Professional Documents

Culture Documents

Slaa881 Whitepaper Ultrasonic Sensing of Gas Flow

Uploaded by

A N ArunkumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slaa881 Whitepaper Ultrasonic Sensing of Gas Flow

Uploaded by

A N ArunkumarCopyright:

Available Formats

White Paper

SLAA881 – January 2019

Ultrasonic sensing of gas flow

Leonardo Estevez and Cash Hao

This white paper describes the implementation of a high-performance ultrasonic gas meter with the Texas

Instruments MSP430FR6043 microcontroller (MCU) and the advantages of a waveform capture method

over the alternative zero-crossing method.

Contents

1 Introduction ................................................................................................................... 2

2 Gas Meter Configuration .................................................................................................... 2

3 Ultrasonic Transmit Signal Configuration ................................................................................. 2

4 Ultrasonic Receive Signal Configuration.................................................................................. 3

5 Signal Flow and ToF Measurement ....................................................................................... 4

6 TI Technology ................................................................................................................ 5

6.1 MSP430FR6043 MCU USS Module ............................................................................. 5

6.2 External Amplifier ................................................................................................... 6

6.3 Advantages .......................................................................................................... 6

7 Results ........................................................................................................................ 6

8 Conclusion .................................................................................................................... 8

List of Figures

1 Trans-Axial and Reflective-Tube Configurations ........................................................................ 2

2 Single Tone, Dual Tone, and Multitone Transducer Response ....................................................... 2

3 Frequency Sweep Response Over Temperature........................................................................ 3

4 Waveform Capture Result .................................................................................................. 4

5 System Block Diagram for a Gas Meter Application Using the MSP430FR6043 ................................... 5

6 USS Functional Block Diagram ............................................................................................ 5

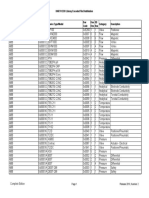

7 Results of Standard Deviation Using the MSP430FR6043 MCU for Gas Metering ................................ 6

8 Results of Zero-Flow Drift Using the MSP430FR6043 MCU for Gas Metering ..................................... 7

9 Results of Variable Gas Flow-Rate Testing Using the MSP430FR6043 MCU ...................................... 8

Trademarks

All trademarks are the property of their respective owners.

SLAA881 – January 2019 Ultrasonic sensing of gas flow 1

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Introduction www.ti.com

1 Introduction

Ultrasonic sensing of gas flow uses the time of flight (ToF) of an ultrasonic wave and its dependency and

behavior in the medium. Volume flow is the measure and calculation of the difference in propagation time

between ultrasonic signals in the upstream and downstream directions. This technology is outstanding at

measuring volume flow rates.

2 Gas Meter Configuration

ToF-based ultrasonic gas meters are often constructed in a trans-axial or reflective-tube configuration (see

Figure 1). While the trans-axial configuration provides a stronger ultrasonic signal (and an improved

signal-to-noise ratio [SNR]), this tube configuration provides lower sensitivity due to the reduced amount of

ultrasonic contact with the flowing gas. The reflective configuration has the added advantage of enabling

the mounting of electronics with transducers on the same side of the pipe.

Figure 1. Trans-Axial and Reflective-Tube Configurations

3 Ultrasonic Transmit Signal Configuration

In gas metering applications, the frequency of transducers is typically between 160 kHz and 600 kHz.

Because higher-frequency ultrasonic waves attenuate more quickly, higher-frequency transducers are

better for space-constrained designs with smaller pipe geometries.

The integrated ultrasonic subsystem in the MSP430FR6043 MCU provides three different excitation

modes: single tone, dual tone, and multitone. While single- and dual-tone excitation work well for

transducers operating with a higher SNR, multitone provides improved performance for transducers

operating with a lower SNR.

The SNR of the ultrasonic signal is determined by a number of different factors, including transducer

sensitivity, spacing and gas attenuation. Figure 2 shows single tone, dual tone, and multitone patterns.

During temperature changes, the gas meter’s frequency response changes. Both transmit and receive

sensitivity can decrease in extreme temperatures. The resulting decrease in SNR can result in decreased

accuracy for single- and dual-tone applications.

Figure 2. Single Tone, Dual Tone, and Multitone Transducer Response

Multitone excitation preserves accuracy under these low SNR conditions by encoding both frequency and

amplitude information for subsequent correlation with the received signal. Multitone excitation also

addresses shifts in the frequency response of the transducer, because it is possible to configure the

excitation band to address these variations.

