Professional Documents

Culture Documents

CD Cfs 2

Uploaded by

nata tOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CD Cfs 2

Uploaded by

nata tCopyright:

Available Formats

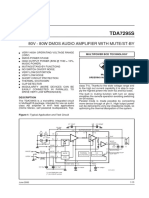

7/8" max

offset

P1

#10 SDS

CFS header (H) (HD-H)

#10 SDS

(HD-C)

P2

Hold Down (HD)

(see chart)

USC/USD Chord (C) 7/8" max

offset

MAXIMUM CAPACITY (LBS)

CFS header (H)

Min Min VERT HORIZ

#10 SDS #10 SDS

Header Chord HD-C P1 P2

HD-H

(mil) (mil) (LBS) (LBS) P1

#10 SDS

2 2 355 165 (HD-H)

033 035

3¹ 2 530 250

2 2 525 220 #10 SDS

043 035 (HD-C)

3¹ 3 790 330

423HD16

2 4 990 395

054 035

3¹ 6 1485 595

2 4 990 500

068 035 P2

3¹ 6 1485 650

2 4 990 500

423HD14 068 035

3¹ 6 1485 750

4 3 710 335 Hold Down (HD)

033 035 USC/USD Chord (C) (see chart)

6 4 1065 500

4 4 1055 440

043 035

6 6 1580 660

426HD14

4 8 1980 795

035

054 6 11 2970 1190

046 6 8 2970 1190

4 8 1980 1000

035

068 6 11 2970 1500

046 6 8 2970 1500

¹ Locate 3rd screw between bend and 7/16" hole

1) Minimum screw spacing = 9/16"

2) Header must be as deep as clip height.

3) Use minimum thickness of header or chord to

determine reaction and horizontal capacities.

4) When truss is 2-ply, connection applied to

each ply.(Capacities doubled)

5) Proper design of support for all reactions is

the responbillity of qualified designer/engineer.

6) Uplift and Horizontal capacities shown are

maximum non-simultaneous values.

7) HD product specified is manufactured by Aegis

Metal Framing. Any substitution is prohibited.

8) Place HD between truss web and chord.

Revision 1/2014 - Updated fastener values, clip, bearing.

9) Material may be USC or USD Revision 5/13/2001 - changed to 423HD16

DETAIL NO.

USC/USD TRUSS TO CFS HEADER CD-CFS-2.2

®

METAL FRAMING

A division of MiTek ®

CATEGORY

www.AegisMetalFraming.com

14515 N. Outer 40 Drive - Suite 110 STANDARD DETAILS

Chesterfield, MO 63017

DATE

Phone: (866) 902-3447 Fax: (314) 434-5234 1/2014

You might also like

- Hiab Product Range OverviewDocument40 pagesHiab Product Range OverviewSergio BelmarNo ratings yet

- Product RangeDocument40 pagesProduct Rangerokas45No ratings yet

- Pioneer VSX-417 SchematicDocument24 pagesPioneer VSX-417 SchematicaaakokotNo ratings yet

- C Ele Lay 700 30938 0Document1 pageC Ele Lay 700 30938 0bensaadallah ahmedNo ratings yet

- Cone Crusher CH Series: Rock Processing Chapter DDocument1 pageCone Crusher CH Series: Rock Processing Chapter DKobbina BaahNo ratings yet

- Acoples Jaure (Regilla - Grid, 3 Pág.)Document3 pagesAcoples Jaure (Regilla - Grid, 3 Pág.)marcelo castilloNo ratings yet

- Haitian Jupiter SeriesDocument4 pagesHaitian Jupiter SeriesRenardNo ratings yet

- Kenwood CD-203-204 DPF-R3010-4010-5010 Service ManualDocument17 pagesKenwood CD-203-204 DPF-R3010-4010-5010 Service ManualBigg Dady100% (1)

- KDC-MP225 KDC-MP4026/G KDC-W4527/G/GY/Y KDC-W427Y: Service ManualDocument32 pagesKDC-MP225 KDC-MP4026/G KDC-W4527/G/GY/Y KDC-W427Y: Service Manualluispider74No ratings yet

