Professional Documents

Culture Documents

Liebherr 9350

Uploaded by

Francisco GonzalezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebherr 9350

Uploaded by

Francisco GonzalezCopyright:

Available Formats

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

New Undercarriage Components for Liebherr®

R9250 Mining Excavator (Backhoe and Face

Shovel Versions).

NEW PRODUCT INTRODUCTION

The continuous demand from the Surface Mining Market for a wider range of products, in addition to

continuous improvement in terms of machine cost per hour performance, has driven ITM® to introduce the new

undercarriage components suitable for Liebherr® R9250 Backhoe and Face Shovel Versions. The products

are the result of extensive engineering activities, new materials and wide variety of laboratory and field tests.

A Titan International, Inc. Brand

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Part No. F14128A0M00000

Track Chain without Shoes - Technical Data

A

B12

Dimensions

Position Units - mm (inch)

B C

A 350 (13,77)

B 102 (4,01)

C 132 (5,2)

F 132 (5,2)

G 255 (10,03)

H 252 (9,92)

I 352 (13,86)

N 357,2 (14,06)

H

O 162 (6,38)

P 133 (5,24)

Q 85,5 (3,36)

S 39,8 (1,57)

U 457 (17,99)

S

Number of Elements Available:

25 Elements

Weight:

25 Elements 3.780 kg (8333 lb)

U

24 Elements 3.560 kg (7848 lb)

P

G

Q

F

O

N

A Titan International, Inc. Brand 2 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Part No. Z1412200N0850V

Double Grouser Shoe with Clipped Corners - Technical Data

Dimensions

Position Units - mm (inch)

A 850 (33,46)

B 352 (13,86)

C 252 (9,92)

D

D 400 (15,74)

E

E 102 (4,01)

F 40 (1,57)

G 60 (2,36)

H 65 (2,55)

Weight:

C 160 kg (352,7 lb)

B

A

H

G

A Titan International, Inc. Brand 3 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Part No. A49940A0M00

Lower Roller with Brackets - Technical Data

Dimensions

Position Units - mm (inch)

A 396 (15,59)

B 326 (12,83)

C 367 (14,45)

D 496 (19,53)

E 650 (25,59)

F 720 (28,35)

G 548 (21,57)

H 160 (6,30)

J 255 (10,03)

L 33 (1,30)

M 230 (9,05)

N 155 (6,10)

V 15°

Weight: 408 kg (899,5 lb)

A Titan International, Inc. Brand 4 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Part No. C1411000Y00

Carrier Roller - Technical Data

F

E

G

S Dimensions

Position Units - mm (inch)

B 280 (11,02)

D 360 (14,17)

E 500 (19,68)

F 555 (21,85)

G 400 (15,75)

B

H 110 (4,33)

J

J 205 (8,07)

L 27 (1,06)

M 160 (6,3)

N 99 (3,9)

S 131 (5,16)

D Weight: 346 kg (762,8 lb)

M

L

N

A Titan International, Inc. Brand 5 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Part No. PV9944D0Y00

Idler with Brackets - Technical Data

Dimensions

Position Units - mm (inch)

A 1215 (47,83)

B 1120 (44,09)

C 180 (7,08)

D 360 (14,17)

E 150 (5.90)

C

F 480 (18,89)

I H G 710 (27,95)

H 200 (7,87)

I 625 (24,6)

L 30 (1,18)

M 170 (6,69)

N 540 (21,26)

Q 270 (10,63)

F Weight: 1703 kg (3761,1 lb)

D

E

L

M

Q

B

A

N

G

A Titan International, Inc. Brand 6 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Part No.R49250A0M01

Sprocket - Technical Data

N

G F

R

Dimensions

Position Units - mm (inch)

L

B

A 1352,3 (53,24)

S

A B 1405 (55,31)

C 1219,3 (48,00)

D 870 (34,25)

D2 1000 (39,37)

F 140 (5,5)

D2

Q

D

C

G 12 (0,47)

L 350 (13,78)

N 160 (6,3)

Q 940 ( 37 )

R 10 (0,4)

S 33 (1,3)

N° Bolts : 45

N° Teeth : 12

Weight: 664 kg (1463,9 lb)

A Titan International, Inc. Brand 7 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

MAIN FEATURES AND BENEFITS

The new track links are manufactured with special

boron steel, quenched, tempered and stress relieved to

guarantee high resistance and support heavy structural

loads.

Track link rail is deep induction hardened to optimize wear

performance in any environment.

The track chain is grease lubricated to reduce pin and

bushing internal wear and, as a consequence, reduce

track chain pitch elongation.

