Professional Documents

Culture Documents

7 Matlab

7 Matlab

Uploaded by

sri krishnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Matlab

7 Matlab

Uploaded by

sri krishnaCopyright:

Available Formats

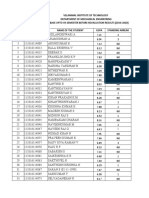

Simulation and Analysis Laboratory Mechanical Engineering

SIMULATION OF VAPOUR COMPRESSION REFRIGERATION

Ex. No:15

DATE:

Aim:

To perform simulation of a vapour compression refrigerator using C.

Problem Statement:

A Vapour compression refrigerator uses R12 as refrigerant and the liquid

evaporates in the evaporator at -15°C. The temperature of this refrigerant at the delivery

from compressor is 20°C when vapour is condensed at 10°C. Find COP if there is no

undercooling. Write a computer program using C or Matlab.

Take specific heat at constant pressure for the speculated vapour as 0.64 KJ/KgK.

Other properties are:

Temperature (°C) hf(KJ/Kg) hg(KJ/Kg) hfg(KJ/Kg)

-15 22.33 180.975 159.145

10 45.37 191.74 146.37

Programming Language: C

Program:

#include<stdio.h>

#include<conio.h>

#include<math.h>

#include<stdlib.h>

main()

{

float hfg5,tc1,tc2,te,cp,hg1,h2,hg2,hf3,hf4,hg4,hfg4,cop,copi,eff,x;

printf("\nEnter the temperature of compressor exit<Celsius> "); scanf("%f",&tc1);

printf("\nEnter the temperature of condenser<Celsius> "); scanf("%f",&tc2);

printf("\nEnter temperature of evaporator<Celcius> "); scanf("%f",&te);

printf("\nEnter the value of cp "); scanf("%f",&cp);

printf("\nEnter the value of Enthalpy at 1(hg1) "); scanf("%f",&hg1);

printf("\nEnter the value of Enthalpy at3(hf3) "); scanf("%f",&hf3);

printf("\nEnter the value of Enthalpy at 2`(hg2`) "); scanf("%f",&hg2);

printf("\nEnter the value of Enthalpy at 4(hfg4);

scanf("%f",&hfg4);

hf4=hf3; hfg5=hg1-hf4;

x=hfg5/hfg4; h2=hg2+cp*(tc1-tc2);

copi=(te+273.0)/(tc2-te);

cop=(hg1-hf4)/(h2-hg1); eff=(cop/copi)*100;

Velammal Institute of Technology 65

Simulation and Analysis Laboratory Mechanical Engineering

printf("\nThe actual cop is %f",cop); printf("\nThe friction after

expansion is %f",x); printf("\nThe ideal cop =%f",copi);

printf("\nSecond law efficiency of the system = %f",eff);

printf("\n%f",h2);

getch();

}

Input Parameters:

Temperature of compressor

Temperature of condenser

Temperature of evaporator

Cp

Value of Enthalpy at 1, 2`, 3, 4

Output Parameters:

Actual COP = 9.242357

Ideal COP = 10.320000

Dryness factor = 0.996846

Second law efficiency = 89.557732

Result:

Thus simulation of vapour compression refrigerator has been done using C.

Viva voice

1.What are the types of loops does MATLAB provides?

Matlab provides loops like

• While Loop

• For Loop

• Nested Loops

2.Explain what is Simulink?

Simulink is an add-on product to MatLab, it provides an interactive, simulating,

graphical environment for modeling and analyzing of dynamic systems.

Velammal Institute of Technology 66

Simulation and Analysis Laboratory Mechanical Engineering

LINEAR DAMPING FORCE

EX.NO:16

DATE:

Aim

The model for a mass attached to a spring with a linear damping force.

Problem Statement:

The response of an undamped single degree of freedom oscillator subject to varied

mass and stiffness parameters. Here we will do the same for a damped single degree of

freedom system.

Again, we begin with the equation of motion, given the system of Figure 3.1. A

simple static analysis …nds that our equation is:

If we divide through by m, we introduce the dimensionless parameters! And

x + 2 !nx + !n2 x = 0:

In the above, !n represents the undamped natural frequency, and is the viscous

damping ratio. For the purposes of this example, we will assume the under damped case

(<1). The solution to this equation is:

x(t) = Ae !nt sin(!dt + ):

This equation is more useful if we write all of the terms as functions of

parameters!n and :

PROGRAM

Programming Language: C

%Initial value entry.

