Professional Documents

Culture Documents

07

Uploaded by

mohammedalathwaryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07

Uploaded by

mohammedalathwaryCopyright:

Available Formats

FRENIC-Lift Series Inverters

for Elevating Machinery

Tetsuya Nomura

Hiroaki Kato

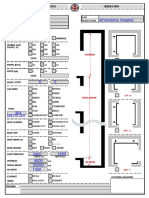

1. Introduction Fig.1 External view of FRENIC-Lift series

In elevator industry, system is transitioning from

geared elevators that use standard induction motors to

gearless elevators that use synchronous motors. Gear-

less elevators has already got the majority of new

construction starts in Japan, and demand for their use

is also increasing in rapidly growing markets in China

and Europe. Inverters that drive gearless elevators

are required to be small, thin, to have high overload Multi-function keypad

capacity, and to deliver high performance and high (option)

functionality.

In consideration of these circumstances, Fuji Elec-

tric has newly developed FRENIC-Lift series inverters

designed specifically for elevator machinery. This

paper introduces the features of FRENIC-Lift series.

2. FRENIC-Lift Specifications and Features

Fig.2 Speed vs. torque characteristics (at low speed)

FRENIC-Lift series was developed to provide pow-

erful and high-performance inverters as well as easy-

to-use. Input voltage is 3-phase 400 V, and output 7.5 r/min 7.5 r/min

capacity ranges from 5.5 to 22 kW. Figure 1 shows

external appearance of 11 kW model. Functionality is Maximum

enhanced with the provision of many custom functions torque increases

for elevator machinery, including the well-established Speed ripple

decreases

vector control with speed sensor.

Torque (%)

Torque (%)

2.1 Hardware configuration for powerful and optimized

elevator machinery

2.1.1 High overload capacity

Since maximum torque is needed during accelera-

tion and deceleration for elevator-related applications, Motor speed

an ample overload capability is important. Moreover, (r/min)

Motor speed

required load inertia (at the motor shaft) of recently (r/min)

popularized gearless elevator is larger than that of

geared elevator, and a larger torque is needed during FRENIC5000G11UD FRENIC-Lift

acceleration and deceleration.

With FRENIC-Lift, specified thermal design based

on operating pattern of elevator and lower generated load capacity of previous model (FRENIC5000G11UD).

loss due to the use of next-generation insulated gate Consequently, FRENIC-Lift series is well suited

bipolar transistor (IGBT) chip enabled the realization for applications for which prior models could not be

of 200 % – 10 s overload capacity. This value is used due to their limited overload capacity such as

significant improvement from the 150 % – 10 s over- relatively high-speed elevators and gearless elevators

FRENIC-Lift Series Inverters for Elevating Machinery 33

Fig.3 Control block diagram

FRENIC-Lift Flux pattern generator Y Synchronous motor

0

Analog N Mechanical

speed ø /I brake

command Automatic

current PWM

Ramp controller

regulator inverter M

Automatic

Speed speed Vibration (ACR)

+

Multi-step command regulator suppression τ /I

speed selector (ASR) + observer PG

command

Imbalanced + Y

Current

load

limiter

0

compensator + Slip N +

Internal monitor

compensator +

Synchronous motor

CAN Speed detector

communication

bus Torque bias

selector

2F

1F

User controller

Load detection signal

having large load inertia (at the motor shaft). Fig.4 Speed response characteristics