Idler wheel is made from special cast steel, with idler rim

induction hardened to increase robustness and optimize

wear performance.

Track shoes are available in Heavy Duty (shoe plate

thickness 60mm -2,362 in.) with “Large Angle” clipped

corners.

Track shoes are quenched and tempered to increase

robustness, avoid bending and, at the same time, resist

wear even in very demanding environment.

An integrated “Trapezoidal”design mud hole is provided to

reduce accumulation of material on the track chain.

A Titan International, Inc. Brand 8 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

Roller shell is made from special boron steel, induction

hardened and stress relieved to increase robustness,

guarantee high resistance and optimize wear performance

in any environment.

The roller shaft is induction hardened, realized with high

surface finishing quality, to resist heavy radial and axial

loads and in the meantime guarantee an adequate internal

oil lubrication.

Upper roller shells are Differential Quenched to increase

the roller wear life, strengths and durability.

The roller shaft is induction hardened, realized with high

surface finishing quality, to resist heavy radial and axial

loads and in the meantime guarantee an adequate internal

oil lubrication.

The new sprocket are quenched and tempered plus

induction hardened to obtain high resistance and, in the

meantime, significantly improve wear performances in any

environment.

A Titan International, Inc. Brand 9 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

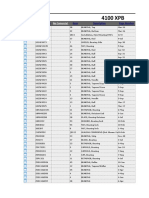

MARKETING INFORMATION AND AVAILABILITY

The reference numbers are listed in the following table. As a consequence superseded products will be

gradually discontinued:

Superseded Main Machine Models

New Part Number Availability Date 1)

Part Number 2) Manufacturer Model

L14122C0M49850 - None - Liebherr® R9250 1th Quarter 2016

L14122B0M25850 - None - Liebherr® R9250 1th Quarter 2016

L14122B0M24850 - None - Liebherr® R9250 1th Quarter 2016

F14128A0M00025 - None - Liebherr® R9250 1th Quarter 2016

F14128A0M00024 - None - Liebherr® R9250 1th Quarter 2016

Z1412200N0850V - None - Liebherr® R9250 1th Quarter 2016

A49940A0M00 - None - Liebherr® R9250 1th Quarter 2016

C1411000Y00 - None - Liebherr® R9250 1th Quarter 2016

PV9944D0Y00 - None - Liebherr® R9250 1th Quarter 2016

R49250A0M01 - None - Liebherr® R9250 1th Quarter 2016

1)

: The availability date is subject to change without notice. Please refer to your ITM® Local Sales Representative or to our ITM® AMK Sales Dpt.

reference personnel for further detailed information.

2)

: The interchangeability with new component part number and superseded part number is intended for the complete item only. Single internal

components interchangeability MUST be verified for each single item. Please refer to ITM® WEB Catalogue for further detailed information.

Please be aware that the list may not fully cover all applications and machines configurations. Please refer to

ITM® WEB Catalogue for special applications, additional not-listed machines in the LIEBHERR® R9250 Class

(like Custom Special Order machines) or further technical information on this product.

A Titan International, Inc. Brand 10 of 12

LIEBHERR R9250_rev00_(29_09_2016)

New Product Introduction

Product Improvement

Technical Information

Number 10 - 2016 Technical Bulletin

INTERCHANGEABILITY

Track chain, shoes , bolts and nuts, idler, upper and lower rollers are fully interchangeable with original

components. Please refer to ITM® WEB Catalogue for further detailed information regarding internal

components interchangeability.

SERVICE INFORMATIONS

For all components wear rates listed in this Technical Bulletin please refer to ITM® “Undercarriage Service

and Wear Limits Handbook”.

Refer also to ITM® “Undercarriage Wear & Care Manual” (available from January 2013) for recommended

undercarriage maintenance usage and repairs.

A Titan International, Inc. Brand 11 of 12

LIEBHERR R9250_rev00_(29_09_2016)

Titan International Muswellbrook, NSW, Australia Titan Steel Wheels Ltd Italtractor ITM SpA

Quincy, IL, USA Perth, WA, Australia Kidderminster, UK Fanano (MO), Italy

Bryan, OH, USA Port Hedland, WA, Australia Ceprano (FR), Italy

Des Moines, IA, USA Sydney, NSW, Australia Titan Distribution (UK) Ltd Potenza, Italy

Freeport, IL, USA Whyala, SA, Australia St. Helens, UK

Saltville, VA, USA Yatala, QLD, Australia Titan Intertractor GmbH

Titan Italia SpA Gevelsberg, Germany

Titan Tire Corporation Crespellano (BO), Italy

Titan Mining Services (TMS) Finale Emilia (MO), Italy Pyrsa Piezas y Rodajes S.A.

