Professional Documents

Culture Documents

Certificate of Conformance (HOA THINH - IV#TT-191008F)

Uploaded by

Trịnh Quốc Tuyến0 ratings0% found this document useful (0 votes)

7 views1 pageHorbart welding consumable certificate

Original Title

Certificate of Conformance(HOA THINH_IV#TT-191008F)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHorbart welding consumable certificate

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageCertificate of Conformance (HOA THINH - IV#TT-191008F)

Uploaded by

Trịnh Quốc TuyếnHorbart welding consumable certificate

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

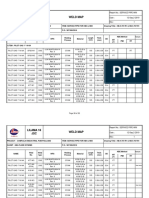

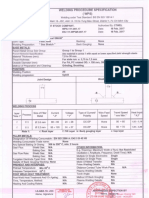

FILLER METALS

l 9 \

eg HOBART

Certificate of Conformance

to Requirements for Welding Electrode

EN 10204 2.2

customer

Procuct: HOBART wnZKAs istomer RO Par Number

Diameter: 40mm Lote, eoszaesecieosze Lot Clssifeation =

Ciessitcation : FTAD-EMI2K Date Tested: 08/3072018 Level of Testing

[Seectication : AWS AS.17:97 Date oflesue : 10/072018

Test Settings

‘es 7 “Temperature

cer | Vots | wes | Shieking Gas | Electrode Stckout ine sas Travel Speed

26 Fs27 ste Fe27

soo | 28 [43pm] NONE 35mm 1841 pm

sores 160 ba18 ul

6 Layers, 2 passes on each layer trough 6; Tih Layer, 3 passes on cap layer, Drecon reversed on each ayer.

Mechanical Properties Lab Test # VE30

iellegGen: | Fecing Gonvitioen | UR Terele Yee ong | _ Impact = =

Shielding Gas | Testing Condi io et, | Fane. | amet | chamy V-notch Valuas tt

es7sz pst | 75082 psi + 3 48 47

“a ASWELDED | 612 Mpa | 520 weal 20 cl Average 43 (58)

Radiographic Fillet Weld Test Moisture %

Inspection: [Conforms | Horzonta NA__| Vertical NA | Overhead: | _NA NA

Bending Test

Chemical Analysis Chem Pad #

Eemens ] cfm] s |] s | Plo

Fiterweiat | 0.09 | 4.10 | 0.24 [0008 | ore | o010

Remarks

Production Date 06/29/2019

Mi wey

(QC Section:.M. Wang

‘Manufacturing, Certification and Limited Warranty Agreement

Data ertne stove suppl reduc ae hoe canes when waked wd insted in accordance wih ha above spcicon AI ats forth above Sasecaton were

‘sted terse arc rouse ray rode doe ous. Tre above suppos peau wate rarufscure by Tan To Seer TW Go asi et Ne

Kata an Rend Ot, Tanan Cy 717, Taian RO Heber Bre proauces wean consumes one’ contrurg qi ape ama eUStad ne

‘spprovedy Lys Regier Guat Aanuarca UntadROA)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Asme Guidance Notes: Prepared by TQ. Hoa - 9/2014Document1 pageAsme Guidance Notes: Prepared by TQ. Hoa - 9/2014Trịnh Quốc TuyếnNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- 1811 611 RC 0 B PDFDocument277 pages1811 611 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- Welding Terminology and DefinitionsDocument66 pagesWelding Terminology and DefinitionsTrịnh Quốc TuyếnNo ratings yet

- 1.0 Typical Duties of Welding InspectorsDocument27 pages1.0 Typical Duties of Welding InspectorsTrịnh Quốc TuyếnNo ratings yet

- 0.0 Welding Inspector ExaminationDocument12 pages0.0 Welding Inspector ExaminationTrịnh Quốc TuyếnNo ratings yet

- 1811 614 RC 0 B PDFDocument201 pages1811 614 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- Tta Power 2015 Vi 001Document31 pagesTta Power 2015 Vi 001Trịnh Quốc TuyếnNo ratings yet

- Described As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Document2 pagesDescribed As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Trịnh Quốc TuyếnNo ratings yet

- Service Pipe Weldmap111Document38 pagesService Pipe Weldmap111Trịnh Quốc TuyếnNo ratings yet

- Joint Efficiency - Pressure Vessel EngineeringDocument5 pagesJoint Efficiency - Pressure Vessel EngineeringMuthuKumar100% (1)

- WPS 111 001.17Document10 pagesWPS 111 001.17Trịnh Quốc TuyếnNo ratings yet