Professional Documents

Culture Documents

How To Take Oil Samples PDF

How To Take Oil Samples PDF

Uploaded by

Catalin Sevastian0 ratings0% found this document useful (0 votes)

16 views3 pagesOriginal Title

How to take oil samples.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesHow To Take Oil Samples PDF

How To Take Oil Samples PDF

Uploaded by

Catalin SevastianCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

MAN B&W Diesel A/S Production Recommendation Baw

fate No deat Naz

3.93815 ME Engines. 07431 19-6.

How to take fluid sample ava

A

fe foe|ssfnfin| aslo male] 2

(Chic Tappa. [Photodate] A.C.

y

This document is valid for the following engine types:

wz

SV [°801C AYR NVI 8661 @ WYEHAdOD

[ear

Suppl Draws |

All ME types added.

‘The Production Recommendation should be regarded as a guideline.

Contents

1. Scope and field of application

2. References

3. How to Take a Fluid Sample

1. Scope and field of application

This Production Recommendation deals with “how to take a fluid sample” during flushing of

the hydraulic system.

2. References

us gy

Poiee 04018 Bue Si o601d Mtge NVI Jo Avodand op

nowy Aued pay fue 0} pasojoeIp oq 0} 04 6

ISO 3722 and ISO 4406

NAS 1638

MAN B&W Diesel A/S Production Recommendation

g ‘dent Noz

3 ME Engines. 07431 19-6.

z How to take fluid sample PageNoz

@ al 2 (3)

3

g a

2 3. How to Take a Fluid Sample

& Note! That for the MAN B&W ME engine it is advisable to use a sampling valve of the

5 “MINIMESS” type.

Sampling valves are installed at a point in the system where the flow is normally constant and

turbulent.

To obtain representative samples, it is essential that only sample bottles cleaned and qualified

in accordance with ISO 3722 are used.

3.1 The procedures below must be followed precisely in order to avoid external

contamination that would invalidate the test result:

au,

aa nv

1. Operate the system for at least half an hour prior to taking the sample in order to

distribute the contamination as evenly as possible within the fluid.

dado 91

. Clean the outside of the sampling valve. Attach a capillary tube to the valve outlet.

Open the sampling valve and flush at least one litre of fluid through the valve. Do not

close the valve after flushing.

. When opening the sampling bottle, avoid tearing the clingfilm. Hold the clingfilm

against the bottle. Before completely removing the cap, lift the film over the cap so

that cap and film are removed together. The cap and film must not be placed on any

surface; they must be held in the hand facing downwards.

. Collect about 200 ml of fluid in the sampling bottle (min, 100 mi).

. Cap the sampling bottle immediately and carefully wipe the bottle. Then close the

sampling valve.

5. Label the sampling bottle with details of the system (number, date, ctc.).

yum oud oyjoeds ey) jnouym AvEd pay) Aue o} pesoAEIp eq 0} JOU ie

da epuepauos oe poison on 19 BU SV OS NAGE NVI

In the testbed lube oil tank, the oil sample must be taken at the evel of the

pump inlet. At least 200 ml of oil should be allowed to flow out before the sample

is taken.

Samples should not be taken from reservoir drain taps.

Continue flushing until the specified level of purity is achieved.

‘BYyoeta wg nvr so wossuued

amuigns uoeg Seu WOYM o}

MAN

Baw

MAN B&W Diesel A/S Production Recommendation

Tato No Tent Noe

393815 ME Engines. 0743119-6.

a How to take fluid sample Page No

Ad 3_(3)

pa on p= Pio ane] ‘Change Replacement exe

PRE Z3_ [ANIME pes added I

3.2 The Hydraulic System on the ME engine requires

ISO 4406 Cleanliness Code x/16/13 correspond to NAS 1638 code 7

‘SIV 19801C NVR@ NVIN 866} @ 148UKdoD

This corresponds to a quantity interval of:

‘Number of particles > 5 um from 32 x 10° to 64 x 10° in 100 ml sample.

