Professional Documents

Culture Documents

2360 Industry Process Safety White Paper

Uploaded by

Atul Choudhari0 ratings0% found this document useful (0 votes)

50 views3 pagesRole of automation in process safety

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRole of automation in process safety

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views3 pages2360 Industry Process Safety White Paper

Uploaded by

Atul ChoudhariRole of automation in process safety

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

WHITE PAPER

The Role of Automation

in Process Safety

“Houston, we have a problem.”

Paul Gruhn,

Global Process Safety Consultant,

Rockwell Automation

Standards

Certification

Education & Training

Publishing

Conferences & Exhibits

The Role of Automation in Process Safety

“Houston, we have a problem.”

How did this happen?

Industry is facing a number of

trends that are having an impact Would you rather learn from the mistakes of others, or make them all your-

on safety: self? Do you want to see your company in the news with disasters similar to

Plants are aging. Many older those that occurred at Bhopal, Pasadena, Texas City, and others? Do you pos-

facilities may not meet today’s sibly feel that those events could never happen at your facility? Do you say to

more stringent requirements for yourself, “We’ve been operating for 20 years without an accident; we are a

safety. safe facility.” Please keep in mind they said that one day before all the above

mentioned accidents. Just because it hasn’t happened yet, doesn’t mean that

Experienced, knowledgeable

it can’t, or won’t.

employees (i.e., the baby boom-

ers) are retiring faster than ever, Several serious process accidents in the US led to the development of CFR

and their knowledge is leaving 1910.119 (Process Safety Management of Highly Hazardous Chemicals)

with them. over 20 years ago. There are similar process safety management regulations

Newer, younger employees around the world that were developed for the same reasons. The US regu-

do not have the experience or lation specifically refers to emergency shutdown systems, alarms, testing, pro-

knowledge of those they are cedures, training, management of change, and much more. OSHA expects

replacing. industry to follow standards and they have specifically acknowledged ISA

With a smaller workforce, a lot standards as RAGAGEP (Recognized And Generally Accepted Good Engineer-

of work is being outsourced to ing Practices). Several companies have been fined for not following the ISA

contractors, who may also not 84 (IEC 61511) standard on safety instrumented systems.

have in-depth, specific knowl-

Following industry standards and best practices should not be viewed as

edge of your facility.

a burden or with a simple ‘tick the box’ mentality. Standards are based on

Budgets are tight. Some com- the combined knowledge of many different organizations—and their inter-

panies no longer wish to pay nal subject matter experts—that all learned the material the hard way. You

for the training of their em- should take advantage of all this material and view it as a gift that can make

ployees, yet this can be the real your enterprise safer, more productive, and more efficient!

differentiator as to the success

of your enterprise. Safety must come from the top down. Companies need to walk the walk,

not just talk the talk. As an example, would you be willing to follow the old

DuPont requirement of having the owner or plant manager live on the facil-

ity, with his family? (For the first 100 years of DuPont, all they made was gun

powder for the US government. Make gun powder for a living and you learn

about process safety, often the hard way!)

The Role of Automation in Process Safety

A solution About the Author:

Ignorance is not bliss. People without experience and training are prone to Paul Gruhn is an ISA instructor and

make mistakes, whether it is an engineer doing a design, or a technician work- a Global Process Safety Consultant

ing on an instrument. Oversights and mistakes can lead to costly accidents. at Rockwell Automation in Houston,

While experience takes time to develop, training can be done relatively quickly Texas. Gruhn is a member of the

and can help increase peoples competence. Their newly acquired knowledge ISA84 committee, co-author of the

can then be used to make your facility safer and more productive. ISA textbook Safety Instrumented

Systems: Design, Analysis and

ISA offers various standards, books and training—along with certification and

Justification, author of many articles,

certificate programs—to improve the knowledge and competency of your

and the developer of a control and

employees. There are courses for managers, engineers, and technicians. Safety

safety system modeling software

related topics include safety instrumented systems, alarm management, human

package. He is a registered

machine interface design, control system security, and more.

professional engineer in Texas, a

Certified Functional Safety Expert—

ISA can help a TÜV certification—and an ISA

Fellow.

Who better to learn from than an industry group that writes industry standards?!

Competing and succeeding in the high-skill, high-tech world economy requires

a well-trained workforce. How well your organization retains core knowledge

and capabilities—through ongoing investment in human capital—may very well

determine your success and growth in the months, years, and decades ahead.

By relying on ISA to deliver leading-edge technical training, you’ll provide your

employees with the skills and expertise needed to optimize their performance

and productivity, and improve your organization’s competitive edge and opera-

tional results.

Plus, ISA can help you achieve all this at your location! Through ISA’s Onsite

Training services, we can bring our industry-leading instructors, proven train-

ing materials, and indispensable hands-on training devices to you. You gain a

customized solution that is highly convenient, cost effective, and flexible—and

one specially designed to help you improve your productivity and efficiency and

avoid unscheduled downtime.

