Professional Documents

Culture Documents

Motor Cummins 4BT

Motor Cummins 4BT

Uploaded by

Luis Alirio Casas Osorio0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

MOTOR CUMMINS 4BT

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageMotor Cummins 4BT

Motor Cummins 4BT

Uploaded by

Luis Alirio Casas OsorioCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

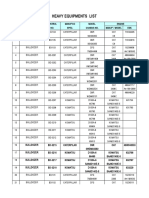

Torque and Rebuild Specifications for Cummins Four and Six Cylinder B Series

Engines in Industrial and Generator Applications with Front Gear Trains

Rocker Cover 18 ft. lbs.

Cylinder Head Bolts

Tighten all to 66ft. lb. in sequence

Tighten Long Bolts(4,5,12,13 on 4B;

4,5,12,13,20,21 on 6B) to 89ft. lb.

Tighten Short Bolts

(All others not noted above) to 66 ft. lb.

Tighten All Long Bolts again to 89ft. lb.

Tighten all in sequence 90 Degrees

37ft. lbs. 44ft. lbs. 66ft. lbs. +90°

Main Bearing Cap Torque

Starting at center main cap and work outwards.

Piston Protrusion 0.024” – 0.028”

Connecting Rod Bolt 22ft. lbs. 44ft. lbs. +60°

Standard Cylinder Bore 4.0161” – 4.0177”

Cylinder Bore Out-of-round 0.0015” Max

Cylinder Bore Taper 0.003” Max

Piston Skirt to Liner Clearance 0.0048” – 0.0089”

Crankshaft End Play 0.004” – 0.017”

Valve Adjust Sequence Cyl 1 Cyl 2 Cyl 3 Cyl 4 Cyl 5 Cyl 6

I E I E I E I E I E I E

TDC #1 X X X X X X

TDC #6 X X X X X X

0.010” Intake

Valve Clearance (set cold)

0.020” Exhaust

You might also like

- D3 G+flash+codeDocument4 pagesD3 G+flash+codeX'mix Đreamer100% (1)

- Cummins N14 NTA14Document1 pageCummins N14 NTA14Jenso GallardoNo ratings yet

- Sistema Lubricacion Cummins Diesel C8.3Document6 pagesSistema Lubricacion Cummins Diesel C8.3Pitricio Campos Del Río100% (2)

- Cummins Cat Al 08-08Document4 pagesCummins Cat Al 08-08FABIAN MARTINEZ50% (2)

- EngineTorqueSpecs - International MaxxForce DT 9 10 - 2010Document2 pagesEngineTorqueSpecs - International MaxxForce DT 9 10 - 2010P Gl100% (1)

- RR Rto-16908llDocument36 pagesRR Rto-16908llgestada023No ratings yet

- 12V Cummins Torque Specs PDFDocument8 pages12V Cummins Torque Specs PDF180976No ratings yet

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- C15 Acert: Industrial Caterpillar Engine SpecificationsDocument4 pagesC15 Acert: Industrial Caterpillar Engine Specificationsyash singhNo ratings yet

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument4 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton miranda100% (1)

- This Is Cummins Q4 - 2016 FinalDocument47 pagesThis Is Cummins Q4 - 2016 FinalDEVIN YHOJAN VIAFARA MANCILLANo ratings yet

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERDocument14 pagesQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakNo ratings yet

- 21414.valvulas e Inyectores Bomba, Ajuste.. Motor Con VEBDocument2 pages21414.valvulas e Inyectores Bomba, Ajuste.. Motor Con VEBFrancisco Alvarado HuenquiaoNo ratings yet

- 4971108Document6 pages4971108Massahiro FilhoNo ratings yet

- D12D425 VHD PDFDocument2 pagesD12D425 VHD PDFMarco Antonio Esparza CastroNo ratings yet

- Code 368 PDFDocument2 pagesCode 368 PDFesquisof0% (1)

- Catálogo Caterpillar C12Document4 pagesCatálogo Caterpillar C12José ArgüelloNo ratings yet

- Caja de Cambio Caracteristicas T318 PDFDocument2 pagesCaja de Cambio Caracteristicas T318 PDFLenny Virgo100% (1)

- Injectores S 60 PDFDocument18 pagesInjectores S 60 PDFfranciscoNo ratings yet

- The Delphi Advantage.: Remanufactured All Makes Diesel Fuel InjectorsDocument2 pagesThe Delphi Advantage.: Remanufactured All Makes Diesel Fuel InjectorsEphrem MichaelNo ratings yet

