Professional Documents

Culture Documents

Planning and Scheduling of Low Income Housing Scheme Project by Line of Balancing Method

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planning and Scheduling of Low Income Housing Scheme Project by Line of Balancing Method

Copyright:

Available Formats

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Planning and Scheduling of Low Income Housing

Scheme Project by Line of Balancing Method

Amey Satish Darange Mahesh B.Sonawane

Department of Civil Engineering, Assistant Professor, Department of Civil Engineering,

Maharashtra Institute of Technology, Maharashtra Institute of Technology,

Pune, India Pune, India

Abstract:- Construction projects comes across various A. Problem statement

milestones, resulting into delay in execution of project, Determining delay in execution of project and

hence there is need to improve techniques in planning so comparing Line Efficiency and Smoothness Index with actual

that project is carried out within stipulated time. The project duration and planned duration using Line of Balance

LOBST (Line Of Balance Scheduling Technique) is a technique and the flow lines are plotted in VICO CONTROL

scheduling method which makes the operations to be software.

carried out effectively and allows activity can be

performed continuously and efficiently in each B. Objectives

consecutive unit. Line Of Balance Scheduling Technique To study and implement the LINE OF BALANCE

is a significant technique that plays important role in method. As LOB method is implemented in repetitive

repetitive construction project. Lack of awareness of scheduling projects. This method is used to plan activities

proper method and techniques increases cost and project and act as important method in project management.

completion time. It becomes very important to adopt Study of VICO CONTROL software and its

proper methodology while doing the housing project for implementation for scheduling of project. Flow lines are

low income group. This paper aims to evaluate the real plotted in this software.

application of line of balance in low income housing Determining non-utilized zones with help of VICO

scheme. Case study of low-income housing project by CONTROL software. The non utilized zones represents

MHADA at Talegaon-Dabhade,Pune. Also supports the that activities are not carried out during that period of

method developed in the paper. The findings point out time.

significant controlling benefits of LOB is comparing with To compare planned activities and its actual

GANNT CHART Method in the project and addresses implementation with planned line balancing.

limitations showing the efficient use of LOB. VICO To estimate amount of delay in the project.

CONTROL software is used to schedule the project by

line of balance technique. It is observed that this method C. Scope

increases line efficiency and minimizes smoothness index. Line of Balance method has various advantages over

other planning methods. Use of this method allows us to

Keywords:- Repetitive Scheduling Method (RSM), Line Of reschedule the project even if it is affected with delays.

Balance (LOB),Cycle Time(CT),Line Efficiency(LE),Work Implementation of this method can be useful for housing

Station(WS). development authority to provide affordable housing

schemes without delay to LIG and EWS section.

I. INTRODUCTION

II. LITERATURE REVIEW

Urban housing shortage in India is prominent across the

economically weaker sections (EWS) and low-income groups Lim Chuan Pei (2002) This paper aimed at

(LIG) which together constitute over 95 percent of the total implementing Line Balancing to improve the productivity. A

housing shortage. There is need to provide housing facilities case study conducted at a manufacturing company. Line

to EWS and LIG section but due to rapid growth in balancing method is used to determine productivity rate and

population and inappropriate planning it can be seen that assembly line balancing is carried out to achieve high

there is huge gap between demand and supply. Delays in productivity rate.

construction project results in collapse of management

techniques and results in cost overrun. Hence, proper Olli Seppänen and Erno Aalto (2005) This paper

planning and scheduling of construction project is required to represented the importance of the Line of Balance (LOB)

meet the demand. scheduling method and showed how this method can be

useful to achieve the practice by using location-based

production controlling tools. The case study consisted of

Business Park with area of 14,500 m2. Its design includes 2

sections casted, independently of each other and of parking

below the main building. And scheduling of activities was

IJISRT19NOV440 www.ijisrt.com 268

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

carried out using Line of Balance method. III. METHODOLOGY

Caroline P. Valente, Germano A. Montenegro (2014) Case study of MHADA (Maharashtra Housing and Area

This paper, through a case study at a Brazilian construction Development Authority) project located at Talegaon

company aims to put forth the guidelines for developing a Dabhade, Pune, India is considered.Authority

LOB for common areas. The results shows that the Line Of planned/scheduled the project by using gannt chart method.

Balance in provided transparency to employees and engineers Scheduled project is analyzed by finding line efficiency and

for planning. This was achieved even with decreased crew Smoothness index. Project rescheduled by line of balance

size. The control over project’s total term was achieved. method by using VICO control software and flow lines are

plotted.

Ms. Harsha Talodhikar, Mrs. Smita V. Pataskar

(2015) This paper includes application of applying Line of A. Data Collection

Balance method to multi storey buildings and draw the graph The data of the project was collected from the authority

of repetitive activities, as applying LOB facilitates the which includes a planned Gantt chart. The below figure

continuous monitoring of the project, at each stage. The shows the planned Gantt chart which was proposed by the

production rate of activities is determined and cost is authority, and its failure of implementation resulted into

compared with actual and delay project. The rate of flow of delay in the construction project work. The planning of total

activities is determined by plotting the graph of activities 26 activities was made by using Gantt.

after crashing and also rate of flow of activities is

determined. The number of crew required is also determined. The table represents the start of project on 4th May,2010

and its completion on 12th September,2011.It can be seen that

total planned number of days for execution of project is 496

days.

