2000.

of correlations between fracture toughness and

[8] Helmerich R. Alte Stähle und Stahlkonstruktio- Charpy-impact-energy. Report 96710. Cam-

nen. Materialuntersuchungen, Ermüdungsver- bridge; 1991.

suche an originalen Brückenträgern und

[22] Bannister AC. Toughness characterisation of

Messungen von 1990 bis 2003. Berlin. Bun-

modern structural steels with relevance to Eu-

desanstalt für Materialforschung und-prüfung;

ropean design codes. Properties and in-service

2005.

performance, Final report EUR 17899. London;

[9] Landes D, Shaffer DH. Statistical Characteriza- 1998.

tion of Fracture in the Transition Region. In:

[23] Bannister AC, Webster SE. SINTAP Procedure

ASTM International (Hg.): ASTM STP 700.

− Final Version: FITNET – European Fitness-

West Conshohocken, PA 1980; 368-382.

for-Service Network; 1999.

[10] Wallin K. The Size Effect in KJc-Results. En-

[24] Sanz G. Essai de mise au point d’une méthode

gineering Fracture Mechanics 1985; 22:149-

quantitative de choix des qualités d’acier vis-à-

163.

vis du risque de rupture fragile. Revue de

[11] Wallin K. Master-Curve Analysis of Ductile to Métallurgie 1980; 621-642.

Brittle Transition Region Fracture Toughness

[25] Huhn H. Ermüdungsfestigkeit von Schrau-

Round Robin Data The ‘Euro’ Fracture

benverbindungen aus feuerverzinkten

Toughness Curve. Espoo: Technical Research

Stahlbauteilen mit gestanzten Löchern. Düssel-

Centre of Finland; 1998.

dorf. VDI-Verlag; 2004.

[12] Wallin K, Nevasmaa P, Laukkanen A, Planman

[26] Stroetmann R, Sieber L, Taras A, Anders J,

T. Master-Curve analysis of inhomogeneous

Kuscher G. Bewertung und Instandsetzung von

ferritic steels. Engineering Fracture Mechanics

Altstahlkonstruktionen. Stahlbaukalender 2017;

2004; 71: 2329-2346.

11: 693-764.Verlag Ernst & Sohn, Berlin.

[13] ASTM E1921: Standard Test Method for De-

termination of Reference Temperature, T0, for

2018, Universitat Politècnica de València

666

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Influence of heat treatment on mechanical properties of 51CrV4 spring steelDocument7 pagesInfluence of heat treatment on mechanical properties of 51CrV4 spring steelChiheb BaNo ratings yet

- Corrosion and its Consequences for Reinforced Concrete StructuresFrom EverandCorrosion and its Consequences for Reinforced Concrete StructuresNo ratings yet

- Unit 1 - NotesDocument19 pagesUnit 1 - NotesAristotle SironNo ratings yet

- Module - 1 Introduction: Advantages and Disadvantages of Steel Structures, Limit State Method Limit State ofDocument12 pagesModule - 1 Introduction: Advantages and Disadvantages of Steel Structures, Limit State Method Limit State of2BA19CV059 Rakshita SarangmathNo ratings yet

- Constraint Loss Correction Enhancing Transferability of F 2023 EngineeringDocument13 pagesConstraint Loss Correction Enhancing Transferability of F 2023 Engineeringjose carlos julca eleraNo ratings yet

- Fracture Toughness and Fracture Behavior of SA508-III Steel at Different TemperaturesDocument9 pagesFracture Toughness and Fracture Behavior of SA508-III Steel at Different TemperaturesFajar Sri Lestari PangukirNo ratings yet

- Artigo Questão 1Document7 pagesArtigo Questão 1eduardoNo ratings yet

- Intro to Concrete Structures DesignDocument42 pagesIntro to Concrete Structures DesignTanvirH.ChowdhuryNo ratings yet

- Microstructure and Mechanical Properties of Two API Steels For Iron Ore PipelinesDocument7 pagesMicrostructure and Mechanical Properties of Two API Steels For Iron Ore PipelinesNilesh MistryNo ratings yet

- Grade On Reliability AnalysisDocument9 pagesGrade On Reliability AnalysisMohd Zain KangdaNo ratings yet

