Professional Documents

Culture Documents

Bolt Nuts IS0 898-1 & 2 1992

Bolt Nuts IS0 898-1 & 2 1992

Uploaded by

Umer Farooq0 ratings0% found this document useful (0 votes)

11 views2 pagesBolt nuts IS0 898-1 & 2 1992

Original Title

Bolt nuts IS0 898-1 & 2 1992

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBolt nuts IS0 898-1 & 2 1992

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesBolt Nuts IS0 898-1 & 2 1992

Bolt Nuts IS0 898-1 & 2 1992

Uploaded by

Umer FarooqBolt nuts IS0 898-1 & 2 1992

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Table 2 — Designation system for nuts with nominal

heights > 0,6)

T

a

| Mating bots

Property | sive | styte2

ut Clean

Property class | THAT | Tiyead van

ty otass | range

4 | aecmas | sue | ome

26 48 48

OTE Im ganaral, nts of a ghar property class can ve

place nurs of 8 lower proparty class. Tia ie dasa

Fotijnet assembly qoing tito # sirece higher than the yld

sires or the sess under proot led

3.2 Nuts with nominal heights > 0,51) but

< 0,8) (effective heights of thread > 0.4) but

< 062)

Nuts with nominal heights > 0.5 but < 0,8 (etfec-

tive height of thread > 0.41) but < 0.60) are desig-

nated by a combination of two numbers. the second

indicates the nominal stress under proo! load on a

hardened test mandrel, while the first indicates that

the loadability of a boll-nut assembly is reduced in

comparison with the loadabilily on a hardened lest

mandrel and also in comparison with a ball-nut as-

sembly described in 3.1, The effective loading ca-

pacity is not only determined by the hardness of the

‘nut and the effective height of thread bul also by the

tensile strength of the bolt with which the nut is as-

sembled, Table3 gives the designation system and

the stresses under proof load of the nuts. Proof

loads are shown in lable 6. A guide for minimum

expected stripping strengths of the joints when

These mits are assembled wilh bolts of various

property classes is shown in table7,

ISO 898-2:1992(E)

Table 3 — Designation system and stresses under

proof load for nuts with nominal heights > 0,50 but

<0.8D

ominal stress | Actual sirese

Property class of | under proottead | under proof toad

= Nim? Newt

om «00 00

05 500) 500

4 Materials

Nuts shall be made of steel conforming to the

chemical composition limits specified in table 4

Chemie

Property class oe

ce [un |e | s

aan en oso | | oceo | 0.180

oa” | 058 | 025 | oe | 0,180

052 | 058 | 020 | oo | ose

we ~ | oss | 04s | oss | oss

1) Nuts of these property classes mey be manufactured

from treating stot uniess othernse agreed between the

fpurchassr and the manufacture. In auch cages the folting

fraxinm suite, phosphorus and leay contents are pe

sullur 0.38 %: phosphorus 0,11 % lead 0.95%.

2). Alloying elements may be added, if necessary, to de

Uniop the mechanical prapertias of tha ns,

Nuts of property classes 05, 8 (style 1 above M16),

40 and 12 shall be hardened and tempered.

5 Mechanical properties

When tested by the methods described in clause 8,

the nuls shall have the mechanical properties set

ut in tabie 5

BS EN ISO 898.1:2009

ISO 898-1:2009(E)

Table 2— Steels

7 i Chemical T =

i ‘composition limits, \ te

roperty | {cast analysis, %] * =

Property Material and neat teatment | {east analysis, %)

bog p js jee ‘

I temin_ | max. | max | max _| max sin

464 | | | :

| — | 059 | 0.080 Joos | = |

aa¢ i i 2

G8° | Gatonsteeoccotonste wih acsines [3 05s | onso oom} g | —

at] — 085 | a950 | 0080 | 3

Be | 0.15 | 0,55 | 0.059 | 0,060

Carbon steel wih adaiives (eg Boren or Wal og]

‘or Cr} quenched and tempered 0.15% | 0.40 | 0,025 | 0,025

or i

' 025 | 08s | 025 | 0026

8.8! | Carbon stael quenched and tempered | ! pore eee

fa | o20 | 05s }o0%8 fooas| |

| Alloy ste quenched and temoared? eet I

Carbon steel with additives (e.g. Boron or Ma ae

| or Cr) quenched and tempered PN AS eter tee i

or | | |

' | 2s | ass | 0025 | a02s ‘

88' | caibon stee! quenched and temgered i Boag es

ie | 920 | 055 | 0025 | ozs

| Aloy seo! quenched and temperea? t |

Carbon steel win adaitves (2-9. Boron or in |g 250 1

or Cr) quenched and tempered 020° | 0.55 | 0.026 | 0.025 |

— 1 |

1 1 | 029 | 055 | 0025 } 0.025 i

10.9" | Carbon stool quenched and tempered I i poe ps

or t

| 0,20 1 0.55 | 0,025 | 0,025

{ Aloy tee! quenched and tempered 9 [97 | !