Figure 2 shows speed vs. torque characteristics at

low speed. Compared to FRENIC5000G11UD, it can 10

be seen that FRENIC-Lift has larger torque and lower

speed ripple, and is thereby capable of powerful and 0

Gain (dB)

stable operation. - 3 dB

2.1.2 Internal encoder interface and braking circuit FRENIC-Lift

-10

Encoder interface and braking circuit are provided

FRENIC5000G11UD

as standard equipment. As a result, it is attachable to

-20

the small space compared with previous models. 10 100 1,000

2.1.3 Safety function Frequency (Hz)

Safety function is provided whereby, regardless of

operating state, when dedicated control input (EN

terminal) is turned OFF, inverter output is cutoff Fig.5 Car vibration (vertical)

immediately and motor drive is stopped reliably. The

process by which drive output is cutoff in response to 0.1

Elevator conditions: 1.75 m/s, 1000 kg

Vertical acceleration (m/s2)

this function is implemented by hardware, which

0.10 m/s2 no load, traveling downward

operates much faster than software processing. Addi- 0.05

tionally, since output cutoff circuit is equipped with

functions for stopping the motor drive reliably even in 0

the case of partial malfunction and for delivering

information outside about the malfunction, it realized - 0.05

enhanced safety feature.

- 0.1

0 5 10 15 20 25

2.2 High-level control performance Time (s)

2.2.1 Greater riding comfort by improved control

response

With FRENIC-Lift, control response has been 2.2.2 Reduced rollback when brake is released

improved significantly with use of higher-speed auto- Unless elevator provides torque compensation in

matic current regulator (ACR). Figure 3 shows a block response to load imbalance between weight of car (with

diagram of FRENIC-Lift control system, and Fig. 4 load) and counterweight, rollback will occur when

shows speed response characteristics of FRENIC-Lift mechanical brake is released.

and the FRENIC5000G11UD. Typically, a signal from load detector attached to

With improved control response of FRENIC-Lift, elevator car has been used to calculate necessary

elevator car vibration (vertical) has been reduced amount of torque to inverter so as to reduce the

compared to previous models, and a vibration charac- occurrence of rollback when the mechanical brake is

teristic less than 0.10 m /s2 (p-p) was achieved in actual released. FRENIC-Lift, however, is equipped with

gearless elevator (See Fig. 5). imbalanced load compensator to calculate and provide

34 Vol. 52 No. 1 FUJI ELECTRIC REVIEW

Fig.6 Reduced rollback when mechanical brake is release Fig.7 Torque characteristics during battery operation

25 r/min

Motor speed

(42 r/min/div)

Torque (%)

Torque current

Motor speed (r/min)

(50 % /div)

Motor acceleration

(0.875 m /s2 /div)

Less mechanical shock at startup

Motor current

(45.3 A /div)

1 s/div

Elevator conditions : 1.75 m /s, 1,000 kg, FRENIC-Lift 48 V DC

Uncompensated Compensated

rated load, traveling upward

2.3.2 Optimization of operating cycle

necessary amount of torque compensation. Generally, just prior to landing elevator (the car is

Figure 6 shows characteristic data of imbalanced approaching loading position), it travels at a low-speed

load compensator. Data on the left is “uncompensated” known as creep speed to reach the landing position

and data on the right is “compensated.” The phenome- accurately. However, FRENIC-Lift is equipped with

non of rollback when mechanical brake is released can creepless operation function that operates when the

be checked with vibration of motor acceleration. Com- elevator is landing. When receives a positioning signal

pensated data shows no fluctuation in motor accelera- as an external command, this creepless operation

tion, and it can be seen that the imbalanced load function generates speed command pattern to move

compensator mitigates the phenomenon of rollback. the elevator from that time to just the specified

Because load detector is unnecessary with this distance, and then to stop the elevator. Therefor it can

function, elevator system can be simplified and reduce eliminate the need for creep speed operation.

its cost. When renewing an elevator, for example, This function enables optimized operating cycle of

imbalanced load compensator is very effective to an elevator.

realize smooth operation even in elevators not 2.3.3 Battery operation characteristics

equipped with load detector. Figure 7 shows speed vs. torque characteristics

2.2.3 Application for gearless elevators (option) during battery operation. The battery voltage is 48 V

For synchronous motors, an optional interface is DC. When in the braking mode, even during battery

available that supports “EnDat 2.1 serial interface operation, stable operation with at least 200 % torque

encoder” and “4-bit gray code and U V W 3-bit code is possible.

