Professional Documents

Culture Documents

Installation and Troubleshooting Guide

Uploaded by

NicoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and Troubleshooting Guide

Uploaded by

NicoCopyright:

Available Formats

Installation and Troubleshooting Guide

All rights reserved. Reproduction or use of content, in any manner, without express written permission by CDI Electronics, Inc., is prohibited.

CDI P/N: 194-5279

This kit will replace all of the 815279, 817411, 830179, 854515 and 883072 series regulator/rectifiers, the 194-3072K1

and the (12082A1 regulator, 62351A1 rectifier, and 17602A1 tachometer terminal combination.)

To replace a regulator having only one red wire, tape off the unused small red wire on the new regulator.

WARNINGS:

This product is designed for installation by a professional marine mechanic. CDI cannot be held liable for injury

or damage resulting from improper installation, abuse, neglect or misuse of this product.

DO NOT USE A MAINTAINENCE FREE, AGM OR DRY CELL BATTERY WITH THIS TYPE REGULATOR/RECTIFIER!!!

NEVER DISCONNECT THE BATTERY WHILE THE ENGINE IS RUNNING AS THIS MAY BURN OUT THE

REGULATOR/RECTIFIER. If the boat is equipped with a battery switch, make sure that it is a make before break

type.

1. Disconnect the battery negative post.

2. Disconnect and remove the old regulator/rectifier.

3. If the unit being replaced has long wires or has plastic connectors on the Red and Yellow wires; Cut the wires off

close to the case of the old regulator/rectifier, and crimp and solder the new terminals on to the wires. Use the

wires on the new rectifier/regulator as a guide for terminal selection.

4. Use a quality heat-sink compound (CDI P/N: 989-8109) on the back of the regulator when you install the new

regulator/rectifier.

SERVICE NOTE: It is recommended that dielectric grease (i.e. CDI P/N 991-9705) be used in the bullet nose connectors

to help prevent corrosion.

INSTALLATION NOTE: These regulator/rectifiers will cause a small spark when you reconnect the battery and will draw a

very small amount of current from the battery (Less than 0.001 amp).

Troubleshooting

Tachometer

1. At 800-1000 RPM, check output on the gray wire, reading should be at least 8 volts with a DVA meter. A low reading

usually indicates a bad regulator if the system is charging the battery.

2. Check the resistance between the gray wire and engine ground. You should read above 100K (100,000) ohms. Gray

to red, and gray to the yellow wires should be a high reading, usually in the M range.

Maximum Output Test

1. Install an ammeter capable of reading at least 40 amperes in-line on the red wire connected to the starter solenoid.

2. Connect a load bank to the battery.

3. In the water or on a Dynometer, start the engine and bring the RPM up to approximately 4500 in gear.

4. Turn on the load bank switches to increase the battery load to equal 40 Amps.

5. Check the ammeter, 16 Amp systems should show approximately 16 Amps and 40 Amp systems will show

approximately 20 amps on each regulator/rectifier.

6. If the amperage is low,

A) Check the load bank for battery draw.

B) Reconnect the ammeter between the red wires from one of the regulator/rectifiers and the terminal strip.

Retest. You should show about 20 Amps from each regulator/rectifier.

C) If the output is still low, check and clean all connections between the battery and the regulator/rectifier plate.

7. If the amperage is correct, but the battery voltage remains low, replace the battery.

Bench Test

Diode plate check: Test the forward diodes between the two yellow wires and the red wire. You should get a reading of

about 45K (45,000) on one and a high reading on the other. Check the resistance from each of the yellow wires to case

ground, you should get a reading of about 56K (56,000) on one and a high reading on the other. The red wire should read

about 14K (14,000) ohms to ground.

