Professional Documents

Culture Documents

Modeling and Simulation of DC Motor Using Simelectronics and Simulink (#557073) - 700506 PDF

Uploaded by

Abdel HassibOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling and Simulation of DC Motor Using Simelectronics and Simulink (#557073) - 700506 PDF

Uploaded by

Abdel HassibCopyright:

Available Formats

Gazi Mühendislik Bilimleri Dergisi

2019, 5(1): 91-100

Araştırma Makalesi/Research Article

gmbd.gazipublishing.com

Modeling and Simulation of DC Motor Using Simelectronics and

Simulink

Ayodeji OKUBANJO*,a, Oluwadamilola OYETOLA a, Olawale OLALUWOYEa , Olufemi

ALAO a, Adeyemi OLATEJUb, Taiwo ABATANb

a,*

Olabisi Onabanjo University, Department of Electrical Electronics Engineering, PMB 2002, Ago Iwoye, NIGERIA

b

Moshood Abiola Polytechnic, Department of Computer Engineering, Ogun State, NIGERIA

ARTICLE ÖZET

INFO

Received: 14.02.2019

Accepted: 20.04.2019

This paper describes the development of mathematical and physical Modeling based simulators in

the Simulink © Simscape TM environment as interactive tools to demonstrate the DC motor

responses in terms of current, speed and torque. This type of Modeling requires to join the physical

Keywords: components with physical connections to define the underlying dynamic equations of the DC

Direct Current Motor, motor. This approach is further compared with the analytical model in Simulink. To support our

Soimulink and proposal, numerical simulations and mathematical Modeling of the DC motor are derived using the

Simelectronics,

Lagrangian and Euler-Lagrange approach contrary to the existing Kirchhoff’s’ and Newton laws.

Hamilton Equation,

Euler-Lagrange, PD The state space model is formulated based on Hamilton’s equation. The simulation models are

developed as part of software laboratory support and to enhance undergraduate control systems

Corresponding and machinery courses at Olabisi Onabanjo UniversityA proportional Derivative (PD) controller is

Authors implemented for both the models to compensate for fast response in the armature current and

okubanjo.ayodeji@oo electromagnetic torque. A comparative study of the model for the separately excited Dc motor has

uagoiwoye.edu.ng shown that the models have their own merits and demerits.

https://dx.doi.org/10.30855/gmbd.2019.01.09

1. INTRODUCTION (GİRİŞ) relation. Hence, a system model can be built in this

To stimulate students’ interest in practical engineering environment in a similar way that a physical system is

based degree and also to bridge the gap between the assembled. Therefore, Simscape as a Virtual Laboratory

practical and theoretical skills, the use of computer - tool enhances students’ motivation to learn and simulate

based software tools has been integrated into the field of dynamic of the complex system in an interactive mode.

Engineering. Presently, educators and researchers In recent times, DC motors have been proven as core

developed a huge variety of resources to enhance the ingredient in speed control and it is gaining a limelight

teaching of Engineering based Laboratory courses. In with integration of renewable energy for most

the Mechatronic and Control field, there are a automobiles and mechatronics applications. It is widely

considerable number of specialized and general purpose used as energy conversion devices[1], serves as a speed

Virtual Laboratory tools available for experimental drive control in electric cars and electric traction[2], [3],

purpose. MATLAB® / Simulink© is introduced to the as an actuators in robotic manipulators [4], [5] and

Engineering curriculum due to their extended use for smart wheelchair[6], used in overhead cranes, medical

both design and the simulation of the control system. treatment, power electronics dc drive applications [7]–

Furthermore, the potential of Simulink© has been [9]. Recently, the demand for DC motors in speed

extended by adding a multitude of toolboxes, among control for hybrid vehicles powered with internal

which are interested in emphasizing Simscape TM for combustion and electric engines is steadily increasing

physical modeling. It is an object-oriented enriched with the attention to reduce fossil-fuel based vehicles

environment which joins the physical components with and to mitigate the global warming gas emissions. The

physical connections to define the underlying dynamic existing works[10]–[12] have been limited to

equation of the system. Unlike other Simulink blocks, formulation of mathematical model using Kirchhoff’s

