Professional Documents

Culture Documents

gx12 PDF

Uploaded by

Sai KrishnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

gx12 PDF

Uploaded by

Sai KrishnaCopyright:

Available Formats

G X12

225+ Amp 12-800 Vdc Contactor

FEATURES

Chassis level power terminals – No need for specially routed power cables, special bus bars, or special lugs.

Rugged EPIC® seal rated to 175°C – Reduced risk of fire or meltdown in over current conditions.

The same technology used for advanced aerospace programs.

Hermetically sealed – Designed to meet: UL1604 for Class I & II, Div 2 and Class III for use in hazardous

locations, IP67 for temporary water immersion for 30 min, IP69K for pressure washing, SAE J1171 - external

ignition protection, and ISO8846 for protection against ignition around flammable gasses.

Optional High Efficiency Dual DC Coils – Very low 12 or 24 VDC continuous coil power with no EMI emissions or

cross-talk on your system control power. Ideal for battery powered systems or where low power is needed.

Built-in coil suppression for all DC coils – Saves you engineering time and parts cost to add external coil suppression.

Stainless steel nuts and mounting inserts, for years of corrosion free service.

Not position sensitive – can be mounted in any position for ease of installation.

ADVANCED SWITCHING SOLUTIONS

Rev 6 10/23/15

225+ Amp 12-800 Vdc

EPIC® Hermetic Sealed DC Contactor G X12

POWER SWITCHING AND

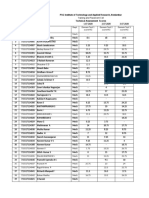

PRODUCT SPECIFICATIONS CURRENT CARRY RATINGS

Specifications Units Data

Contact Arrangement

Main Form X SPST-NO

Auxilary (2A, 24VDC)1 Form A or B SPST-NO or DC POWER SWITCHING CYCLES9

SPST-NC

1,000,000

Mechanical Life Cycles 1,000,000

Contact Resistance2

Max mohms 0.4

100,000

Typical mohms 0.15 to 0.3

Insulation Resistance4 Mohms 100

Dielectric At Sea Level (Leakage < 1mA) VRMS 2,200

CYCLES

Shock, 1/2 Sine, 11ms G peak 20 10,000

Vibration, Sinusoidal (500-2000 Hz Peak) G 15

Ambient Temp Range

Operating5 ˚C -55 to +85 1,000

Storage ˚C -70 to +150

Weight, Typical Kg (Lb) 0.5 (1.1)

Environmental Seal Exceeds IP67 & IP69K 100

Salt Fog MIL-STD-810 25 50 75 100 125 150 175 200 225

CURRENT (A)

24V 300V 450V 600V

COIL RATINGS at 25˚C

Coil P/N Designation B C F H J K L S T CURRENT CARRY vs TIME

Coil Voltage, Nominal (VDC) 120 240 with 85ºC terminal temperature rise

12 24 48 72 120 12 24

VAC VAC

Coil Voltage, Max (V) 16 32 64 96 140 140 280 16 32 10,000

Pick-Up Voltage, Max (V)7 8 16 28 46 72 80 160 96, 8 156, 8

375A max

Drop-Out Voltage, Max (V)7 3 7 10 14 18 30 60 4.5 7

4/0 conductor

Drop-Out Voltage, Min (V)7 0.5 0.5 1.8 2.7 4.5 4.5 9 1 1.5

1,000

TIME (sec)

Pick-Up Current, Max (A) 350A max

N/A N/A N/A N/A N/A N/A N/A 1.8 1

(75 ms)7 2/0 conductor

Coil Current (A)7 0.68 0.28 0.16 0.095 0.06 0.06 0.04 0.082 0.057

Coil Power (W)7 8 6.8 7.6 6.8 7.2 7.2 9.6 1 1.4 100

Operate Time, Max (ms)3 20 20 30 30 20 30 30 20 20

Release Time, Max (ms) 12 12 12 12 12 50 55 12 12

Internal Coil Suppression 10

CONTROL CIRCUIT

0 500 1,000 1,500 2,000

Coil Back EMF (V) 55 55 80 115 175 N/A N/A 55 55 CURRENT (A)

