Professional Documents

Culture Documents

Flars101 PDF

Uploaded by

TGM KalimantanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flars101 PDF

Uploaded by

TGM KalimantanCopyright:

Available Formats

Flowserve Desuperheaters

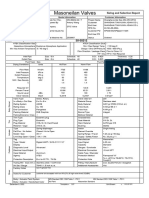

TECHNICAL REQUIREMENT SHEET

Customer name: Project: Representative/AE:

End user: Job site location: Quantity:

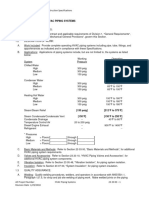

V apor C ool Fixed Nozzle Desuperheater

Product specifications

Steam pipe size range: 4” – 48”

Pressure class range: 150 – 2500

Cv range: 0.06 – 20

Rangeability: up to 1:5

Mounting flange1: 3” – 12”

Cooling water flange1: 0.5” – 4”

Cooling water valve is required

1

Up to ANSI Class 2500 Figure 1: VaporCool Desuperheater Schematic

V C ari ool Variable Nozzle Desuperheater

Product specifications

Steam pipe size range: 6” – 40”

Pressure class range: 150 – 2500

Cv range: 0.15 – 7.37

Rangeability: up to 1:23

Mounting flange2: 3” or 4”

Cooling water flange2: 1” or 1.5”

Cooling water valve is not required

2

Up to ANSI Class 2500 Figure 2: VariCool Desuperheater Schematic

Process Requirements

Maximum Design Minimum Other

STEAM CONDITIONS Condition Condition Condition Condition

Upstream Temperature T1

Upstream Pressure P1

Upstream Mass Flow Rate M1

Downstream Temperature T2

COOLING WATER CONDITIONS

Upstream Temperature Tw

Upstream Pressure Pw

Upstream Mass Flow Rate (optional) Mw

STEAM PIPE SPECIFICATIONS COOLING WATER PIPE SPECIFICATIONS

Pipe size Pressure class Pipe size Pressure class

Pipe schedule Pipe material Pipe orientation No. (see Figure 2, Section A-A)

TEE SPOOL REQUIRED?

Yes Insulation thickness (inches) Face to face length (inches) L

No Desuperheater mounting flange size Desuperheater mounting flange pressure class

Distance from centerline to mounting flange face F Do flange holes straddle steam pipe centerline?

DESUPERHEATER MATERIAL

Carbon Steel Stainless Steel

Desuperheater Technical Requirement Sheet 03/2003 © Flowserve Corporation, Flow Control Division, Tel. 1+ 801.489.8611

You might also like

- m43 Aux. BoilerDocument657 pagesm43 Aux. BoilerPavel PaskarNo ratings yet

- 00 Cheat SheetDocument7 pages00 Cheat SheetNiell Anakeen dela CruzNo ratings yet

- Direct Contact Desuperheaters TI-P475-01Document9 pagesDirect Contact Desuperheaters TI-P475-01LucasZanaNo ratings yet

- SAMSON ANTI CAVITATION 3 TrimsDocument8 pagesSAMSON ANTI CAVITATION 3 TrimsShaheen HydrosNo ratings yet

- Boiler Data Sheet: Process Design ConditionsDocument6 pagesBoiler Data Sheet: Process Design ConditionsecsuperalNo ratings yet

- RAMC GS01R01B02-00E-E Ed28 Pub22032019Document24 pagesRAMC GS01R01B02-00E-E Ed28 Pub22032019zaffarNo ratings yet

- Instrumentation Scheme of Thermal Power Plant: By: Shilpa Mishra ME, IC, Panjab UniversityDocument39 pagesInstrumentation Scheme of Thermal Power Plant: By: Shilpa Mishra ME, IC, Panjab UniversityKadiyam VijayNo ratings yet