Tachometer Circuit:

Check the resistance between the gray wire and engine ground. You should read above 100K (100,000) ohms. Gray to

red, and gray to the yellow wires should be a high reading, usually in the M range

Thank you for using CDI Electronics 1/26/2008

CDI Electronics • 111 Commerce Circle • Madison, AL 35758 • Fax 256-772-5701 • www.cdielectronics.com

You might also like

- Alternator Delco With Integral RegulatorDocument10 pagesAlternator Delco With Integral Regulatormad659100% (1)

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- Winco 60711-018 Rotating Field Ts GuideDocument4 pagesWinco 60711-018 Rotating Field Ts GuideZeck100% (1)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- CDI Electronics installation guideDocument1 pageCDI Electronics installation guideGrosse FraudeNo ratings yet

- Milti TesterDocument5 pagesMilti Testerkdm004xxNo ratings yet

- Chassis CTC186 187ABDocument20 pagesChassis CTC186 187ABjujorokoNo ratings yet

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDocument7 pagesTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNo ratings yet

- Manual de Uso Mastech Mas838Document11 pagesManual de Uso Mastech Mas838Mario Carrasco DiazNo ratings yet

- Rca ctc179cm Chassis (ET)Document32 pagesRca ctc179cm Chassis (ET)titoritomex100% (1)

- Danger Warning Caution: Safety InformationDocument7 pagesDanger Warning Caution: Safety InformationcombaheeNo ratings yet

- Lucas Generator and Control Box Tests 1963Document28 pagesLucas Generator and Control Box Tests 19632humbersNo ratings yet

- IRMC Transistor CheckDocument7 pagesIRMC Transistor ChecksebifuenteNo ratings yet

- 2000-2001 CR250 Ignition Service ManualDocument13 pages2000-2001 CR250 Ignition Service ManualHeidi Hanson0% (1)

- AnaAnalizador de Bateriaslizador de BateriasDocument6 pagesAnaAnalizador de Bateriaslizador de BateriasFranco CondoriNo ratings yet

- DCVG Holiday DetectorDocument20 pagesDCVG Holiday DetectorAgus EskenaziNo ratings yet

- Lucas Generator and Control Box Tests PDFDocument28 pagesLucas Generator and Control Box Tests PDFdkjohnbarjoNo ratings yet

- Alpha ReguladorDocument7 pagesAlpha ReguladormruizNo ratings yet

- Industrial Electrician Red Seal Exam Practice QuestionDocument7 pagesIndustrial Electrician Red Seal Exam Practice Questionbrowningw25% (4)

- Medidor CAudal Seametrics AG2000 - 2Document4 pagesMedidor CAudal Seametrics AG2000 - 2Marcos Aldana VillaldaNo ratings yet

- Stator - Bobina Carregadora BateriaDocument1 pageStator - Bobina Carregadora BateriaArtur ValNo ratings yet

- Lucas Generator and Control Box TestsDocument28 pagesLucas Generator and Control Box Testsruben_balea100% (1)

- Testing and AdjustingDocument11 pagesTesting and Adjustingahmad sulaimanNo ratings yet

- Motor Test InstructionsDocument2 pagesMotor Test Instructionssender2000No ratings yet

- PowerDriveDocument12 pagesPowerDriveaxelNo ratings yet

- 174 2075K2Document1 page174 2075K2bojanNo ratings yet

- Smart Charger Assembly GuideDocument4 pagesSmart Charger Assembly Guideanirudh.r.s.No ratings yet

- MRTPDocument20 pagesMRTPStephen Crawford100% (1)

- TRNSFRMR 194-230Document37 pagesTRNSFRMR 194-230SukumaraNo ratings yet

- Alternator DiagnosticDocument19 pagesAlternator Diagnosticvickers100% (1)

- Fluke On Electrical Tests - PART1Document12 pagesFluke On Electrical Tests - PART1Hernàn NùñezNo ratings yet

- Crown Pulse Series Service Documenation: Caution AvisDocument46 pagesCrown Pulse Series Service Documenation: Caution AvisComsa MariusNo ratings yet

- Alternator and RegulatorDocument6 pagesAlternator and Regulatorsonny1234No ratings yet

- TestingDocument14 pagesTestingRaj Kumar PrajapatiNo ratings yet

- Mecc Alte Portable Ts GuideDocument9 pagesMecc Alte Portable Ts GuidesfeNo ratings yet

- Relay Switch Relay Switch Relay Switch Relay SwitchDocument1 pageRelay Switch Relay Switch Relay Switch Relay SwitchrabitosanNo ratings yet

- Spectrum Analyzer: User ManualDocument40 pagesSpectrum Analyzer: User ManualBenjaminBaezNo ratings yet

- Tenma Multimeter 72-7735Document45 pagesTenma Multimeter 72-7735tititwister100% (1)

- Trouble Shooting Pancake GeneratorsDocument7 pagesTrouble Shooting Pancake GeneratorsRomel José Londoño CamachoNo ratings yet

- O & M of Sub StationDocument94 pagesO & M of Sub StationAlbert Sekar100% (2)

- Anti-Lock Brake SystemDocument21 pagesAnti-Lock Brake SystemWoong-Sub LeeNo ratings yet

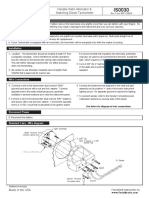

- Faria Diesel Tach Installation Is0030fDocument2 pagesFaria Diesel Tach Installation Is0030fMichael TrimNo ratings yet

- General Radio Company: Operating Instructions FOR TYPE 615 A Heterodyne Frequency MeterDocument19 pagesGeneral Radio Company: Operating Instructions FOR TYPE 615 A Heterodyne Frequency MeterGeorgeNo ratings yet

- Questions For ElectricianDocument87 pagesQuestions For ElectricianMohammad TammamNo ratings yet

- Digital Multimeter DT830 Series ManualDocument12 pagesDigital Multimeter DT830 Series ManualJohn G.75% (4)

- 6/14/02 Chapter 14: Use of Electrical Test Equipment 1/20Document20 pages6/14/02 Chapter 14: Use of Electrical Test Equipment 1/20LeonardNo ratings yet

- 6/14/02 Chapter 14: Use of Electrical Test Equipment 1/20Document20 pages6/14/02 Chapter 14: Use of Electrical Test Equipment 1/20asfaw getuNo ratings yet

- AV1000 + Assembly + ManualDocument22 pagesAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"Document2 pagesInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"thailanNo ratings yet

- Installation Manual for ES53 Control ModuleDocument18 pagesInstallation Manual for ES53 Control ModuleEiseo ObregonNo ratings yet

- Kawa Ninja 650-Charging SystemDocument20 pagesKawa Ninja 650-Charging SystemFrancisco Alberto Comas Garcia100% (2)

- Use of 4C4911 Battery Load Tester For 6, 8 and 12 Volt Lead Acid Batteries (0785, 1401)Document6 pagesUse of 4C4911 Battery Load Tester For 6, 8 and 12 Volt Lead Acid Batteries (0785, 1401)Cristopher LaosNo ratings yet

- GM 3.1L & 3.4L Icm TestingDocument4 pagesGM 3.1L & 3.4L Icm TestingJoeNo ratings yet

- RS2 NAKED Esquemas Electricos PDFDocument131 pagesRS2 NAKED Esquemas Electricos PDFPablo Diáñez GómezNo ratings yet

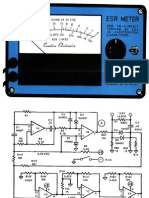

- ESR Meter Circuit Operation GuideDocument5 pagesESR Meter Circuit Operation GuideOscar PachecoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Newsletter - VCFDocument1 pageNewsletter - VCFNicoNo ratings yet

- 30 40 PDFDocument584 pages30 40 PDFNicoNo ratings yet

- 30 40 PDFDocument584 pages30 40 PDFNicoNo ratings yet

- 30 40 PDFDocument584 pages30 40 PDFNicoNo ratings yet

- 30 40 PDFDocument584 pages30 40 PDFNicoNo ratings yet

- EMI Chapter 3 GuideDocument60 pagesEMI Chapter 3 Guidemahalekshmi anilNo ratings yet

- Practical Electronics 1978 01Document84 pagesPractical Electronics 1978 01Marcelo KraiserNo ratings yet

- Splice Closure In-Line BR-112038-EN PDFDocument8 pagesSplice Closure In-Line BR-112038-EN PDFTiziano D'IncàNo ratings yet

- Manual de Partes Martillos Hidráulicos Furukawa Modelo F35-XPDocument49 pagesManual de Partes Martillos Hidráulicos Furukawa Modelo F35-XPRicky Vil100% (1)

- DH-DHRS Series Commission Report FormDocument3 pagesDH-DHRS Series Commission Report Formandy habibiNo ratings yet

- Prime Conduit Schedule 40 & 80 Conduit & ElbowsDocument15 pagesPrime Conduit Schedule 40 & 80 Conduit & ElbowsSam YangNo ratings yet

- Prime Lens Sensor Coverge Chart - Master Sheet1 - 5Document7 pagesPrime Lens Sensor Coverge Chart - Master Sheet1 - 5Shriram MoovaaNo ratings yet

- Complete Pump Solutions Fire Protection BrochureDocument4 pagesComplete Pump Solutions Fire Protection BrochureOsmar AraujoNo ratings yet

- I. Answer The Following Question. Encircle The Letter of The Correct AnswerDocument2 pagesI. Answer The Following Question. Encircle The Letter of The Correct AnswerAngelyn Abangco Pamisa - BolositoNo ratings yet

- Iris Power Stator Wedge Analyzer SWA BrochureDocument2 pagesIris Power Stator Wedge Analyzer SWA BrochureLeandro AriasNo ratings yet

- Echo CatalogueDocument11 pagesEcho CatalogueJIYADHNo ratings yet

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocument44 pagesTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsToto TotoroNo ratings yet

- RspMan2612 Full RSP MFV PDFDocument210 pagesRspMan2612 Full RSP MFV PDFPurshottam SharmaNo ratings yet

- Master Plan Service 10 - 2022Document105 pagesMaster Plan Service 10 - 2022Yoseph Freinademetz100% (1)

- Cyberpunk 2020 - CP3461 Blackhand's Street WeaponsDocument50 pagesCyberpunk 2020 - CP3461 Blackhand's Street WeaponsJaksáGonagas100% (1)

- Amiga 500/600/1200 Floppy Recap / Capacitor List: Track Zero Sensor Warning !Document3 pagesAmiga 500/600/1200 Floppy Recap / Capacitor List: Track Zero Sensor Warning !Octavio PereiraNo ratings yet

- Study of Level and Levelling StaffDocument4 pagesStudy of Level and Levelling Staffhaggai ngosaNo ratings yet

- Crestline Dampening Systems: Installation InstructionsDocument73 pagesCrestline Dampening Systems: Installation InstructionsSergey PhilippovNo ratings yet

- Bushing Insulators: Other Medium Voltage EquipmentDocument4 pagesBushing Insulators: Other Medium Voltage EquipmentjalilemadiNo ratings yet

- Sewage April 2015Document2 pagesSewage April 2015Claudio SantellanesNo ratings yet

- Catalago Pá Lonking CDM 816Document138 pagesCatalago Pá Lonking CDM 816Diego ValensuelaNo ratings yet

- Juki MS-26Document11 pagesJuki MS-26Richard AquinoNo ratings yet

- Installation and Operation Manual BR Series Module: WAAREE Energies LTDDocument11 pagesInstallation and Operation Manual BR Series Module: WAAREE Energies LTDfghNo ratings yet

- 9 Akk 107331Document96 pages9 Akk 107331Roger Gustavo Gutierrez HuanquiriNo ratings yet

- Butterfly Valves Purushotham: Pro R&D PVT LTDDocument7 pagesButterfly Valves Purushotham: Pro R&D PVT LTDPurushothamNo ratings yet

- GX531GS - GM - ServiceGuide - Chapter01-V1.0Document7 pagesGX531GS - GM - ServiceGuide - Chapter01-V1.0Dima RozhencovNo ratings yet

- 50 Ways To Save EnergyDocument2 pages50 Ways To Save EnergyXristosEuthumiopoulqNo ratings yet

- III - Adjusting Clutch Play Between - K1-And - K2-: To Adjust The Clutch Play, Install Components Without Shim(s) (ItemDocument9 pagesIII - Adjusting Clutch Play Between - K1-And - K2-: To Adjust The Clutch Play, Install Components Without Shim(s) (ItemВадим УрупаNo ratings yet

- Unit-5-Industrial Electrical Systems-IIDocument12 pagesUnit-5-Industrial Electrical Systems-IIvikram patilNo ratings yet

- Pressure Parts ListDocument2 pagesPressure Parts ListRaji SuriNo ratings yet