Cooler Efficiency

Attapong Sathitmanothum

Cement (Thung Song)

30 June 2005

Siam Cement Industry Co.,Ltd.

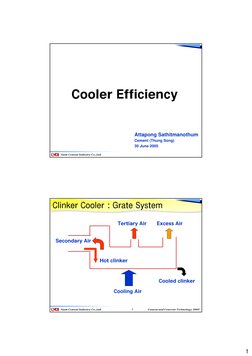

Clinker Cooler : Grate System

Tertiary Air Excess Air

Secondary Air

Hot clinker

Cooled clinker

Cooling Air

Siam Cement Industry Co.,Ltd. 2 Cement and Concrete Technology 2005’

1

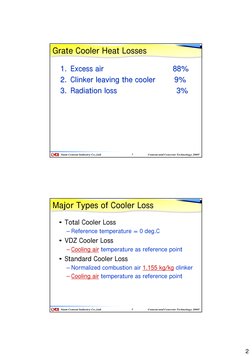

�Grate Cooler Heat Losses

1. Excess air 88%

2. Clinker leaving the cooler 9%

3. Radiation loss 3%

Siam Cement Industry Co.,Ltd. 3 Cement and Concrete Technology 2005’

Major Types of Cooler Loss

• Total Cooler Loss

– Reference temperature = 0 deg.C

• VDZ Cooler Loss

– Cooling air temperature as reference point

• Standard Cooler Loss

– Normalized combustion air 1.155 kg/kg clinker

– Cooling air temperature as reference point

Siam Cement Industry Co.,Ltd. 4 Cement and Concrete Technology 2005’

2

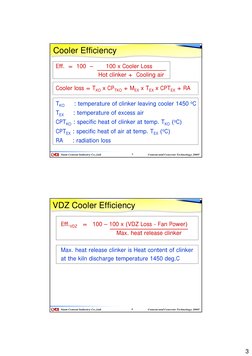

�Cooler Efficiency

Eff. = 100 – 100 x Cooler Loss

Hot clinker + Cooling air

Cooler loss = TKO x CPTKO + MEX x TEX x CPTEX + RA

TKO : temperature of clinker leaving cooler 1450 oC

TEX : temperature of excess air

CPTKO : specific heat of clinker at temp. TKO (oC)

CPTEX : specific heat of air at temp. TEX (oC)

RA : radiation loss

Siam Cement Industry Co.,Ltd. 5 Cement and Concrete Technology 2005’

VDZ Cooler Efficiency

Eff.VDZ = 100 – 100 x (VDZ Loss - Fan Power)

Max. heat release clinker

Max. heat release clinker is Heat content of clinker

at the kiln discharge temperature 1450 deg.C

Siam Cement Industry Co.,Ltd. 6 Cement and Concrete Technology 2005’

3

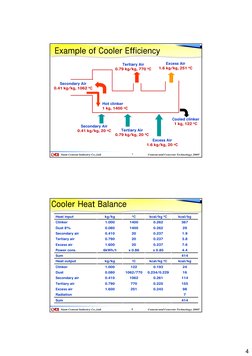

�Example of Cooler Efficiency

Tertiary Air Excess Air

0.79 kg/kg, 770 oC 1.6 kg/kg, 251 oC

Secondary Air

0.41 kg/kg, 1062 oC

Hot clinker

1 kg, 1400 oC

Cooled clinker

1 kg, 122 oC

Secondary Air

0.41 kg/kg, 20 oC Tertiary Air

0.79 kg/kg, 20 oC

Excess Air

1.6 kg/kg, 20 oC

Siam Cement Industry Co.,Ltd. 7 Cement and Concrete Technology 2005’

Cooler Heat Balance

Heat input kg/kg oC kcal/kg oC kcal/kg

Clinker 1.000 1400 0.262 367

Dust 8% 0.080 1400 0.262 29

Secondary air 0.410 20 0.237 1.9

Tertiary air 0.790 20 0.237 3.8

Excess air 1.600 20 0.237 7.6

Power cons. 6kWh/t x 0.86 x 0.85 4.4

Sum 414

Heat output kg/kg oC kcal/kg oC kcal/kg

Clinker 1.000 122 0.193 24

Dust 0.080 1062/770 0.234/0.229 16

Secondary air 0.410 1062 0.261 114

Tertiary air 0.790 770 0.225 155

Excess air 1.600 251 0.243 98

Radiation 7

Sum 414

Siam Cement Industry Co.,Ltd. 8 Cement and Concrete Technology 2005’