- Variable Reach 1101 Serie Top Loading Arm: Technical SpecificationsDocument2 pagesVariable Reach 1101 Serie Top Loading Arm: Technical SpecificationsRenalyn TorioNo ratings yet

- Calculation Header: Rtkcalc Powered by Conval® Version 2.0 (Build 2.0.2)Document3 pagesCalculation Header: Rtkcalc Powered by Conval® Version 2.0 (Build 2.0.2)Ahmed KhairiNo ratings yet

- Bopp & Reuther CatalogueDocument60 pagesBopp & Reuther CatalogueIrfan BagwanNo ratings yet

- Feed Water TanksDocument4 pagesFeed Water TanksvirtualmecanicaNo ratings yet

- Vortex Flow Meter - Vetrix VT Series - Dpstar GroupDocument1 pageVortex Flow Meter - Vetrix VT Series - Dpstar GroupamirulNo ratings yet

- Data Sheet For DP Flow Transmitter - JBF Manglore PTA PlantDocument3 pagesData Sheet For DP Flow Transmitter - JBF Manglore PTA Plantmayukhguha1988No ratings yet

- II 3 Technical Data - HVACDocument206 pagesII 3 Technical Data - HVACAnh Vân Trần100% (1)

- Tigris K5/M5: Technical DatasheetDocument2 pagesTigris K5/M5: Technical DatasheetHana MustofaNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterJane Umali CastilloNo ratings yet

- Diaphragm Pump 3NDocument12 pagesDiaphragm Pump 3Nnanivenkat459No ratings yet

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaNo ratings yet

- 32 - Seamless EO Steel Tubes Material E235N (St. 37.4)Document6 pages32 - Seamless EO Steel Tubes Material E235N (St. 37.4)samohaomer001No ratings yet

- PIP Line ListDocument2 pagesPIP Line Listomgmatt100% (1)

- Therma V Split Dec 2012Document52 pagesTherma V Split Dec 2012Osmar Franco PiresNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- 2.4. Sistema de Flotacion de Aire (5450-DAF-001)Document3 pages2.4. Sistema de Flotacion de Aire (5450-DAF-001)Jennifer FigueroaNo ratings yet

- Data Sheet Daniel Series 700 Model v788 en 6385002Document10 pagesData Sheet Daniel Series 700 Model v788 en 6385002Marcelo PinheiroNo ratings yet

- Jspl-Refilling StationDocument21 pagesJspl-Refilling StationNaveen Kumar ChauhanNo ratings yet

- B 202 TW 042 - 201105 00406 - EnglishDocument1 pageB 202 TW 042 - 201105 00406 - EnglishNavid DavaniNo ratings yet

- Sta-Rite PRO-Storm DSS Series: Multi-Stage Sprinkler PumpsDocument2 pagesSta-Rite PRO-Storm DSS Series: Multi-Stage Sprinkler PumpsDagoberto CerrudNo ratings yet

- Pump Sizing CalculationDocument12 pagesPump Sizing Calculationionutlaur86No ratings yet

- Pipe 3 Pipe Details: Pipeline ReportDocument4 pagesPipe 3 Pipe Details: Pipeline ReportAdil RasheedNo ratings yet

- F Ans S SysytemDocument5 pagesF Ans S SysytemShivani SinghNo ratings yet

- ANEXO II - de NadaDocument2 pagesANEXO II - de NadaRafael BarretoNo ratings yet

- PRV47-valvula Reguladora Presion PiloteadaDocument8 pagesPRV47-valvula Reguladora Presion PiloteadareneNo ratings yet

- Specifications POMPADocument4 pagesSpecifications POMPAArataNo ratings yet

- DE420008 P2.x P2.8xDocument6 pagesDE420008 P2.x P2.8xseve1No ratings yet

- ELT-01-EP-TS-0005 - Specification For Manual Valve - R0Document20 pagesELT-01-EP-TS-0005 - Specification For Manual Valve - R0jorgekarlosprNo ratings yet