%The while loop in the zeta initialization section prevents %certain values for zeta

from being entered, since such %values would crash the program.

%wn=input(’Enter the natural frequency. ’);

x0=input(’Enter the initial displacement. ’);

v0=input(’Enter the initial velocity. ’);

tf=input(’Enter the time duration to test, in seconds. ’); for

zi=1:3 zeta(zi)=12;

while(zeta(zi)<0 j zeta(zi)>=1) % The pipe (j) means “or”. zeta(zi)=input([’Enter

damping coe¢ cient value ’, num2str(zi),’.’]);

if (zeta(zi)>=1 j zeta(zi)<0)

fprintf(’Zeta must be between 0 and 1!’); zeta(zi)=12;

end

end

end

Velammal Institute of Technology 67

Simulation and Analysis Laboratory Mechanical Engineering

%

%Now, having !n and , the !d values can be found.

%

for i=1:3 wd(i)=wn*sqrt(1-zeta(i)^2);

end

%

%Solving for the response. Note the use of the array %multiplication command (.*) in the

expression for x(t). %This command is necessary, else the program gives a

%multiplication error.

t=0:tf/1000:tf; for j=1:3

a=sqrt((wn*x0*zeta(j)+v0)^2+(x0*wd(j))^2)/wd(j);

phi=atan2(wd(j)*x0,v0+zeta(j)*wn*x0); x(j,:)=a*exp(-zeta(j)*wn*t).*sin(wd(j)*t+phi);

end

%

%Now, the program plots the results in a subplot format.

%

subplot(3,1,1)

plot(t,x(1,:))

title([’Response for zeta=’,num2str(zeta(1))]) ylabel(’Response x’)

grid subplot(3,1,2) plot(t,x(2,:))

title([’Response for zeta=’, num2str(zeta(2))]) ylabel(’Response x’)

grid subplot(3,1,3) plot(t,x(3,:))

title([’Response for zeta=’, num2str(zeta(3))]) ylabel(’Response x’)

xlabel(’Time, seconds’) grid

Result:

The model for a mass attached to a spring with a linear damping force has been done using C.

Viva voice

1. What is the damping force?

Damping Coefficient. When a damped oscillator is subject to a damping force which

is linearly dependent upon the velocity, such as viscous damping, the oscillation will

have exponential decay terms which depend upon a damping coefficient.

2. What are the effects of damping?

In physics, damping is any effect that tends to reduce the amplitude of vibrations. In

mechanics, the internal friction may be one of the causes of such damping effect.

Velammal Institute of Technology 68

Simulation and Analysis Laboratory Mechanical Engineering

Compression on a Two Column Structure

EXPT NO:1

DATE:

AIM:

To calculate the displacement of a structure consisting of two circular columns of

equal length but different diameters (as seen below). The lower member is fixed and a 10000

pound load is applied to the top so that both members are placed in compression.

PROCEDURE:

Step 1 - Create a new Patran database.

1) Click on New from the File menu or from the Defaults Toolbar as shown.

2) Type the name of the new database as two_columns and click OK.

Step 2 - Create the geometry of the columns using the information from the problem

statement.

1) Under the Geometry tab, click on Point and select XYZ.

2)Input the following point coordinates and click Apply after each point: [0 0 0], [0 10 0],

and [0 -10 0]. There are no units in Patran, and therefore it is important to stay consistent in

units.

3) Under the Geometry tab, click on Curves and select Point.

4) With Auto Execute checked, click on Point 1 then Point 2, and Point 1 then Point 3.

Step 3 - Create the isotropic material: elastic modulus of 10×106.

1) Under the Properties tab, select Isotropic.

2) Input Material as the Material Name and then select Input Properties .

3) Input 10×106 as the Elastic Modulus. Click OK and Apply.

Step 4- Create a 1D surface physical property and apply the isotropic material to the

model.

1) Click on Rod under the 1D Properties section.

2) Input Top_Column as the Property Set Name and then click on Input Properties.

3)Click on Select Material and select Material. Enter 1.5 as the Area. Click OK.

4) Click on Select Application Region and then click on the Select Members box. Screen pick

the top curve. Click Add, OK then Apply.

5) Repeat the above steps for the bottom curve except input Bottom_Column as the Property

Set Name and enter 2 as the area.