2 Ultrasonic sensing of gas flow SLAA881 – January 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Ultrasonic Receive Signal Configuration

To determine an appropriate excitation band, the Ultrasonic Design Center graphical user interface (GUI)

provides a frequency response tool that produces a real-time graphical representation of the frequency

response at a given operating temperature. To determine an appropriate excitation band, it’s best to

characterize several representative meters for their frequency response at temperature extremes, thus

ensuring variability in transducer manufacturing. Figure 3 shows a frequency response for a transducer

pair at –35°C, 25°C, and 65°C.

Figure 3. Frequency Sweep Response Over Temperature

After determining an appropriate excitation band, an incremental increase in the number of pulses can

obtain robust results under flow.

4 Ultrasonic Receive Signal Configuration

To get a quality, stable and robust receive signal, the capture window and gain of the received signal

should be adjusted to accommodate anticipated shifts and amplitude variations caused by flow and

temperature. Figure 4 shows a waveform capture from the GUI. Adjust the GUI settings as follows to

ensure a good receive signal:

• Adjust the programmable gain amplifier (PGA) setting to make the amplitude of the received signal

±800 analog-to-digital converter (ADC) counts.

• Adjust the gap between pulse start and waveform capture to give at least 50 µs of delay between the

start of the waveform capture and the start of the received ultrasonic signal.

• Adjust the capture duration to give at least 50 µs of delay between the tail of the received ultrasonic

signal and the end of the waveform capture.

SLAA881 – January 2019 Ultrasonic sensing of gas flow 3

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Signal Flow and ToF Measurement www.ti.com

Figure 4. Waveform Capture Result

5 Signal Flow and ToF Measurement

The MSP430FR6043 MCU performs the complete excitation and acquisition process using an ultrasonic

sensing (USS) module. At the beginning of the sequence, the MSP430FR6043 device sends a train of

excitation pulses to the first transducer. A second transceiver then receives and captures the signal after a

propagation time, T12. The difference in time between transmission and reception determines the upstream

ToF (ToFUPS).

The MSP430FR6043 device repeats the same process in the opposite direction during downstream

excitation and capture resulting in propagation time T21, which represents the downstream ToF (ToFDNS).

The delta time of flight (DToF) is calculated as the difference between T12 and T21.

DToF is typically measured using two different techniques: zero crossing with a time-to-digital converter or

correlation with a waveform capture of the signal using an ADC and the associated excitation signal.

The MSP430FR6043 MCU uses the ADC-based correlation technique to calculate ToF with all required

functions included in the USS library.

4 Ultrasonic sensing of gas flow SLAA881 – January 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com TI Technology

6 TI Technology

TI’s ultrasonic flow sensing solution comprises an MCU with an operational amplifier that connects to two

ultrasonic transducers. Figure 5 shows the system block diagram for this solution. Unlike other solutions,

this system and associated transducers can be powered from a 3-V battery without additional voltage

boosting.

Figure 5. System Block Diagram for a Gas Meter Application Using the MSP430FR6043

6.1 MSP430FR6043 MCU USS Module

The MSP430FR6043 MCU comprises an USS intellectual property block that enables ultra-low-power

metering with low-cost integration. Figure 6 shows a block diagram of the USS. The USS module includes

a universal power supply, a power sequencer, a programmable pulse generator, a physical driver and

impedance matching network, a PGA, a high-speed phase-locked loop, a sigma-delta high-speed ADC,

and an acquisition sequencer. Each of these blocks is configurable through the MCU to enable the

independent excitation and capture of upstream and downstream ultrasonic signals.

USS or USS_A module

USSXT

USSXTIN USSXTOUT USSXT_BOUT

SAPH or SAPH_A

CH0_OUT OSC

PPG or

CH1_OUT ASQ

PPG_A

PLL

PHY

PVSS HSPLL

UUPS

PVCC Vout PLL_CLK

PVSS

SDHS

CH1_IN

SD 12 or 14 RAM

CH0_IN PGA MOD Filter DTC (shared with LEA)

XPB0

Optional

external Bias Generator

signal

on SAPH_A only

handling

XPB1

GPIO

Px.y

(software controlled)

Figure 6. USS Functional Block Diagram

SLAA881 – January 2019 Ultrasonic sensing of gas flow 5

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TI Technology www.ti.com

6.2 External Amplifier

Although the USS can provide up to 30 dB of gain, an external amplifier is required to provide enough

gain to get at least 1600 ADC counts of a received signal under gas-attenuating conditions. The OPA838

operational amplifier operates over a power-supply range of 2.7 V to 5.4 V with a single supply. For

solutions requiring a lower operating voltage (2.5 V), the OPA836 is a pin-compatible drop-in alternative.