Union City, TN, USA PT Titan Wheels Indonesia Jesi (AN), Italy Monreal del Campo

Jakarta, Indonesia (Teruel), Spain

Titan Pneus do Brasil Ltda

São Paulo, Brazil Titan Mining Services (TMS) Titan France SAS

Flers, France Intertractor America Corp.

Titan Wheels South Africa Elkhorn, WI, USA

Voltyre-Prom (Pty) Ltd Titan Asia A.S. Winston-Salem, NC, USA

Volgograd, Russia Nuffield, Springs, SA Aydin, Turkey

ITM Latin America Ltda

Titan Mining Services (TMS) Titan Mining Services (TMS) Wheels India Ltd Atibaia, São Paulo, Brazil

SWT Aros del Pacifico S.A.C. Tamilnadu, India

Saskatoon, SK, Canada Lima, Peru (Minority Share) ITM Track (Tianjin) Ltd

Tianjin, P.R. of China

Titan Mining Services (TMS) Titan Mining Services (TMS)

Titan Australia Pty Ltd Aros del Pacifico S.A. Titan ITM (Tianjin) Co. Ltd

Emerald, QLD, Australia Santiago, Chile WDA Tianjin, P.R. of China

Kalgoorlie, WA, Australia Iquique, Chile

Karratha, WA, Australia Titan ITM Japan Ltd

Mildura, VIC, Australia Yokohama, Japan

www.group-itm.com

www.titan-intl.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Session4 Automotive Front End DesignDocument76 pagesSession4 Automotive Front End DesignShivprasad SavadattiNo ratings yet

- Catalog Crowd 495BIDocument10 pagesCatalog Crowd 495BIFrancisco Gonzalez100% (1)

- Catalog Crowd 495BIDocument10 pagesCatalog Crowd 495BIFrancisco Gonzalez100% (1)

- TB - 11 - 2016 - CATERPILLAR D10N, D10R, D10T - (PPR) - Rev00 - (29 - 09 - 2016)Document12 pagesTB - 11 - 2016 - CATERPILLAR D10N, D10R, D10T - (PPR) - Rev00 - (29 - 09 - 2016)Francisco GonzalezNo ratings yet

- Dipper Door Assembly Part No R72209F1 PDFDocument3 pagesDipper Door Assembly Part No R72209F1 PDFFrancisco Gonzalez0% (1)

- TB 03 2016 Liebherr R9350Document12 pagesTB 03 2016 Liebherr R9350Francisco Gonzalez100% (1)

- Propel Transmission 7495HR CaterpillarDocument4 pagesPropel Transmission 7495HR CaterpillarFrancisco GonzalezNo ratings yet

- Assy Propel Trans 7495HRDocument2 pagesAssy Propel Trans 7495HRFrancisco GonzalezNo ratings yet

- LM2TB8 2018 (Online)Document252 pagesLM2TB8 2018 (Online)SandhirNo ratings yet

- Dipper Door Assembly Part No R72209F1 PDFDocument3 pagesDipper Door Assembly Part No R72209F1 PDFFrancisco GonzalezNo ratings yet

- Digital SLR AstrophotographyDocument366 pagesDigital SLR AstrophotographyPier Paolo GiacomoniNo ratings yet

- BUCYRUS 495HR Propel TransmisionDocument2 pagesBUCYRUS 495HR Propel TransmisionFrancisco GonzalezNo ratings yet

- Better Photography - April 2018 PDFDocument100 pagesBetter Photography - April 2018 PDFPeter100% (1)

- TB - 07 - 2016 - L0174700M00000 495HRDocument4 pagesTB - 07 - 2016 - L0174700M00000 495HRFrancisco GonzalezNo ratings yet

- Rodamientos Palas 4100Document12 pagesRodamientos Palas 4100Francisco GonzalezNo ratings yet

- Transmisión de Propel 4100XPC ACDocument1 pageTransmisión de Propel 4100XPC ACFrancisco GonzalezNo ratings yet

- QR370 Parts ManualDocument28 pagesQR370 Parts ManualFrancisco Gonzalez100% (1)

- Copia de Catalogo Transmision de Propel en Parte Bucyrus 495HRDocument3 pagesCopia de Catalogo Transmision de Propel en Parte Bucyrus 495HRFrancisco GonzalezNo ratings yet