Velammal Institute of Technology 70

Simulation and Analysis Laboratory Mechanical Engineering

Step 5 - Create boundary conditions: Constrain all degrees of freedom along the bottom of the

structure.

1) Under the Load/BCs tab, select Displacement Constraint.

2) Input fixed_end as the New Set Name and then click on Input Data.

3) Input <0,0,0> for Translations (to prevent any translational movement), but leave the

Rotations blank, < > (to NOT prevent any rotational movement). Click OK.

4) Click on Select Application Region and then click on the Select Geometry Entries box.

Screen select Click Point 3. Click Add, OK then Apply.

Step 6 - Create the load of 10000 lb to the top of the structure.

1) Click on Force under the Nodal section.

2) Input top_load and click on Input Data.

3) Input <0,-10000,0> as the Force. Click OK.

4) Click on Select Application Region and then click on the Select Geometry Entries box.

Screen select Point 2. Click Add, OK, then Apply.

Step 7 - Create a mesh seed and a finite element curve mesh.

1) Under the Meshing tab, click on Uniform Mesh Seeds.

2)Set the Number of Elements to 1, and with Auto Execute checked, select each curve.

3) Under the Meshing tab, click on Curve Meshers.

4) Click on the Select Curve List box. Screen click both curves using the Shift key. Click

Apply.

5) Set Action to Equivalence and click Apply (This will eliminate duplicate nodes at the

intersection of the two curves).

Step 8 - Run a steady state analysis using MSC Nastran.

1) Under the Analysis tab, select Entire Model. Ensure that the Job Name box is filled with a

name and click Apply.

Step 9 - Attach results file, then create fringe and deformation plots. Record maximum displacement

and stresses.

1) Click on XDB under the Access Results submenu. .

2) Ensure the appropriate Job Name is selected and click Apply.

3) Under the Results tab, select Fringe/Deformation.

4)Plot Displacements, Translational and Displacements, Translational. Click Apply.

Velammal Institute of Technolog0 71

Simulation and Analysis Laboratory Mechanical Engineering

Fig17.1 Compression on a Two Column Structure

RESULT:

Hence the displacement of a structure consisting of two circular columns is

analyzed by MSC Nastran.

Velammal Institute of Technology 72

Simulation and Analysis Laboratory Mechanical Engineering

Design and analysis of Crane Hook

EXPT NO:2

DATE:

AIM:

To calculate the stresses at point A and point B by a 5000 lb load is placed at the

center of the radius and center of the thickness of a crane hook with a rectangular cross

section: b = 0.75 in. and h = 4 in.

PROCEDURE:

Step 1 - Create a new Patran database.

1) Click on New from the File menu or from the Default Toolbar.

2) Type the name of the new database as hook then click OK.

3) Click OK on the New Model Preference.

Step 2 - Create a Curve using 2 Points

1) First click on the Geometry tab, select Points, and choose XYZ.

2)IType [0 0 0] for the Point Coordinates list, then uncheck Auto Execute and then click

Apply. If Auto Execute is checked, then once the Points are entered it will automatically

create the point after hitting enter, without the need to click Apply. Becareful if Auto Execute

is on and Apply is clicked then a duplicate point will be created.

3) Change the Point Coordinates List to [4 0 0] then click Apply.

4)Now change the Object to Curve then choose the Starting Point List as Point 1 and Ending

Point List as Point 2 then click Apply.

Step 3 - Create a Surface using 2 Curves.

1) First lets create another curve using XYZ method. Change the Method to XYZ then

change the Vector Coordinates List to <4 0 0>, and change the Orgin Coordinate List to [0 4

0]. Then click Apply since Auto Execute is not turned on.

2) Now change the Object to Surface. The surface will be created using 2 curves, so set the

Method to Curve and then choose Curve 2 as the Starting Curve List and choose Curve 1 as

the Ending Curve List. Since Auto Execute is on it will automatically generate the surface

without the need to click Apply.

Step 4- Create a Solid using a Surface.

1)First change the Object to Solid and the Method to Extrude.

2) Change the Translation Vector to <0 0 0.75> and for Surface List choose Surface 1. The

Translation Vector shows that the surface is being extruded 0.75 in the Z direction.

Velammal Institute of Technology 73

Simulation and Analysis Laboratory Mechanical Engineering

Step 5 - Create a Coordinate system using 3 Points.