Transients, Max (V) (13 ms) N/A N/A N/A N/A N/A N/A N/A ±50 ±50

4/0 2/0

Reverse Polarity (V) N/A N/A N/A N/A N/A N/A N/A 16 32

G I G AVA C ® - 6 3 8 2 R o s e L a n e - C a r p i n t e r i a , C A 93 013 - p h +1- 8 0 5 - 6 8 4 - 8 4 01 - f a x +1- 8 0 5 - 6 8 4 - 8 4 02

i n f o @ g i ga v a c.c o m - w w w.g i ga v a c.c o m - © C o p y r i g h t 2 0 03 -2 014 G I G AVA C, L LC.

225+ Amp 12-800 Vdc

EPIC® Hermetic Sealed DC Contactor G X12

DIMENSIONS

2.20

55.9

1.75

.21

44.5

5.3

MOUNTING

1.15 .98 1.75

2.35 44.5

59.8 29.2 25

MOUNTING

3.33

84.6

Mounting

4.52

M5 Bolts 114.8

Case Material

.95

DuPont Zytel FR50 24.2

.87

(25% Glass Filled Nylon) MOUNTING

22

2.25

Power Connection 57.3

Stainless M10x1.5 Bolt

Stainless M10x1.5 Flanged Nut

Torque 14-20Nm [125-175in-lb] .40

10.2

Coil Wire Power Contacts Auxiliary contacts

(optional)

Silicone, 20 AWG, UL: VW-1

T1

A2(+) NO:

T2

A1(-)

T1

NC:

X2(-) T2

X1(+)

G I G AVA C ® - 6 3 8 2 R o s e L a n e - C a r p i n t e r i a , C A 93 013 - p h +1- 8 0 5 - 6 8 4 - 8 4 01 - f a x +1- 8 0 5 - 6 8 4 - 8 4 02

i n f o @ g i ga v a c.c o m - w w w.g i ga v a c.c o m - © C o p y r i g h t 2 0 03 -2 014 G I G AVA C, L LC.

225+ Amp 12-800 Vdc

EPIC® Hermetic Sealed DC Contactor G X12

PART NUMBER SYSTEM

Notes & Definitions:

GX12 B A B

1 Auxillary contact rating is 2A, 24Vdc Resistive load, 100,000

Coil Voltage B = 12 Vdc, Internal Coil

cycles. Minimum current is 0.1mA, 5V. The auxiliary contact is

Suppression

mechanically linked to the main power contacts.

C = 24 Vdc, Internal Coil

2 Contact resisitance measured at currents higher than 100A.

Suppression

F = 48 Vdc, Internal Coil 3 Operation time is measured at 25°C and includes maximum

Suppression 7ms bounce.

H = 72 Vdc, Internal Coil 4 Insulation resistance is 50 Mohms after life.

Suppression 5 Contactor can operate up to 125°C in special cases - contact

J = 120 Vdc, Internal GIGAVAC for details.

Coil Suppression 6 Contactor has two coils. Both are used for pick-up, and

K = 120 Vac, Internal then in approximately 75 milliseconds, one coil is electronically

Coil Suppression removed from the coil drive circuit. The remaining coil supplies

low continuous hold power sufficient for the contactor to meet

L = 240 Vac, Internal all of its specified performance specifications. This provides low

Coil Suppression coil power without PWM electronics that can cause EMI emissions

S = 12 Vdc, Low Power, and/or cross-talk on control power.