12.9%" [Alloy steel quenched and temaered 9 | 0.30 | 0.50 | 0025 | 0.025 | 000s [425

Tai | Carbon siesi with additives (e.g. Boron or Mn |

128'" | orcrortelyodenum) quenched and tempered | °26 | 9.50 | 0,025 | 0.028 | 0.005 cu

3 nease of dspute, te product analysis applies

‘Boron content can reath 0,005 %. provided inst nar-etective boron is cantaled by addon of Ltanium andlor aluminium

© For cold forged fasteners of propery classes 46 and 5.5, heat trealmert ofthe wire used for col forging oof the ais forges

fastener itself may be necessary 10 azneve required ductty

4 Free cuting steels alow for these property lasses vvth the folevang mavimum suiphut. phosphorus and lead contents

suipnt 0.94%, phosphorus 0,71 lead 0.35%,

© Incase of pian cargon boron stat wth a earbon content below 0.25 % (cas analysis), the minimum manganese content shel be

0.6 %tor property cles 88 and 0.7 % for a8 and 109

For tha materials of these property classes. there shall be 9 suffient hardenablity to ensure 3 structure consisting of

appronimately 90s martensite nthe Cove of re headed sections fr the fasteners inthe “as-hardenee” condion before temsering.

0 This alloy ste! shat conlain atleast one of the Tofoving etements in ine minmum quantity gan. chvomium 0:30°%, nickel

0,30 %. molybdenum 0.29 % vanadium 0,19. Whara elements af specified in combinatians of hwo, thre or four and have alloy

‘contenis less than those glen above th ir valu fo be appied for steel cass determination 6 70% ofthe Sum othe inact Bent

‘yaluzs showin above forthe two, tae 0” four elomorts concerned

|A melalograpivealy detectable whe phosphorus enviched layer net pormites for property lass 129172. W shal be detected

by asulable ast metho

' Cauionie advied wien the use of propery class 129112 8 is corsiared. The capably of the fastener manufacturer, the senace

cenditons and the wrencring methods shoud be cansiered. Envirarments may cause stess corrosion cracking of fasteners 28

proceseed ae well a Hote coated

18180 2008 Al ight reserved 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AL1 Programmer 2017Document34 pagesAL1 Programmer 2017Umer Farooq75% (4)

- SBP Portal: Case SubmittedDocument1 pageSBP Portal: Case SubmittedUmer FarooqNo ratings yet

- Apex Arcade LiftDocument1 pageApex Arcade LiftUmer FarooqNo ratings yet

- MS. DYNAST ASSOCIATES (TOPCITY-1) Top Associates ProjectDocument1 pageMS. DYNAST ASSOCIATES (TOPCITY-1) Top Associates ProjectUmer FarooqNo ratings yet

- Mel 03 - 08F1 - Double EntraDocument1 pageMel 03 - 08F1 - Double EntraUmer FarooqNo ratings yet

- Lift Inspection ReportDocument6 pagesLift Inspection ReportUmer FarooqNo ratings yet

- Construction DWG (S-17)Document1 pageConstruction DWG (S-17)Umer FarooqNo ratings yet

- Screenshot 2022-06-09 at 5.12.36 PMDocument2 pagesScreenshot 2022-06-09 at 5.12.36 PMUmer FarooqNo ratings yet

- Mel 03 - 08C4 - Offset-LDocument1 pageMel 03 - 08C4 - Offset-LUmer FarooqNo ratings yet

- Mel 03 - 08e1 - Back Rt.Document1 pageMel 03 - 08e1 - Back Rt.Umer FarooqNo ratings yet

- Mel 03 - 08D2 - RightDocument1 pageMel 03 - 08D2 - RightUmer FarooqNo ratings yet

- Aad03040d OlDocument212 pagesAad03040d OlUmer FarooqNo ratings yet

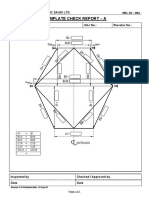

- Template Check Report - D1: Mitsubishi Electric Saudi LTDDocument1 pageTemplate Check Report - D1: Mitsubishi Electric Saudi LTDUmer FarooqNo ratings yet

- Project #: Project Name: Elevator #: Installed By: Inspected By: DateDocument1 pageProject #: Project Name: Elevator #: Installed By: Inspected By: DateUmer FarooqNo ratings yet

- Mel 03 - 08e2 - Back Lt.Document1 pageMel 03 - 08e2 - Back Lt.Umer FarooqNo ratings yet

- Mel 03 - 08C1 - Elenessa-LDocument1 pageMel 03 - 08C1 - Elenessa-LUmer FarooqNo ratings yet

- Mel 03 - 08C4 - Offset-LeftDocument1 pageMel 03 - 08C4 - Offset-LeftUmer FarooqNo ratings yet

- Catalog From ValiaDocument40 pagesCatalog From ValiaUmer FarooqNo ratings yet

- Mel 03 - 08B1 (Straight OfsetDocument1 pageMel 03 - 08B1 (Straight OfsetUmer FarooqNo ratings yet

- Mel 03 - 08C2 - ElenessaDocument1 pageMel 03 - 08C2 - ElenessaUmer FarooqNo ratings yet

- Mel 03 - 08C3 - Offset-RiDocument1 pageMel 03 - 08C3 - Offset-RiUmer FarooqNo ratings yet

- Installation StandardDocument219 pagesInstallation StandardUmer FarooqNo ratings yet

- Template Check Report - A: Mitsubishi Electric Saudi LTDDocument1 pageTemplate Check Report - A: Mitsubishi Electric Saudi LTDUmer FarooqNo ratings yet

- CV320 (L, LL) Riding-Comfort Adjustment Procedure Instruction ManualDocument73 pagesCV320 (L, LL) Riding-Comfort Adjustment Procedure Instruction ManualUmer Farooq100% (3)

- BS Stds For Elev EscDocument2 pagesBS Stds For Elev EscUmer FarooqNo ratings yet

- Spare Part ListDocument8 pagesSpare Part ListUmer FarooqNo ratings yet

- Swline User ManualDocument32 pagesSwline User ManualUmer FarooqNo ratings yet