Professional Documents

Culture Documents

Appendix

Uploaded by

Dilla WahabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix

Uploaded by

Dilla WahabCopyright:

Available Formats

Lampiran 1

Sifat-sifat Uap Air

Sumber : Holman. J. P. 1993.

T ρ cp µ (kg/m v (m2/s) k (W/m α (m2/s) Pr

(K) (kg/m3) (kJ/kg 0C) s) 0C)

380 0.5863 2.060 12.71 x 10-6 2.16 x 10-5 0.0246 0.2036 x 10-4 1.060

400 0.5542 2.014 13.44 x 10-6 2.42 x 10-5 0.0261 0.2338 x 10-4 1.040

450 0.4902 1.980 15.25 x 10-6 3.11 x 10-5 0.0299 0.307 x 10-4 1.010

500 0.4405 1.985 17.04 x 10-6 3.86 x 10-5 0.0339 0.387 x 10-4 0.996

550 0.4005 1.997 18.84 x 10-6 4.70 x 10-5 0.0379 0.475 x 10-4 0.991

600 0.3652 2.026 20.67 x 10-6 5.66 x 10-5 0.0422 0.573 x 10-4 0.986

650 0.3380 2.056 22.47 x 10-6 6.64 x 10-5 0.0464 0.666 x 10-4 0.995

700 0.3140 2.085 24.26 x 10-6 7.72 x 10-5 0.0505 0.772 x 10-4 1.000

750 0.2931 2.119 26.04 x 10-6 8.88 x 10-5 0.0549 0.883 x 10-4 1.005

800 0.2739 2.152 27.86 x 10-6 10.20 x 10-5 0.0592 1.001 x 10-4 1.010

850 0.2579 2.186 29.69 x 10-6 11.52 x 10-5 0.0637 1.130 x 10-4 1.019

*Adaptasi ke satuan SI dari E. R. G. Eckert dan R. M. Drake, “Heat and Mass Transfer” 2d ed.,

McGraw-Hill Book Company, New York, 1959.

114

Universitas Sumatera Utara

Lampiran 2

Harga Roughness (ɛ) Material

Sumber: Jack b. Evett. 1987.

Material (new) Roughness (ɛ)

ft m

Riveted 0.003 – 0.03 0.0009 – 0.009

Concrate 0.001 – 0.01 0.0003 – 0.003

Wood Stave 0.0006 – 0.003 0.0002 – 0.0009

Cast Iron 0.00085 0.00026

Galvanized Iron 0.0005 0.00015

Asphalted Cast Iron 0.0004 0.0001

Comerrcial Stell or Wrought Iron 0.00015 0.000046

Drawn Brass or Copper Tubing 0.000005 0.0000015

Glass and Plastic smooth smooth

115

Universitas Sumatera Utara

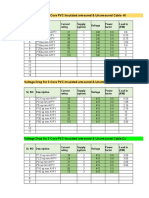

Lampiran 3

Koefesien Kerugian Instalasi Pipa

Sumber: Jack B. Evett. 1987.

Nominal Diameter Screwed Flanged

½ 1 2 4 1 2 4 8 20

Valves (fully open):

Globe 14 8.2 6.9 5.7 13 8.5 6.0 5.8 5.5

Gate 0.3 0.24 0.16 0.11 0.8 0.35 0.16 0.07 0.03

Swing chek 5.1 2.9 2.1 2.0 2.0 2.0 2.0 2.0 2.0

Angle 9.0 4.7 2.0 1.0 4.5 2.4 2.0 2.0 2.0

Elbows:

450 reguler 0.39 0.32 0.3 0.29

450 long radius 0.21 0.20 0.19 0.16 0.14

900 reguler 2.0 1.5 0.95 0.64 0.5 0.39 0.30 0.26 0.21

900 long radius 1.0 0.72 0.41 0.23 0.41 0.30 0.19 0.15 0.10

1800 reguler 2.0 1.5 0.95 0.64 0 0.35 0.30 0.25 0.20

1800 long radius 40 0.30 0.21 0.15 0.10

Tess:

Line flow 0.9 0.9 0.9 0.9 0.24 0.19 0.14 0.10 0.07

Branch flow 2.4 1.8 1.4 1.1 1.0 0.80 0.64 0.58 0.41

116

Universitas Sumatera Utara

Lampiran 4

Tabel Uap Panas Lanjut

Sumber: Cengel. A. Yunus. 1994.