- Toyota 2021 Water Borne Paint ScheduleDocument5 pagesToyota 2021 Water Borne Paint ScheduleVel Murugan0% (1)

- KETO Quotation 32659 - K-HH300S22 (Skid+Pontoon) - Rev 2Document4 pagesKETO Quotation 32659 - K-HH300S22 (Skid+Pontoon) - Rev 2alimfakihsalehNo ratings yet

- Cessna Standard Repair ListDocument44 pagesCessna Standard Repair ListKJ Dhiman100% (1)

- 10 P 130 Das 001Document6 pages10 P 130 Das 001Muhammad AkmaluddinNo ratings yet

- Aoc Le32m3370Document17 pagesAoc Le32m3370Aldo RepectoNo ratings yet

- Bridge 076 layout planDocument1 pageBridge 076 layout planC-pang MinorityNo ratings yet

- DD311 Development Drill: Technical SpecificationDocument2 pagesDD311 Development Drill: Technical SpecificationEMGUSACNo ratings yet

- SD200/DRILL CAT - UPE - Media mesa y sus componentesDocument43 pagesSD200/DRILL CAT - UPE - Media mesa y sus componentesKevin BaylonNo ratings yet

- MTO - Oil Processing and Produced Water TreatmentDocument5 pagesMTO - Oil Processing and Produced Water TreatmentRodrigoNo ratings yet

- SET X Y DA Center of Gravity: ISO 5211 Interface Pressure ConnectionDocument2 pagesSET X Y DA Center of Gravity: ISO 5211 Interface Pressure Connectionhamr01No ratings yet

- Part 1 Alternators and Starters - 2011 - 2012Document1,297 pagesPart 1 Alternators and Starters - 2011 - 2012Иван ШадринNo ratings yet

- Small Diesel Scooptram LHDS: Vehicle SpecificationDocument3 pagesSmall Diesel Scooptram LHDS: Vehicle SpecificationKenny CasillaNo ratings yet

- Schema-Hp Pavilion Dm1 Intel-1018tu 1128tu Fp7-0526 1100Document35 pagesSchema-Hp Pavilion Dm1 Intel-1018tu 1128tu Fp7-0526 1100deden rsendeNo ratings yet

- DatasheetDocument4 pagesDatasheetSoud FarhanNo ratings yet

- BBS of All Pier Foundations of MAYARDocument16 pagesBBS of All Pier Foundations of MAYARAmanjot Singh0% (1)

- COMPAL LS-3807P (JBL00, JBL01, JBL02) 2008-06-10, Rev 1.0 (A00) - Sniffer Board PDFDocument4 pagesCOMPAL LS-3807P (JBL00, JBL01, JBL02) 2008-06-10, Rev 1.0 (A00) - Sniffer Board PDFGerman ValenciaNo ratings yet

- KVT 715 DVDDocument76 pagesKVT 715 DVDEu Pitzi BogdanNo ratings yet

- Ch660 Specification SheetDocument1 pageCh660 Specification SheetDiego MurandaNo ratings yet

- Ma 01 Fbs-Ii-8-14-Gvz All V1Document4 pagesMa 01 Fbs-Ii-8-14-Gvz All V1Alberto MasanetNo ratings yet

- Single Girder EOT Cranes (SG-EOT)Document5 pagesSingle Girder EOT Cranes (SG-EOT)Nikhil PoriyaNo ratings yet

- Kenwood Service Manual kdc-w3534 PDFDocument36 pagesKenwood Service Manual kdc-w3534 PDFnewNo ratings yet

- Steel Qty 159+808 (30'skew) BCDocument19 pagesSteel Qty 159+808 (30'skew) BCsriharsha boyapatiNo ratings yet

- Report Spreader (14 May 2022, Shift Pagi)Document2 pagesReport Spreader (14 May 2022, Shift Pagi)Hamid RockAloneNo ratings yet

- KDC-218A: Service ManualDocument14 pagesKDC-218A: Service ManualGustavo de Vargas DiasNo ratings yet

- WWW - Vinafix.vn: Mobile CPUDocument42 pagesWWW - Vinafix.vn: Mobile CPUAphe TaiasuNo ratings yet

- Octagonal PoleDocument2 pagesOctagonal PoleARUN RAWATNo ratings yet

- ReceivedDocument4 pagesReceivedDHANEESH VELLILAPULLINo ratings yet

- U/S D/S: Horizontal Scale or As ShownDocument1 pageU/S D/S: Horizontal Scale or As ShownAjay SinghNo ratings yet

- 5326 DP-R6090 R7090 D-R350etcDocument22 pages5326 DP-R6090 R7090 D-R350etcroca9oNo ratings yet

- PE0363 Design ParametersDocument1 pagePE0363 Design ParametersMohammad MushtaqNo ratings yet

- L42_SchemeticDocument10 pagesL42_Schemeticbaburoy266366No ratings yet

- Lay Out Taso Gudang PLB 15-03-2024Document2 pagesLay Out Taso Gudang PLB 15-03-2024ferikomangNo ratings yet

- Ford Packaging Specification for Global PartsDocument2 pagesFord Packaging Specification for Global Partstony_gstNo ratings yet

- HP Mini 110-3700 Foxcon EdwardsDocument40 pagesHP Mini 110-3700 Foxcon Edwardsluxman86No ratings yet

- LNG Badak - Presentation PDFDocument12 pagesLNG Badak - Presentation PDFRonny FitriadiNo ratings yet

- Mitsubishi - Jms MCC PanelDocument27 pagesMitsubishi - Jms MCC PanelhukmranNo ratings yet

- Waveform - 17.01.23 13.09.09.30pDocument6 pagesWaveform - 17.01.23 13.09.09.30pCostache DanNo ratings yet

- This Document Shall Be Used Only For Reference: Engenharia Ieept/IepsaDocument5 pagesThis Document Shall Be Used Only For Reference: Engenharia Ieept/IepsaRodrigoNo ratings yet

- LCD TV/DVD Combination: Circuit DiagramsDocument32 pagesLCD TV/DVD Combination: Circuit DiagramsAndromeda AndradeNo ratings yet

- Frontier Oil Tools F1 Rotating Liner Hanger Packer 4.5x7Document7 pagesFrontier Oil Tools F1 Rotating Liner Hanger Packer 4.5x7Sakhtolid88No ratings yet

- MB401A1Document44 pagesMB401A1Juan Pablo Cerdá Marzani75% (4)

- Sony Vaio MS80 - Rev 0.1 PDFDocument44 pagesSony Vaio MS80 - Rev 0.1 PDFJoseni FigueiredoNo ratings yet

- Emco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426Document282 pagesEmco Winnc Heidenhain TNC 426 Conversational The Emco Winnc Heidenhain TNC 426AyoubNo ratings yet

- RT Request 005Document8 pagesRT Request 005Anonymous AdofXEYAgENo ratings yet

- Ecs Mb40ia Rev b1Document44 pagesEcs Mb40ia Rev b1Cassio Jose FonsecaNo ratings yet

- TDA7295S: 80V - 80W Dmos Audio Amplifier With Mute/St-ByDocument13 pagesTDA7295S: 80V - 80W Dmos Audio Amplifier With Mute/St-ByLucio DeschiNo ratings yet

- HP Mini DM1 FP7Document35 pagesHP Mini DM1 FP7Yetawa GuaviareNo ratings yet

- Dma 4013 Pentaksiran Teori 1Document6 pagesDma 4013 Pentaksiran Teori 1Leo GamersNo ratings yet

- 105 Jersey Road Barrier V Interlock Double FemaleDocument1 page105 Jersey Road Barrier V Interlock Double FemaleNaelNo ratings yet

- Schematic Diagram: Af Assy AWX7111Document3 pagesSchematic Diagram: Af Assy AWX7111OrshanetzNo ratings yet

- 121 BriefDocument4 pages121 BriefChen Ping OoiNo ratings yet

- Dissertation On BambooDocument61 pagesDissertation On BambooPrachi Agarwal100% (2)

- CE G612-Advance Steel Structures As Per AGSRD Guidelines PDFDocument4 pagesCE G612-Advance Steel Structures As Per AGSRD Guidelines PDFaayushi doshiNo ratings yet

- Analysis & Design of Steel Pipe BridgeDocument78 pagesAnalysis & Design of Steel Pipe BridgePraveen Kumar DusiNo ratings yet

- Chapter 3 Analysis of Statically Determinate TrussDocument9 pagesChapter 3 Analysis of Statically Determinate TrussAngelie Claire GrospeNo ratings yet

- Beam SelectionDocument24 pagesBeam SelectionGustavNo ratings yet

- Calatrava 1 PDFDocument100 pagesCalatrava 1 PDFKawaii Sherly-Shop0% (1)

- AGBT07-18 Guide To Bridge Technology Part 7 Maintenance and Management of Existing BridgesDocument239 pagesAGBT07-18 Guide To Bridge Technology Part 7 Maintenance and Management of Existing BridgesRandy BenemeritoNo ratings yet

- Revision 3 of Specification For Escalator PDFDocument74 pagesRevision 3 of Specification For Escalator PDFAniket PradhanNo ratings yet

- Design of Bolted Connections in Steel StructuresDocument4 pagesDesign of Bolted Connections in Steel StructuresHarish T S Gowda0% (1)

- Etasr 3317Document9 pagesEtasr 3317Zatul IzattyNo ratings yet

- NN7fP: Antiseismic Bridge Highway-Railway FramedDocument2 pagesNN7fP: Antiseismic Bridge Highway-Railway FramedTeo Peng KeatNo ratings yet

- Steel BridgeDocument261 pagesSteel BridgeZoran Vlašić100% (3)

- AWC NDS2015 Commentary PrintableDocument107 pagesAWC NDS2015 Commentary PrintableTerry TriestNo ratings yet

- Structural Mechanics NoRestrictionDocument649 pagesStructural Mechanics NoRestrictionofegor75% (4)

- SkyscraperDocument12 pagesSkyscraperMatei SilviuNo ratings yet

- Tutorial 4Document2 pagesTutorial 4Beesam Ramesh KumarNo ratings yet

- Module 111Document8 pagesModule 111Sol SolNo ratings yet

- Intenship Report Word File Sample PVDocument22 pagesIntenship Report Word File Sample PVPsychology ExpertNo ratings yet

- Truss Lecture (1) - Mechanics of MaterialsDocument46 pagesTruss Lecture (1) - Mechanics of MaterialsMichael ChavezNo ratings yet

- Step ColDocument21 pagesStep ColamachmouchiNo ratings yet

- Ce323 Introduction To Structural Mechanics Assigned Problems #1 / (No Submission) Name: GradeDocument3 pagesCe323 Introduction To Structural Mechanics Assigned Problems #1 / (No Submission) Name: GradeSean TraverNo ratings yet

- Preliminary Design Rules of ThumbDocument11 pagesPreliminary Design Rules of Thumbnimal1234No ratings yet

- High-Strength Steel RoofDocument9 pagesHigh-Strength Steel RoofalbertofgvNo ratings yet

- Evaluation Exam Theory of Structures Nov 2021Document5 pagesEvaluation Exam Theory of Structures Nov 2021Joseph Lanto0% (1)

- Structural Investigation of the Centre Pompidou-Metz Roof LatticeDocument19 pagesStructural Investigation of the Centre Pompidou-Metz Roof Latticeyarikh870% (1)

- Chapter 3 - Analysis and Design of Tension Members (Part 1)Document6 pagesChapter 3 - Analysis and Design of Tension Members (Part 1)John Philip NuñezNo ratings yet

- Seismic Design Factors for Industrial StructuresDocument73 pagesSeismic Design Factors for Industrial StructuresALONSO GOMEZ100% (2)

- NSC - Design of Structural Tee in Bending - July2019TechDocument3 pagesNSC - Design of Structural Tee in Bending - July2019Techantonv0421No ratings yet

- Barclays Centre BIMDocument5 pagesBarclays Centre BIMCaio GomesNo ratings yet