Internal Coil Suppression 7 Contactor is operated by a coil that changes resistance

T = 24 Vdc, Low Power, with temperature. Since Pick-up Current, Coil Current and Coil

Internal Coil Suppression Power are specified at Nominal Voltage, they will be lower than

indicated at temperatures above 25°C and higher than indicated

Coil A = Flying leads at temperatures below 25°C. Similarly, Pick-up and Drop-out

Termination 38 cm (15 in) Voltages will be higher than indicated at temperatures above

B = Flying leads 25°C and lower than indicated at temperatures below 25°C.

61 cm (24 in)

8 For pick-up testing of contactors with dual coils, the voltage

C = Flying leads can not be ramped up slowly, but must be applied instantly to at

122 cm (48 in) least the maximum Pick-up Voltage. Otherwise, the contactor will

not pick-up.

Auxiliary Blank = None

Contact 9 Limit make current to 500A to avoid contact welding. For AC

B = SPST,

power switching cycles, contact factory.

Normally Open

C = SPST,

Normally Closed

APPLICATION NOTES

• Contactors feature internal transorb for coil suppression. No external

diodes should be added across the coil. The use of additional external coil

suppression can slow the release time and invalidate the life cycle ratings,

or can cause the contactor not to be able to interrupt the maximum current

specified. If lower coil back EMF is required, please contact GIGAVAC for

assistance.

• Power switching lifecycles are based on current flow from A2(+) to A1(-).

For best breaking performance, the contactor should be installed so that

current flows from A2(+) to A1(-). There are cases where the contactor will

interrupt power in the opposite direction but please contact GIGAVAC to

confirm suitability. Direction of current flow is not relevant during make

or when flowing on closed contacts. For bi-directional contactors, please

contact GIGAVAC.

• Applications with capacitors will require a pre-charge circuit.

• Electrical life rating is based on resistive load with 27µH maximum

inductance in circuit. Because your application may be different, we

suggest you test the contactor in your circuit to verify life is as required.

• End of life is defined as when the dielectric, insulation resistance or

contact resistance fails the specifications listed.

G I G AVA C ® - 6 3 8 2 R o s e L a n e - C a r p i n t e r i a , C A 93 013 - p h +1- 8 0 5 - 6 8 4 - 8 4 01 - f a x +1- 8 0 5 - 6 8 4 - 8 4 02

i n f o @ g i ga v a c.c o m - w w w.g i ga v a c.c o m - © C o p y r i g h t 2 0 03 -2 014 G I G AVA C, L LC.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Optimal Design of A Thermoelectric Cooling - Heating System For Car PDFDocument118 pagesOptimal Design of A Thermoelectric Cooling - Heating System For Car PDFYuva RajNo ratings yet

- Akula RomanDocument5 pagesAkula Romandllabarre100% (1)

- Structural Evaluation of A Motorcycle ChassisDocument107 pagesStructural Evaluation of A Motorcycle Chassisnguyen hoan100% (1)

- How To Make PCB at Home-PcbwayDocument11 pagesHow To Make PCB at Home-PcbwayIced CoolzNo ratings yet

- Physics of Power Dissipation in CMOS FET DevicesDocument70 pagesPhysics of Power Dissipation in CMOS FET DevicesPunith Gowda M BNo ratings yet

- KP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Document7 pagesKP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Utku Can Kılıç100% (2)

- Anna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Document5 pagesAnna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Sai KrishnaNo ratings yet

- Technical Test - MechDocument2 pagesTechnical Test - MechSai KrishnaNo ratings yet

- Overall Expense 488300: Cost Estimate For Each Components of The Subsystem (Baja)Document1 pageOverall Expense 488300: Cost Estimate For Each Components of The Subsystem (Baja)Sai KrishnaNo ratings yet

- Technical Test - MechDocument4 pagesTechnical Test - MechSai KrishnaNo ratings yet

- Aptitude TestDocument12 pagesAptitude TestSai KrishnaNo ratings yet

- Overall Expense 488300: Cost Estimate For Each Components of The Subsystem (Baja)Document1 pageOverall Expense 488300: Cost Estimate For Each Components of The Subsystem (Baja)Sai KrishnaNo ratings yet