A-1

117

Universitas Sumatera Utara

A-2 (Lanjut)

118

Universitas Sumatera Utara

Lampiran 5

Tabel Uap Jenuh

Sumber: Cengel. A. Yunus. 1994.

B-1

119

Universitas Sumatera Utara

B-2 (lanjut)

120

Universitas Sumatera Utara

C-1

121

Universitas Sumatera Utara

C-2 (lanjut)

122

Universitas Sumatera Utara

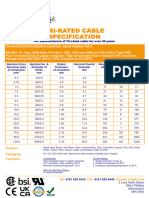

Lampiran 6

Bahan Pipa Waterwall, Superheater, dan Backpass

Sumber: Croker. Sabin. 1973.

123

Universitas Sumatera Utara

Lampiran 7

Dimensi Pipa menurut Standard JIS dan ANSI

Sumber: http://test2.urs.com.tw/b6/diekson/e43.htm

Outside Nominal

Nominal Wall Thickness

Diameter Pipe Size

Sch Sch Sch Sch Sch Sch

Sch 40 XS XXS JIS ANSI A

60 80 100 120 140 160

2.2 2.4 (3.0) 3.0 - - - - - 13.8 13.7 8

2.3 2.8 (3.2) 3.2 - - - - - 17.3 17.1 10

2.8 3.2 (3.7) 3.7 - - - 4.7 7.5 21.7 21.3 15

2.9 3.4 (3.9) 3.9 - - - 5.5 7.8 27.2 26.7 20

3.4 3.9 (4.5) 4.5 - - - 6.4 9.1 34.0 33.5 25

3.6 4.5 (4.9) 4.9 - - - 6.4 9.7 42.7 42.2 32

3.7 4.5 (5.1) 5.1 - - - 7.1 10.2 48.6 48.3 40

3.9 4.9 (5.5) 5.5 - - - 8.7 11.1 60.5 60.3 50

5.2 6.0 (7.0) 7.0 - - - 9.5 14.0 76.3 73.0 65

5.5 6.6 (7.6) 7.6 - - - 11.1 15.2 89.1 88.9 80

5.7 7.0 (8.1) 8.1 - - - 12.7 - 101.6 101.6 90

6.0 7.1 (8.6) 8.6 - 11.1 - 13.5 17.1 114.3 114.3 100

6.6 8.1 (9.5) 9.5 - 12.7 - 15.9 19.0 139.8 141.3 125

7.1 9.3 (11.0) 11.0 - 14.3 - 18.2 21.9 165.2 168.3 150

- - - - - - - - - 190.7 - 175

8.2 10.3 (12.7) 12.7 15.1 18.2 20.6 23.0 22.2 216.3 219.1 200

- - - - - - - - - 241.8 - 225

9.3 12.7 12.7 15.1 18.3 21.4 25.4 28.6 25.4 267.4 273.1 250

10.3 14.3 12.7 17.4 21.4 25.4 28.6 33.3 25.4 318.5 323.9 300

11.1 15.1 12.7 19.0 23.8 27.8 31.8 35.7 - 355.6 355.6 350

12.7 16.7 12.7 21.4 26.2 30.9 36.5 40.5 - 406.4 406.4 400

14.3 19.0 12.7 23.8 29.4 34.9 39.7 45.2 - 457.2 457.2 450

15.1 20.6 12.7 26.2 32.5 38.1 44.4 50.0 - 508.0 508.0 500

- 22.2 12.7 28.6 34.9 41.3 47.6 54.0 - 558.8 558.8 550

17.5 24.6 12.7 31.0 38.9 46.0 52.4 59.5 - 609.6 609.6 600

- - 12.7 - - - - - - 660.4 660.4 650

- - 12.7 - - - - - - 711.2 711.2 700

- - 12.7 - - - - - - 762.0 762.0 750

17.5 - 12.7 - - - - - - 812.8 812.8 800

17.5 - 12.7 - - - - - - 863.6 863.6 850

19.1 - 12.7 - - - - - - 914.4 914.4 900

- - 12.7 - - - - - - 965.2 965.2 950