Simscape directly represents physical elements or law and Newton’s law of motion which is further

92 Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100

converted to frequency domain-Laplace transform to

obtain the system transfer function. However, this paper

proposed a novel Lagrangian and Euler-Lagrange

coupled with Hamilton’s approaches to formulate the

mathematical models and developed two different

simulation models to simulate the system dynamic of

the DC motor accurately and emphasis the usefulness of

such approaches in the field of electrical engineering to

support teaching in automatic control. The general

configuration, dynamic equation, analysis, characteristic

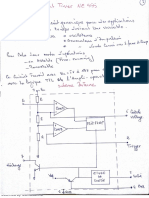

and control of DC motor are presented in Nise[13]. Figure 1. The System Structure of a DC Motor

Pal[14] proposed a generalized dynamic modeling of

DC motor based on state space approach. In Khanna[15] 2.1 Lagrange’s equation (Lagrange denklemi)

presented a model predictive control model for a DC The dynamic equation of the DC motor is determined using

motor. Some models and simulation software based Lagrange’s equation of the second kind. First, we calculate the

related to DC motor are presented in [16]–[18] and kinetic energy T and potential energy, U , of the system and

Gencer[19] further extended model to brushless DC the Rayleigh’s dissipative function is integrated into

Lagrange’s equation to account for the damping and resistive

motor in Simulink. Chen[11] further introduced a

forces in the electromechanical system. In order to describe

Simulink based model. Venu[20] proposed a PID the physical motion of the electromechanical DC motor, we

controller algorithm for DC motor control in state space

domain. A performance comparative analysis of PI choose charge, q1 and the angle of the rotor, q 2 as the

controller and Artificial Intelligent control is generalized coordinates, such that q1 q1, q2 and the

investigated in Abdulrahman[21], [22]. Jafar et al [23] first derivative as generalized current and speed as

proposed an improve rotor speed of a brushless Dc

q1 ia t , q 2 t Thus, the Lagrange function L is

. .

motor using fuzzy controller. In [24] a proportional-

integral (PI) controller is implemented to improve the defined as the difference of the system’s kinetic and potential

battery performance of electric motor vehicle. A java energy.

web-application software is developed for a DC motor

position control in[25] . Similarly, a virtual electrical

machine laboratory tool for Dc the motor is developed L T U (1)

to enhance practical electronic learning of DC moor Denoting by T0 ,U 0 and T1 ,U 1 , the kinetic and

dynamic and responses [26], [27]. The main objective of potential energy in the electrical part and mechanical

this paper is to show the advantages of using physical part respectively. We obtain

modeling to develop interactive resources to support L T0 T1 U 0 U1 (2)

teaching and learning in Automatic Control. Thus, the

idea is to build a simulator for laboratory courses with

which the students can validate their designed controller According to conservation of energy, the kinetic and

so as to provide an alternative to the use of real platform potential energy for the electromechanical DC motor are

that needs a heavy budget in terms of resources. as follows:

2. MATERIAL AND METHODS (MALZEME VE 1 . 2 1 . 2

YÖNTEMLER) T L a q1 J q 2 (3)

2 2

The electromechanical dynamic model of a separately

excited DC motor is formulated based on Lagrange U Vs Vb q1 (4)

equations and Hamilton equation. The system structure

of a DC motor is depicted in Fig.1, including the

armature resistance 𝑅𝑎 and the winding leakage Rayleigh dissipative function in the electromechanical

inductance 𝐿𝑎 . In most servo applications, dc motors are DC motor is:

used in the neighbourhood of linear region of the

magnetization curve, such that the airgap flux ϕ is 1 . 1 .

proportional to the field current. For a separately excited R Ra q 21 B m q 22 (5)

dc motors, the field constant is held constant, so that the 2 2

motor generates a torque 𝑇𝑚 proportional to the

armature current and the back emf 𝑉𝑏 is proportional to Substituting equation 1 3 into the Lagrangian 2

angular velocity of the rotor in the motor. Obviously, gives:

the motor will encounter two external sources, the input

voltage 𝑉𝑠 (𝑡) to drive the motor and the torque

𝑇𝐿 (𝑡) reacted from the load.

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100 93

L L a q 21 J m q 22 V sVb q 1

1 . 1 .

(6)

d

q1 t i a t

2 2 dt

d2 di t

q q1 t a

q i 1 as the generalized

2

Define the vector dt dt

(14)

q 2

0

d

q 2 t m t

coordinate and the matrix H dt

where T m

T mT L d2 d t

2

q 2 t m

is the generalized coordinate torque exerted on q 2 and dt dt

T L as the load torque. Then, the generalized Euler-

Substituting the derived derivatives in equation 14 into

Lagrange equation can be written as

Eqs. 10 and 11 lead to:

di a t R a K

i a t b m t V s t

1

d L L R

H dt La La La (15)

dt qi. qi. q.

(7)

i

d m t K t B

i a t m m t

Lagrange’s equations of the second kind for the 1

electromechanical DC motor in terms of generalized

TL (16)

dt Jm Jm Jm

coordinates are as:

2.1.1. Hamilton’s equation (Hamilton'un denklemi)

d L L R

dt q. q. q.

0 (8)

The Hamiltonian function q, p, t , which is

1 1 1 defined as the sum of the system’s kinetic (inductive)

energy and potential (capacitive) energy can be used to

describe the dynamic equations of an electromechanical

system such as a DC motor. Hence, Hamilton’s function

d L L R

dt q. . . T mT L (9) is expressed as:

2 q2 q2 H T U (17)

L a q 21 J q 22 V sVb q1

1 . 1 .

(18)

After substitution of the partial derivatives, we obtain 2 2

the set of the following second-order differential

equations: Then, Hamilton’s equations:

q i

L a q1 t R a q1 t V b t V s(t )

..

(10) (19)

t p i

J m q 2 t T m t B m q 2 t T L)

.. .

(11)

. G

p1 (20)

q i q i

Thus, the back emf E b t and the torque T m t are

expressed as:

State variables of the DC motor from Fig.1 are the

E b t K b q 2 t

.

(12) charge flowing in the armature circuit and the angle of

the rotor q 1 ,q 2 respectively and momentum p1 , p 2 .

The kinetic (inductive) energy in terms of momentum is

T m t K t q1

.

(13) expressed as:

2 2 2

Hence, the first and second derivatives of the 1 . 1 . p1 p2

generalized coordinates are: L q1 J q 2 2 (21)

2 a 2 2L a 2 J

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

94 Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100

Potential (capacitive) energy In matrix form:

U V sV b q i (22) dq1 t

dt

Rayleigh’s dissipative function or content of the system dp t q1 t

1

dt A. p1 t B.Vs t

dq 2 t q 2 t

T t

1 . 1 . (33)

G R a q 2i B m i q 2i , i 1,2 (23) L

2 2 dt p 2 t

dp t

Generalized linear force for viscous (resistive) damping 2

is expressed as the content of the system function as: dt

G Based on (29), (30),(31), (32) , (14) and choosing the

Qi , i 1,2 (24) state vector x q1 t ,q 2 t ,i a t , t T ,the

q i

dynamic equation of the Dc motor can be expressed in

Generalized forces state space description as:

State equation:

Q e1 0,Q e2 T m t T L t (25)

xt Ax t Bu t

.

(34)

Dynamic equation of the electromechanical DC motor

are obtain in the form: Output equation:

. dq t yt Cxt (34)

q 1 1 (26)

q1 dt

Where the state vector is

. dq t q1 t

q 2 2 (27)

q 2 dt i t

xt a

q 2 t

(35)

dp1 t

m t

Q1 Q e1 (28)

dt q1

and the input vector is:

dp 2 t

Q 2 Q e 2 V t

u t s

(29)

dt q 2

T L t

(36)

So that, Figure 1Figure2. Control loop with PD Controller

and the system matrices are:

dq1 t p1 t 1 0 0 0

(30) R a K b

dt La 0 0

La La

A (37)

dp1 t R 0 1 0 0

.

Vs Vb R a q1 Vs Vb a p1(10 0 Kt B m

0

dt La ) Jm J m

0 0

dq 2 t p 2 t 1

(31)

L 0

dt J

B a (38)

0 0

dp 2 t 0 1

B m q 2 t T m t T L t

.

(32)

dt J m

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100 95

0 1 0 0

C (39)

0 0 0 1

In most dynamic models of the DC motor the variables

to control are predominantly the armature current

(electrical variable), i a t and the angular velocity

(mechanical variable), m t of the motor; in such

case, the system matrices A and B are in the form of

[28].

R a K b 1

L L 0

La

A a , B a (40)

Kt B m 0 1

J m J m J m Figure2. Control loop with PD Controller

and the output is angular velocity m t .

In this model, the full voltage is applied to the armature

2.1.2. PID Controller Implementation (Gecikmeli türev terminals with the varying load torques to investigate

eşitliği tabanlı kaotik sistem modeli)

the speed, current and torque characteristic. Based on

this, a Simulink model for the DC motor is established

The control goal is to stabilize both the current and on the derived Euler-Lagrange and Hamilton’s. Hence,

torque by minimizing the error and to achieve this a physical system is built in Simelectronics as illustrated

stated objective a proportional-Derivative controller is in Figure.3 and Figure.4 respectively. The parameters of

implemented in such a way that the gain of the a separately excited Dc motor in Fig.1are R a 0.5 Ω,

proportional controller, kp, is high to produce a fast La 1.5 mH, J m 0.00025 kgm , K t 0.05 N-m/A,

2

system and the derivative gain kp, is select in a

manner to decrease the oscillation. The PD controller K b 0.05 V/(rad/s). Terminal voltage of the motor is

algorithm combines the P-action and D-action to adjust v s t 2 V. The parameter values are initialized and

the system. It is a two-term controller that is coined

from the PID controller by setting the integral action to simulations are run for several values of load torque in

zero. The term domain expression for PD controller is

the range of TL 0 0.5 N-m. Furthermore, the model is

given as: simulated related to the speed m of DC motor

det

u t k p et k D t (41) without load TL 0 , with load 1 TL 0.3 Nm and load 2

dt

Where u (t) is the control signal, the error signal e (t) is TL 0.5 Nm. Figure 5a and figure 5b show the obtained

defined as e (t) =r (t)-y (t), and r (t) is the reference simulation results of the current and speed respectively.

input signal. In the Simulink and Simelectronics From these figures, it can deduce that it is challenging

models, a PD controller is implemented from the PD to stabilize the responses with the proportional

block in the Simulink toolbox library and converted to a controller alone irrespective of the value of gain K

physical system with Simulink-PS converter for the chosen, hence, a combination of proportional and the

Simelectronics. The tuning of control parameters is derivative controller is implemented to compensate for

done using PID tuner and the best performance of the fast response and steady error respectively. Figure.6

controller parameter values are selected. illustrates the electromagnetic torque and armature

current response with PD controller. Again, from these

2.1.3. Results and Discussion (Sonuçlar ve tartışma) figures we can observe the robustness of the proposed

controller. A comparative study of the model for the

This work presents a novel DC motor modeling based separately excited DC motor has shown that the models

simulators to support teaching in automatic control. The have their own merits and demerits as illustrated in

simulation of the DC model was implemented directly Table1. Furthermore, it can also be deduced from the

using MATLAB/Simulink/Simelectronics. table.1 that students do not need to master the

mathematical equations before using the simulator. In

much related research work [29], the dynamics are

modeled with Kirchhoff’s law and transformed into

transfer function model using Laplace transformation to

aids system analyze in the frequency domain. However,

the novel Simelectronics approach allows for the

description of physical structure of a system rather than

the causal mathematics. The study conducted for the

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

96 Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100

undergraduate students on the use of Simulink and counterpart Simulink tool. Hence, the summary of the

Simscape at Olabisi Onabanjo University revealed that model evaluation is presented in Table1.