parallel interface encoders,” which are used often in Additionally, during battery operation, an uninter-

elevator industry. Additionally, offset tuning function ruptible power supply (UPS) or the like may be used as

of magnetic pole position is also provided to adjust the an auxiliary power input to inverter control circuit.

magnet pole position offset values automatically. Since UPS output voltage matches the voltage of the

As a result, set-up work for gearless elevator is power distribution system, it often differs from the

simplified. voltage at the motor power inputs (3-phase power

supply). For example, in the case where 3-phase power

2.3 Functions suited for elevator applications supply is 380 V and the power distribution system

2.3.1 Standard CAN bus interface voltage is single-phase 220 V, a voltage drop of more

Controller area network (CAN) bus is a highly than 40 % will occur at time of changeover to the UPS.

reliable network having a track record of many Fuji Electric’s general-purpose inverters only guaran-

successful applications. Moreover, due to low protocol tee proper operation for up to 15 % drop in power

overhead and high-speed communication capability of supply voltage. However with FRENIC-Lift, design of

CAN bus, high-speed response can be achieved that is the DC-DC converter load has been optimized to

approximately 10 times RS-485 communication perfor- guarantee proper operation during this type of wide

mance used in conventional general-purpose inverter. voltage variation. By reducing DC-DC converter load

Because CAN bus is provided as standard inter- during battery-powered operation, 400 V series invert-

face, inverter control can be realized via communica- er can allow 200 V control power input during a power

tion lines, and as a result, less wiring is possible. failure.

FRENIC-Lift Series Inverters for Elevating Machinery 35

Fig.8 Trace function tively severe environments such as inside an elevator

control console, machine room, or the like, a dust-

Historical trace

protecting fan is used to improve the capability of the

inverter against such environments.

2.4.3 Other functions

An elevator control system consists of user control-

ler, inverter and peripheral circuitry. FRENIC-Lift

series is system-oriented, and is equipped with many

convenient functions.

One of such function is providing door open-close

control signal. This signal equipped on inverter side

make it easy to control the elevator door when the

elevator has landed.

Another convenient function is selection of positive

or negative logic for each I / O signal. The decision of

whether each signal is normal ON, or abnormal ON,

depends on the type of control signal and the system

2.4 Ease of use design. With FRENIC-Lift, all I / O signal active logic

2.4.1 Trace function can be switched easily with the parameter settings.

Windows*1-compatible FRENIC loader enables

trace function that is capable of monitoring such 3. Future Outlook

waveforms as inverter’s internal reference speed and

reference torque, etc. 3.1 Global standard conformance

Trace function allows for real-time traces, which Fuji Electric intends to conform with EC directive

display the current state as a continuous waveform, (CE mark) required in the European markets, and the

and historical traces, which display waveforms before UL standards and cUL certification required in the

and after when trigger conditions are met (See Fig. 8). North American markets. Furthermore, although

Because this function allows parameters to be inverters are presently exempt, in consideration of the

adjusted during test runs, maintenance, waveform growing sense of environmental awareness in the

monitoring, and the like, operation efficiency is im- market, Fuji Electric is also making preparations to

proved and set-up time is reduced. facilitate conformance with RoHS directive*2.

2.4.2 Environment-friendly functions

Since elevators are public facility, the level of 3.2 Product series expansion

acoustic noise emitted from an inverter’s cooling fan In the future, Fuji Electric plans to develop a

when elevator is stopped, may be undesired in some large-capacity 400 V series and a 200 V series.

cases. With FRENIC-Lift, the conventional cooling fan

control has been improved such that, as long as the 4. Conclusion

inverter’s heat sink temperature does not rise, the

cooling fan will not operate. As a result, not only Features of FRENIC-Lift series inverters for eleva-

reduction of acoustic noise from the cooling fan, but tor machinery have been presented. Fuji Electric

also extension of service life of cooling fan is per- intends to continue to develop inverters that meet the

formed. needs of the market and to incorporate insights from

Additionally, since inverters are installed in rela- end users to create even better products in the future.