- - 12.7 - - - - - - 1016.0 1016.0 1000

- - 12.7 - - - - - - 1066.8 1066.8 1050

- - 12.7 - - - - - - 1117.6 1117.6 1100

- - 12.7 - - - - - - 1168.4 1168.4 1150

- - 12.7 - - - - - - 1219.2 1219.2 1200

- - *12.7 - - - - - - 1270.0 1270.0 1250

Outside Nominal

Nominal Wall Thickness

Diameter Pipe Size

124

Universitas Sumatera Utara

Sch Sch Sch Sch Sch Sch

Sch 40 XS XXS JIS ANSI A

60 80 100 120 140 160

- - *12.7 - - - - - - 1320.8 1320.8 1300

- - *12.7 - - - - - - 1371.6 1371.6 1350

- - *12.7 - - - - - - 1422.4 1422.4 1400

- - *12.7 - - - - - - 1473.2 1473.2 1450

- - *12.7 - - - - - - 1524.0 1524.0 1500

125

Universitas Sumatera Utara

Lampiran 8

Entalphi Api dan Gas Asap

Sumber: Babcock and Wilcox. 1969.

126

Universitas Sumatera Utara

127

Universitas Sumatera Utara

Lampiran 9

Kehilangan Panas ke Udara Luar

Sumber: Gaffert. Gustaf A. “Steam Power Station”. Fourth Edition.

128

Universitas Sumatera Utara

Lampiran 10

Emisivitas dan Faktor Koreksi CO2 dan H2O

Sumber: Holman, J.P. , 1993.

Emisivitas CO2

Faktor koreksi emisivitas CO2

129

Universitas Sumatera Utara

Emisivitas H2O

Faktor koreksi emisivitas H2O

130

Universitas Sumatera Utara

Faktor koreksi gabungan CO2 dan H2O

131

Universitas Sumatera Utara

Lampiran 11

Tabel Sifat-sifat Udara

Sumber: Holman, J.P. , 1993.

132

Universitas Sumatera Utara

Lampiran 12

Faktor Koreksi Superheater

Sumber: Holman, J.P. , 1993.

133

Universitas Sumatera Utara

Lampiran 13

Koefesien Konduktifitas Bentuk Benda

Sumber: Holman, J.P. , 1993.

134

Universitas Sumatera Utara

Lampiran 14

Nilai Konduktivitas Logam

Sumber: Holman, J.P. , 1993.

Sifat-sifat pada 20 0C Konduktivitas termal k (W/m 0C)

ρ cp k α -1000C 00C 100 200 300 400 600 800 1000 12

0 0 0 0 0 0 0 0

Logam C C C C C C C C

(kg/m3) (kJ/kg (W/m (m2/s x -1480F 320F

0 0

C) C) 105) 2120 3920 5720 7520 1112 1472 1832 21

0 0 0 0

F F F F F F F F

Aluminum:

Murni 2.707 0.896 204 8.418 215 202 206 215 228 249

Al-Cu (Duralumin), 94-

96% Al, 3-5% Cu, runut 2.787 0.883 164 6.676 126 159 182 194

Mg.

Al-Si(Silumin,

mengandung tembaga), 2.659 0.867 137 5.933 119 137 144 152 161

86.5% Al, 1% Cu.

Al-Si (Alusil), 78-80%

2.627 0.854 161 7.172 144 157 168 175 178

Al, 20-22% Si.

Al-Mg-Si, 97% Al,

1%Mg, 1%Si, 1% Mn.