4

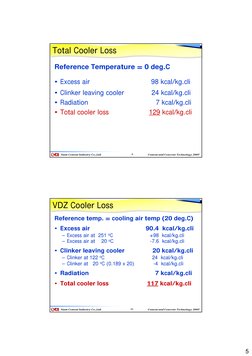

�Total Cooler Loss

Reference Temperature = 0 deg.C

• Excess air 98 kcal/kg.cli

• Clinker leaving cooler 24 kcal/kg.cli

• Radiation 7 kcal/kg.cli

• Total cooler loss 129 kcal/kg.cli

Siam Cement Industry Co.,Ltd. 9 Cement and Concrete Technology 2005’

VDZ Cooler Loss

Reference temp. = cooling air temp (20 deg.C)

• Excess air 90.4 kcal/kg.cli

– Excess air at 251 oC +98 kcal/kg.cli

– Excess air at 20 oC -7.6 kcal/kg.cli

• Clinker leaving cooler 20 kcal/kg.cli

– Clinker at 122 oC 24 kcal/kg.cli

– Clinker at 20 oC (0.189 x 20) -4 kcal/kg.cli

• Radiation 7 kcal/kg.cli

• Total cooler loss 117 kcal/kg.cli

Siam Cement Industry Co.,Ltd. 10 Cement and Concrete Technology 2005’

5

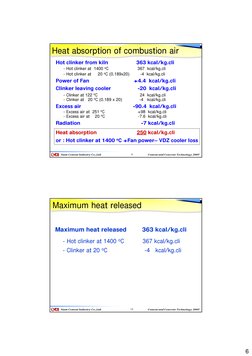

�Heat absorption of combustion air

Hot clinker from kiln 363 kcal/kg.cli

- Hot clinker at 1400 oC 367 kcal/kg.cli

- Hot clinker at 20 oC (0.189x20) -4 kcal/kg.cli

Power of Fan +4.4 kcal/kg.cli

Clinker leaving cooler -20 kcal/kg.cli

- Clinker at 122 oC 24 kcal/kg.cli

- Clinker at 20 oC (0.189 x 20) -4 kcal/kg.cli

Excess air -90.4 kcal/kg.cli

- Excess air at 251 oC +98 kcal/kg.cli

- Excess air at 20 oC -7.6 kcal/kg.cli

Radiation -7 kcal/kg.cli

Heat absorption 250 kcal/kg.cli

or : Hot clinker at 1400 oC +Fan power– VDZ cooler loss

Siam Cement Industry Co.,Ltd. 11 Cement and Concrete Technology 2005’

Maximum heat released

Maximum heat released 363 kcal/kg.cli

- Hot clinker at 1400 oC 367 kcal/kg.cli

- Clinker at 20 oC -4 kcal/kg.cli

Siam Cement Industry Co.,Ltd. 12 Cement and Concrete Technology 2005’

6

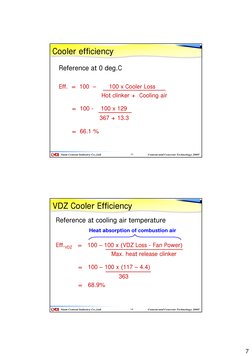

�Cooler efficiency

Reference at 0 deg.C

Eff. = 100 – 100 x Cooler Loss

Hot clinker + Cooling air

= 100 - 100 x 129

367 + 13.3

= 66.1 %

Siam Cement Industry Co.,Ltd. 13 Cement and Concrete Technology 2005’

VDZ Cooler Efficiency

Reference at cooling air temperature

Heat absorption of combustion air

Eff.VDZ = 100 – 100 x (VDZ Loss - Fan Power)

Max. heat release clinker

= 100 – 100 x (117 – 4.4)

363

= 68.9%

Siam Cement Industry Co.,Ltd. 14 Cement and Concrete Technology 2005’

7

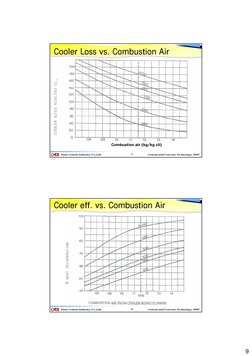

�VDZ cooler loss vs. Combustion Air

Siam Cement Industry Co.,Ltd. 15 Cement and Concrete Technology 2005’

Example

Siam Cement Industry Co.,Ltd. 16 Cement and Concrete Technology 2005’

8

�Cooler Loss vs. Combustion Air

Combustion air (kg/kg cli)

Siam Cement Industry Co.,Ltd. 17 Cement and Concrete Technology 2005’

Cooler eff. vs. Combustion Air

Siam Cement Industry Co.,Ltd. 18 Cement and Concrete Technology 2005’

9

� End

Siam Cement Industry Co.,Ltd. 19 Cement and Concrete Technology 2005’

10