International Society of Automation

Contact one of our ISA Learning Consultants to learn more about our training, 67 T.W. Alexander Drive

P.O. Box 12277

certification and certificate programs: Research Triangle Park, NC 27709

PHONE +1 919-549-8411

Heidi Cooke Andy Hayworth Matt Rothkopf

FAX +1 919-549-8288

hcooke@isa.org ahayworth@isa.org mrothkopf@isa.org EMAIL info@isa.org

+1 919-990-9405 +1 919-990-9255 +1 919-990-9403 www.isa.org

You might also like

- 10 - Chapter 5Document35 pages10 - Chapter 5Atul ChoudhariNo ratings yet

- 09 - Chapter 6Document86 pages09 - Chapter 6Atul ChoudhariNo ratings yet

- PTQ Q3 08 Improving Crude Vacuum Unit Performance PDFDocument5 pagesPTQ Q3 08 Improving Crude Vacuum Unit Performance PDFAtul ChoudhariNo ratings yet

- Draft Report On Hydrogen Energy and Fuel Cells A Way ForwardDocument78 pagesDraft Report On Hydrogen Energy and Fuel Cells A Way ForwardAtul ChoudhariNo ratings yet

- Heat ExchagersDocument4 pagesHeat ExchagersAtul ChoudhariNo ratings yet

- 2018 Media Planner: Print - Digital - Editorial - Events - Lead GenerationDocument16 pages2018 Media Planner: Print - Digital - Editorial - Events - Lead GenerationAtul ChoudhariNo ratings yet

- 3DTCOS Reduces Overhead Corrosion Control CH-1960Document4 pages3DTCOS Reduces Overhead Corrosion Control CH-1960Atul ChoudhariNo ratings yet

- Vacuum Column DesignDocument6 pagesVacuum Column DesignAtul ChoudhariNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Content Area ResourcesDocument3 pagesContent Area Resourcesapi-312565527No ratings yet

- Seats in IITsDocument8 pagesSeats in IITsNishit kumarNo ratings yet

- Lesson 4.4 The NanoworldDocument38 pagesLesson 4.4 The NanoworldcadoarvinNo ratings yet

- European CV Format-1Document2 pagesEuropean CV Format-1BayisaGebre100% (1)

- 20d-Stepped Masonry Retaining Wall-Stability CheckDocument6 pages20d-Stepped Masonry Retaining Wall-Stability CheckParthiban Arivazhagan100% (1)

- IilmDocument3 pagesIilmAMIT PANDEYNo ratings yet

- MCR SlabDocument5 pagesMCR SlabAswin KumarNo ratings yet

- Reviewer InteriorDocument8 pagesReviewer InteriorLaurence Emmanuel BenedictosNo ratings yet

- ABS - Part 4 - e PDFDocument700 pagesABS - Part 4 - e PDFMuhammad Fauzan Mauliawan100% (1)

- Avoiding Plagiarism Through ParaphrasingDocument36 pagesAvoiding Plagiarism Through ParaphrasingJan Iriesh EspinosaNo ratings yet

- Lab Manual - EEE18R171Document86 pagesLab Manual - EEE18R171K.V. PrabhasNo ratings yet

- Reinf TableDocument2 pagesReinf TableRigel NapaNo ratings yet

- IDC TechnologiesDocument5 pagesIDC Technologiesidctech0% (1)

- Interior Designers List GurgaonDocument53 pagesInterior Designers List GurgaonKevin HansonNo ratings yet

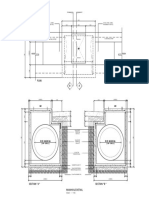

- Drainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Document1 pageDrainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Jayson DaiganNo ratings yet

- Hauling & Disposal of Unsuitable Materials EstimateDocument2 pagesHauling & Disposal of Unsuitable Materials EstimatereynoldNo ratings yet

- PAES 224 - Rice Combine - SpecsDocument11 pagesPAES 224 - Rice Combine - Specslennahfe19No ratings yet

- MoS For Piping Support InstallationDocument19 pagesMoS For Piping Support Installationilliasuddin100% (1)

- Resume FormateDocument1 pageResume FormateShesharamChoudharyNo ratings yet

- 05698665Document8 pages05698665Lalo PatoNo ratings yet

- Recycled Concrete AggregateDocument28 pagesRecycled Concrete AggregatePrashant pande100% (1)

- KITS RamtekDocument162 pagesKITS RamtekdmadekaNo ratings yet

- Che 413 IntroDocument23 pagesChe 413 IntroAbdur RashidNo ratings yet

- 7251 08 103 Pipe Outfall PDFDocument1 page7251 08 103 Pipe Outfall PDFKBNo ratings yet

- Buckling Restrained Braced FrameDocument24 pagesBuckling Restrained Braced Framedanish khanNo ratings yet

- Socotec Profile & Capability Statement 2024Document21 pagesSocotec Profile & Capability Statement 2024EKNo ratings yet

- Good Practices For Requirements EngineeringDocument4 pagesGood Practices For Requirements EngineeringJessicaNo ratings yet

- Academic Chairs of Sultan Qaboos II EnglishDocument5 pagesAcademic Chairs of Sultan Qaboos II EnglishFatema SalahNo ratings yet

- Chapter 14 Security Engineering 1Document48 pagesChapter 14 Security Engineering 1Fattah MuhyiddeenNo ratings yet

- Educational Textbook CollectionDocument39 pagesEducational Textbook CollectionSisi IbrahimNo ratings yet