2.707 0.892 177 7.311 175 189 204

Timbal

11.373 0.130 35 2.343 36.9 35.1 33.4 31.5 29.8

Besi:

Murni 7.897 0.452 73 2.034 87 73 67 62 55 48 40 36 35 3

Besi Tempa, 0,55 C 7.849 0.46 59 1.626 59 57 52 48 45 36 33 33 3

Baja (C maks ≈ 1,5%):

Baja Karbon

C ≈ 0.5% 7.833 0.465 54 1.474 55 52 48 45 42 35 31 29 3

C ≈ 1.0% 7.801 0.473 43 1.172 43 43 42 40 36 33 29 28 2

C ≈ 1.5% 7.753 0.486 36 0.970 36 36 36 35 33 31 28 28 2

Baja Nikel

Ni ≈ 0% 7.897 0.452 73 2.026

Ni ≈ 20% 7.933 0.46 19 0.526

135

Universitas Sumatera Utara

Lampiran 15

Pendekatan Nilai Koefesien Perpindahan Panas Menyeluruh (Uo)

Sumber: Holman, J.P. , 1993.

Approximate values of overall heat transfer coefficient

U

Physical situation

Btu/h-ft2 0F W/m2 0C

Brick exterior wal, plaster interior, uninstalated 0.45 2.55

Frame exterior, wall, plaster interior, uninstalated 0.25 1.42

With rock-wool insulaton 0.07 0.4

Plate-glass window 1.10 6.2

Double plate-glass window 0.40 2.3

Steam condenser 200-1000 110-5600

Feedwater heater 200-1500 1100-8500

Freon-12 condenser with water coolant 50-150 280-850

Water-to-water heat exchanger 150-300 850-1700

Finned-tube heat exchanger, water in tubes, air

5-10 25-55

accros tubes

Water-to-oil heat exchanger 20-60 110-350

Gas to light fuel oil 30-60 170-340

Gas to heavy fuel oil 10-30 56-170

Gas to kerosene or gasoline 50-200 280-1140

Finned-tube heat exchanger, steam in tubes, air

5-50 28-280

over tubes

Amonia condenser, water in tubes 150-250 850-1400

Alcohpl Condenser, water in tunes 45-120 255-680

Gas-to-gas heat exchanger 2-8 10-40

136

Universitas Sumatera Utara

Lampiran 16

Jenis-jenis Bahan Isolasi dan Penerapannya

Jangkauan suhu Konduktifitas termal Densitas

Jenis penerapan

(0C) (W/m 0C) (kg/m3)

Superisolasi Linde hampa -240-1100 0.0015-0.72 Berbagai Banyak

Busa uretana -180-150 16-20 25-48 Pipa panas dan dingin

Busa uretana -170-110 16-20 32 Tangki

Block kaca sel -200-200 29-108 110-150 Tangki dan pipa

Selubung kaca serat sebagai Pipa dan sambungan

-28-290 22-78 10-50

pembungkus

Selubung kaca serat Drum dan alat tangki

-170-230 25-86 10-50

pipa

Kaca serat pra cetak bentukan -50-230 32-55 10-50 Pipa

Lembaran elastomer 40-100 36-39 70-100 Tangki

Anyaman kaca serat 60-370 30-55 10-50 Pipa dan sambungan

Elastomer pracetak bentukan -40-100 36-39 70-100 Pipa sambungan

Kaca serat dengan selubung Pipa pendingin

-5-70 29-45 10-32

uap

Kaca serat tanpa selubung uap 250 29-45 24-48 Pipa panas

Papan kaca serat 20-450 33-52 25-100 Ketel uap dan tangki

Papan dan blok kaca sel 20-450 29-108 110-150 Pipa panas

Papan dan blok busa uretana 100-150 16-20 24-65 Pipa

Bentukan pra cetak serat Pipa panas

650 33-91 125-100

mineral

Selubung serat mineral 750 37-81 125 Pipa panas

Blok wol mineral 450-1000 52-130 175-290 Pipa panas

Papan dan blok kalsium Ketel uap, drum

230-1000 32-85 100-106

silikat

Blok serat mineral 1100 52-130 210 Ketel, tangki

137

Universitas Sumatera Utara

Lampiran 17

Tabel Kecepatan Fluida

Velocities generely used in steam generating system

Velocity

Nature of service

(ft/min)