6.3 Advantages

The waveform capture-based technique provides these advantages over the zero-crossing technique:

• Improved accuracy. The correlation acts as a digital filter to suppress noise, which results in a benefit

of approximately three to four times lower-noise standard deviation. Similarly, the correlation approach

also acts as a low-pass filter that suppresses other interference like line noise.

• Improved robustness against amplitude variations. The correlation between the excitation and

received signal is insensitive to the received signal amplitude, transducer-to-transducer variation and

temperature variations.

• Improved zero-flow drift. It is possible to minimize variations in zero-flow DToF due to the shifting

transducer frequency response over temperature by exciting the transducers across a frequency band

that accommodates these shifts. This reduced drift often enables simplified and cost-effective meter

calibration.

• Low power. TI’s solution provides a complete set of measurement results, with less than 20 µA of

current consumed per measurement per second.

7 Results

Single-shot standard deviation of the DToF is a measure used to express the expected variance of the

output at zero flow and ambient temperature. The standard deviation is calculated at a zero-flow condition.

Figure 7 shows that the standard deviation using the MSP430FR6043 MCU for gas metering is less than

500 ps. These results were obtained using the OPA838 external amplifier.

Figure 7. Results of Standard Deviation Using the MSP430FR6043 MCU for Gas Metering

6 Ultrasonic sensing of gas flow SLAA881 – January 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Results

Zero-flow drift is a measure used to express the expected drift of the DToF at zero flow across

temperature. This measure also impacts the minimal detectable flow of the meter over temperature.

Figure 8 shows a standard deviation using the MSP430FR6043 MCU for gas metering that is less than

500 ps.

Figure 8. Results of Zero-Flow Drift Using the MSP430FR6043 MCU for Gas Metering

SLAA881 – January 2019 Ultrasonic sensing of gas flow 7

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Conclusion www.ti.com

Conducting variable flow-rate testing ensures linearity in the calibrated operation of a flow meter. This test

is typically conducted with a reference meter to determine the error over the dynamic range of the meter.

Figure 9 shows the results of flow-rate testing using the MSP430FR6043 MCU for gas metering using a

3D-printable tube.

Figure 9. Results of Variable Gas Flow-Rate Testing Using the MSP430FR6043 MCU

8 Conclusion

The USS subsystem integrated with the MSP430FR6043 MCU contains a number of advanced

peripherals that enable robust gas meter products. The waveform capture-based technique implemented

in this solution enables improved accuracy, robustness, and zero-flow drift over competing zero crossing-

based solutions. The combination of the MSP430FR6043 MCU and the OPA838 offers enhanced system

level performance with ultra-low power consumption.

8 Ultrasonic sensing of gas flow SLAA881 – January 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2019, Texas Instruments Incorporated

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- IEEE Digital Time-Of-Flight Measurement For Ultrasonic-SensorsDocument6 pagesIEEE Digital Time-Of-Flight Measurement For Ultrasonic-SensorsA N ArunkumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Snaa284a TI Analog Electronics Design To Improve Performance of Ultrasonic Gas Flow MeterDocument19 pagesSnaa284a TI Analog Electronics Design To Improve Performance of Ultrasonic Gas Flow MeterA N ArunkumarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- HART EDD Library Encoded File Distribution DDList19 - 2Document53 pagesHART EDD Library Encoded File Distribution DDList19 - 2A N ArunkumarNo ratings yet

- Sensors Accurate Estimation of Airborne Ultrasonic Time-Of-flight For Overlapping Echoes-13-15465-V2Document24 pagesSensors Accurate Estimation of Airborne Ultrasonic Time-Of-flight For Overlapping Echoes-13-15465-V2A N ArunkumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Tidua10a Ultrasonic Water Flow Measurement Design Guide Using MSP430FR6972Document13 pagesTidua10a Ultrasonic Water Flow Measurement Design Guide Using MSP430FR6972A N ArunkumarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Flow Metering Tutorial - Part 2 - Pulse-Based Counting in Flow Meters - EDNDocument11 pagesFlow Metering Tutorial - Part 2 - Pulse-Based Counting in Flow Meters - EDNA N ArunkumarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Flow Metering Tutorial - Part 1 - Understanding The Fundamentals - EDNDocument10 pagesFlow Metering Tutorial - Part 1 - Understanding The Fundamentals - EDNA N ArunkumarNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ultrasound Distance Measurement and Ultrasonic Doppler EffectDocument4 pagesUltrasound Distance Measurement and Ultrasonic Doppler EffectA N ArunkumarNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- NDA For Consulting ServicesDocument8 pagesNDA For Consulting ServicesA N ArunkumarNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Snia020 TI Ultrasonic Sensing For Water Flow Meters and Heat MetersDocument14 pagesSnia020 TI Ultrasonic Sensing For Water Flow Meters and Heat MetersA N ArunkumarNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- OS Series Miniature Slide Switches: Features/Benefits Typical ApplicationsDocument8 pagesOS Series Miniature Slide Switches: Features/Benefits Typical ApplicationsA N ArunkumarNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- THVD 1512Document41 pagesTHVD 1512reza_azadNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Summer Training Report at Doordharsan Delhi: Submitted byDocument5 pagesSummer Training Report at Doordharsan Delhi: Submitted byHarshit AgrawalNo ratings yet