- Series 240 Type 3244-1 and Type 3244-7 Pneumatic Control Valves Type 3244 Three-Way ValveDocument16 pagesSeries 240 Type 3244-1 and Type 3244-7 Pneumatic Control Valves Type 3244 Three-Way ValveDaniela Margarita BarreraNo ratings yet

- TIP 651mHNK - enDocument4 pagesTIP 651mHNK - enJanez PartNo ratings yet

- Problem Statement:: Bleed Valve (0 - 90)Document3 pagesProblem Statement:: Bleed Valve (0 - 90)MFUHNo ratings yet

- Man Sse Nae 8Document8 pagesMan Sse Nae 8Jorge Gustavo GoyecheaNo ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- DS0256 Standard US ENDocument4 pagesDS0256 Standard US ENkicsnerNo ratings yet

- Process Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VDocument6 pagesProcess Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VadjiNo ratings yet

- HIPPOValve Catalog DoubleBfly 950106Document12 pagesHIPPOValve Catalog DoubleBfly 950106maxh blumNo ratings yet

- Melegvíz TartályokDocument5 pagesMelegvíz TartályokKovács TamásNo ratings yet

- Avf7000v1 1Document4 pagesAvf7000v1 1keykakyNo ratings yet

- Bơm EurofloDocument8 pagesBơm EuroflokimcucspktNo ratings yet

- AFT Trolley 50-02Document2 pagesAFT Trolley 50-02Forum PompieriiNo ratings yet

- Technical Details of 1 Ton Jute BoilerDocument12 pagesTechnical Details of 1 Ton Jute BoilerPial KhanNo ratings yet

- Centravac Centrifugal Chiller Product ReportDocument6 pagesCentravac Centrifugal Chiller Product ReportHiei ArshavinNo ratings yet

- 800KW Evaporative Condenser ProposalDocument3 pages800KW Evaporative Condenser ProposalGeofry Joan Jimenez TorresNo ratings yet

- 23 20 00 Hvac Piping SystemsDocument14 pages23 20 00 Hvac Piping Systemsamirshahi2019No ratings yet

- Manual Valve List: For Information For Review For Construction ForDocument43 pagesManual Valve List: For Information For Review For Construction Forraul gonzalezNo ratings yet

- 42gwc New Catalogue PDFDocument12 pages42gwc New Catalogue PDFAugusto OrellanaNo ratings yet

- LPG Compressor SpecsDocument11 pagesLPG Compressor SpecsabhishekNo ratings yet

- DS ERHARD BEV Sewage Air Valves enDocument9 pagesDS ERHARD BEV Sewage Air Valves enSijo JoyNo ratings yet

- Think Safety !: Cat. No. GC-100 Vol.2Document16 pagesThink Safety !: Cat. No. GC-100 Vol.2Ahmed SaidNo ratings yet

- Pump Duty Points - DesDocument8 pagesPump Duty Points - DesMaqsood NishatNo ratings yet

- Parker 341 SolenoidDocument2 pagesParker 341 SolenoidIan SanNo ratings yet

- Medidor Caudal Kobold Aleta TSKDocument6 pagesMedidor Caudal Kobold Aleta TSKBase SistemasNo ratings yet

- Experimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionFrom EverandExperimental Fluid Mechanics: The Commonwealth and International Library: Thermodynamics and Fluid Mechanics DivisionRating: 4 out of 5 stars4/5 (2)

- Pulmonary EmbolismDocument48 pagesPulmonary Embolismganga2424100% (3)

- Design and Analysis of Modified Front Double Wishbone Suspension For A Three Wheel Hybrid VehicleDocument4 pagesDesign and Analysis of Modified Front Double Wishbone Suspension For A Three Wheel Hybrid VehicleRima AroraNo ratings yet

- C4 Vectors - Vector Lines PDFDocument33 pagesC4 Vectors - Vector Lines PDFMohsin NaveedNo ratings yet