1) Change the Object to Coord and the Method to 3Point.

2) For the Orgin type [-2 0 0], change the Point on Axis 3 to[-2 0 1] and change the Point on

Plane 1-3 to [1 0 0].

Step 6 - Create a Solid by Revolving a Surface.

1) First choose Object as Solid, and Method as Revolve.

2) Choose Coord 1 for the Refer. Coordinate Frame, type Coord 1.3 for the Axis. This means

that it is using coordinate 1 with rotation in the 3rd axis. Finally change the Total Angle to -

180.0.

3)Choose the Surface Solid 1.5. Solid 1.5 means that the surface is in solid 1 with a surface

number 5.

Step 7 - Create a Primitive Solid Cylinder.

1) First change the Object to Solid, the Method to Primitive and choose the Cylinder.

2)For the Height List type 0.75, the Radius List type 2.0 and for the Thickness List type 0.0.

3) For the Base Center Point List type [-6 0 0], for the Axis List type Coord 0.3, and then

click Apply.

Step 8 - Use Boolean to merge the solids together.

1) Set the Action to Edit, Object to Solid and the Method to Boolean.

2) Click on the Add icon, which is to merge 2 solids together. The second icon subtract one

solid from another and the thrid icon keeps the intersection of 2 solids.

3) For the Solid List Choose Solid 1:3 then click Apply.

4) Now let change the view to smooth shaded by Right Clicking, choose ViewPort Display

and choose Smooth Shaded.

Velammal Institute of Technology 74

Simulation and Analysis Laboratory Mechanical Engineering

Fig 18.1 Hook Design

Fig 18.1 Hook Analysis Report

RESULT:

Hence the stresses at point A and point B of crane hook is analyzed by MSC Nastran

Velammal Institute of Technology 75

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Differential Equations With Boundary Value Problems SolutionsDocument9 pagesDifferential Equations With Boundary Value Problems SolutionsAbdu Abdoulaye67% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Modave2005 PDFDocument298 pagesModave2005 PDFpolickNo ratings yet

- Polymer Handbook PDFDocument1,217 pagesPolymer Handbook PDFPrasanna Kumar S Mural85% (33)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 16 Weeks Get Shredded: New Years Cut Workout PlanDocument3 pages16 Weeks Get Shredded: New Years Cut Workout Plansri krishnaNo ratings yet

- RFIDDocument10 pagesRFIDsri krishnaNo ratings yet

- Week 2 - Monday Back and Triceps: - Weighted Lying Single Arm Dumbbell Extension 6 Sets (20 Reps) Are For EachDocument3 pagesWeek 2 - Monday Back and Triceps: - Weighted Lying Single Arm Dumbbell Extension 6 Sets (20 Reps) Are For Eachsri krishnaNo ratings yet

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2019 (R-2017) (Reval./Photo.) - Page 1/6Document6 pagesAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2019 (R-2017) (Reval./Photo.) - Page 1/6sri krishnaNo ratings yet

- Hariprakash. V - AiceDocument17 pagesHariprakash. V - Aicesri krishnaNo ratings yet

- Hariprakash. V - PPC - CT-2Document14 pagesHariprakash. V - PPC - CT-2sri krishnaNo ratings yet

- Placement DBDocument6 pagesPlacement DBsri krishnaNo ratings yet

- Academic StrategyDocument1 pageAcademic Strategysri krishnaNo ratings yet

- Anna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2019 (Review) - Page 1/2Document2 pagesAnna University:: Chennai - 600025. Office of The Controller of Examinations Provisional Results of Nov. / Dec. Examination, 2019 (Review) - Page 1/2sri krishnaNo ratings yet

- Crack Me ChallengeDocument8 pagesCrack Me Challengesri krishnaNo ratings yet

- ILLUSTRATOR Mithun ResumeDocument1 pageILLUSTRATOR Mithun Resumesri krishnaNo ratings yet

- Velammal Institute of Technology - Nambakam Charan - Mechanical Engineering - 8.25 PDFDocument1 pageVelammal Institute of Technology - Nambakam Charan - Mechanical Engineering - 8.25 PDFsri krishnaNo ratings yet

- April 2020 Cycle Test ScheduleDocument1 pageApril 2020 Cycle Test Schedulesri krishnaNo ratings yet

- Velammal ChennaiDocument21 pagesVelammal Chennaisri krishnaNo ratings yet

- COMFOTEC Engineering PVT LTD CAMPUS DBDocument4 pagesCOMFOTEC Engineering PVT LTD CAMPUS DBsri krishnaNo ratings yet

- Kriya DBDocument7 pagesKriya DBsri krishnaNo ratings yet

- KDocument1 pageKsri krishnaNo ratings yet

- Johnson Control - Velammal DBDocument56 pagesJohnson Control - Velammal DBsri krishna100% (1)

- Hiring: JR Design EngineerDocument2 pagesHiring: JR Design Engineersri krishnaNo ratings yet

- LisozymDocument7 pagesLisozymnandaNo ratings yet

- 11 Key Carbonyl MechanismsDocument1 page11 Key Carbonyl Mechanismsfali92100% (1)

- Water Structure From Scattering Experiments and Simulation: Teresa Head-GordonDocument20 pagesWater Structure From Scattering Experiments and Simulation: Teresa Head-GordonVrahant NagoriaNo ratings yet

- 1 s2.0 S2772571522000298 MainDocument13 pages1 s2.0 S2772571522000298 MainRishi Paresh JoshiNo ratings yet

- What Is A Circuit BreakerDocument18 pagesWhat Is A Circuit Breakersrinu247No ratings yet

- DR Abdus SalamDocument12 pagesDR Abdus SalamSam JamNo ratings yet

- 2020 TheFutureOfEnergyDocument399 pages2020 TheFutureOfEnergyRoman PetersonNo ratings yet

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinNo ratings yet

- Review-10 1 1 159Document34 pagesReview-10 1 1 159guille.ix9882No ratings yet

- Hough2 PDFDocument20 pagesHough2 PDFsaiankita anandNo ratings yet

- CHEG 320 - Electrode Kinetics - Extended NotesDocument13 pagesCHEG 320 - Electrode Kinetics - Extended NotesAzzkikrasdfNo ratings yet

- Lesson 10 Steady Groundwater Flow To WellsDocument27 pagesLesson 10 Steady Groundwater Flow To WellsRajesh Khadka100% (1)

- Adapting Dissolved Air Flotation For The Clarification of SeawaterDocument5 pagesAdapting Dissolved Air Flotation For The Clarification of SeawaterAndreia FalcoNo ratings yet

- Amberlyst® 47: For More Information About DOW™ Resins, Call The Dow Water & Process Solutions BusinessDocument1 pageAmberlyst® 47: For More Information About DOW™ Resins, Call The Dow Water & Process Solutions BusinessjorgeNo ratings yet

- Chemistry Atomic Structure Presentation in Lavander Red Blue Illustrative S - 20240402 - 121914 - 0000Document13 pagesChemistry Atomic Structure Presentation in Lavander Red Blue Illustrative S - 20240402 - 121914 - 0000albedo.jujuNo ratings yet

- Buckingham Pi TheoremDocument4 pagesBuckingham Pi TheoremamdevaNo ratings yet

- Particle Size AnalysisDocument27 pagesParticle Size AnalysisPhan Nee100% (1)

- Sample Paper - 7Document19 pagesSample Paper - 7ShwetaNo ratings yet

- Fourier Transform ApplicationsDocument29 pagesFourier Transform ApplicationsMauricio MallmaNo ratings yet

- CH 15 C 11 Marks 1 and 2 QuesDocument7 pagesCH 15 C 11 Marks 1 and 2 QuesVikrant Shivajirao SambheraoNo ratings yet

- Analog Meters-1 PDFDocument120 pagesAnalog Meters-1 PDFSayak DasguptaNo ratings yet

- Machinery Audit - Blow Room, Carding and Ring FrameDocument5 pagesMachinery Audit - Blow Room, Carding and Ring FrameSENTHIL KUMAR100% (1)

- Reflections TaskDocument3 pagesReflections Taskapi-293995991No ratings yet

- Heat Transfer CalculationsDocument727 pagesHeat Transfer CalculationsManuel Corona Cárdenas50% (2)

- Investigations On The Theory of The Photographic Process - Sheppard and MeesDocument366 pagesInvestigations On The Theory of The Photographic Process - Sheppard and MeesJorgeCamachoNo ratings yet

- Re91401 A2foDocument20 pagesRe91401 A2foTaz Juan GNo ratings yet