Air

Air heater 1000-5000

Coal and air lines, pulverized coal 3000-4500

Compresed air lines 1500-2000

Forced draft ducks 1500-3600

Forced draft duct, entrance to burners 1500-2000

Register grills 300-600

Ventilating ducks 1000-3000

Crude oil lines

Fuel gas 60-360

Air heater 1000-5000

Boiler gas passes 3000-6000

Induced draft flues and breeching 2000-5000

1000-1500

Natural gas lines

Steam

Steam lines

High pressure 8000-12000

Velocities generely used in steam generating system

Velocity

Nature of service

(ft/min)

138

Universitas Sumatera Utara

Low pressure 12000-15000

Vacuum 20000-40000

Superheater tubes 5000-10000

Water

Boiler circulation 70-700

Economizer tubes 150-300

Pressurized water reactors

Fuel assembly channels 400-1300

Reactor coolant piping 2400-3600

Water lines, general 500-750

139

Universitas Sumatera Utara

Lampiran 18

Susunan Tabung Superheater, Backpass. Harga C dan m

Sumber: Incropera Frank, 1985.

Susunan pipa

Harga C dan m

140

Universitas Sumatera Utara

Lampiran 19

Faktor Keefektifan Pipa Waterwall

Sumber: Babcock and Wilcox, 1969.

141

Universitas Sumatera Utara

You might also like

- Sound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)Document50 pagesSound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)sherio amrousyNo ratings yet

- Manufacturers of Vibration Control Products and Pipe Accessories Data SheetDocument2 pagesManufacturers of Vibration Control Products and Pipe Accessories Data Sheetbman0051401No ratings yet

- Acsr Al Bare-Rev 04Document1 pageAcsr Al Bare-Rev 04Ae SuwaphanNo ratings yet

- Nichrome - WikipediaDocument12 pagesNichrome - Wikipediamei krismahariyantoNo ratings yet

- IWF Wide Flange Steel Beams GuideDocument4 pagesIWF Wide Flange Steel Beams GuideandNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- DESIGN OF TWO WAY SLABDocument3 pagesDESIGN OF TWO WAY SLABSyeda NafeezaNo ratings yet

- Anubhav Gupta PPT THDC-ILDocument27 pagesAnubhav Gupta PPT THDC-ILAsdf LkjhNo ratings yet

- Expansion Calculations and Loop SizingDocument2 pagesExpansion Calculations and Loop SizingmusNo ratings yet

- Pipe Conversion ChartDocument7 pagesPipe Conversion ChartramyzottyNo ratings yet

- Nalco Sound SpeedDocument27 pagesNalco Sound SpeedTule WilliamsNo ratings yet

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document26 pagesAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98No ratings yet

- Vibrator SpecDocument2 pagesVibrator Specsubha sethiNo ratings yet

- Curva Conduit Rgs X 90 Deg Ul UniverDocument12 pagesCurva Conduit Rgs X 90 Deg Ul UniveraasfaskjlNo ratings yet

- 1.0 Objective:: Unconfined Compression TestDocument13 pages1.0 Objective:: Unconfined Compression TestsitiNo ratings yet

- 1200 1300Document18 pages1200 1300wyerengrNo ratings yet

- Prunte Kettenwerk GMBH Co. KGDocument6 pagesPrunte Kettenwerk GMBH Co. KGAhmed SadekNo ratings yet

- Voltage Drop-CalculationDocument4 pagesVoltage Drop-CalculationvjtheeeNo ratings yet

- Voltage Drop-CalculationDocument4 pagesVoltage Drop-CalculationvjtheeeNo ratings yet

- SEGI UNIVERSITY KOTA TENSILE TESTING LAB REPORTDocument12 pagesSEGI UNIVERSITY KOTA TENSILE TESTING LAB REPORTAhmed ElqazazNo ratings yet

- HY-8 Culvert Analysis Report: Crossing Discharge DataDocument14 pagesHY-8 Culvert Analysis Report: Crossing Discharge Datamoto8styleNo ratings yet