- Coorosion 3Document9 pagesCoorosion 3Ramin ShojaNo ratings yet

- Comparative Study On Materials Used in Various Codes For Design of RC and Steel StructuresDocument6 pagesComparative Study On Materials Used in Various Codes For Design of RC and Steel StructuresgetNo ratings yet

- Cronidur Equivalent J.matchar.2019.110049Document15 pagesCronidur Equivalent J.matchar.2019.110049IltefatNo ratings yet

- Engineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerDocument17 pagesEngineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerShubhom PaulNo ratings yet

- Fractal and Probability Analysis of Creep Crack Growth Behaviorin 2.25Cr-1.6W Steel Incorporating Residual StressesDocument9 pagesFractal and Probability Analysis of Creep Crack Growth Behaviorin 2.25Cr-1.6W Steel Incorporating Residual StressesSatish Kumar GautamNo ratings yet

- Pre-Strain Effect of On Fracture Performance of High-Strength Steel WeldsDocument7 pagesPre-Strain Effect of On Fracture Performance of High-Strength Steel WeldsThiago Amaro RodriguesNo ratings yet

- Comparative Study On The Behavior of Slender RC Walls With TwoDocument8 pagesComparative Study On The Behavior of Slender RC Walls With TwoAmina AzlafNo ratings yet

- Fatigue in High Strength BoltDocument10 pagesFatigue in High Strength BoltEgyptian ResearcherNo ratings yet

- Connection Characteristics in Seismic Proof Steel ConstructionDocument12 pagesConnection Characteristics in Seismic Proof Steel Constructionroma_luNo ratings yet

- 2013 05 24 2013 Heistermann C JCSRDocument11 pages2013 05 24 2013 Heistermann C JCSRst_luiseNo ratings yet

- Damage PlasticityDocument12 pagesDamage PlasticityVibhanshu Mishra100% (1)

- Determination of True Stress Strain CharacteristicDocument9 pagesDetermination of True Stress Strain CharacteristicEng Hinji RudgeNo ratings yet

- tmp705 TMPDocument17 pagestmp705 TMPFrontiersNo ratings yet

- Metals: Weldability and Lamellar Tearing Susceptibility of High-Strength SN 490C Steel PlatesDocument16 pagesMetals: Weldability and Lamellar Tearing Susceptibility of High-Strength SN 490C Steel PlatesRendra Maha Putra JfNo ratings yet

- Structural Automotive App enDocument11 pagesStructural Automotive App enStein ChenNo ratings yet

- Strain Compatibility Between HPFRCC and Steel ReinforcementDocument2 pagesStrain Compatibility Between HPFRCC and Steel ReinforcementRachida KrachaiNo ratings yet

- Effect of Alloying Elements on Corrosion Resistance of Reinforcing Bar SteelDocument7 pagesEffect of Alloying Elements on Corrosion Resistance of Reinforcing Bar SteelJosé AntonioNo ratings yet

- TWI Knowledge Summary - Fitness For PurposeDocument5 pagesTWI Knowledge Summary - Fitness For Purposedhurusha100% (1)

- 1 s2.0 S0734743X04001034 MainDocument16 pages1 s2.0 S0734743X04001034 MainHany KhalifaNo ratings yet

- Baterlle Two CurveDocument20 pagesBaterlle Two CurveAdam ThomsonNo ratings yet

- Low Cyclic Tests On Headed Stud Connectors in Hybrid Shear Wall SystemsDocument8 pagesLow Cyclic Tests On Headed Stud Connectors in Hybrid Shear Wall SystemsSanNo ratings yet

- Mechanical Properties of Thermally Stable Nanocrystalline Bainitic SteelsDocument13 pagesMechanical Properties of Thermally Stable Nanocrystalline Bainitic SteelsP. R. SREENIVASANNo ratings yet

- The New Penstock For The High Head Hydropower Plant KaunertalDocument9 pagesThe New Penstock For The High Head Hydropower Plant KaunertalStalyn SimbañaNo ratings yet

- Bratina 2005Document19 pagesBratina 2005Malek GolNo ratings yet

- Fatigue Behavior of Weathered Steel ComponentsDocument10 pagesFatigue Behavior of Weathered Steel ComponentsSREEJITH S NAIRNo ratings yet