Fig 1:- Gantt-chart planned by authority before project execution

IJISRT19NOV440 www.ijisrt.com 269

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

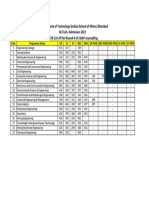

Table 1:- Planned number of Days for each activity

The above figure shows the planned duration, start date and end date of the activities. From obtained Gantt Chart the

following table is prepared and duration of each activities can be easily determined. So, planned duration of project consists of

496 days.

Fig 2:- Actual number of Days for each activity after execution

IJISRT19NOV440 www.ijisrt.com 270

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The above table obtained from the authority, shows the actual number of days required for the completion of each activity. It

can be seen that the project was completed on 28th October,2011 which was scheduled to finish on 12th sepetember,2011.Hence it

can be seen that the project required additional 46 days to complete than the planned duration. This shows that there is delay in

execution of project.

Table 2:- Actual Durations required to complete project

The above figure shows the actual duration required to execute each activity. This indicates that the activities are completed

on 28th October,2011 rather than 12th September,2011.

B. Methodology

The following figure shows plotting of flow lines in This technique is Line of Balance technique and by this

VICO CONTROL software. This software is used for method delay can be avoided. This avoidance of clashing of

determining the nature and productivity rates of the activities. activities can be done by allotting the buffer.

When activity is plotted for different floors these flow lines

are combined to summary task which gives the nature of the Another point of clashing takes place between internal

work that has been carried out and also gives productivity plaster, providing and fixing mild steel grill, internal

rates. plumbing where the clashing of activities need to be avoided.

In the figure below depicts the clashing of the activities Also the area where there are no flow lines which

which means that one activity has higher production rate than indicates the region where no proper utilization of time has

the other which implies that the activity with higher taken place. This areas need to be avoided for increasing the

production rate has to wait or stand idle until completion of line balancing which is our ultimate goal.

the other activity with lower production rate takes place. This

causes delay in construction project work. So basic aim to As per the graph drawn using VICO software,

avoid the crossing of the activities so that none of the activity construction of “RCC columns” was started on 2 august,

depends upon other for its completion and does not have to 2010. It took 121 days for completion of all units. Then its

wait idle to decrease the efficiency. successor activity is construction of “RCC slab, beams, and

lintels”. It means that this activity is purely depends upon

The below figure shows that the Brick Masonry and first activity for its completion i.e. we cannot construct RCC

Chajja these both activities clash each other the productivity slab, beams, lintels until the construction of columns have

rate of chajja is more than the brick masonry work and done. Therefore, as shown in the graph, these two activities

according to precedence relationship chajja cannot be are not clashing with each other. but the second activity took

constructed before the brick masonry work is completed so, 135 days for its completion.

here it is necessary to avoid the clashing of the activities.

IJISRT19NOV440 www.ijisrt.com 271

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Now, after the construction of beam, slab, lintels have each other. These is happened because production rate for

started, the construction of “Brick masonry” can be started “RCC chajjas” is greater than that of “Brick masonry” work.

as shown in the graph. After this, construction of “RCC Brick masonry is taking 155 days for its completion while

chajjas” is the successor activity of the Brick masonry. It that of RCC chajjas are taking only 130 days. Therefore, in

means that the RCC chajjas for one unit cannot be planning, we can delay the “RCC chajja ” work so that it

constructed until its brick work have done. But from the will finished just after the completion of brick masonry work.

graph , it is seen that , these two activities are clashing with

Fig 3:- Flowlines plotted in VICO CONTROL software of actual duration of project

After the RCC chajjas work had been started, work for “ plastering was started. But , the rate of internal plumbing

providing and fixing MS grills” can be started as per shown work ,as per the actual schedule, is too slow that it is carrying

in the graph. It is also depends upon the brick masonry work out even after the internal plastering have been done. It is

and RCC chajjas work i.e. it cannot be started until the RCC clashing with so many activities. After that, the water

chajjas work for one unit had been done. Here also, as per in proofing work and dado works are done .As per shown in the

the graph, the production rate for “providing and fixing MS graph, these two activities have almost same production

grills” is greater .so , it should be adjusted in such a way that rates. but the “dado” work is successor activity of water

it will finish just after the construction of RCC chajjas. proofing work. It cannot be completed until the water

proofing has done.

After the “providing and fixing MS grills” work had

been started, work for “internal cement plaster” can be The “flooring and skirting” work and work for “kitchen

started as per shown in the graph. It is also depends upon otta” are started after the dado work for one unit has been

completion of its previous work. Internal cement plastering done. As per in the graph, they both have the same

work can be finished after MS grills have been provided. production rates. “Oil bound distemper” can be started

applying after the completion of “flooring and skirting” and

Here ,as shown in the actual schedule, the “Internal “kitchen otta ” work.

plumbing” work is started on the day when internal cement

IJISRT19NOV440 www.ijisrt.com 272

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

“Fixing doors” and fixing aluminum sliding windows” many activities. And after completion of external painting,”

are the successor activities of the “oil bound distemper” laying of Shahabad stones “ had been done. At the end, the

work. These two activities cannot be finished until the oil “cleaning and handover” work had been done. Overall, actual

bound distemper work have been done. schedule concludes that it took total “542 days” for

Then, after that, as per the actual schedule, they had completion of project. The project can be managed and

started a work of “applying apex white external paint” after planned in such a way that it will take less number of days

the doors and windows fixing. As per the schedule, the for its completion. To achieve this, we are going to use a

“applying sand faced external plaster” and “external Line of Balancing (LOB) technique for scheduling of

plumbing” had already done earlier that had clashed with so activities.

