0% found this document useful (0 votes)

457 views9 pagesWarehouse Processes

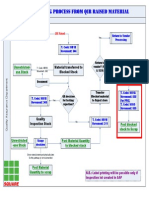

The document discusses various warehouse processes including receiving, put away, storage, picking, shipping prep, and shipping. It evaluates factors that affect the performance of each process such as coordinating delivery and packing needs, storage location planning, picking route optimization, and dispatch coordination. Picking processes are discussed in further detail, outlining order and batch picking approaches. The key is to minimize travel time and backtracking through efficient routing strategies and clear signage while ensuring safety and real-time system updates across all warehouse functions.

Uploaded by

Ritesh VeerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

457 views9 pagesWarehouse Processes

The document discusses various warehouse processes including receiving, put away, storage, picking, shipping prep, and shipping. It evaluates factors that affect the performance of each process such as coordinating delivery and packing needs, storage location planning, picking route optimization, and dispatch coordination. Picking processes are discussed in further detail, outlining order and batch picking approaches. The key is to minimize travel time and backtracking through efficient routing strategies and clear signage while ensuring safety and real-time system updates across all warehouse functions.

Uploaded by

Ritesh VeerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd