Professional Documents

Culture Documents

Important Questions For Weak Students

Uploaded by

Dhanabal Palanisamy P0 ratings0% found this document useful (0 votes)

23 views1 pageStrength of materials important questions

Original Title

Important Questions for Weak Students

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStrength of materials important questions

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageImportant Questions For Weak Students

Uploaded by

Dhanabal Palanisamy PStrength of materials important questions

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

Part-A

1. Define modulus of resilience and proof resilience. (April 2017)

2. Define: "Factor of safety" (Nov/Dec 2015)

3. Determine the force required to punch a hole of 20mm diameter in a 5mm thick plate with ultimate shear

strength of 250MPa. (Nov 2014)

4. What are the methods used to improve fatigue strength? (Dec 2013)

5. State Rankine theory of failure and its limitations.

Part-B

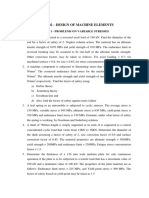

1. A machine component is subjected to fluctuating stress that varies from 50 to 100 N/mm 2. The corrected

endurance limit stress for the machine component is 270 N/mm 2. The ultimate tensile strength and yield

strength of material are 600 and 400 N/mm 2 respectively. Find the factor of safety using: (i) Soderberg line

(iii) Goodman line and (iv) Also, find factor of safety against static failure. (13 Mark)

2. A circular bar of 500 mm length is supported freely at its two ends. It is acted upon by a central concentrated

cyclic load having a minimum value of 30 kN and a maximum value of 60 kN. Determine the diameter of bar

by taking a factor of safety of 1.5, size effect of 0.85, surface finish factor of 0.9. The material properties of

bar are given by ultimate strength of 650 MPa, yield strength of 500 MPa and endurance strength of 350 MPa.

[AU, N/D 2011]

Part-A

1. Define modulus of resilience and proof resilience. (April 2017)

2. Define: "Factor of safety" (Nov/Dec 2015)

3. Determine the force required to punch a hole of 20mm diameter in a 5mm thick plate with ultimate shear

strength of 250MPa. (Nov 2014)

4. What are the methods used to improve fatigue strength? (Dec 2013)

5. State Rankine theory of failure and its limitations.

Part-B

3. A machine component is subjected to fluctuating stress that varies from 50 to 100 N/mm 2. The corrected

endurance limit stress for the machine component is 270 N/mm 2. The ultimate tensile strength and yield

strength of material are 600 and 400 N/mm 2 respectively. Find the factor of safety using: (i) Soderberg line

(iii) Goodman line and (iv) Also, find factor of safety against static failure. (13 Mark)

4. A circular bar of 500 mm length is supported freely at its two ends. It is acted upon by a central concentrated

cyclic load having a minimum value of 30 kN and a maximum value of 60 kN. Determine the diameter of bar

by taking a factor of safety of 1.5, size effect of 0.85, surface finish factor of 0.9. The material properties of

bar are given by ultimate strength of 650 MPa, yield strength of 500 MPa and endurance strength of 350 MPa.

[AU, N/D 2011]

Part-A

5. Define modulus of resilience and proof resilience. (April 2017)

6. Define: "Factor of safety" (Nov/Dec 2015)

7. Determine the force required to punch a hole of 20mm diameter in a 5mm thick plate with ultimate shear

strength of 250MPa. (Nov 2014)

8. What are the methods used to improve fatigue strength? (Dec 2013)

9. State Rankine theory of failure and its limitations.

Part-B

10. A machine component is subjected to fluctuating stress that varies from 50 to 100 N/mm 2. The corrected

endurance limit stress for the machine component is 270 N/mm 2. The ultimate tensile strength and yield

strength of material are 600 and 400 N/mm 2 respectively. Find the factor of safety using: (i) Soderberg line

(iii) Goodman line and (iv) Also, find factor of safety against static failure. (13 Mark)

11. A circular bar of 500 mm length is supported freely at its two ends. It is acted upon by a central concentrated

cyclic load having a minimum value of 30 kN and a maximum value of 60 kN. Determine the diameter of bar

by taking a factor of safety of 1.5, size effect of 0.85, surface finish factor of 0.9. The material properties of

bar are given by ultimate strength of 650 MPa, yield strength of 500 MPa and endurance strength of 350 MPa.

[AU, N/D 2011]

You might also like

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- M.D-I Final Tutorial and AssignmentDocument16 pagesM.D-I Final Tutorial and AssignmentnageshNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Machine Design Question BankDocument4 pagesMachine Design Question BankManivannanNo ratings yet

- Stress concentration factor and fatigue analysisDocument5 pagesStress concentration factor and fatigue analysisUday NarasimhaNo ratings yet

- Important Dome MaterialsDocument24 pagesImportant Dome MaterialsAnonymous DQGLUZxHNo ratings yet

- Unit - 1 - Variable StressesDocument1 pageUnit - 1 - Variable Stressesgangadharan tharumarNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- Iat 1 DmeDocument3 pagesIat 1 DmesathishskymechNo ratings yet

- ME131604 Machine Design AssignmentDocument2 pagesME131604 Machine Design AssignmentriyNo ratings yet

- Mech-V-Design of Machine Elements I (10me52) - AssignmentDocument10 pagesMech-V-Design of Machine Elements I (10me52) - AssignmentArunNo ratings yet

- Maharaja Engineering Question Bank for Machine DesignDocument91 pagesMaharaja Engineering Question Bank for Machine Designmagesh.mxNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- 34412501-Design of MC ElementDocument8 pages34412501-Design of MC Elementsmg26thmayNo ratings yet

- UNIT-1: Department of Mechanical EngineeringDocument14 pagesUNIT-1: Department of Mechanical EngineeringManivannan JeevaNo ratings yet

- KINGS COLLEGE MECHANICAL ENGINEERING QUESTION BANKDocument11 pagesKINGS COLLEGE MECHANICAL ENGINEERING QUESTION BANKVenkat RajaNo ratings yet

- Part B - 16 Mark QuestionsDocument5 pagesPart B - 16 Mark QuestionssubramanikcemechNo ratings yet

- Pressure Vessel Thickness CalculationDocument16 pagesPressure Vessel Thickness CalculationAtul KhodeNo ratings yet

- Unit IiDocument1 pageUnit Iimahesh babu bandiNo ratings yet

- ME 1302 - MACHINE DESIGN (5th Mech)Document7 pagesME 1302 - MACHINE DESIGN (5th Mech)Madhu MithaNo ratings yet

- ME2303Document5 pagesME2303Galih PramuditaNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- ME1302 Design Machine Elements Question BankDocument21 pagesME1302 Design Machine Elements Question BankmeindyaNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsKarthikeyanNo ratings yet

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadNo ratings yet

- Design of Machine Element ProblemsDocument2 pagesDesign of Machine Element Problemsmaxpayne5550% (1)

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaNo ratings yet

- Machine Elements Design QuestionsDocument5 pagesMachine Elements Design QuestionsbalameckNo ratings yet

- Machine Design Document SummaryDocument14 pagesMachine Design Document SummaryJeevanandam ShanmugaNo ratings yet

- Mech-V-Design of Machine Elements I (10me52) - SolutionDocument63 pagesMech-V-Design of Machine Elements I (10me52) - SolutionTolbert D'SouzaNo ratings yet

- Machine Members Design AssignmentDocument13 pagesMachine Members Design AssignmentHafiz Mahar28No ratings yet

- Unit - 1Document8 pagesUnit - 1Dhileepan KumarasamyNo ratings yet

- Me2303 PDFDocument5 pagesMe2303 PDFBas RamuNo ratings yet

- Question Bank 2Document2 pagesQuestion Bank 2Cholan PillaiNo ratings yet

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- ME2303-Design of Machine ElementsDocument17 pagesME2303-Design of Machine ElementsSith AnanthanNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Assignment 1Document3 pagesAssignment 1Pawan Kumar GoyalNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine Elementsdsathiya0% (1)

- QuestionsDocument11 pagesQuestionsSundara MoorthyNo ratings yet

- Machine Design Tutorial Sheet QuestionsDocument3 pagesMachine Design Tutorial Sheet Questionsabhishek chaurasiyaNo ratings yet

- DME Question BankDocument4 pagesDME Question BankILAYAPERUMAL KNo ratings yet

- Assignment 1Document3 pagesAssignment 1Pawan Kumar GoyalNo ratings yet

- BE MECH 6C0078-Design of Machine Elements 10601Document4 pagesBE MECH 6C0078-Design of Machine Elements 10601Anonymous MFFOxujrRNo ratings yet

- TUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignDocument8 pagesTUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignCharles OndiekiNo ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Assignment 01Document3 pagesAssignment 01RamNocturnalNo ratings yet

- VMKV Engineering College Question Bank on Machine Design ElementsDocument14 pagesVMKV Engineering College Question Bank on Machine Design ElementsSatwik PriyadarshiNo ratings yet

- ME-503 Assignment Design ElementsDocument2 pagesME-503 Assignment Design ElementsSupratim Bhattacharjee100% (1)

- DME Unitwise Question BankDocument24 pagesDME Unitwise Question BanksureshkumarNo ratings yet

- T I TR NG Đ NGDocument40 pagesT I TR NG Đ NGVũ Hải HưngNo ratings yet

- Dme QP Series 1 2019Document1 pageDme QP Series 1 2019AADARS M SNo ratings yet

- Macine Element I Worksheet for Final ExamDocument4 pagesMacine Element I Worksheet for Final Examdagimawgchew777No ratings yet

- Masonry and Its TypesDocument94 pagesMasonry and Its TypesDhanabal Palanisamy PNo ratings yet

- Masonry and Its TypesDocument94 pagesMasonry and Its TypesDhanabal Palanisamy PNo ratings yet

- Q. 1 - Q. 5 Carry One Mark Each.: GATE 2019 General Aptitude (GA) Set-2Document22 pagesQ. 1 - Q. 5 Carry One Mark Each.: GATE 2019 General Aptitude (GA) Set-2Mohammed SiddiqueNo ratings yet

- Flooring in Civil EngineeringDocument21 pagesFlooring in Civil EngineeringDhanabal Palanisamy PNo ratings yet

- Technical Note On How To Upload A Youtube VideoDocument1 pageTechnical Note On How To Upload A Youtube VideoDhanabal Palanisamy PNo ratings yet

- SME015 - 4PD0240I C Engine TerminologyDocument54 pagesSME015 - 4PD0240I C Engine TerminologyzetseatNo ratings yet

- Computer Aided Process Computer Aided Process PlanningDocument9 pagesComputer Aided Process Computer Aided Process PlanningDick Man0% (1)

- AI in CAPPDocument6 pagesAI in CAPPDhanabal Palanisamy PNo ratings yet

- Heat and Mass TransferDocument16 pagesHeat and Mass TransferDhanabal Palanisamy PNo ratings yet

- Thermal Engineering Exam QuestionsDocument4 pagesThermal Engineering Exam QuestionsDhanabal Palanisamy PNo ratings yet

- Design Optimization of Industrial Robots Using ModelicaDocument5 pagesDesign Optimization of Industrial Robots Using ModelicaRyan ValenciaNo ratings yet

- Termodinamik Proplemleri ÇözümleriDocument33 pagesTermodinamik Proplemleri ÇözümleriTarah HurstNo ratings yet

- WCECS2012 pp1330-1333Document4 pagesWCECS2012 pp1330-1333Dhanabal Palanisamy PNo ratings yet

- 4 Development of Computer Aided Process Planning (CAPP) For Rotational PartsDocument9 pages4 Development of Computer Aided Process Planning (CAPP) For Rotational PartsDhanabal Palanisamy PNo ratings yet

- 171904Document1 page171904Dhanabal Palanisamy PNo ratings yet

- Thermal Engineering Exam QuestionsDocument4 pagesThermal Engineering Exam QuestionsDhanabal Palanisamy PNo ratings yet

- Computer Aided Process Computer Aided Process PlanningDocument9 pagesComputer Aided Process Computer Aided Process PlanningDick Man0% (1)

- Pdmapp 9Document16 pagesPdmapp 9Dhanabal Palanisamy PNo ratings yet

- 171904Document1 page171904Dhanabal Palanisamy PNo ratings yet

- Pdmapp 9Document16 pagesPdmapp 9Dhanabal Palanisamy PNo ratings yet

- B.E. Degree Examinations: April/May 2011Document4 pagesB.E. Degree Examinations: April/May 2011Dhanabal Palanisamy PNo ratings yet

- 12 Required Properties of Idea RefrigerantsDocument1 page12 Required Properties of Idea RefrigerantsDhanabal Palanisamy PNo ratings yet

- B.E. Degree Examinations: Nov/Dec 2010: A F B F B BF A BF A F B F A BF B AfDocument4 pagesB.E. Degree Examinations: Nov/Dec 2010: A F B F B BF A BF A F B F A BF B AfDhanabal Palanisamy PNo ratings yet

- FEM SlidesDocument31 pagesFEM SlidesAnya CooperNo ratings yet

- Peng 11 2010 0170Document7 pagesPeng 11 2010 0170Dhanabal Palanisamy PNo ratings yet

- Inspired Engineers @: DesignDocument8 pagesInspired Engineers @: DesignDhanabal Palanisamy PNo ratings yet

- FEM SlidesDocument31 pagesFEM SlidesAnya CooperNo ratings yet

- 12 Required Properties of Idea RefrigerantsDocument1 page12 Required Properties of Idea RefrigerantsDhanabal Palanisamy PNo ratings yet

- 12 Required Properties of Idea RefrigerantsDocument1 page12 Required Properties of Idea RefrigerantsDhanabal Palanisamy PNo ratings yet

- Comparison Between SKS 3 and SCM 440 Steel Materials For The Location PIN of Welding JIGDocument5 pagesComparison Between SKS 3 and SCM 440 Steel Materials For The Location PIN of Welding JIGFortune FireNo ratings yet

- Discussion of Extended Drucker-Prager Yield Criterion in Slope Stability AnalysisDocument4 pagesDiscussion of Extended Drucker-Prager Yield Criterion in Slope Stability AnalysisAbdelmoez ElgarfNo ratings yet

- Dynamic Crystallization of Dark Chocolate As Affected by Temperature and Lipid AdditivesDocument7 pagesDynamic Crystallization of Dark Chocolate As Affected by Temperature and Lipid AdditivesIndra bayuNo ratings yet

- Lec # 24 Universal MotorsDocument15 pagesLec # 24 Universal MotorsBuriro HayatNo ratings yet

- BE 8256 - Basic Mechanical Engineering / U – II / Compiled by R.Arul KamalakumarDocument24 pagesBE 8256 - Basic Mechanical Engineering / U – II / Compiled by R.Arul KamalakumararulrakkNo ratings yet

- Tor Ferita 4C6 blf177 2Document2 pagesTor Ferita 4C6 blf177 2cana_robertNo ratings yet

- Pentens T-201 Data SheetDocument6 pagesPentens T-201 Data Sheetamelinda jocelinNo ratings yet

- IndustrialCatalog ArmorX PDFDocument28 pagesIndustrialCatalog ArmorX PDFjuan pablo castro gallegoNo ratings yet

- Half Harmonic Oscillator PDFDocument6 pagesHalf Harmonic Oscillator PDFArkayan Laha0% (1)

- Applications for capillary rheometers in polymer testingDocument68 pagesApplications for capillary rheometers in polymer testingpopmart21No ratings yet

- NPSHDocument4 pagesNPSHrex tanongNo ratings yet

- Orifice Plate CalculationDocument30 pagesOrifice Plate CalculationSatish SohaniNo ratings yet

- Oil Water Separator Sizing Calculation FormulaDocument1 pageOil Water Separator Sizing Calculation Formulaarnel_ado4412No ratings yet

- Asme Sa-179-2021Document3 pagesAsme Sa-179-2021MargaritaNo ratings yet

- Deflection Calculation Sheet: Units ReferenceDocument4 pagesDeflection Calculation Sheet: Units Referenceabdul khaderNo ratings yet

- ProCAST User ManualDocument770 pagesProCAST User ManualKelly May100% (8)

- CSCE 613: Fundamentals of VLSI Chip Design: Instructor: Jason D. BakosDocument26 pagesCSCE 613: Fundamentals of VLSI Chip Design: Instructor: Jason D. BakosbhawnaNo ratings yet

- An Exploratory Study of GFRP Rebar With Ribs Containing Milled Glass FibersDocument9 pagesAn Exploratory Study of GFRP Rebar With Ribs Containing Milled Glass FibersShoban Senapathi MNo ratings yet

- The Design of Vibro Replacement (Stone Column)Document17 pagesThe Design of Vibro Replacement (Stone Column)sirtiendungNo ratings yet

- Astm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaDocument6 pagesAstm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaAVINASHRAJNo ratings yet

- Heat Transfer - ExercisesDocument4 pagesHeat Transfer - ExercisesKareem HamzaNo ratings yet

- Konstanta Pegas Dan Interaksi Struktur TanahDocument10 pagesKonstanta Pegas Dan Interaksi Struktur Tanahlimara65No ratings yet

- Basic Properties of Tapes Containing Variable Amounts of Special Additive For MaintenanceDocument7 pagesBasic Properties of Tapes Containing Variable Amounts of Special Additive For MaintenancekinfeNo ratings yet

- Imec M01A: Science of Engineering MaterialsDocument23 pagesImec M01A: Science of Engineering MaterialsJimmyNo ratings yet

- Dow Thermal MaterialsDocument16 pagesDow Thermal MaterialsRudyXPNo ratings yet

- Dental Materials: Investment MaterialDocument4 pagesDental Materials: Investment MaterialErwin GunawanNo ratings yet

- Materials and Qualification Procedures For Ships: Book ADocument15 pagesMaterials and Qualification Procedures For Ships: Book AJavier del AngelNo ratings yet

- Shell Dish Design Pressure VesselDocument26 pagesShell Dish Design Pressure VesselAKSHAY BHATKARNo ratings yet

- Timber Calculations Tables ADocument3 pagesTimber Calculations Tables AcdmaaNo ratings yet

- Welcome To MSE 694A Class!Document10 pagesWelcome To MSE 694A Class!Sam vermNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)From EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)No ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)