- Rodgers ReportDocument7 pagesRodgers ReportSceva AquilaNo ratings yet

- Copper Pipes To BS EN 1057Document12 pagesCopper Pipes To BS EN 1057wkcNo ratings yet

- PNS 1207 2005 - Annealed Copper Wires Specification - Stranded - THHN - THW - TWDocument9 pagesPNS 1207 2005 - Annealed Copper Wires Specification - Stranded - THHN - THW - TWshivam dwivediNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- PVC and XLPE Cable Current RatingDocument25 pagesPVC and XLPE Cable Current RatingMahamud MusaNo ratings yet

- PCV CableDocument12 pagesPCV CableMahamud MusaNo ratings yet

- Lab 1 Calibration of ThermocoupleDocument2 pagesLab 1 Calibration of ThermocoupleVishnu SomarajuNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoNo ratings yet

- STRUCTURAL DESIGN OF MO-P-DR2 (2)Document35 pagesSTRUCTURAL DESIGN OF MO-P-DR2 (2)sudhirkumarsharma1966No ratings yet

- Hard Alloy Tube CapabilitiesDocument7 pagesHard Alloy Tube CapabilitiesJM SVNo ratings yet

- Uniflow Copper Tubes TDSDocument7 pagesUniflow Copper Tubes TDSFilorNo ratings yet

- Coiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingDocument16 pagesCoiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingNardo AvalosNo ratings yet

- Lab#3-Impact of A JetDocument8 pagesLab#3-Impact of A JettareqNo ratings yet

- Oel Report Mos-1Document14 pagesOel Report Mos-1Muhammad Hassan Syed BSCVE2021No ratings yet

- STRENGTH OF ANGLE SECTIONDocument7 pagesSTRENGTH OF ANGLE SECTIONkrunalNo ratings yet

- Creep and Creep-Rupture Behaviour Bainitic 2 1/4 Cr-1 Mo SteelDocument21 pagesCreep and Creep-Rupture Behaviour Bainitic 2 1/4 Cr-1 Mo SteelStephen JonesNo ratings yet

- Design of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992Document76 pagesDesign of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992bhargavramudu 2019No ratings yet

- Lecture 4 - Elevated Circular TankDocument22 pagesLecture 4 - Elevated Circular TankUsama AhmedNo ratings yet

- Tri-rated-Cable-SpecDocument1 pageTri-rated-Cable-Specalpha7beta6No ratings yet

- Tensile Test Lab ReportDocument5 pagesTensile Test Lab ReportLudik CarvalhoNo ratings yet

- Timber Design FinalDocument22 pagesTimber Design FinalChristian ConsignaNo ratings yet

- Measurement of The Drag Coefficients of Spherical ParticlesDocument10 pagesMeasurement of The Drag Coefficients of Spherical Particlessr3shNo ratings yet

- Cu-Mica-Epr-Eva-Swb-Eva CableDocument2 pagesCu-Mica-Epr-Eva-Swb-Eva CableMohd Haziq Mohd YunusNo ratings yet

- 220029-Bicester DS P7 - Compressed-26-70Document45 pages220029-Bicester DS P7 - Compressed-26-70barlaa02No ratings yet

- Flare CalculationDocument22 pagesFlare CalculationHomer SilvaNo ratings yet

- Expansion Chart PipeDocument15 pagesExpansion Chart PipechabibNo ratings yet

- 600/1000V Cu/PVC cable technical data sheetDocument1 page600/1000V Cu/PVC cable technical data sheetCiwa DoankNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- Technical Data Sheet Product CatalogueDocument16 pagesTechnical Data Sheet Product CatalogueKamalNo ratings yet

- ISO 10243.die SpringsDocument12 pagesISO 10243.die SpringsКонстантин Косарев100% (1)

- JIS and European Standard Channels Dimensions and PropertiesDocument5 pagesJIS and European Standard Channels Dimensions and PropertiesRuri IswadiNo ratings yet

- 316L Stainless Steel PipeDocument9 pages316L Stainless Steel PipeSmail MiloudiNo ratings yet

- Drainage Pipe Flow - Manning Formula (1.1)Document1 pageDrainage Pipe Flow - Manning Formula (1.1)parrykambo99No ratings yet

- Unconfined Compression TestDocument8 pagesUnconfined Compression TestYogesh NautiyalNo ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- Development of Large-Scale Hydrogen Liquefaction Processes ReviewDocument10 pagesDevelopment of Large-Scale Hydrogen Liquefaction Processes ReviewPaulita BuenoNo ratings yet

- Integrated Design For Demonstration of Efficient Liquefaction of HydrogenDocument4 pagesIntegrated Design For Demonstration of Efficient Liquefaction of HydrogenDilla WahabNo ratings yet

- Hydrogen Liquefaction ReportDocument33 pagesHydrogen Liquefaction ReportDilla WahabNo ratings yet

- Economically Viable Large-Scale Hydrogen Liquefaction PDFDocument9 pagesEconomically Viable Large-Scale Hydrogen Liquefaction PDFDilla WahabNo ratings yet

- Hydrogen Liquefaction Costs Estimated at $50M-$800MDocument10 pagesHydrogen Liquefaction Costs Estimated at $50M-$800MDilla WahabNo ratings yet

- Efficient Liquefaction of Hydrogen - Results of The IDEALHY ProjectDocument8 pagesEfficient Liquefaction of Hydrogen - Results of The IDEALHY ProjectDilla WahabNo ratings yet

- Analysis and Assessment of A Novel Hydrogen Liquefaction ProcessDocument10 pagesAnalysis and Assessment of A Novel Hydrogen Liquefaction ProcessDilla WahabNo ratings yet

- Concepts For Efficient Hydrogen LiquefactionDocument16 pagesConcepts For Efficient Hydrogen LiquefactionDilla WahabNo ratings yet

- Conceptual Design and Analysis of A Novel Process For Hydrogen Liquefaction PDFDocument24 pagesConceptual Design and Analysis of A Novel Process For Hydrogen Liquefaction PDFDilla WahabNo ratings yet

- Concepts For Large Scale Hydrogen Liquefaction Plants PDFDocument179 pagesConcepts For Large Scale Hydrogen Liquefaction Plants PDFDilla Wahab100% (1)

- Boundary Layer Profile on a Flat Plate: 99% Thickness, Momentum Thickness, and Displacement ThicknessDocument3 pagesBoundary Layer Profile on a Flat Plate: 99% Thickness, Momentum Thickness, and Displacement ThicknessDilla WahabNo ratings yet

- No. Criteria: ParameterDocument4 pagesNo. Criteria: ParameterDilla WahabNo ratings yet

- Paints Industry Raw Materials Unit Operations Equipment Manufacturing Quality TestsDocument46 pagesPaints Industry Raw Materials Unit Operations Equipment Manufacturing Quality TestsEvansChombaNo ratings yet

- No. Criteria: ParameterDocument4 pagesNo. Criteria: ParameterDilla WahabNo ratings yet

- 2018 Lect4 Types of PumpDocument36 pages2018 Lect4 Types of PumpDilla WahabNo ratings yet

- Compressibility Chart & Comp Liq TableDocument2 pagesCompressibility Chart & Comp Liq TableDilla WahabNo ratings yet

- How Many HatsDocument1 pageHow Many HatsDilla WahabNo ratings yet

- Itung ItunganDocument14 pagesItung ItunganDilla WahabNo ratings yet

- 2Document5 pages2Dilla WahabNo ratings yet

- BakorDocument9 pagesBakorDilla WahabNo ratings yet

- I-Xii Movement Operations in FCIDocument146 pagesI-Xii Movement Operations in FCIankur sharmaNo ratings yet

- Iata Ahm Data F100: Ground Services Aircraft Handling Policies Montenegro AirlinesDocument31 pagesIata Ahm Data F100: Ground Services Aircraft Handling Policies Montenegro AirlinesSHERIEFNo ratings yet