- Mtu 20VDocument2 pagesMtu 20VGLIEDRNo ratings yet

- Engine BIG CAM III - Familiarization PDFDocument61 pagesEngine BIG CAM III - Familiarization PDFJorge Castillo Hdz100% (1)

- C13 TorqueDocument1 pageC13 TorqueScribdTranslationsNo ratings yet

- High Pressure Fuel Lines and Transfer Tubes Removal and Installation Procedure Has Been UpdatedDocument10 pagesHigh Pressure Fuel Lines and Transfer Tubes Removal and Installation Procedure Has Been UpdatedTaufan ArifNo ratings yet

- Weller Reman CatalogDocument36 pagesWeller Reman CatalogEmerson AugustoNo ratings yet

- Description Description: Replacement Engine Brake Parts For JacobsDocument6 pagesDescription Description: Replacement Engine Brake Parts For JacobsAaronGomezNo ratings yet

- Vs. Caterpillar 3126E/C7: International InternationalDocument5 pagesVs. Caterpillar 3126E/C7: International InternationalClaudia Montes100% (1)

- Ajuste de Piston Esclavo Freno MotorDocument4 pagesAjuste de Piston Esclavo Freno MotorMuriel RembertoNo ratings yet

- PDF - Isx MotorDocument4 pagesPDF - Isx MotorJanier100% (1)

- HP125Document6 pagesHP125Qike FlowersNo ratings yet

- 6 Cylinder MBE906: Engine PerformanceDocument2 pages6 Cylinder MBE906: Engine Performanceguillermo meza huamanNo ratings yet

- Service Bulletin Trucks: 2140 05 02 03 Valves and Injectors, AdjustmentDocument19 pagesService Bulletin Trucks: 2140 05 02 03 Valves and Injectors, AdjustmentJ JNo ratings yet

- Especificaciones PERKINS 1104CDocument5 pagesEspecificaciones PERKINS 1104CJesús Manuel Paz GonzálezNo ratings yet

- Specifications KTA38 G DRIVEDocument2 pagesSpecifications KTA38 G DRIVEMehdi ChakrouneNo ratings yet

- Calibracion de ValvulasDocument3 pagesCalibracion de ValvulasJose FavaNo ratings yet

- Caterpillar Engine Service Manual CT S Eng d343Document7 pagesCaterpillar Engine Service Manual CT S Eng d343Farshaaad HkNo ratings yet

- Og Ws Isx15 Isx PDFDocument5 pagesOg Ws Isx15 Isx PDFCarlos OchoaNo ratings yet

- FS-5406N TransmisionDocument19 pagesFS-5406N TransmisionEduardo SantanaNo ratings yet

- 64L Torque Charts PDFDocument22 pages64L Torque Charts PDFDavid Stutzman50% (2)

- Cummins IsxDocument3 pagesCummins IsxFaudy Jonas Gonzalez CastilloNo ratings yet

- Listado Caterpillar C13 CTPDocument2 pagesListado Caterpillar C13 CTPFranco bucciarelliNo ratings yet

- G3406 Connecting Rod BearingsDocument4 pagesG3406 Connecting Rod BearingsnobodymagdesignNo ratings yet

- Cojinetes de Bancada de Cigueñal - Instalar PDFDocument4 pagesCojinetes de Bancada de Cigueñal - Instalar PDFfernando castro padillaNo ratings yet

- MANUAL 6305B Eaton-Fuller-FS-6305B-Transmission-Parts-ManualDocument18 pagesMANUAL 6305B Eaton-Fuller-FS-6305B-Transmission-Parts-ManualNelson Chamorro LunaNo ratings yet

- Bendix BX 2150Document36 pagesBendix BX 2150Marcos Valdez100% (1)

- Air Intake System Exhaust System Exhaust GasDocument2 pagesAir Intake System Exhaust System Exhaust Gassinger50No ratings yet

- Installation Instruction: Lubricating Oil Filter Bypass ValveDocument6 pagesInstallation Instruction: Lubricating Oil Filter Bypass ValveSean DuncanNo ratings yet

- Mack Maxitorque Es 10 Speed Transmission t310Document3 pagesMack Maxitorque Es 10 Speed Transmission t310Octavio Bellido100% (1)

- Jacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040BDocument4 pagesJacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040Bvasanth kumar100% (1)

- 100-6920 ADAPTER Cat® Parts StoreDocument1 page100-6920 ADAPTER Cat® Parts StoreMohmed Abo Elftoh100% (1)

- Catalogo Bushing Stemco para Kenworth PDFDocument7 pagesCatalogo Bushing Stemco para Kenworth PDFJuan Carlos FuentesNo ratings yet

- API 650 Manhole Torque Values PDFDocument2 pagesAPI 650 Manhole Torque Values PDFRufina Reyes100% (1)

- ss3104c Pegasus Atc 800Document4 pagesss3104c Pegasus Atc 800iBusinessLogicNo ratings yet

- 6S750 SpareParts1 PDFDocument10 pages6S750 SpareParts1 PDFLuisYFer1No ratings yet

- Thermal Recirculation Valve Installation InstructionsDocument7 pagesThermal Recirculation Valve Installation InstructionsSean DuncanNo ratings yet

- Copia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Document73 pagesCopia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Gallego CarlosNo ratings yet

- 3406C GENERATOR SET ENGINE CaterpillarDocument1 page3406C GENERATOR SET ENGINE CaterpillarAmazonas ManutençãoNo ratings yet

- Cumins n14Document2 pagesCumins n14Faudy Jonas Gonzalez CastilloNo ratings yet

- Static Injector TimingDocument12 pagesStatic Injector TimingMohamed Mohamed100% (1)

- TR Cummins C TSLDocument1 pageTR Cummins C TSLmaher mlbaseNo ratings yet

- TR Cummins C TSLDocument1 pageTR Cummins C TSLNaveedNo ratings yet

- BdjsjjaDocument10 pagesBdjsjjaX'mix ĐreamerNo ratings yet

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDocument4 pagesSilicon NPN Power Transistors: Savantic Semiconductor Product SpecificationX'mix ĐreamerNo ratings yet

- Spareparts, Service and Technical Supplay ForDocument1 pageSpareparts, Service and Technical Supplay ForX'mix ĐreamerNo ratings yet

- Adjust Valve Lash PDFDocument7 pagesAdjust Valve Lash PDFX'mix ĐreamerNo ratings yet

- Product Knowledge 2 Engine 4JB1: Isuzu Training Center - 1Document14 pagesProduct Knowledge 2 Engine 4JB1: Isuzu Training Center - 1X'mix ĐreamerNo ratings yet

- Product Knowledge 2 Engine 4JB1: Isuzu Training Center - 1Document14 pagesProduct Knowledge 2 Engine 4JB1: Isuzu Training Center - 1X'mix ĐreamerNo ratings yet

- Hydraulic Breaker Specification PDFDocument1 pageHydraulic Breaker Specification PDFX'mix ĐreamerNo ratings yet

- EC25C32 32kbits SPI Serial EEPROM: General DescriptionDocument16 pagesEC25C32 32kbits SPI Serial EEPROM: General DescriptionX'mix ĐreamerNo ratings yet

- DS/DA-T Series: Instruction ManualDocument1 pageDS/DA-T Series: Instruction ManualX'mix ĐreamerNo ratings yet

- Ds Da T en Ma 20171107 HeDocument36 pagesDs Da T en Ma 20171107 HeX'mix ĐreamerNo ratings yet

- RM25C32DS 32-Kbit 1.65V Minimum Non-Volatile Serial EEPROM Spi BusDocument36 pagesRM25C32DS 32-Kbit 1.65V Minimum Non-Volatile Serial EEPROM Spi BusX'mix ĐreamerNo ratings yet

- Automotive Electronics Automotive Electronics Product Information Evaluation Circuit For Sensor Impedance Ratios - CC215Document2 pagesAutomotive Electronics Automotive Electronics Product Information Evaluation Circuit For Sensor Impedance Ratios - CC215X'mix ĐreamerNo ratings yet

- DMN-EDC Release-1 Quick Schematics: GND +12v Drain Source GateDocument1 pageDMN-EDC Release-1 Quick Schematics: GND +12v Drain Source GateX'mix Đreamer100% (1)

- GetApplicationAttachment PDFDocument216 pagesGetApplicationAttachment PDFX'mix ĐreamerNo ratings yet

- Honeywell Sensing Temperature Sensors Line Guide 0 1109480Document12 pagesHoneywell Sensing Temperature Sensors Line Guide 0 1109480X'mix ĐreamerNo ratings yet

- Cpci Ea221 o I de en UsDocument40 pagesCpci Ea221 o I de en UsX'mix ĐreamerNo ratings yet

- Diagnostico Backup Switch 320DDocument1 pageDiagnostico Backup Switch 320DX'mix ĐreamerNo ratings yet

- Buk98180 100aDocument12 pagesBuk98180 100aX'mix ĐreamerNo ratings yet

- AD7730 EvalBoardDocument8 pagesAD7730 EvalBoardX'mix ĐreamerNo ratings yet

- SOT223Document5 pagesSOT223X'mix ĐreamerNo ratings yet