C. Calculation of Line Efficiency on actual duration of project:

Fig 4:- Precedence relationship between activities

For scheduling of project through line of balance activities depends upon the others for their completion. This

technique it is necessary to know the precedence relationship. precedence relationship is required for the scheduling of the

The above figure depicts the relationship between the project by using line of balance technique.

activities based on precedence network diagram. As the

relation between the activities is Finish to Finish relationship Based on the precedence network in above figure the

(FF) relationship i.e. second activity (successor)cannot be activities are symbolized by numeral digits in the following

finished unless first activity (preceding) does not finish. Like figure the activities with symbols and its duration is shown.

for example, internal cement plaster cannot finish unless and

until its successor brick masonry is completed. This is finish D. Precedence relationship

to finish relationship between the activities. The figure below shows the summary of the precedence

network diagram. Various activities with its preceding

The above figure shows various dependency of the activity is summarized from the precedence network

activities. The following figure depicts the symbol used for diagram.

various activities and their dependency with other activity

can be determined by the above precedence diagram. For The precedence relationship is used to solve line

example in the above figure activity with symbol 9 is brick balancing problem. In this project Longest Candidate Rule is

masonry, activity 12 is internal electric work,13 is providing used to determine line efficiency. For this method it is

and fixing ms grill,14 is internal cement plaster,15 is internal necessary to know the precedence relationship between the

plumbing now according to the precedence relationship activities. It just simply mean that we should know the

activity 12,13,14 and 15 cannot start until activity 9 (brick logical relationship between the activities.

work) is completed. This precedence relation shows which

IJISRT19NOV440 www.ijisrt.com 273

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 3:- Activities with symbols for precedence relation Table 4:- Precedence relationship and time required for each unit

The above figure shows that total time duration is 542 days for 37 units. For 1 unit total task time accounts for 89.82 days.

The total task time for each unit is calculated by dividing the total duration of each activity by number of units (37) and adding the

duration required for each activity for 1 unit. This total accounts for 89.82 which is sum of task times for per unit production. It is

essential to calculate the minimum number of work stations required for the production.

E. Determination of Cycle Time:

Cycle Time (CT) = Total time available

Desired output

= 542

37

= 14.64 days

F. Determination of Minimum Number of Work Stations:

Minimum number of = (Total task time for unit production)

Work Stations (Cycle Time)

= 89.82

14.64

= 6.13

= 7 stations (number of stations to be rounded off)

Minimum number of work stations =7

G. Longest Candidate Rule:

Procedure:

Step 1. List all elements in descending order of Te value, largest Te at the top of the list.

IJISRT19NOV440 www.ijisrt.com 274

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Step 2. To assign elements to the first workstation, start at the top of the list and work done, selecting the first feasible element for

placement at the station. A feasible element is one that satisfies the precedence requirements and does not cause the sum of the Tej

value at station to exceed the cycle time Tc.

Step 3. Repeat step 2.

Table 5:- Calculation using Largest candidate rule for actual duration of project

The above figure shows the use of longest candidate rule which is based on the precedence diagram.The idle time is

calculated from the formula given below:

Idle time (total unproductive time for all stations)

= { nc – Σt} [min] where,n = number of stations

H. Determination of Line Efficiency:

Line Efficiency = sum of task times for each unit x100

Number of workstations x cycle time

= 89.820 x 100

7 x 14.64

= 87.26 %

Thus, line efficiency is 87.26%

Larger the Line Efficiency value, more efficient the line.

IJISRT19NOV440 www.ijisrt.com 275

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

I. Calculation of Smoothness Index :

Smoothness Index = SI =

{(Smax – Sj)2}0.5 Where, Smax = Cycle Time

Sj = Cumulative Time at ecah station

= {(14.64-14.3)2 + (14.64-13.47)2 + (14.64-11.77)2 + (14.64-12.8)2 + (14.64-14.4)2 + (14.64-12.04)2 + (14.64-

11.06)2}0.5

= {(0.34)2 + (1.17)2 + (2.87)2 + (1.84)2 + (0.24)2 + (2.6)2 + (3.58)2}0.5

= {32.74}0.5

= 5.72

Smaller the Smoothness Index better it is for Line. Ideally it should be zero.

J. Scheduling of Project by Line of Balance method

Now, at first stage, we are finding out the number of In this way, buffer can be provided at the end if the rate

days taken for construction of each activities. Then ,we found of succeeding activity is greater than the previous one. And,

out the rate in days required/unit for each activity. it can be provided at the beginning when the rate of

succeeding activity is slower than previous activity rate.