- Service: Guide For Using TrailersDocument39 pagesService: Guide For Using TrailersGabrielDanielNo ratings yet

- Identifying Genuine Admiralty ProductsDocument2 pagesIdentifying Genuine Admiralty ProductsGinni Bajwa GurinderNo ratings yet

- Standard Briefing For AIRBUS FLEETDocument3 pagesStandard Briefing For AIRBUS FLEETJoanes SyNo ratings yet

- OutputDocument1,997 pagesOutputbluejacker22No ratings yet

- ISO Shipbuilding Standards ListDocument14 pagesISO Shipbuilding Standards ListGEORGE.K.C100% (2)

- CR Ipc 1 0 00 - R8Document490 pagesCR Ipc 1 0 00 - R8FelipeNo ratings yet

- Maritimestatistics 2009Document181 pagesMaritimestatistics 2009niamhcadwalladrNo ratings yet

- Tata Indigo DicorDocument190 pagesTata Indigo DicorxtempNo ratings yet

- Hydraulic Traffic Reduction System OriginalDocument8 pagesHydraulic Traffic Reduction System OriginalChandra shekar RaoNo ratings yet

- Glengormley MasterplanDocument6 pagesGlengormley MasterplanGreen-M7No ratings yet

- Abu Dhabi Police GHQ - E-Services - Fine's DetailsDocument3 pagesAbu Dhabi Police GHQ - E-Services - Fine's Detailsali kandkjiNo ratings yet

- Roads and Transport6Document16 pagesRoads and Transport6Agel TobiasNo ratings yet

- Blackfriars Bridge Display BoardDocument1 pageBlackfriars Bridge Display BoardthamestunnelNo ratings yet

- Sastra Inggris - Report TeksDocument12 pagesSastra Inggris - Report TeksTasyaNo ratings yet

- КЛАСИЧЕСКА ОБИКОЛКА НА ИТАЛИЯDocument5 pagesКЛАСИЧЕСКА ОБИКОЛКА НА ИТАЛИЯWhy so serious?No ratings yet

- Osmolarity&tonicitypracticeproblemsfrominternetDocument14 pagesOsmolarity&tonicitypracticeproblemsfrominternetbsktblbabe88No ratings yet

- Design, Analysis and Fabrication of Split Braking SystemDocument6 pagesDesign, Analysis and Fabrication of Split Braking Systemhabib nawazNo ratings yet

- Transfer Box and Final Drive PDFDocument67 pagesTransfer Box and Final Drive PDFGabo AguilarNo ratings yet

- Compliance of Rail Border AgreementsDocument181 pagesCompliance of Rail Border AgreementsJohn SirautNo ratings yet

- Design and Analysis of Composite Leaf SpringDocument18 pagesDesign and Analysis of Composite Leaf Springarun_gs_60% (1)

- City of Fort Worth: Temporary Street Use Request Form For Solicitation of FundsDocument1 pageCity of Fort Worth: Temporary Street Use Request Form For Solicitation of FundsMud PyeNo ratings yet

- Carbon Footprint Calculator OfflineDocument6 pagesCarbon Footprint Calculator Offlinevinuye100% (1)

- CraneStatisticsandCaseStudies PDFDocument40 pagesCraneStatisticsandCaseStudies PDFShadab Ahmed GhazalyNo ratings yet

- HMIS Newsetter 14Document8 pagesHMIS Newsetter 14sonusk777No ratings yet

- Valley Hot News Vol. 2 No.4Document8 pagesValley Hot News Vol. 2 No.4Philtian MarianoNo ratings yet

- Robinson Crusoe Chapter 2 Summary and AnalysisDocument1 pageRobinson Crusoe Chapter 2 Summary and AnalysisمہۣۗاسہٰتۣۗرزيۣۗNo ratings yet

- Gendrive Series 2000 Gx5 for Power Generation with Air CoolingDocument4 pagesGendrive Series 2000 Gx5 for Power Generation with Air CoolingPrince ChaudharyNo ratings yet

- Airplane GeneralDocument57 pagesAirplane GeneralMorgan MendozaNo ratings yet