Professional Documents

Culture Documents

Exhaust System: Section

Uploaded by

skpppOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exhaust System: Section

Uploaded by

skpppCopyright:

Available Formats

ENGINE

SECTION

EXHAUST SYSTEM

EX EX

E

CONTENTS

SERVICE INFORMATION ............................ 2 EXHAUST SYSTEM ........................................... 3 F

Checking Exhaust System ........................................ 3

PREPARATION ................................................... 2 Removal and Installation .......................................... 3

Commercial Service Tool .......................................... 2 G

Revision: 2009 February EX-1 2008 350Z

PREPARATION

< SERVICE INFORMATION >

SERVICE INFORMATION

PREPARATION

Commercial Service Tool INFOID:0000000001646085

(Kent-Moore No.)

Description

Tool name

Power tool Loosening nuts and bolts

PBIC0190E

Revision: 2009 February EX-2 2008 350Z

EXHAUST SYSTEM

< SERVICE INFORMATION >

EXHAUST SYSTEM

A

Checking Exhaust System INFOID:0000000001646086

Check exhaust pipes, muffler and mounting for improper attachment, EX

leaks, cracks, damage or deterioration.

• If anything is found, repair or replace damaged parts.

C

SMA211A E

Removal and Installation INFOID:0000000001646087

CAUTION: F

• Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

• Perform the operation with the exhaust system fully cooled down because the system will be hot

G

just after engine stops.

• Be careful not to cut your hand on the insulator edge.

P

JPBIA1487GB

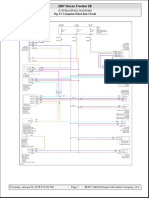

1. Main muffler 2. Mounting rubber 3. Mounting bracket

4. Mounting rubber 5. Center muffler 6. Gasket

7. Exhaust front tube 8. Gasket 9. Dynamic damper

10. Mounting bracket 11. Mounting bracket 12. Mounting rubber

Revision: 2009 February EX-3 2008 350Z

EXHAUST SYSTEM

< SERVICE INFORMATION >

13. Ground cable 14. Ring gasket 15. Mounting bracket

16. Three way catalyst

• Refer to GI-8, "Component" for symbol marks in the figure.

REMOVAL

• Disconnect each joint and mounting with power tool.

• When removing main muffler, remove main muffler mounting bracket bolts.

• For removing and installing parts around propeller shaft, be careful of the following caution.

CAUTION:

Be sure to prevent propeller shaft from interfering parts and tools. If necessary, install protector to

propeller shaft to prevent damage.

For propeller shaft protector, refer to PR-5.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Tighten main muffler mounting bracket bolts in numerical order as

shown in the figure.

PBIC1675E

When reassembling main muffler only.

1. Temporarily tighten connecting flange (A).

2. Move main muffler front/rear/left/right so that clearance between

tail tube and bumper is even.

3. Tighten connecting flange (A) to the specified torque.

When reassembling center muffler.

1. Temporarily tighten connecting flanges in order of (A) and (B).

2. Move main muffler front/rear/left/right so that clearance between

tail tube and bumper is even.

3. Tighten connecting flanges in order of (A) and (B) to the speci-

fied torque.

PBIC2104E

When reassembling exhaust front tube.

1. Temporarily tighten connecting flanges of center muffler in order of (B) and (C).

2. Move main muffler front/rear/left/right so that clearance between tail tube and bumper is even.

3. Tighten connecting flanges in order of (B) and (C) to the specified torque.

CAUTION:

• Always replace exhaust tube gaskets with new ones when reassembling.

• If heat insulator is badly deformed, repair or replace it. If deposits such as mud pile up on heat insu-

lator, remove them.

• When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid gas

leakage.

• Temporarily tighten mounting nuts on the exhaust manifold side and mounting bolts on the vehicle

side. Check each part for unusual interference, and then tighten them to the specified torque.

• When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left

directions.

INSPECTION AFTER INSTALLATION

• Check that clearance between tail tube and bumper is even.

• With engine running, check exhaust tube joints for gas leakage and unusual noises.

Revision: 2009 February EX-4 2008 350Z

EXHAUST SYSTEM

< SERVICE INFORMATION >

• Check that mounting brackets and mounting rubbers are installed properly and free from undue stress.