As per tha plan, we have total 37 units. So, if we divide

the duration required for completion of each activity by 37, We are providing a minimum 5 days buffer. Consider a

we will get the number of days required for completion of another activity example, the rate of “water proofing “

one unit. activity is grater than “dado” working activity. but the “dado”

activity is its successor activity. So ,we are providing a 5

We can take it as a rate in days/unit. As per the above days buffer at the start of “dado” activity so that there will be

table, it is seen that the rate in days/unit is different for not a clashing of these two activities.

different activities. In this, we are going to take the same

durations as required during actual construction. Thus, the In these way, we have provided a suitable buffers for

productivity rate in days/unit for each activity will not activities and have drawn a graph using VICO software. It

change. We are taking a same rate as taken during actual has duration on its X-axis and number of units i.e.37 units on

construction. Y-axis. The main objective is to find out whether providing

buffers only is feasible or not so as to make a project well

In this stage of planning, we are only going to give a planned and managed. After plotting a graph, we found out

suitable “buffer” for activities so that no activities will clash that duration for completion of project have been increased to

with each other . For achieving this, first we are required to 595 days though the activities are not clashing and well

know that whether should we have to give a suitable buffer planned.

for the activities. As per the table, for the first 8 activities,

there is no need to give a buffer because among these first 8 Now, our main objective is that, to decrease the duration

activities, no activity is clashing with any of the activity. for completion of overall project, we have to increase a

productivity rate of each activity so that the duration required

Now, as per the actual schedule graph, ”RCC chajja” for completion of that activity will automatically decreases

activity is intersects with “brick masonry”. The rate of “RCC and hence the overall project duration can be reduced.

chajja” activity is greater than that of “brick masonry”

activity. Therefore, we have to give a suitable buffer at the LOB graph for planning via increasing the rate of

end of brick masonry activity, so that after that buffer, means productivity of each activity by decreasing the duration

at that time, the activity RCC chajja can be completed required to complete one unit in each activity and assuming

without clashing with the previous activity. desired rate for activities.

IJISRT19NOV440 www.ijisrt.com 276

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig 5:- Plotting of flowline in VICO CONTROL software after giving required buffer and implementing Line of Balance method

Table 6:- Activity duration and production rate along with buffer after scheduling by Line of Balance method

In this stage, we are going to plot a LOB graph by Now, here, from observing a last plotted graph and

taking the desired production rate for all the activities so that actual rates in days/unit, we can fix what desired rate we can

there will not be any clashes between any of the activity. As take so that most of the activities can be done according to

we already provided a buffers in last plotted graph, we are that desired rate taken. After analyzing all the actual rates, we

just going to change the rate for each activity and keeping the are going to take “3.5 days/unit” as our desired rate for all the

same desired rate. activities.

IJISRT19NOV440 www.ijisrt.com 277

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Let us consider a example: fixing MS grills.

Total actual numbers of days required for completion of

“brick masonry” work are 155 days for 37 units. So, the no of So, if we taken a desired rate as 3.5days/unit for

days required to complete one unit = 155/37 =4.18 providing and fixing MS grills , total no of days for

days/unit.Here, 4.18 days/unit is the actual rate for completion of providing and fixing MS grills would be =

completion of brickwork. 3.5*37 =129.5 days= 130 days.

So, if we taken a desired rate as 3.5days/unit for Here, one can say that the duration for the completion is

brickwork, total no of days for completion of brickwork increased. But, as the “providing and fixing MS grills” work

would be = 3.5*37 =129.5 days= 130 days. is successor activity of brick masonry, it should not be

finished until brickwork has done. so ,as the actual rate for

So, with this, we can complete the brickwork 25 days “providing and fixing MS grills” is greater than brickwork, it

earlier the date it had actually finished. For this, we will have should be reduced to avoid clashes between these two

to increase the labors working per day. It will depends upon adjacent activities.

the quantity of the brickwork which is to be done per day and

labor working rate per day. In case of “internal plumbing”, ” internal electric work”,

”external plumbing”, the desired rate is taken as 4days/unit

Let us consider another example: because these activities are actually taking too much time for

Total actual number of days required for completion of its completion. Therefore, instead of 3.5days/unit, we are

“providing and fixing MS grills” work is 115 days for 37 taking a 4 days/unit.In case of “laying of kota for riser and

units. tread” and “laying of Shahabad stones”, the actual rate is

1.97days/unit and 1.35 days/unit respectively. Therefore,

So, the no of days required to complete one unit = instead of taking 3.5days/unit which may took longer period

115/37 =3.10 days/unit. for completion, we have taken a rate of 1.5days/unit so that

the activities will not intersect with each others avoiding the

Here, 3.10 days/unit is the actual rate for completion of clashes.

Fig 6:- Gantt chart after scheduling by Line of Balance with desired output

IJISRT19NOV440 www.ijisrt.com 278

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 7:- Time For Each Unit After Lob scheduling and using precedence relationship

Here we have scheduled the project by using Line of Balance technique by adjusting the production rate.The above table is

prepared by using Line of Balance Method.