- Martensitic Steel Sheets of 1300 and 1500mpa GradesDocument5 pagesMartensitic Steel Sheets of 1300 and 1500mpa Gradesmohamed ahmedNo ratings yet

- Common Root Causes of Pressure Vessel Failures: A Review: Akademia BaruDocument16 pagesCommon Root Causes of Pressure Vessel Failures: A Review: Akademia BaruJuan David RRiosNo ratings yet

- High-Strength Corrosion-Resistant Steels of The Austenitic-Martensitic ClassDocument1 pageHigh-Strength Corrosion-Resistant Steels of The Austenitic-Martensitic ClassakhileshNo ratings yet

- Modeling Creep and Fatigue of Copper Alloys for High-Heat ApplicationsDocument12 pagesModeling Creep and Fatigue of Copper Alloys for High-Heat ApplicationsValentin CedilloNo ratings yet

- Metallographic and Fracture Characteristics of TWIP STEELS SPOT WELDEDDocument10 pagesMetallographic and Fracture Characteristics of TWIP STEELS SPOT WELDEDJoselo HRNo ratings yet

- Effect of Main Inclusions On Crack Initiation in Bearing Steel in The Very High Cycle Fatigue RegimeDocument7 pagesEffect of Main Inclusions On Crack Initiation in Bearing Steel in The Very High Cycle Fatigue RegimeAkshay29No ratings yet

- Journal of Constructional Steel Research: Jin Jiang, Mingshan ZhaoDocument9 pagesJournal of Constructional Steel Research: Jin Jiang, Mingshan ZhaoSaid HaggagNo ratings yet

- A Study On Transverse Weld Cracks PDFDocument8 pagesA Study On Transverse Weld Cracks PDFRifani ImamNo ratings yet

- Design of Prestressed Concrete Decks: Coventry University MSC Bridge Engineering ModuleDocument7 pagesDesign of Prestressed Concrete Decks: Coventry University MSC Bridge Engineering Moduleaggrey noahNo ratings yet

- BSCE - Reinforced Concrete StructuresDocument125 pagesBSCE - Reinforced Concrete StructuresArjun Mullu100% (1)

- 2005 Indian Hot-Rolled SERCDocument23 pages2005 Indian Hot-Rolled SERCDipen ThakurNo ratings yet

- Tests On Ultimate Strength of Hull Box Girders Made of High Tensile SteelDocument21 pagesTests On Ultimate Strength of Hull Box Girders Made of High Tensile SteelvunhNo ratings yet

- Metals: A Creep Damage Model For High-Temperature Deformation and Failure of 9Cr-1Mo Steel WeldmentsDocument20 pagesMetals: A Creep Damage Model For High-Temperature Deformation and Failure of 9Cr-1Mo Steel WeldmentsPraveen CNo ratings yet

- 1 s2.0 S1350630722006033 MainDocument18 pages1 s2.0 S1350630722006033 Mainimanz5No ratings yet

- Effective Stiffness For Structural Analysis of Buildings in EarthquakeDocument8 pagesEffective Stiffness For Structural Analysis of Buildings in EarthquakeNick Darwin Sanchez HuatayNo ratings yet

- Efecto Del Precalentamiento en La Soldadura de La Sensibilidad Al Agrietamiento en Frío Del Acero Martensítico de Baja Activación de China PDFDocument7 pagesEfecto Del Precalentamiento en La Soldadura de La Sensibilidad Al Agrietamiento en Frío Del Acero Martensítico de Baja Activación de China PDFReyna RoblesNo ratings yet

- PP MMMS2020Document7 pagesPP MMMS2020lethao2011No ratings yet

- Design Data: A. General. The Specific Concrete Properties Used inDocument10 pagesDesign Data: A. General. The Specific Concrete Properties Used inAnoop GuptaNo ratings yet

- Tekken en Acero Weldonx 1300Document8 pagesTekken en Acero Weldonx 1300nestor leonardonNo ratings yet

- Development of Microstructure and Residual Stress in Electron Beam Welds in Low Alloy Pressure Vessel SteelsDocument23 pagesDevelopment of Microstructure and Residual Stress in Electron Beam Welds in Low Alloy Pressure Vessel SteelsfarahNo ratings yet