Simscape simulation tool has more advantages than the

Table 1.Performance Comparison of the Models

Model Controller Model Responses Easy of Performance Model Students’

Formulation Set-up Accuracy Adaptability

Simulink PD Mathematical Excellent complex Good Prone to Yes, but require

model is required model error continuous

practice

Simelectronics PD Required physical Excellent easy Excellent Free from Yes

network model error

connection

Figure 4.DC motor Simelectronics model

Figure 4. DC motor Simulink model

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100 97

(b)

(a) (b)

Figure.5 Simulation results in Simelectronics and Simulink for (a) current and (b) speed

(b)

(b)

(b)

(a)

Figure.6. Simulation results in Simelectronics and Simulink with PD controller for (a) Electromagnetic Torque and

(b) Armature current.

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

98 Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100

3. CONCLUSION (SONUÇ) Arboleda, “Smart wheelchair with dual control

using touchpad and android mobile device,”

The paper presents modeling and simulation of the Indones. J. Electr. Eng. Informatics, vol. 6, no.

dynamic equations of electromechanical DC motor in 1, pp. 86–96, 2018.

Simelectronics and Simulink and to simulate the

dynamic accurately Lagrange’s and Hamilton’s [7] M. R. Khan, “Speed Control of DC Motor under

equations were adopted contrary to the conventional Varying Load Using PID Controller,” Int. J.

Kirchhoff’s and Newton’s laws methods. Results are Eng., no. 9, pp. 38–48.

shown graphically and the calculation is done for a [8] A. B. Yildiz, “Electrical Power and Energy

model with speed, torque and load in MATLAB to

Systems Electrical equivalent circuit based

illustrate the methodology. The validation of

modeling and analysis of direct current motors,”

Simelectronics model are done with the state space

Int. J. Electr. POWER ENERGY Syst., vol. 43,

model built in Simulink. This validation is done to

ensure that Simelectronics model can be used to no. 1, pp. 1043–1047, 2012.

replicate the behaviour of a DC motor dynamic. In [9] A. Budianto and K. B. Tawi, “Modeling and

addition to modeling, a PD controller are implemented simulation for micro DC motor based on

on the Simelectronics simulation model and the simulink Modeling and simulation for micro DC

Simulink model. Results obtained are then compared motor based on simulink,” in IOP Conf. Series:

and found to be in close agreement. The contribution of Materials Science and Engineering (ICAMMT

this work is significantly expedient in the field of 2017), 2017, pp. 0–7.

automobile, mechatronics, and control systems and

educative for hand-on laboratory. It also provides a [10] M. R. Corapsiz and H. Kahveci, “The speed

novel approach to simulate the electromechanical control of DC motor under the load condition

system in a concise and precise method. using PI and PID controllers,” 2017, vol.

020116, p. 020116.

ACKNOWLEDGMENT (TEŞEKKÜR)

[11] G. Chen and X. Shang, “Simulation used in

education for a separately excited DC motor,”

The authors would like to say thank you to Olabisi

Onabanjo University for providing facilities and World Trans. Eng. Technol. Educ., vol. 12, no.

support. 1, pp. 14–19, 2014.

[12] I. Al-abbas, R. Issa, and H. Sarhan, “Separately

REFERENCES (KAYNAKLAR) Excited DC Motor Parametric Control Using

Electronic Workbench,” vol. 2, no. 3, pp. 51–

[1] E. Can and H. H. Sayan, “THE 58, 2012.

PERFORMANCE OF THE DC MOTOR BY

THE PID CONTROLLING PWM DC-DC [13] N. S. Nise, Control systems engineering. Wiley,

BOOST CONVERTER,” Tech. J., vol. 6168, 2011.

pp. 182–187, 2017. [14] D. Pal, “Modeling , Analysis and Design of a

[2] A. A. Mahfouz and F. A. Salem, “Modeling , DC Motor based on State Space Approach,” Int.