K. Determination of Cycle Time:

Cycle Time (Ct) = Total Time Available

Desired Output

= 442

37

= 11.94 days

L. Determination of Minimum Number of Work Stations:

Minimum Number of = (Total Task Time For unit Production)

Work Stations (Cycle Time)

= 75.31

11.94

= 6.13

= 7 Stations (Number of stations to be rounded off)

Minimum Number of Work Stations =7

IJISRT19NOV440 www.ijisrt.com 279

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 8:- Calculation using Largest candidate rule after scheduling of project through Line of Balance method

M. Determination of Line Efficiency:

Line Efficiency = sum of task times for each unit X100

Number of workstations x cycle time

= 75.31 x 100

7 x 11.94

= 90.1 %

Thus, line efficiency is 90.1%

Larger the Line Efficiency, value more efficient the line.

N. Calculation of Smoothness Index :

Smoothness Index = SI=

{(Smax – Sj)2}0.5

= {(11.94-10.48) + (11.94-11.02)2 + (11.94-11.02)2 + (11.94-10.53)2 + (11.94-11.02)2 + (11.94-10.54)2 + (11.94-8.7)2}0.5

2

= {(1.46)2 + (0.92)2 + (0.92)2 + (1.41)2 + (0.92)2 + (1.4)2+ (3.24)2}0.5

IJISRT19NOV440 www.ijisrt.com 280

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

= {19.116}0.5

= 4.3

Smaller the smoothness index better it is for line. Ideally it should be zero.

Table 9:- Quantity of work and associated production rates for actual and planned duration respectively

IV. RESULTS Consider activity Brick Masonary the obtained quantity

is 3495.9 sqm from the authority the actual production rate

The above table shows the actual quantities of various which is implemented was 22.55 sqm/day we planned the

activities and actual duration required for completion of duration using LOB and its duration was reduced to 130 days

each of the activity.The result in above shows how the and so for its completion within duration production rate of

production rate is to be carried out for efficient project 26.89 sqm/day must be followed.

implementation.From this data,we found out the By using VICO CONTROL software it is possible to

productivity rate of each activity in "quantity/day".As ,we schedule the project by line of balance technique.The

have planned the durations and we have actual actual duration was 542 days and after scheduling with

durations,we can found out what productivity rate should line of balance technique it is possible to complete the

be taken for completion of each activity in that planned project in 442 days which is less than the actual duration

duration. taken to complete the project.The project can be worked

The above table shows the production rates that is needed out before 100 days of actual duration required thus line

to be adjusted for getting parallel flow lines so that there of balance method is quite efficient.

is no clashing of activities.

IJISRT19NOV440 www.ijisrt.com 281

Volume 4, Issue 11, November – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 10:- Summary of line efficiency and smoothness index

V. CONCLUSION REFERENCES

In multi storey high rise buildings, same activities are [1]. W.Y. Thabet and Y.J. Beliveau,” HVLS: Horizontal and

repeated on each floor. In order to trace which activity is Vertical Logic Scheduling for Multistory Projects,” J.

going on particular floor, Line of Balance method can be Constr. Eng. and Mgmt., ASCE, Vol. 120 (4), pp. 875-

used. 892 ,1994.

It is a graphical representation of repetitive activities [2]. Kartam, S., Ballard G., and Ibbs, C.W. “Introducing a

where project manager can compare the planned and new concept and approach to modeling construction.”

actual rate of production and if the project is lagging J. Constr. Engrg. and Mgmt., 123 (1), Mar, 89-97. 1997.

behind the planned schedule, the project manager can [3]. Robert B. Harris1, Fellow, ASCE, and Photios G.

take suitable action. LOB and CPM method can be Ioannou2 , Member, ASCE, “Scheduling Project with

integrate for scheduling repetitive activities, since to crash Repetitive Activities”, Journal of Construction

the activity, critical activity should be known therefore Engineering and Management, vol. 124, No.4,

CPM can be used in Line of Balance method. July/August 1998

Since the activities are crashed to reduce the duration of [4]. Yamin, R. &Harmelink, D. Comparison of Linear

the project, but the cost of the project will increase since Scheduling Method (LSM) and Critical Path Method

the resources have to increase for the project to be (CPM).Journal of Construction Engineering and

completed in stipulated time. Therefore total cost of the Management, 127. 2001.

project will increase by some amount. The study is [5]. David Arditi, M.ASCE1 ;Onur B. Tokdemir2 and

limited to the projects where activities are repeated in Kangsuk Suh3, “Challenges in Line of-Balance

linear way or non-linear way Scheduling”, Journal of Construction Engineering and

By using VICO CONTROL software it is possible to Management, vol. 128, No.6, 2002.

schedule the project by line of balance technique. The [6]. Gregory A. Duffy, Garold D. Oberlender; and David

actual duration was 542 days and after scheduling with HyungSeok Jeong, “ Linear Scheduling Model with

line of balance technique it is possible to complete the Varying Production Rates”, “Journal of Construction

project in 442 days which is less than the actual duration Engineering and Management” , The Journal of

taken to complete the project. Construction and Management, Vol.I, pp (254-

The project can be worked out before 100 days of actual 266)2011.

duration required thus line of balance method is quite

efficient.

Line efficiency is increased and there is decrease in

smoothness index.

IJISRT19NOV440 www.ijisrt.com 282

You might also like

- Planning and Scheduling Residential Building Using Primavera Soft WareDocument6 pagesPlanning and Scheduling Residential Building Using Primavera Soft Wareramraj0% (1)

- Project Estimating and Cost ManagementFrom EverandProject Estimating and Cost ManagementRating: 4.5 out of 5 stars4.5/5 (12)

- Stock Market Training CourseDocument13 pagesStock Market Training Coursev guptaNo ratings yet

- Planning, Scheduling and Allocation of Resources For Multi-Storied Structure Using Oracle's Primavera P6 SoftwareDocument7 pagesPlanning, Scheduling and Allocation of Resources For Multi-Storied Structure Using Oracle's Primavera P6 SoftwareAnonymous kw8Yrp0R5rNo ratings yet

- An Analysis On Resource Planning, Cost Estimation and Tracking of Project by Earned Value ManagementDocument7 pagesAn Analysis On Resource Planning, Cost Estimation and Tracking of Project by Earned Value ManagementGanesh SppmNo ratings yet

- Planning Scheduling Using PrimaveraDocument10 pagesPlanning Scheduling Using PrimaveraMohammedNo ratings yet

- Project Management Using Primavera P6Document7 pagesProject Management Using Primavera P6IJRASETPublicationsNo ratings yet

- Scheduling and Monitoring of Ongoing Bypass Construction Connecting NH 218 & NH 63 Using Primavera P6Document13 pagesScheduling and Monitoring of Ongoing Bypass Construction Connecting NH 218 & NH 63 Using Primavera P6International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Cost Planning and Estimation For Residential BuildingDocument4 pagesCost Planning and Estimation For Residential BuildingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Earned Value Management For Design and Construction ProjectDocument21 pagesEarned Value Management For Design and Construction ProjectEditor IJTSRDNo ratings yet

- Planning Scheduling Tracking and ApplicaDocument7 pagesPlanning Scheduling Tracking and ApplicaPiere Christofer Salas HerreraNo ratings yet

- AdidasDocument1 pageAdidasBlabar PisanNo ratings yet

- Project Control Methods and Best Practices: Achieving Project SuccessFrom EverandProject Control Methods and Best Practices: Achieving Project SuccessNo ratings yet

- Advanced Work PackagesDocument24 pagesAdvanced Work Packagescfsolis100% (1)

- Final Sip Inventory ManagementDocument45 pagesFinal Sip Inventory ManagementHemant Chavan100% (2)

- Project Scheduling and Monitoring: Current Research StatusDocument13 pagesProject Scheduling and Monitoring: Current Research StatusالمهندسالمدنيNo ratings yet

- Business 42001 - KnezDocument16 pagesBusiness 42001 - Knezapi-19678498No ratings yet

- Introduction to Project Management: The Quick Reference HandbookFrom EverandIntroduction to Project Management: The Quick Reference HandbookNo ratings yet

- Gamuda BerhadDocument2 pagesGamuda BerhadHui EnNo ratings yet

- Oman Roads and Bridges Project Snapshot: Batinah Coastal Road - Phase 2Document4 pagesOman Roads and Bridges Project Snapshot: Batinah Coastal Road - Phase 2ScribdInOmanNo ratings yet

- Line of BalanceDocument20 pagesLine of BalanceAyah100% (16)

- Ijisrt19nov4401 PDFDocument15 pagesIjisrt19nov4401 PDFAmey DarangeNo ratings yet

- A Case Study Line of Balance LOB Method For High Rise Residential Project Ijariie5728Document8 pagesA Case Study Line of Balance LOB Method For High Rise Residential Project Ijariie5728M.sipil mercubuanaNo ratings yet

- Application of Lob in High Rise StructureDocument6 pagesApplication of Lob in High Rise StructureAnonymous izrFWiQNo ratings yet

- Planning and Scheduling Construction Projects Using Primavera Software A Case StudyDocument11 pagesPlanning and Scheduling Construction Projects Using Primavera Software A Case StudyEditor IJTSRDNo ratings yet

- Ijresm V5 I5 54Document9 pagesIjresm V5 I5 54CHENANo ratings yet

- A Study On Cost and Schedule Analysis On High-Rise Building by Using Earned Value ManagementDocument6 pagesA Study On Cost and Schedule Analysis On High-Rise Building by Using Earned Value ManagementJule LobresNo ratings yet

- Construction Management in Residential Building Using PrimaveraDocument9 pagesConstruction Management in Residential Building Using PrimaveraAhmed Sassi100% (1)

- Method Statement For Multistoried BuildingDocument9 pagesMethod Statement For Multistoried BuildingomersonNo ratings yet

- Analysis of Academic Building by PlanninDocument10 pagesAnalysis of Academic Building by PlanninAshish Kumar GuptaNo ratings yet

- Earned Value Analysis of Construction Project at Rashtriya Sanskrit Sansthan, BhopalDocument6 pagesEarned Value Analysis of Construction Project at Rashtriya Sanskrit Sansthan, BhopalShowki WaniNo ratings yet

- Gestión Del Valor Ganado Como Herramienta de Gestión de ProyectosDocument5 pagesGestión Del Valor Ganado Como Herramienta de Gestión de ProyectosEdinsonRodriguezNo ratings yet

- IRJET Time and Cost Control Using EarnedDocument9 pagesIRJET Time and Cost Control Using EarnedWong KenFNo ratings yet

- IOP Conference Series: Materials Science and Engineering - Analysis of Schedule and Cost Project Management IndicatorsDocument7 pagesIOP Conference Series: Materials Science and Engineering - Analysis of Schedule and Cost Project Management IndicatorsCesar CaminoNo ratings yet

- Optimization Study of Cost and Duration of Project Implementation Case Study Spillway Construction of Bendo Dam Project - IrjietDocument8 pagesOptimization Study of Cost and Duration of Project Implementation Case Study Spillway Construction of Bendo Dam Project - IrjietEvie AlNo ratings yet

- Optimum Activity Overlapping Strategy For Construction Management Using Analytical ApproachDocument9 pagesOptimum Activity Overlapping Strategy For Construction Management Using Analytical ApproachIJRASETPublicationsNo ratings yet

- Project Management Using Primavera p6 IJERTV7IS040201Document4 pagesProject Management Using Primavera p6 IJERTV7IS040201Saipem Rel2No ratings yet

- Preplanning Method For Multi-Story Building Construction UsDocument9 pagesPreplanning Method For Multi-Story Building Construction UsRicardo Fernando DenoniNo ratings yet

- Analysis of Cost Control and Project Time in Performance Process With Earned Value Method, Case Study Improvement of Maliku-Bantanan Road in Pulang Pisau District, IndonesiaDocument7 pagesAnalysis of Cost Control and Project Time in Performance Process With Earned Value Method, Case Study Improvement of Maliku-Bantanan Road in Pulang Pisau District, IndonesiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Jeas 0919 7900Document12 pagesJeas 0919 7900albert husinNo ratings yet

- International Journal of EngineeringDocument9 pagesInternational Journal of EngineeringAnita GutierrezNo ratings yet

- Construction Planning and Management of Residential Building Using PrimaveraDocument13 pagesConstruction Planning and Management of Residential Building Using PrimaveraShravan_redNo ratings yet

- 5 Irjet-V4i7561Document8 pages5 Irjet-V4i7561mogaliess sultanNo ratings yet

- Cost variance analysis of similar scope energy projectsDocument10 pagesCost variance analysis of similar scope energy projectslassasaNo ratings yet

- Research MethodologyDocument6 pagesResearch MethodologyTanvi RaneNo ratings yet

- Earned Value Analysis SoftwareDocument9 pagesEarned Value Analysis SoftwareosemavNo ratings yet

- Construction of Buildings: Time and Cost Control Using Primavera P6 inDocument5 pagesConstruction of Buildings: Time and Cost Control Using Primavera P6 inqwerNo ratings yet

- Factors That Hinder The Effectiveness of The Budget Execution of Malahayati Merchant Marine PolytechnicDocument2 pagesFactors That Hinder The Effectiveness of The Budget Execution of Malahayati Merchant Marine PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparing Precast Erection MethodsDocument11 pagesComparing Precast Erection MethodsArief MaulanaNo ratings yet

- Ijeit1412201410 08 PDFDocument7 pagesIjeit1412201410 08 PDFRitodip BhattacharyaNo ratings yet

- 5 Irjet-V4i7561Document8 pages5 Irjet-V4i7561Saja AliNo ratings yet

- Analysis of Construction Project Using Earned ValueDocument10 pagesAnalysis of Construction Project Using Earned ValueIbrahim TadjerNo ratings yet

- Mini Project: Work Related To Scheduling of Activities of A Project Using PrimaveraDocument9 pagesMini Project: Work Related To Scheduling of Activities of A Project Using PrimaverarahulprajapNo ratings yet

- Application-of-integrated-project-delivery-and-virtual-design-and-construction-to-reduce-the-impact-of-incompatibilities-in-the-design-stage-in-residential-buildingsAplicacin-de-integrated-project-delivery-y-virtuaDocument8 pagesApplication-of-integrated-project-delivery-and-virtual-design-and-construction-to-reduce-the-impact-of-incompatibilities-in-the-design-stage-in-residential-buildingsAplicacin-de-integrated-project-delivery-y-virtuaDarwin Sasari ChoquenairaNo ratings yet

- Comparative Cost Estimation of ResidentiDocument7 pagesComparative Cost Estimation of ResidentiSamiullah M QaisraniNo ratings yet

- New Applications of Line of Balance On Scheduling of Multi-Storey BuildingsDocument9 pagesNew Applications of Line of Balance On Scheduling of Multi-Storey BuildingsDaniel Stiven Santana ZambranoNo ratings yet

- Review On Planning and Scheduling of Construction Project by Management Tool Primavera P6Document3 pagesReview On Planning and Scheduling of Construction Project by Management Tool Primavera P6Editor IJTSRDNo ratings yet

- SCM FinalDocument28 pagesSCM FinalAPS PlacementsNo ratings yet

- Application of The Last Planner System in A Sports Infrastructure Project in PeruDocument12 pagesApplication of The Last Planner System in A Sports Infrastructure Project in PeruJose PerezNo ratings yet