- Chinese Paper Cutting Work SheetDocument4 pagesChinese Paper Cutting Work Sheet黃梓No ratings yet

- The Privatization PolicyDocument14 pagesThe Privatization PolicyRIBLEN EDORINANo ratings yet

- Pipe Cleaner Lesson PlanDocument2 pagesPipe Cleaner Lesson PlanTaylor FranklinNo ratings yet

- DS Agile - Enm - C6pDocument358 pagesDS Agile - Enm - C6pABDERRAHMANE JAFNo ratings yet

- Bandhan Neft Rtgs FormDocument2 pagesBandhan Neft Rtgs FormMohit Goyal50% (4)

- The Wayland News October 2014Document16 pagesThe Wayland News October 2014Julian HornNo ratings yet

- Biology Key Stage 4 Lesson PDFDocument4 pagesBiology Key Stage 4 Lesson PDFAleesha AshrafNo ratings yet

- Application of Geoelectric Method For GroundwaterDocument11 pagesApplication of Geoelectric Method For GroundwaterMunther DhahirNo ratings yet

- Airport & Harbour Engg-AssignmentDocument3 pagesAirport & Harbour Engg-AssignmentAshok Kumar RajanavarNo ratings yet

- ZygalDocument22 pagesZygalShubham KandiNo ratings yet

- All Day Breakfast: .Served With Cappuccino or Espresso or Lime Juice or TeaDocument7 pagesAll Day Breakfast: .Served With Cappuccino or Espresso or Lime Juice or TeaBryan KuoKyNo ratings yet

- Artificial Intelligence Techniques For Encrypt Images Based On The Chaotic System Implemented On Field-Programmable Gate ArrayDocument10 pagesArtificial Intelligence Techniques For Encrypt Images Based On The Chaotic System Implemented On Field-Programmable Gate ArrayIAES IJAINo ratings yet

- Sankranthi PDFDocument39 pagesSankranthi PDFMaruthiNo ratings yet

- Gracie Warhurst WarhurstDocument1 pageGracie Warhurst Warhurstapi-439916871No ratings yet

- EVOM ManualDocument2 pagesEVOM ManualHouston WhiteNo ratings yet

- Multimodal Essay FinalDocument8 pagesMultimodal Essay Finalapi-548929971No ratings yet

- Computers in Industry: Hugh Boyes, Bil Hallaq, Joe Cunningham, Tim Watson TDocument12 pagesComputers in Industry: Hugh Boyes, Bil Hallaq, Joe Cunningham, Tim Watson TNawabMasidNo ratings yet

- Practical Modern SCADA Protocols. DNP3, 60870.5 and Related SystemsDocument4 pagesPractical Modern SCADA Protocols. DNP3, 60870.5 and Related Systemsalejogomez200No ratings yet

- Elpodereso Case AnalysisDocument3 pagesElpodereso Case AnalysisUsama17100% (2)

- Smart Gas Leakage Detection With Monitoring and Automatic Safety SystemDocument4 pagesSmart Gas Leakage Detection With Monitoring and Automatic Safety SystemYeasin Arafat FahadNo ratings yet

- Smart Protein Plant Based Food Sector Report 2Document199 pagesSmart Protein Plant Based Food Sector Report 2campeon00magnatesNo ratings yet

- CAA Safety Plan 2011 To 2013Document46 pagesCAA Safety Plan 2011 To 2013cookie01543No ratings yet

- 1.SDH Basics PDFDocument37 pages1.SDH Basics PDFsafder wahabNo ratings yet

- Arduino Uno CNC ShieldDocument11 pagesArduino Uno CNC ShieldMărian IoanNo ratings yet

- Ring and Johnson CounterDocument5 pagesRing and Johnson CounterkrsekarNo ratings yet

- Mathematics Mock Exam 2015Document4 pagesMathematics Mock Exam 2015Ian BautistaNo ratings yet

- BARUDocument53 pagesBARUhueuaNo ratings yet