- Oan551 Sensors and Transducers Part B & Part C Questions - Unit WiseDocument2 pagesOan551 Sensors and Transducers Part B & Part C Questions - Unit WiseSai KrishnaNo ratings yet

- Mechanical Design and FEM Analysis of Electric Motorcycle's Swing ArmDocument11 pagesMechanical Design and FEM Analysis of Electric Motorcycle's Swing ArmSai KrishnaNo ratings yet

- Mohamadnasrulfaezbinjuharimh13003 PDFDocument67 pagesMohamadnasrulfaezbinjuharimh13003 PDFSai KrishnaNo ratings yet

- Introduction To Hypermesh and Hyperview by Marius MuellerDocument17 pagesIntroduction To Hypermesh and Hyperview by Marius MuellerTuanNguễnNo ratings yet

- Design and Analysis of Single Sided Swing Arm For Modified BikeDocument4 pagesDesign and Analysis of Single Sided Swing Arm For Modified BikeSai KrishnaNo ratings yet

- Front and Rear Swing Arm Design of An Electric Racing MotorcycleDocument10 pagesFront and Rear Swing Arm Design of An Electric Racing MotorcycleSai KrishnaNo ratings yet

- CD 8175Document24 pagesCD 8175kaustubh girgasNo ratings yet

- FMM AbhishekDocument43 pagesFMM AbhishekSai KrishnaNo ratings yet

- Impact Analysis On E-Bike Chassis Frame: P. N. V Balasubramanyam, A.Sai Nadh, P.Monika, CH - RaghavaDocument4 pagesImpact Analysis On E-Bike Chassis Frame: P. N. V Balasubramanyam, A.Sai Nadh, P.Monika, CH - RaghavaSai KrishnaNo ratings yet

- Artigo Tese v4 Versao Fenix PDFDocument10 pagesArtigo Tese v4 Versao Fenix PDFRajath UpadhyaNo ratings yet

- Structural Analysis and Optimization of Bicycle FRDocument10 pagesStructural Analysis and Optimization of Bicycle FRMIKE LESIBA CHOKOENo ratings yet

- Instrument TransformersDocument19 pagesInstrument TransformersEzeldeen AgoryNo ratings yet

- Bevan Smith - MSC Research Report - Updated 22 May 2014Document146 pagesBevan Smith - MSC Research Report - Updated 22 May 2014Sai KrishnaNo ratings yet

- FMM AkshayDocument67 pagesFMM AkshaySai KrishnaNo ratings yet

- Development of A Motorcycle Frame As A Problem-Based Learning Experience in Design Courses For Mechanical Engineering StudentsDocument6 pagesDevelopment of A Motorcycle Frame As A Problem-Based Learning Experience in Design Courses For Mechanical Engineering StudentsThomas DyeNo ratings yet

- Power Measurement Wattmeter MethodDocument4 pagesPower Measurement Wattmeter MethodSai KrishnaNo ratings yet

- Transducers: One Form To Another Form of EnergyDocument24 pagesTransducers: One Form To Another Form of EnergySai KrishnaNo ratings yet

- Cathode Ray Oscilloscope (Cro)Document25 pagesCathode Ray Oscilloscope (Cro)Sai KrishnaNo ratings yet

- Scanned With CamscannerDocument8 pagesScanned With CamscannerSai KrishnaNo ratings yet

- Measuring InstrumentsDocument9 pagesMeasuring InstrumentsSai KrishnaNo ratings yet

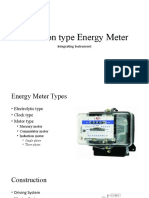

- Induction Type Energy Meter: Integrating InstrumentDocument4 pagesInduction Type Energy Meter: Integrating InstrumentSai KrishnaNo ratings yet

- BJT FetDocument14 pagesBJT FetSai KrishnaNo ratings yet

- Silicon Ingot Production: Czochralski-And Float-Zone TechniqueDocument2 pagesSilicon Ingot Production: Czochralski-And Float-Zone TechniqueKarajá PtahNo ratings yet