- Ref 8 The Prediction of The Mechanical Properties ForDocument18 pagesRef 8 The Prediction of The Mechanical Properties Formohammadreza hajialiNo ratings yet

- Maraging and Nickel-Molybdenum Trip-SteelsDocument8 pagesMaraging and Nickel-Molybdenum Trip-SteelsSinhrooNo ratings yet

- Composite Columns IDocument15 pagesComposite Columns IHeng Kimseng100% (1)

- 99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsDocument9 pages99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsbllldNo ratings yet

- 334 Test 4Document4 pages334 Test 4Kim AnhNo ratings yet

- Introduction To Geo-TechnologyDocument45 pagesIntroduction To Geo-TechnologyEngr Muhammad WaseemNo ratings yet

- Life Cycle AssesmentDocument34 pagesLife Cycle AssesmentMayank Joshi100% (1)

- GID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringDocument6 pagesGID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringAkash SharmaNo ratings yet

- Olt Config CuyDocument21 pagesOlt Config CuyEron RamdanyNo ratings yet

- Expansion Socket DesignDocument12 pagesExpansion Socket DesignNwachukwu UmehNo ratings yet

- Testing of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedDocument5 pagesTesting of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedKok WaiNo ratings yet

- Study pointers in C with examplesDocument6 pagesStudy pointers in C with examplespremsagarNo ratings yet

- AIR Modeller 2019-04-05 83Document68 pagesAIR Modeller 2019-04-05 83Tomeu Llompart100% (8)

- Directional Drilling Short Answer Questions 2016Document7 pagesDirectional Drilling Short Answer Questions 2016AKSHAY SHEKHAWAT0% (2)

- Guide-To Visual InspectionDocument25 pagesGuide-To Visual InspectionMatthew ShieldsNo ratings yet

- VOIP On Packet Tracer PDFDocument10 pagesVOIP On Packet Tracer PDFHead Bang100% (2)

- Alpha Lubricator Manual MC-2.5Document283 pagesAlpha Lubricator Manual MC-2.5diansulaeman100% (2)

- Stake Out Data Analysis and ComparisonDocument15 pagesStake Out Data Analysis and ComparisonDewy Widya ningsihNo ratings yet

- Cycle of Copper Reactions LabDocument6 pagesCycle of Copper Reactions LabbigfoottedNo ratings yet

- Princecraft Bateaux enDocument70 pagesPrincecraft Bateaux enkhussonNo ratings yet

- Brazed Tool ArDocument5 pagesBrazed Tool ArRoni MustafiqNo ratings yet

- Complete Lesson 4 Assessment Task On The Maneuver of The ShipDocument2 pagesComplete Lesson 4 Assessment Task On The Maneuver of The ShipMixed VideosNo ratings yet

- Physics Cambridge Igcse Year 10 Paper 1Document18 pagesPhysics Cambridge Igcse Year 10 Paper 1Adibah AliasNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document8 pages400 Bad Request 400 Bad Request Nginx/1.2.9bahramhooNo ratings yet

- Oracle BOM Mass Changes - Oracle Functionality - ManojDocument29 pagesOracle BOM Mass Changes - Oracle Functionality - ManojVijay PawarNo ratings yet

- Government College of Engineering Jalgaon (M.S) : Coursewise Grade Report of Theory CoursesDocument7 pagesGovernment College of Engineering Jalgaon (M.S) : Coursewise Grade Report of Theory CoursesQweNo ratings yet

- Byv10ed 600pDocument10 pagesByv10ed 600pdavid.gjeorgevskiNo ratings yet

- OOSE03 - Basing Software Development OnDocument48 pagesOOSE03 - Basing Software Development Onfaiz10march6456No ratings yet

- Ettus B100Document2 pagesEttus B100Philip GaddiNo ratings yet

- AVImark ReadMe Enhancements 2009.0.0Document33 pagesAVImark ReadMe Enhancements 2009.0.0William OglesbyNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Easyscan2 Short ManualDocument8 pagesEasyscan2 Short ManualRamon RelosaNo ratings yet

- Shotcrete Slope StabilizationDocument7 pagesShotcrete Slope StabilizationJ. Kumar Infraprojects Ltd100% (1)

- Kyocera FS-600 Parts Manual PDFDocument19 pagesKyocera FS-600 Parts Manual PDFliviumaraNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet