Professional Documents

Culture Documents

Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"

Uploaded by

thailan0 ratings0% found this document useful (0 votes)

97 views2 pagesinstall

Original Title

118031 Diesel Tach[1]

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstall

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

97 views2 pagesInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"

Uploaded by

thailaninstall

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PRECAUTIONS:

118031

Rev 1: 12/15/04

Installation Instructions

Read ALL instructions before installing instrument.

Follow ALL safety precautions when working on vehicle-wear

safety glasses!

ALWAYS disconnect (-) negative battery cable before making

electrical connections.

HELP?:

Diesel/Alternator Tachometer 3-3/8 & 5

If after reading these instructions you dont fully understand

how to install your instrument(s), contact your local Stewart

Warner distributor, or contact our Technical Support Team toll

free at 1-866-797-7223 (SWP-RACE).

Additional applications information may be found at

www.SW-Performance.com.

GENERAL APPLICATION:

12-volt DC negative (-) ground electrical systems (11-20 VDC

operating voltage range for the tachometer, 11-16 VDC for the

Light bulb).

Signal source from alternator AC tap (R terminal).

Adjustment range: 10.7 21.3 PPR (Pulses Per Revolution).

PPR = (Poles/2)*(Crank pulley dia./Alternator pulley dia.)

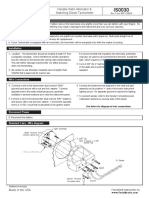

TACHOMETER MOUNTING (Figure 1 & 2):

NOTE: Instructions apply to 3-3/8 & 5 Tachometer.

Recommended panel cut-out (hole size) for 3-3/8 for the 33/8 tachometer 4-5/8 for the 5 tachometer if recessed to the

bezel, or 3-3/8 if recessed to the step (figure 1).

Secure the tachometer in the hole using the supplied bracket

for the 3-3/8 and the 5. Remove the 3 Torx screws using a

T10 Torx driver. Insert the 3 studs (no more than 8 turns) and

install lock washers and nuts to secure the rear cover. Install

the bracket as shown in figure 2 and tighten the 3 locking nuts

(5 in. Lb. max).

TIP: Calibrate the tachometer before final installation.

When mounting on the dash or roll cage or steering column,

use the cushioned strap & bracket as shown in figure 3.

TACHOMETER HOOK-UP (Figure 3):

1.

2.

3.

4.

5.

6.

7.

Disconnect negative (-) battery cable.

Using 18-ga. wire, connect the (BLACK) wire to a clean

(rust/paint-free) ground, preferably battery negative terminal.

Using 18-ga. wire, connect the (RED) wire to a switched +12V

source, like the ignition wire.

Using 18-ga. wire, connect the (GREEN) wire alternator AC tap

terminal (R terminal).

There are two (2) wires for the lighting; Connect the (WHITE)

lighting wire to the dash lighting circuit or to a +12V switched

circuit. Connect the (BLACK) lighting wire to a chassis ground.

Reconnect the negative (-) battery cable & test instrument to

ensure that it is working (will not be accurate until calibrated).

Calibrate the tachometer. Refer to the calibration set-up

section.

Figure 2

Figure 1

3-3/8 Installation

5 Installation

Figure 3

TACHOMETER SIGNAL INFORMATION:

Since diesel engines do not have an ignition system, the engine

speed signal is supplied from the alternator AC tap or

sometimes called the R terminal.

This signal comes from the windings in the alternator before its

rectified to DC and regulated to the system charge voltage. Not

all alternators come with this terminal.

Its best to check with the alternator manufacturer, or a

good local alternator shop for AC tap availability.

If it is not available, it may be possible to add the terminal

to the alternator. Consult a local alternator repair shop for

exact details.

Since the signal comes from the alternator, the number of

cylinders in the engine has nothing to do with the tachometer

calibration.

The PPR (Pulses Per Revolution) calibration range is 10.7 to

21.3 (refer to the SIGNAL CALCULATION section for

additional information).

SIGNAL CALCULATION:

Given the continual introduction of alternator styles, it is

advisable to determine the PPR of the application before

installation.

The PPR calculation is PPR = P*R/2

P is the number of poles in the alternator.

R is the pulley ratio. Determine the pulley ratio by

dividing the crank pulley diameter by the alternator pulley

diameter.

Example:

# of poles 18

Crank pulley diameter is 4.5

Alternator pulley diameter is 2.

PPR = (18*(4.5/2))/2 = 20.25 PPR, which falls into the

calibration range and should work well.

CALIBRATION SET-UP (Figure 4):

NOTE: Stewart Warner Performance Diesel Tachometers must be

calibrated after installation for accurate operation. See DIP-switch

setting chart for additional applications.

1. Remove the 3 Torx screws using a T10 Torx driver.

2. Start the engine and determine the actual engine RPM using a

reference tachometer (optical, non-contact tachometer

recommended).

3. Set the DIP Switches, as a course calibration, so that the tach

indicates the closest to actual engine RPM.

TIP: A small screwdriver or pick may aide in the switch setting.

4. Adjust the calibration potentiometer, as a fine adjustment, until

the tachometer indicates actual engine RPM.

TIP: A 5/32 or 2mm hex driver works best to adjust the calibration

potentiometer.

5. Replace the rear cover and 3 Torx screws. Be sure that the rear

sealing o-ring stays in place.

Figure 4

10

9

TROUBLESHOOTING:

Q:

A:

My tachometer does not respond at all, what do I do?

Check all of the wiring connections and power to the

tachometer.

1.

If the tachometer needle goes to zero when powered up,

but does not respond when the engine is started, there is

no signal to the green wire. Check to ensure that the

green wire is hooked to the proper location for a valid

signal.

2.

Q:

A:

If the tachometer needle doesnt go to zero when powered

up, the tachometer is not grounded properly or does not

have power to the (RED) wire. Check to ensure a good

chassis ground, preferably at the battery ground. Verify

that the (RED) wire has a 12VDC supply.

My tachometer does not read correctly, what do I do?

The Diesel Tachometers must be calibrated for each installation

for proper operation.

1. Recalibrate the tachometer (refer to the CALIBRATION

SET-UP section for more information).

2. Be sure that the reference tachometer is functioning

properly and providing accurate RPM values.

11

CLEANING DIRECTIONS:

For proper cleaning of instrumentation/accessories, use a glass

cleaner or mild detergent with a spray on and wipe method.

WARRANTY INFORMATION:

TWO (2) YEAR LIMITED WARRANTY. SWP products are

warranted against defects in workmanship and materials for a period

of two (2) years from the date of purchase. Proof-of-purchase is

required; otherwise, the warranty period shall default to two (2)

years from date-of-manufacture (as indicated by the date code on

the product). See detailed Warranty Policy for other Terms &

Conditions.

STEWART WARNER PERFORMANCE

1-866-SWP-RACE (797-7223)

www.SW-Performance.com

12

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"Document2 pagesInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"heartofdixieNo ratings yet

- Aetna Tachometer Manual-Rev-7.0Document27 pagesAetna Tachometer Manual-Rev-7.0Alfonso Vallejo AguilarNo ratings yet

- Dp6014 Jeep TJ 1997-2006 New Fuel Program Rev. 8292022Document8 pagesDp6014 Jeep TJ 1997-2006 New Fuel Program Rev. 8292022Eduar AcvdoNo ratings yet

- DP6011 Jeep CJ Digital Dash 1955-1986 8292022Document5 pagesDP6011 Jeep CJ Digital Dash 1955-1986 8292022Eduar AcvdoNo ratings yet

- DYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDocument18 pagesDYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDavid Coronado100% (1)

- AP5001 68 Chevelle Dash Panel Rev 8242021Document10 pagesAP5001 68 Chevelle Dash Panel Rev 8242021Juan Miguel Martinez AguilarNo ratings yet

- Magnetic Sensor TachometerDocument3 pagesMagnetic Sensor Tachometerdominicimlach98No ratings yet

- AEMS Installation InstructionDocument8 pagesAEMS Installation Instructionalexcus1539No ratings yet

- IS0030DDocument2 pagesIS0030DRomie HarieNo ratings yet

- DP6013 Jeep 1992-96 Rev 08292022Document10 pagesDP6013 Jeep 1992-96 Rev 08292022Eduar AcvdoNo ratings yet

- Faria Diesel Tach Installation Is0030fDocument2 pagesFaria Diesel Tach Installation Is0030fMichael TrimNo ratings yet

- DP1301 90-98 Mazda Miata Rev 01312022Document6 pagesDP1301 90-98 Mazda Miata Rev 01312022pasie2022No ratings yet

- Gecko Drive g340 - 815e28e418 PDFDocument7 pagesGecko Drive g340 - 815e28e418 PDFRemus PopescuNo ratings yet

- DC Motor Control ManualDocument15 pagesDC Motor Control Manualatgordon1No ratings yet

- Volkswagen - New Beetle - Wiring Diagram - 2007 - 2008Document13,861 pagesVolkswagen - New Beetle - Wiring Diagram - 2007 - 2008Harshad NaringrekarNo ratings yet

- Tekin RS / RS Pro ManualDocument2 pagesTekin RS / RS Pro Manualanon_643529962No ratings yet

- EPA07 MBE 4000 Standard Grid Heater Relay Installation InstructionsDocument6 pagesEPA07 MBE 4000 Standard Grid Heater Relay Installation InstructionsАндрейNo ratings yet

- Tea Sensor de Velocidade 3Document7 pagesTea Sensor de Velocidade 3Valmaq Prestação Serviço LdaNo ratings yet

- Testing and AdjustingDocument11 pagesTesting and Adjustingahmad sulaimanNo ratings yet

- Actros .Rve..Alternatorinstallation Instructions 18siDocument2 pagesActros .Rve..Alternatorinstallation Instructions 18siVasile SilvioNo ratings yet

- Datcon Tachometer Installation Instructions PDFDocument2 pagesDatcon Tachometer Installation Instructions PDFHanNo ratings yet

- Manual R25 PDFDocument8 pagesManual R25 PDFluis martinezNo ratings yet

- Alternator Pulsed Tachometer InstallationDocument2 pagesAlternator Pulsed Tachometer InstallationDiego Alvarez Alvarez100% (2)

- Installation and Troubleshooting GuideDocument1 pageInstallation and Troubleshooting GuideNicoNo ratings yet

- 3 / " & 5" Electric Speedometer: QuestionsDocument3 pages3 / " & 5" Electric Speedometer: Questionsfouzan4493No ratings yet

- Troubleshooting For M38 InstrumentsDocument7 pagesTroubleshooting For M38 Instrumentsm606No ratings yet

- 3300 S Tech Time Timing Unit Operating Instructions Tiempo DieselDocument4 pages3300 S Tech Time Timing Unit Operating Instructions Tiempo DieselJean CarlosNo ratings yet

- Alternator Delco With Integral RegulatorDocument10 pagesAlternator Delco With Integral Regulatormad659100% (1)

- Tools & Equipment BulletinDocument3 pagesTools & Equipment BulletinBRAHMADEOSINGHNo ratings yet

- Fuel Rack Solenoid - TestDocument6 pagesFuel Rack Solenoid - TestAdolfo Dario SaavedraNo ratings yet

- Alternator DiagnosticDocument19 pagesAlternator Diagnosticvickers100% (1)

- Jvs Manual JRC 122-124Document4 pagesJvs Manual JRC 122-124ashutosh2009No ratings yet

- Honda - Prelude - Wiring Diagram - 1992 - 1999Document4,712 pagesHonda - Prelude - Wiring Diagram - 1992 - 1999Kristin OlsonNo ratings yet

- Installation Guide - Owner'S Guide: Universal Bypass Module - Model 781Document9 pagesInstallation Guide - Owner'S Guide: Universal Bypass Module - Model 781DW BetancourtNo ratings yet

- Installation Instructions 30-5130Document8 pagesInstallation Instructions 30-5130alexcus1539No ratings yet

- Jacobs Electronics Instructions Pro Street Kit 372546 370506Document8 pagesJacobs Electronics Instructions Pro Street Kit 372546 370506tubetyme100% (2)

- Instructions For 35si HP 36si HP Replacing Delco Remy 21si, 22si, 23si, 33si, 34si, 35si and 36siDocument2 pagesInstructions For 35si HP 36si HP Replacing Delco Remy 21si, 22si, 23si, 33si, 34si, 35si and 36sishinichieNo ratings yet

- ST400 Series Tachometers: User ManualDocument22 pagesST400 Series Tachometers: User ManualEdison100No ratings yet

- Installation Instructions For 3-3/8" Programmable Speedometer Before You StartDocument2 pagesInstallation Instructions For 3-3/8" Programmable Speedometer Before You Startjulio797No ratings yet

- Rca ctc179cm Chassis (ET)Document32 pagesRca ctc179cm Chassis (ET)titoritomex100% (1)

- ST2715Document20 pagesST2715mamz4uNo ratings yet

- EN EG Dynamic User Manual v2 7 1 Dated 2021-06-22Document12 pagesEN EG Dynamic User Manual v2 7 1 Dated 2021-06-22Musab Mohamed AliNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- Alternator Lesnewile 4000Document21 pagesAlternator Lesnewile 4000help3rNo ratings yet

- Sabertooth 2x10 User's Guide: February 2007Document19 pagesSabertooth 2x10 User's Guide: February 2007Hrishikesh GarudNo ratings yet

- Tea Sensor de Velocidade 2Document7 pagesTea Sensor de Velocidade 2Valmaq Prestação Serviço LdaNo ratings yet

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- MAX1538EVKITDocument9 pagesMAX1538EVKITohoboho79No ratings yet

- En EG-Dynamic User Manual v110Document12 pagesEn EG-Dynamic User Manual v110safvanshaikhNo ratings yet

- Sensor Signal (PWM) - Test: TroubleshootingDocument6 pagesSensor Signal (PWM) - Test: Troubleshootingronald0% (1)

- General Radio Company: Operating Instructions FOR TYPE 615 A Heterodyne Frequency MeterDocument19 pagesGeneral Radio Company: Operating Instructions FOR TYPE 615 A Heterodyne Frequency MeterGeorgeNo ratings yet

- 641 - 2051B ManualDocument10 pages641 - 2051B ManualPirv Maria AncaNo ratings yet

- I - Systemcomponent TestsDocument34 pagesI - Systemcomponent TestsJose PichinteNo ratings yet

- DC Faultr Location FinderDocument26 pagesDC Faultr Location Findergaurang1111No ratings yet

- Digital Sensor: SupplyDocument6 pagesDigital Sensor: SupplyYUDI WAHYUDI 17249No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Ar Industrial Catalog en 2016 WebDocument120 pagesAr Industrial Catalog en 2016 WebthailanNo ratings yet

- Miniskaff Assembly Instructions PDFDocument2 pagesMiniskaff Assembly Instructions PDFthailanNo ratings yet

- Hyundai spare parts catalog download/TITLEDocument2 pagesHyundai spare parts catalog download/TITLEthailanNo ratings yet

- Miniskaff Assembly Instructions PDFDocument2 pagesMiniskaff Assembly Instructions PDFthailanNo ratings yet

- 2016 Mining Catalogue MASTERDocument79 pages2016 Mining Catalogue MASTERthailanNo ratings yet

- MV99 - Load Sensing VVDocument46 pagesMV99 - Load Sensing VVthailanNo ratings yet

- Portable Repair WorkshopsDocument24 pagesPortable Repair WorkshopsthailanNo ratings yet

- 40 Foot Container DimensionsDocument3 pages40 Foot Container DimensionsthailanNo ratings yet

- Possible Frame IssueDocument10 pagesPossible Frame IssuethailanNo ratings yet

- Norma Normaquick Quick ConnectorDocument16 pagesNorma Normaquick Quick ConnectorthailanNo ratings yet

- HILUX Electrical Wiring Diagram GuideDocument244 pagesHILUX Electrical Wiring Diagram Guidethailan100% (2)

- Bul SAE J2044 PDFDocument8 pagesBul SAE J2044 PDFthailanNo ratings yet

- Alemite CatalogDocument177 pagesAlemite CatalogthailanNo ratings yet

- AMastersGuidetoContainerSecuring2ndEdition 3 PDFDocument50 pagesAMastersGuidetoContainerSecuring2ndEdition 3 PDFthailanNo ratings yet

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Document52 pagesSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanNo ratings yet

- Alemite CatalogDocument177 pagesAlemite CatalogthailanNo ratings yet

- 3 o Ring Guide Issue 7 PDFDocument32 pages3 o Ring Guide Issue 7 PDFthailanNo ratings yet

- 520L0893 PDFDocument240 pages520L0893 PDFthailanNo ratings yet

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 pageUnc Unf Metric Thread Chart Northwest FastenerthailanNo ratings yet

- NPTDocument6 pagesNPTthailanNo ratings yet

- 38 Alemite Product Catalog PDFDocument277 pages38 Alemite Product Catalog PDFthailan100% (1)

- 3c EngDocument2 pages3c EngthailanNo ratings yet

- Type of ThreadDocument13 pagesType of ThreadVils ArabadzhievaNo ratings yet

- Cummins Heavy Duty Product Guide PDFDocument22 pagesCummins Heavy Duty Product Guide PDFthailanNo ratings yet

- Dseries Eng PDFDocument3 pagesDseries Eng PDFthailanNo ratings yet

- How To Identify Fluid Ports and ConnectorsDocument24 pagesHow To Identify Fluid Ports and ConnectorsKathryn WorkmanNo ratings yet

- JIS ThreadsDocument7 pagesJIS Threadsthailan0% (1)

- Mounting Flange HZW EngDocument2 pagesMounting Flange HZW EngthailanNo ratings yet

- Ourproductconcept Eng PDFDocument8 pagesOurproductconcept Eng PDFthailan100% (1)

- Mounting Flange HZW EngDocument2 pagesMounting Flange HZW EngthailanNo ratings yet

- Kon 17 I2c en PDFDocument4 pagesKon 17 I2c en PDFFelipe Vasquez MedinaNo ratings yet

- The Linearly Variable Differential Transformer (LVDT)Document13 pagesThe Linearly Variable Differential Transformer (LVDT)SagarNo ratings yet

- Unit 29 Three-Phase TransformersDocument6 pagesUnit 29 Three-Phase TransformersEdward YanezNo ratings yet

- Diodo CL04Document4 pagesDiodo CL04Helder Dos SantosNo ratings yet

- Seco-Larm 941SA Data SheetDocument1 pageSeco-Larm 941SA Data SheetJMAC SupplyNo ratings yet

- Unisonic Technologies Co., LTD: Power TransistorDocument4 pagesUnisonic Technologies Co., LTD: Power TransistorCode HetroNo ratings yet

- ACSI Device and Part NumbersDocument1,797 pagesACSI Device and Part NumbersTejano RockNo ratings yet

- Out Products: Monolithic IC MM192x SeriesDocument16 pagesOut Products: Monolithic IC MM192x SeriesIbrain MoranNo ratings yet

- ELE3114 Electrical Machines and Drives I Final Exam May 2022 Ver 3Document4 pagesELE3114 Electrical Machines and Drives I Final Exam May 2022 Ver 3Kerera DeograciousNo ratings yet

- Circuit Breaker - Wikipedia, The Free EncyclopediaDocument14 pagesCircuit Breaker - Wikipedia, The Free EncyclopediaAriesFranandaPanjaitanNo ratings yet

- Spectralert® Series: Horns, Strobes, and Horn/StrobesDocument4 pagesSpectralert® Series: Horns, Strobes, and Horn/Strobesmechengineer3No ratings yet

- Rca rs2625Document5 pagesRca rs2625luis urrozNo ratings yet

- 3271005648XX309F1001 As On 110619Document19 pages3271005648XX309F1001 As On 110619kaasroNo ratings yet

- Technical Proposal For Setting Up A Model Substation For TrainingDocument14 pagesTechnical Proposal For Setting Up A Model Substation For Trainingjigyesh sharmaNo ratings yet

- SK6406 PDFDocument6 pagesSK6406 PDFjddgNo ratings yet

- AVHP6600DVDDocument60 pagesAVHP6600DVDTrevor AliNo ratings yet

- Description Mechanical Dimensions: 1 Watt ZENER DIODES (3.3V To 100V)Document2 pagesDescription Mechanical Dimensions: 1 Watt ZENER DIODES (3.3V To 100V)Arace Silva SilvaNo ratings yet

- Manual E5ac Pr2asm 804 Open&CloseDocument2 pagesManual E5ac Pr2asm 804 Open&CloseNguyễn Hào QuangNo ratings yet

- Microwave Sharp R-244 Service ManualDocument28 pagesMicrowave Sharp R-244 Service ManualminhtqNo ratings yet

- Lucas OPUS ignition system for Jaguar V12 enginesDocument9 pagesLucas OPUS ignition system for Jaguar V12 enginesBo BoboNo ratings yet

- BML MonglaDocument57 pagesBML MonglaStrato VariusNo ratings yet

- ETAB SoftwareDocument16 pagesETAB SoftwareParvathy UdaiNo ratings yet

- The RCD Handbook: Beama Guide To The Selection and Application of Residual Current Devices (RCDS)Document42 pagesThe RCD Handbook: Beama Guide To The Selection and Application of Residual Current Devices (RCDS)winusNo ratings yet

- ITP (Electrical)Document6 pagesITP (Electrical)petroniko8880% (5)

- Troubleshooting Manual Triol AK06 Line UD (UL, UMKA07)Document87 pagesTroubleshooting Manual Triol AK06 Line UD (UL, UMKA07)napo3t100% (1)

- Catalog VCB - LS PDFDocument56 pagesCatalog VCB - LS PDFmuchamad yasinNo ratings yet

- Solar & Energy Saving ProductsDocument249 pagesSolar & Energy Saving ProductsSeaworks CompanyNo ratings yet

- Horno de Microondas Sharp R481cwaDocument40 pagesHorno de Microondas Sharp R481cwaErick RodriguezNo ratings yet

- ApoorvaDocument25 pagesApoorvaSiddhant GuptaNo ratings yet

- M0097147M0097147-00 SisDocument8 pagesM0097147M0097147-00 SisNicole SmithNo ratings yet