- Construction Management and Scheduling of Residential Building Using PrimaveraDocument11 pagesConstruction Management and Scheduling of Residential Building Using PrimaveraInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Towards Production Control On Multi-Story BuildingDocument13 pagesTowards Production Control On Multi-Story BuildingSPACE GHOSTNo ratings yet

- CONSTRUCTIOIN PLANNING AND CONTROL USING PRIMAVERA P6 Ijariie10596Document5 pagesCONSTRUCTIOIN PLANNING AND CONTROL USING PRIMAVERA P6 Ijariie10596ابراهيم خليلNo ratings yet

- Implementation of 4d Bim Virtual Tools To Improve The Planning of The El Parque Project, Surco District, Lima, 2023 (2) (1) .Document8 pagesImplementation of 4d Bim Virtual Tools To Improve The Planning of The El Parque Project, Surco District, Lima, 2023 (2) (1) .jvazinhoNo ratings yet

- IJRTI1807004Document5 pagesIJRTI1807004Atul JaiswalNo ratings yet

- An Analysis on Mental Health Issues among IndividualsDocument6 pagesAn Analysis on Mental Health Issues among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation for Translating Global Languages into Indian LanuagesDocument7 pagesHarnessing Open Innovation for Translating Global Languages into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractDocument7 pagesExploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolDocument31 pagesThe Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research Technology100% (1)

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 8850 Wotc Tax FormDocument2 pages8850 Wotc Tax Formapi-127186411No ratings yet

- Chapter 10 ATW 108 USM Tutorial SlidesDocument18 pagesChapter 10 ATW 108 USM Tutorial Slidesraye brahmNo ratings yet

- T-Sonic Facial Cle Ansing & Massaging DeviceDocument5 pagesT-Sonic Facial Cle Ansing & Massaging DeviceAnnesa Fadhila SariNo ratings yet

- Spend or Save?: CASH Internet Banking PicDocument2 pagesSpend or Save?: CASH Internet Banking PicRolando ValenciaNo ratings yet

- Business Standard PDFDocument12 pagesBusiness Standard PDFarunNo ratings yet

- 55TH Unclaimed Dividends - 2015Document80 pages55TH Unclaimed Dividends - 2015kirat palNo ratings yet

- Newspaper Stratergy (Good)Document50 pagesNewspaper Stratergy (Good)Alan Chan Tee SiongNo ratings yet

- ACCT CONCEPTS-TIME PERIOD,ENTITY,ACCRUALDocument2 pagesACCT CONCEPTS-TIME PERIOD,ENTITY,ACCRUALZaid Zckid100% (1)

- List of Properties Where Arrear Above Rs 50000Document219 pagesList of Properties Where Arrear Above Rs 50000Siddharth Kumar50% (2)

- ETHICS-LESSON 14.WPS OfficeDocument2 pagesETHICS-LESSON 14.WPS OfficeRichie EscoltaNo ratings yet

- Green Logistics Leader: Byd Forklift With Global Presence inDocument6 pagesGreen Logistics Leader: Byd Forklift With Global Presence insubhashNo ratings yet

- Autonomous DrivingDocument25 pagesAutonomous DrivingAditya 苏巴马廉 IyerNo ratings yet

- Brief Exercise 17.5Document2 pagesBrief Exercise 17.5Zoiba EkramNo ratings yet

- Starbucks Case Write UpDocument2 pagesStarbucks Case Write UpJess RazzNo ratings yet

- Types of Export Finance ExplainedDocument14 pagesTypes of Export Finance Explainedsamy7541No ratings yet

- M.Tech. Admission 2021 Indian Institute of Technology (Indian School of Mines) DhanbadDocument1 pageM.Tech. Admission 2021 Indian Institute of Technology (Indian School of Mines) Dhanbadashish singhNo ratings yet

- 4 Programs That Can Help You Pay Your Medical Expenses: MedicaidDocument3 pages4 Programs That Can Help You Pay Your Medical Expenses: Medicaidapi-309082881No ratings yet

- 2023 Tax Policy - Inequality and Welfare (Babilla)Document15 pages2023 Tax Policy - Inequality and Welfare (Babilla)LIANo ratings yet

- Working Capital Management at NALCO: Analysis and RecommendationsDocument11 pagesWorking Capital Management at NALCO: Analysis and RecommendationsAniket JaggiNo ratings yet

- DdsafDocument3 pagesDdsafRenzo RiveraNo ratings yet

- DTR, Form 6Document3 pagesDTR, Form 6Angela Quezada RuleteNo ratings yet

- Cir 174 06 2022 CGSTDocument5 pagesCir 174 06 2022 CGSTNM JHANWAR & ASSOCIATESNo ratings yet

- Business, Government & Society: Brexit and Latest DevelopmentsDocument20 pagesBusiness, Government & Society: Brexit and Latest Developmentssameer prasadNo ratings yet

- Stale Check Is A Check That Is Presented To Be Cashed or Deposited at A Bank SixDocument3 pagesStale Check Is A Check That Is Presented To Be Cashed or Deposited at A Bank SixAlexanderJacobVielMartinezNo ratings yet

- What is CRR, Repo Rate, Reverse Repo Rate and how RBI uses themDocument6 pagesWhat is CRR, Repo Rate, Reverse Repo Rate and how RBI uses themSoaib Al-MahbubNo ratings yet