Improper installation could result in excessive noise and vibration. A

EX

Revision: 2009 February EX-5 2008 350Z

You might also like

- Ex PDFDocument6 pagesEx PDFCarlos Tito AmésquitaNo ratings yet

- Exhaust System: SectionDocument7 pagesExhaust System: SectionTony RojasNo ratings yet

- Escaape NissanDocument6 pagesEscaape NissanpruebaclavesNo ratings yet

- Exhaust System: SectionDocument7 pagesExhaust System: SectionjasleenNo ratings yet

- Ex PDFDocument6 pagesEx PDFOscar VillaseñorNo ratings yet

- Exhaust System GuideDocument6 pagesExhaust System GuideMaiChiVuNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionHakob AdamyanNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionRuhu royNo ratings yet

- Exhaust System GuideDocument7 pagesExhaust System GuideDiego496No ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionSlava SlickNo ratings yet

- Exhaust System: SectionDocument8 pagesExhaust System: SectionABBAS ALINo ratings yet

- Engine Exhaust System GuideDocument6 pagesEngine Exhaust System GuidejasleenNo ratings yet

- Nissan Titan 13/exDocument6 pagesNissan Titan 13/exgiancarlo sanchezNo ratings yet

- Exhaust System: SectionDocument7 pagesExhaust System: SectionederengNo ratings yet

- Engine Exhaust System GuideDocument7 pagesEngine Exhaust System GuideZona Educación Especial ZacapaoaxtlaNo ratings yet

- EX Nissan Sentra 2014Document7 pagesEX Nissan Sentra 2014Rum Zin ApellidosNo ratings yet

- EXHAUST SYSTEM ExDocument6 pagesEXHAUST SYSTEM Exciro_svNo ratings yet

- Nissan March k13 Htr12de Factory Service ManualDocument20 pagesNissan March k13 Htr12de Factory Service ManualWillie100% (45)

- EX Nissan Sentra 2015Document8 pagesEX Nissan Sentra 2015Wilder M. LopezNo ratings yet

- Exhaust System: SectionDocument5 pagesExhaust System: SectionDudu RodriguesNo ratings yet

- Exhaust System: SectionDocument5 pagesExhaust System: SectionAnonymous 64HDY7IiN0No ratings yet

- Accelerator Control System OverviewDocument4 pagesAccelerator Control System OverviewHanselPerezAguirreNo ratings yet

- Exhaust System: SectionDocument7 pagesExhaust System: SectioncesarNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionDozer KamilNo ratings yet

- Accelerator Control System: SectionDocument3 pagesAccelerator Control System: SectionRolfy Jampol AyzanoaNo ratings yet

- Exhaust System: SectionDocument7 pagesExhaust System: SectionWilmer Elias Quiñonez HualpaNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: Sectionภาคภูมิ ถ้ำทิมทองNo ratings yet

- Suspension and Wheel GuideDocument4 pagesSuspension and Wheel GuideJuan Miguel Ossa OspinaNo ratings yet

- Exhaust system guideDocument6 pagesExhaust system guideCarlos Eduardo ZelidonNo ratings yet

- Exhaust System: SectionDocument5 pagesExhaust System: SectionOscar Jhonyffer Pereda RiscoNo ratings yet

- Accelerator Control System GuideDocument4 pagesAccelerator Control System GuideSmith Jara CunyaNo ratings yet

- Exhaust SystemDocument4 pagesExhaust Systemshortbus22No ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionmadurangaNo ratings yet

- Exhaust System: SectionDocument9 pagesExhaust System: SectionmadurangaNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionNestor RosalesNo ratings yet

- Accelerator Control SystemDocument3 pagesAccelerator Control SystemNapiNo ratings yet

- Nissan D40 Exhaust SystemDocument4 pagesNissan D40 Exhaust SystemBuddhika HidurangalaNo ratings yet

- Exhaust System: SectionDocument4 pagesExhaust System: SectionKelvin CarrionNo ratings yet

- Acc PDFDocument4 pagesAcc PDFIsaac Galvez EscuderoNo ratings yet

- Auto Cruise Control System Repair GuideDocument2 pagesAuto Cruise Control System Repair GuideskpppNo ratings yet

- Accelerator Control System: SectionDocument5 pagesAccelerator Control System: SectionOmar MolinaNo ratings yet

- Accelerator Control System OverviewDocument3 pagesAccelerator Control System OverviewmadurangaNo ratings yet

- Nissan-Urvan 2012 en Manual de Taller 3c04e85411Document1,680 pagesNissan-Urvan 2012 en Manual de Taller 3c04e85411Diana SalazarNo ratings yet

- ACCELERATOR CONTROL SYSTEM OVERVIEWDocument4 pagesACCELERATOR CONTROL SYSTEM OVERVIEWAnonymous h1FnZlNNo ratings yet