*1: Windows is a registered trademark of Microsoft Corp. in *2: RoHS directive is restriction on the use of certain

the US and other countries. hazardous substances in electric and electronic devices.

36 Vol. 52 No. 1 FUJI ELECTRIC REVIEW

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Easytronic Micro II (2012 Revision15) ControllerDocument11 pagesEasytronic Micro II (2012 Revision15) Controllermohammedalathwary56% (9)

- Lead Funnels On Funnel Swipe File - TrelloDocument5 pagesLead Funnels On Funnel Swipe File - TrelloKatherie BriersNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- GDKDocument30 pagesGDKRobert Aguilar100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- List of Electronics Manufacturing Companies in Noida - ElectronicsmediaDocument2 pagesList of Electronics Manufacturing Companies in Noida - ElectronicsmediaBlue Oceon50% (4)

- GBA 26800 H IV OVF 20 Service - ToolDocument31 pagesGBA 26800 H IV OVF 20 Service - ToolPeter80% (15)

- Elevator Control ManualDocument29 pagesElevator Control ManualJouny Wael100% (4)

- Elevator Control ManualDocument29 pagesElevator Control ManualJouny Wael100% (4)

- Precision Escalator Parts CatalogDocument10 pagesPrecision Escalator Parts CatalogmohammedalathwaryNo ratings yet

- Smart Home Automation Using AndroidDocument8 pagesSmart Home Automation Using Androidultimatekp144100% (1)

- Sky301-V3 User ManualDocument16 pagesSky301-V3 User Manualمحمدحماد100% (1)

- Break SpecificationsDocument1 pageBreak SpecificationsmohammedalathwaryNo ratings yet

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDocument7 pagesTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMaicol Rodolfo CaizaNo ratings yet

- Break Reless Chapter 1 IntroDocument1 pageBreak Reless Chapter 1 IntromohammedalathwaryNo ratings yet

- Chapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnDocument1 pageChapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnmohammedalathwaryNo ratings yet

- Lift Control Panels & Push ButtonsDocument1 pageLift Control Panels & Push ButtonsmohammedalathwaryNo ratings yet

- VanderGraaf INSTALL-MANUAL PDFDocument18 pagesVanderGraaf INSTALL-MANUAL PDFJonathan Omar Martinez HernandezNo ratings yet

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Document1 pageSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNo ratings yet

- P Ja 51687 Av TF32 VDDocument3 pagesP Ja 51687 Av TF32 VDrabreyNo ratings yet

- EWD-RL-J2 Elevator Device ManualDocument12 pagesEWD-RL-J2 Elevator Device Manualmohammedalathwary100% (4)

- De DP016Document14 pagesDe DP016mohammedalathwaryNo ratings yet

- Car Operating Panels & Landing Push Stations: Lift ComponetsDocument1 pageCar Operating Panels & Landing Push Stations: Lift ComponetsmohammedalathwaryNo ratings yet

- Alhamdany Hospital: Partner Asansör FormDocument1 pageAlhamdany Hospital: Partner Asansör FormmohammedalathwaryNo ratings yet

- Electronics Prom Programmer Series Ii User Manual MODELS 160 170 180 200Document31 pagesElectronics Prom Programmer Series Ii User Manual MODELS 160 170 180 200mohammedalathwaryNo ratings yet

- Warnings: Device Usage and Operation SequenceDocument9 pagesWarnings: Device Usage and Operation Sequencemohammedalathwary100% (1)

- HGL10 Operation Service ManualDocument49 pagesHGL10 Operation Service ManualmohammedalathwaryNo ratings yet

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Document1 pageSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNo ratings yet

- Manual For EncoderDocument2 pagesManual For EncodermohammedalathwaryNo ratings yet