Number of particles > 15 ym from 4x 10° to 8x 10° in 100 ml sample.

‘The permissible operating kinematic viscosity range for the fluid is:

Min (cSt= mm/s) .....16

Max (cSt= mm/s) .....1000

‘Where 1000 cSt is only valid during the startup period of an engine.

‘The permissible operating temperature range for the fluid

ue Si

+10

z

3

Ff

z

g

S

2

;

:

=

z

3

=

3

eS

yun ovd oyoods ex non ued pay fun 0 pasopaip 09 ou

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Performance Adjustment On ME Engine CheckDocument26 pagesPerformance Adjustment On ME Engine CheckCatalin Sevastian91% (11)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Electroclean A Quick Dry PDFDocument8 pagesElectroclean A Quick Dry PDFCatalin SevastianNo ratings yet

- 2 SEP 2013-Near Miss Report No.2Document1 page2 SEP 2013-Near Miss Report No.2Catalin SevastianNo ratings yet

- Air Cooler CleanerDocument9 pagesAir Cooler CleanerCatalin SevastianNo ratings yet

- Material Safety Data SheetDocument6 pagesMaterial Safety Data SheetCatalin SevastianNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetCatalin SevastianNo ratings yet

- Boiler Sludge ConditionerDocument7 pagesBoiler Sludge ConditionerCatalin SevastianNo ratings yet

- Air Cooler Cleaner LTDocument9 pagesAir Cooler Cleaner LTCatalin SevastianNo ratings yet

- Marine: Exhaust Gas Cleaning SolutionsDocument24 pagesMarine: Exhaust Gas Cleaning SolutionsCatalin SevastianNo ratings yet

- Brochure Service - A4 3Document4 pagesBrochure Service - A4 3Catalin SevastianNo ratings yet

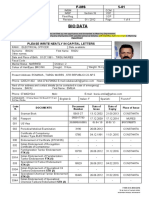

- F-IMS 5-01 Bio Data Rev 01-2012 - BACIUDocument4 pagesF-IMS 5-01 Bio Data Rev 01-2012 - BACIUCatalin SevastianNo ratings yet

- Brochure RenewablesDocument5 pagesBrochure RenewablesCatalin SevastianNo ratings yet

- Test H2SDocument1 pageTest H2SCatalin SevastianNo ratings yet

- 001 Pcsopep Annex ArielDocument18 pages001 Pcsopep Annex ArielCatalin SevastianNo ratings yet

- MPC Connections PDFDocument1 pageMPC Connections PDFCatalin SevastianNo ratings yet

- Salwico MN 3000 MalfunctionDocument1 pageSalwico MN 3000 MalfunctionCatalin SevastianNo ratings yet

- How To Take Oil SamplesDocument3 pagesHow To Take Oil SamplesCatalin SevastianNo ratings yet

- MAN Diesel & Turbo Teglholmsgade 41 2450 Copenhagen SV, Denmark Phone +45 33 85 11 00 Fax +45 33 85 10 30Document27 pagesMAN Diesel & Turbo Teglholmsgade 41 2450 Copenhagen SV, Denmark Phone +45 33 85 11 00 Fax +45 33 85 10 30Catalin SevastianNo ratings yet

- ME Power Calculation 29.07.13Document1 pageME Power Calculation 29.07.13Catalin SevastianNo ratings yet

- 3362-WBM-1 Ariel - Ballast Water Management Plan (No Bep) PDFDocument386 pages3362-WBM-1 Ariel - Ballast Water Management Plan (No Bep) PDFCatalin SevastianNo ratings yet

- Oil Water Separator Tupe: Tmpb-5: Programming Mode Tupe: Omd 2005Document2 pagesOil Water Separator Tupe: Tmpb-5: Programming Mode Tupe: Omd 2005Catalin SevastianNo ratings yet