- Engine Accelerator Control System GuideDocument11 pagesEngine Accelerator Control System GuideJoe CanchicaNo ratings yet

- Steering System: SectionDocument5 pagesSteering System: Sectionguta wondemu mamoNo ratings yet

- ACCELERATOR CONTROL SYSTEM OVERVIEWDocument4 pagesACCELERATOR CONTROL SYSTEM OVERVIEWRuddy RalNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionChristian Josue Teni BremerNo ratings yet

- Front Axle: SectionDocument14 pagesFront Axle: SectionJimmyNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionIRAKLI DVALADZENo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: Sectionmacau apNo ratings yet

- Acc PDFDocument4 pagesAcc PDFJavier GuerreroNo ratings yet

- Exhaust System GuideDocument6 pagesExhaust System GuideihsanjuNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionOleksandrNo ratings yet

- Exhaust System: SectionDocument9 pagesExhaust System: SectioncameronmerazNo ratings yet

- Accelerator Control System GuideDocument1 pageAccelerator Control System GuideMuhammad ArifNo ratings yet

- Exhaust System: SectionDocument6 pagesExhaust System: SectionRifki AwaludinNo ratings yet

- Acc PDFDocument5 pagesAcc PDFAlexAnder CortezNo ratings yet

- Acc PDFDocument4 pagesAcc PDFCarlos Tito AmésquitaNo ratings yet

- 11.sistema de Frenos AntibloqueoDocument93 pages11.sistema de Frenos AntibloqueoskpppNo ratings yet

- EcDocument143 pagesEcTomas FleitasNo ratings yet

- Diagrama Sistema de Datos Nissan Frontier SE 2007 PDFDocument1 pageDiagrama Sistema de Datos Nissan Frontier SE 2007 PDFskppp100% (2)

- BRDocument34 pagesBRskpppNo ratings yet

- Enos de TamborDocument41 pagesEnos de TamborskpppNo ratings yet

- Sintermetal Manual DIESEL 2015 DigitalDocument120 pagesSintermetal Manual DIESEL 2015 DigitalBrian OrtegaNo ratings yet

- 6 DireccionDocument40 pages6 DireccionskpppNo ratings yet

- Enos de DiscoDocument125 pagesEnos de DiscoskpppNo ratings yet

- Manual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFDocument148 pagesManual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFskpppNo ratings yet

- CLDocument19 pagesCLSmith Jara CunyaNo ratings yet

- Optimized Fuel System GuideDocument12 pagesOptimized Fuel System GuideskpppNo ratings yet

- Front Axle: SectionDocument7 pagesFront Axle: SectionskpppNo ratings yet

- Engine Mechanical: SectionDocument145 pagesEngine Mechanical: SectionskpppNo ratings yet

- Exterior & Interior: SectionDocument47 pagesExterior & Interior: SectionskpppNo ratings yet

- Driver Information System: SectionDocument87 pagesDriver Information System: SectionskpppNo ratings yet

- Engine Control System: SectionDocument665 pagesEngine Control System: SectionskpppNo ratings yet

- Engine Cooling System: SectionDocument29 pagesEngine Cooling System: SectionskpppNo ratings yet

- Accelerator Control System GuideDocument4 pagesAccelerator Control System GuideSmith Jara CunyaNo ratings yet

- Brake Control System: SectionDocument126 pagesBrake Control System: SectionskpppNo ratings yet

- Auto Cruise Control System Repair GuideDocument2 pagesAuto Cruise Control System Repair GuideskpppNo ratings yet

- Body, Lock & Security System: SectionDocument226 pagesBody, Lock & Security System: SectionskpppNo ratings yet

- Audio Visual, Navigation & Telephone Sys-TEM: SectionDocument103 pagesAudio Visual, Navigation & Telephone Sys-TEM: SectionskpppNo ratings yet

- Engine Mechanical: SectionDocument145 pagesEngine Mechanical: SectionskpppNo ratings yet

- BcsDocument15 pagesBcsSmith Jara CunyaNo ratings yet

- Acs PDFDocument2 pagesAcs PDFskpppNo ratings yet

- Section: SERVICE INFORMATION ...........................Document72 pagesSection: SERVICE INFORMATION ...........................skpppNo ratings yet

- Accelerator Control System GuideDocument4 pagesAccelerator Control System GuideSmith Jara CunyaNo ratings yet

- Brake System: SectionDocument55 pagesBrake System: SectionskpppNo ratings yet

- Automatic Air Conditioner: SectionDocument125 pagesAutomatic Air Conditioner: SectionskpppNo ratings yet