- ICsoftware quick start guide: add elevators, controllers & assign access cardsDocument5 pagesICsoftware quick start guide: add elevators, controllers & assign access cardsmohammedalathwaryNo ratings yet

- SJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9Document16 pagesSJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9mohammedalathwary100% (2)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Document7 pages标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Document7 pages标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- MN00119 Unicom LT User ManualDocument45 pagesMN00119 Unicom LT User ManualPhilipp A IslaNo ratings yet

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocument24 pagesGalvanized and Black Malleable Iron Pipe Fittings SpecificationsdeniNo ratings yet

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksNo ratings yet

- Educ 1301 Field Experience 1 ThielenDocument4 pagesEduc 1301 Field Experience 1 Thielenapi-610903961No ratings yet

- Gmail LogoDocument12 pagesGmail Logovinodram993480No ratings yet

- WaidhanDocument86 pagesWaidhanPatel Nitesh OadNo ratings yet

- Guidlines Norms For Grant of Permission For Construction of Acce001Document6 pagesGuidlines Norms For Grant of Permission For Construction of Acce001Abhi Corleone BallackNo ratings yet

- Proposal BP3IP FinalDocument3 pagesProposal BP3IP FinalGiant SeptiantoNo ratings yet

- b25d b30d Mkiii HydraulicsDocument28 pagesb25d b30d Mkiii HydraulicsErmias100% (3)

- Me8072 Renewable Sources of EnergyDocument13 pagesMe8072 Renewable Sources of EnergyNallappan Rajj ANo ratings yet

- 5 Axis MachinesDocument33 pages5 Axis MachinesgsNo ratings yet

- Methanol Technical Data Sheet FactsDocument1 pageMethanol Technical Data Sheet FactsmkgmotleyNo ratings yet

- PC 4 Product List 2019 - Pc4Document28 pagesPC 4 Product List 2019 - Pc4ShNo ratings yet

- Writing Emails Part 1 Informal British English Teacher Ver2Document7 pagesWriting Emails Part 1 Informal British English Teacher Ver2Madalina MandiucNo ratings yet

- Instruction Manual Series 854 XTG Level GaugeDocument60 pagesInstruction Manual Series 854 XTG Level GaugeJandri JacobNo ratings yet

- CA 1 - Đề thi AV5 - CLC - Made - efDocument5 pagesCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenNo ratings yet

- Air Cooled Screw Chiller Performance SpecificationDocument2 pagesAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- Fire InsuranceDocument108 pagesFire Insurancem_dattaias88% (8)

- 5R Invention Activity: Science LabDocument12 pages5R Invention Activity: Science LabricardoNo ratings yet

- Kerala University 2013 Admission ProspectusDocument50 pagesKerala University 2013 Admission ProspectusMuneer SainulabdeenNo ratings yet

- List of SDAsDocument4 pagesList of SDAsAthouba SagolsemNo ratings yet

- DVOR Principle 코이카 양식Document71 pagesDVOR Principle 코이카 양식Undral Batbayar100% (1)

- Data Sheet: High-Speed DiodesDocument7 pagesData Sheet: High-Speed DiodesZoltán ÁgostonNo ratings yet

- +GF+ Pressure Retaining Valve Type 586Document4 pages+GF+ Pressure Retaining Valve Type 586ROMNANo ratings yet

- ¿Cómo Hacerlo?: Dr. Jorge Ramírez Medina, Dr. Guillermo Granados Ruíz EGADE Business SchoolDocument17 pages¿Cómo Hacerlo?: Dr. Jorge Ramírez Medina, Dr. Guillermo Granados Ruíz EGADE Business Schoolgalter6No ratings yet

- Handy 2010 Case StudyDocument6 pagesHandy 2010 Case Studycancer6No ratings yet

- Evolution of The Fire SprinklerDocument11 pagesEvolution of The Fire SprinklerPedro DudesonNo ratings yet

- CanReg5 InstructionsDocument150 pagesCanReg5 InstructionsdiyafersanNo ratings yet