- Tle Eim10 Q4 M3Document11 pagesTle Eim10 Q4 M3Ramil ObraNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MultiProFL OperatingInstructions TD-3191011 V1 3 LiteDocument236 pagesMultiProFL OperatingInstructions TD-3191011 V1 3 LiteRodrigo Silva100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- M High Efficiency Horizontal Multistage Pump: E-Hm™ SeriesDocument3 pagesM High Efficiency Horizontal Multistage Pump: E-Hm™ Seriesgolivares17No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- NRF 24 L 01Document13 pagesNRF 24 L 01Truong Sinh NguyenNo ratings yet

- PROF 1 Modular ComponentsDocument3 pagesPROF 1 Modular ComponentsLhsan RajawiNo ratings yet

- Power Supply Control ICDocument2 pagesPower Supply Control ICsjehaberNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WCN Unit IDocument71 pagesWCN Unit IvmspraneethNo ratings yet

- KBB 1000 PDFDocument43 pagesKBB 1000 PDFJohan SanchezNo ratings yet

- ELEC 210 Exam Sheet PDFDocument7 pagesELEC 210 Exam Sheet PDFshafikatwiNo ratings yet

- Rana TahirDocument35 pagesRana TahirIrfan UllahNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- CD Micro System SC-PM600 Operating InstructionsDocument2 pagesCD Micro System SC-PM600 Operating InstructionsdavidspyNo ratings yet

- Direct Semi-Blind MMSE Equalization For Space Time Block Coding SystemsDocument11 pagesDirect Semi-Blind MMSE Equalization For Space Time Block Coding SystemsdhullparveenNo ratings yet

- Eee446 Lab Manual Spring2015Document23 pagesEee446 Lab Manual Spring2015vognarNo ratings yet

- Multiple Choice QuestionsDocument6 pagesMultiple Choice QuestionsMelvin AntonyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Datasheet - Solis (215 255) K EHV 5GDocument2 pagesDatasheet - Solis (215 255) K EHV 5GTashin WongprasertsiriNo ratings yet

- Detectomat (Incendiu) - CatalogDocument100 pagesDetectomat (Incendiu) - CatalogTibi0% (1)

- CCR Load Calculator 2014-03-13Document41 pagesCCR Load Calculator 2014-03-13Yahya AlkaffNo ratings yet

- HSDPA WCDMA Air InterfaceDocument5 pagesHSDPA WCDMA Air InterfaceСлава ВетровNo ratings yet

- Hissan Physics Set A and BDocument4 pagesHissan Physics Set A and BVaskar Humagain100% (1)

- Electric Charges and Fields - AllDocument238 pagesElectric Charges and Fields - AllRAKSHITA CHAUHAN14No ratings yet

- ASK-2500 SM-E Rev1 PDFDocument80 pagesASK-2500 SM-E Rev1 PDFEduard OsipovNo ratings yet

- Question Bank-NASDocument7 pagesQuestion Bank-NASAmit RajputNo ratings yet

- ARM Cortex-M0 DesignStart ReleaseNoteDocument21 pagesARM Cortex-M0 DesignStart ReleaseNoteyiqingqazwsxNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888walid kawsarNo ratings yet

- Strand Century Lighting 1066 Television Lighting & Control Package Brochure 6-77Document6 pagesStrand Century Lighting 1066 Television Lighting & Control Package Brochure 6-77Alan MastersNo ratings yet

- Week 3 1 PDFDocument33 pagesWeek 3 1 PDFosmanriazNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cenelec: European Standard Norme Europeenne Europäische NormDocument21 pagesCenelec: European Standard Norme Europeenne Europäische NormBuțurcă DănuțNo ratings yet