- Copia de Catalogo Transmision de Propel en Parte Bucyrus 495HRDocument3 pagesCopia de Catalogo Transmision de Propel en Parte Bucyrus 495HRFrancisco GonzalezNo ratings yet

- Gearbox Pump Drive Pit Viper 351Document2 pagesGearbox Pump Drive Pit Viper 351Francisco Gonzalez100% (1)

- Transmision de Levante (Pulldown) 49HRDocument6 pagesTransmision de Levante (Pulldown) 49HRFrancisco GonzalezNo ratings yet

- Benko Gambit-Jacobs and Kinsman, 1999Document163 pagesBenko Gambit-Jacobs and Kinsman, 1999johnson Greker100% (3)

- Sistema de Penetracion 2800XPADocument2 pagesSistema de Penetracion 2800XPAFrancisco Gonzalez100% (1)

- Hoist Drum Assy 4100XPCDocument3 pagesHoist Drum Assy 4100XPCFrancisco GonzalezNo ratings yet

- Locking Assembly Crowd 7495HR CATERPILLARDocument4 pagesLocking Assembly Crowd 7495HR CATERPILLARFrancisco GonzalezNo ratings yet

- Catalogo Air End S011053Document4 pagesCatalogo Air End S011053Francisco GonzalezNo ratings yet

- Catalogo Air End S011053Document4 pagesCatalogo Air End S011053Francisco GonzalezNo ratings yet

- PV351 Upgrades 2018Document6 pagesPV351 Upgrades 2018Francisco GonzalezNo ratings yet

- Internship ReportDocument36 pagesInternship ReportM.IMRAN0% (1)

- Ac1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTDocument50 pagesAc1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTHung Faat ChengNo ratings yet

- Chap9 PDFDocument144 pagesChap9 PDFSwe Zin Zaw MyintNo ratings yet

- Chem Resist ChartDocument13 pagesChem Resist ChartRC LandaNo ratings yet

- Report On Marketing Strategy of Nestle MILKPAKDocument13 pagesReport On Marketing Strategy of Nestle MILKPAKAzeem Ahmad100% (1)

- Clash of Clans Hack Activation CodeDocument2 pagesClash of Clans Hack Activation Codegrumpysadness7626No ratings yet

- Uneb U.C.E Mathematics Paper 1 2018Document4 pagesUneb U.C.E Mathematics Paper 1 2018shafickimera281No ratings yet

- PDF of Tally ShortcutsDocument6 pagesPDF of Tally ShortcutsSuraj Mehta100% (2)

- Lect.1-Investments Background & IssuesDocument44 pagesLect.1-Investments Background & IssuesAbu BakarNo ratings yet

- F5 Chem Rusting ExperimentDocument9 pagesF5 Chem Rusting ExperimentPrashanthini JanardananNo ratings yet

- MCQs - Chapters 31 - 32Document9 pagesMCQs - Chapters 31 - 32Lâm Tú HânNo ratings yet

- Code ExplanantionDocument4 pagesCode ExplanantionVivek JadiyaNo ratings yet

- Health and Safety For The Meat Industry: Guidance NotesDocument198 pagesHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicNo ratings yet

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocument2 pagesTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUNo ratings yet

- NGCP EstimatesDocument19 pagesNGCP EstimatesAggasid ArnelNo ratings yet

- Mitsubishi FanDocument2 pagesMitsubishi FanKyaw ZawNo ratings yet

- Bigbazaar PDFDocument14 pagesBigbazaar PDFazhagu sundaramNo ratings yet

- FSM Syllabus20071228 1Document3 pagesFSM Syllabus20071228 1Institute of Fengshui BaziNo ratings yet

- 2a Unani Medicine in India - An OverviewDocument123 pages2a Unani Medicine in India - An OverviewGautam NatrajanNo ratings yet

- Hindi ShivpuranDocument40 pagesHindi ShivpuranAbrar MojeebNo ratings yet

- 200150, 200155 & 200157 Accelerometers: DescriptionDocument16 pages200150, 200155 & 200157 Accelerometers: DescriptionJOSE MARIA DANIEL CANALESNo ratings yet

- Standard nfx15-211Document2 pagesStandard nfx15-211Luis Enrique Cóndor PorrasNo ratings yet

- Toxemias of PregnancyDocument3 pagesToxemias of PregnancyJennelyn LumbreNo ratings yet

- Intervensi Terapi Pada Sepsis PDFDocument28 pagesIntervensi Terapi Pada Sepsis PDFifan zulfantriNo ratings yet

- HandsoutDocument3 pagesHandsoutloraine mandapNo ratings yet