- Elect 3 PDFDocument22 pagesElect 3 PDFmudasirNo ratings yet

- EZC250H3150Document2 pagesEZC250H3150Σπίθας ΣπιθαμήNo ratings yet

- ZedBoard HW UG v1 1Document38 pagesZedBoard HW UG v1 1mrithyunjaysivNo ratings yet

- Seminar Report ON Lab On A Chip BY PRANJAL GUPTA - 170106026 HARSH SARAF-170106015Document16 pagesSeminar Report ON Lab On A Chip BY PRANJAL GUPTA - 170106026 HARSH SARAF-170106015PRANJAL GUPTA BTech MCA II YRNo ratings yet

- Irgp 50 B 60 PD 1Document11 pagesIrgp 50 B 60 PD 1pufipufi5No ratings yet

- Ternary Circuits: Why R 3 Is Not The Optimal Radix For ComputationDocument9 pagesTernary Circuits: Why R 3 Is Not The Optimal Radix For ComputationAlex LaiknNo ratings yet

- MDU1931 Datasheet - MagnaChip SemiconductorDocument6 pagesMDU1931 Datasheet - MagnaChip Semiconductortr.deepakNo ratings yet

- Diyot, BJT Ve MOS Yapısı, SPICE Parametreleri, Kütüphane Kullanımı, MakromodelDocument68 pagesDiyot, BJT Ve MOS Yapısı, SPICE Parametreleri, Kütüphane Kullanımı, MakromodelKerem YamanNo ratings yet

- Tl072 Low Noise Dual J-Fet OpampsDocument9 pagesTl072 Low Noise Dual J-Fet OpampssfvNo ratings yet

- Solar Water Pumpimp PDFDocument21 pagesSolar Water Pumpimp PDFArafath AmerNo ratings yet

- Digital Fiber Sensor Amplifier FX-301 (P) : WarningDocument4 pagesDigital Fiber Sensor Amplifier FX-301 (P) : WarningGaurav KNo ratings yet

- Ae Practical MCQDocument13 pagesAe Practical MCQDeependra SinghNo ratings yet

- Power Electronics SeminarDocument25 pagesPower Electronics Seminarsreemukhi100% (3)

- EXP10 JFET Transistor CharacteristicsDocument5 pagesEXP10 JFET Transistor CharacteristicsMohammed Dyhia Ali100% (2)

- 2SC1586 PDFDocument3 pages2SC1586 PDFisaiasvaNo ratings yet

- Zener Barrier: 2002 IS CatalogDocument1 pageZener Barrier: 2002 IS CatalogabcNo ratings yet

- AP1117/AP1117I: 1A Dropout Positive Adjustable or Fixed-Mode RegulatorDocument13 pagesAP1117/AP1117I: 1A Dropout Positive Adjustable or Fixed-Mode Regulatorivo rodriguesNo ratings yet

- Acs Error CodesDocument3 pagesAcs Error CodesMalik udinNo ratings yet

- MT174 Polyphase MeterDocument2 pagesMT174 Polyphase MeterYigit SarıkayaNo ratings yet

- PCB Layout NotesDocument3 pagesPCB Layout NotesMehmet KibarNo ratings yet

- Electonics Lab Experiment No 8&9 NadineAlsadiDocument13 pagesElectonics Lab Experiment No 8&9 NadineAlsadiNadine alsadiNo ratings yet

- Paper English Laporan Kerja PraktekDocument4 pagesPaper English Laporan Kerja PraktekKelik Fazar Hadi SaputroNo ratings yet

- EIKILC-XT4U LCD Projector Service ManualDocument160 pagesEIKILC-XT4U LCD Projector Service Manualcoldfusion161No ratings yet

- A Manual To A LabDocument6 pagesA Manual To A Lab1d22No ratings yet