- Pressure Data Logger PDFDocument2 pagesPressure Data Logger PDFMuhammad Akbar WalennaNo ratings yet

- Properties of Materials - Part A - 1Document115 pagesProperties of Materials - Part A - 1Prasad MadhavanNo ratings yet

- MID LEC 2 User Interfaec DesignDocument10 pagesMID LEC 2 User Interfaec DesignspartaaaanNo ratings yet

- Paper - Update On Subsea LNG Pipeline TechnologyDocument11 pagesPaper - Update On Subsea LNG Pipeline TechnologyfralgiugiaNo ratings yet

- Goldman+Sachs+Interview+Process My+CompilationDocument3 pagesGoldman+Sachs+Interview+Process My+CompilationPraveen NagarajanNo ratings yet

- Music Appreciation Quiz #1Document3 pagesMusic Appreciation Quiz #1KristinNo ratings yet

- Open Source Frequency Counter DIY Kit 10Hz-250MHzDocument10 pagesOpen Source Frequency Counter DIY Kit 10Hz-250MHzBruno Santos de Miranda100% (1)

- Quality Control Tools For Improving Processes: Supplement 6Document55 pagesQuality Control Tools For Improving Processes: Supplement 6janssen.villian3621No ratings yet

- Omni Antenna HG2408U-NF - 2DDocument1 pageOmni Antenna HG2408U-NF - 2DedgarNo ratings yet

- Compression Techniques For Digital Hearing AidsDocument77 pagesCompression Techniques For Digital Hearing AidsDario SevieriNo ratings yet

- Report of The Special Group On Targeting Ten Million Employment Opportunities Per Year Over The Tenth Plan PeriodDocument180 pagesReport of The Special Group On Targeting Ten Million Employment Opportunities Per Year Over The Tenth Plan PerioddeputykrishanNo ratings yet

- Seminar On Substation TrainingDocument24 pagesSeminar On Substation TrainingPankaj SharmaNo ratings yet

- 1STC804013D0207 PDFDocument376 pages1STC804013D0207 PDFDiego PeñaNo ratings yet

- ch05Document13 pagesch05Engine Tuning UpNo ratings yet

- RA PHARMA DAVAO Mar2019 PDFDocument21 pagesRA PHARMA DAVAO Mar2019 PDFPhilBoardResultsNo ratings yet

- Smart Key System - KhaphamKJGUDocument41 pagesSmart Key System - KhaphamKJGUthu vuNo ratings yet

- Unidrive M700-M701 and M702 Control UG Issue 2 (0478-0353-02) - ApprovedDocument286 pagesUnidrive M700-M701 and M702 Control UG Issue 2 (0478-0353-02) - Approvednorbert0% (1)

- Manual Ecograf Portabil WED 9618Document76 pagesManual Ecograf Portabil WED 9618dorian0887% (15)

- Learning Mastercam X8 Step by Step LATHEDocument180 pagesLearning Mastercam X8 Step by Step LATHEatgordon167% (3)

- ERP Training ProcessDocument28 pagesERP Training Processritesh_gandhi_7100% (1)

- Instrumentation Cable & Communication Cable Material ListDocument2 pagesInstrumentation Cable & Communication Cable Material ListMathavan ABMNo ratings yet

- Securiton Smoke Detector Performance DeclarationDocument2 pagesSecuriton Smoke Detector Performance DeclarationAnonymous YWmB9HDgNo ratings yet

- Ilovepdf MergedDocument33 pagesIlovepdf MergedNavneet KaurNo ratings yet

- Manual Montaje Mecanico Precision PlantingDocument173 pagesManual Montaje Mecanico Precision PlantingJose luis CeaNo ratings yet

- BFSK ReportDocument8 pagesBFSK ReportSneh Sagar RajputNo ratings yet

- Lean PokaYokeDocument2 pagesLean PokaYokemilou88No ratings yet

- MODEL NO: 417-4032 Hydraulic Systems: Revision: 2 GROUP NUMBER: 64546336 5-1Document47 pagesMODEL NO: 417-4032 Hydraulic Systems: Revision: 2 GROUP NUMBER: 64546336 5-1Jesus Angel AVNo ratings yet

- Mud Logger Training Manual PDFDocument4 pagesMud Logger Training Manual PDFAnonymous oe5mdI0% (1)

- Rize Build June 2ND WeekDocument8 pagesRize Build June 2ND WeekAbhishek RajputNo ratings yet