Simulation and Dynamics Analysis Issues of J. Eng. Res. Technol., vol. 5, no. 02, pp. 293–

Electric Motor , for Mechatronics Applications , 297, 2016.

Using Different Approaches and Verification by [15] A. Khanna and T. Gaur, “Model Predictive

MATLAB / Simulink ( I ).,” I.J. Intell. Syst. Control Of Dc Motor Model In Matlab,” Int. J.

Appl., no. April, pp. 39–57, 2013. Sci. Eng. Res., vol. 8, no. 4, pp. 82–85, 2017.

[3] Z. Bitar, S. Al, and I. Khamis, “Modeling and [16] P. Niveditha, N Venkatesan, G Santhoshini,

Simulation of Series DC Motors in Electric “ijpam.eu,” Int. J. Pure Appl. Math., vol. 117,

Car,” Energy Procedia, vol. 50, pp. 460–470, no. 16, pp. 35–41, 2017.

2014.

[17] S. Ayasun, “DC Motor Speed Control Methods

[4] M. Kim, W. Moon, D. Bae, and I. Park, Using MATLAB / Simulink and Their

“Dynamic simulations of electromechanical Integration into Undergraduate Electric

robotic systems driven by DC motors,” Machinery Courses,” Comput Appl Eng Educ,

Robotica, vol. 22, no. 5, pp. 523–531, 2004. vol. 15, pp. 347–354, 2007.

[5] N. P. Mahajan and S. B. Deshpande, “Study of [18] N. Patrascoiu, “Modeling and Simulation of the

Nonlinear Behavior of DC Motor Using,” Int. J. DC Motor Using Matlab and LabVIEW *,” Int.

Sci. Res. Publ., vol. 3, no. 3, pp. 1–6, 2013. J. Eng. Educ., vol. 21, no. 1, pp. 49–54, 2005.

[6] Y. V. P. Paulite, N. J. C. Carandang, and E. R. [19] C. Gencer and M. Gedikpinar, “688-691.pdf,” J.

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100 99

Appl. Sci., vol. 6, no. 3, pp. 688–691, 2006. [27] M. Işik F., M. & Güngör A., “AWERProcedia

Information Technology & Computer Science

[20] K. V. C. R. V. Rajasekhar, “Design and

Virtual Laboratory Application for Direct

Analysis of DC Motor With PID Controller - A

Current Motor Experiments,” in AWERProcedia

State Space Approach,” ITSI Trans. Electr.

Information Technology & Computer Science,

Electron. Eng., vol. 1, no. 3, pp. 11–14, 2013.

2016, no. February, pp. 552–57.

[21] A. A. A. Emhemed and R. Bin Mamat,

[28] A.A.Okubanjo and O.K.Oyetola, “Modeling and

“Modelling and simulation for Industrial DC

Simulation of Hybrid PV- Thermal (PVT)

Motor using Intelligent control,” in Procedia

Systems for Energy Efficiency in Nigeria,”

Engineering, 2012, vol. 41, no. Iris, pp. 420–

Amity J. Eng. Technol. J. Eng. Technol., vol. 2,

425.

no. 1, pp. 7–15, 2017.

[22] C. Felipe and R. Rodas, “A performance

[29] D. Puangdownreong, A. Nawikavatan, and C.

comparison of nonlinear and linear control for a

Thammarat, “Optimal Design of I-PD

DC series motor Una comparación de

Controller for DC Motor Speed Control System

desempeño del control Lineal y no lineal de un

by Cuckoo Search,” Procedia - Procedia

motor de corriente continua,” Cienc. en

Comput. Sci., vol. 86, no. March, pp. 83–86,

Desarro., vol. 8, no. 1, pp. 41–50, 2017.

2016.

[23] J. Mostafapour, J. Reshadat, and M. Farsadi,

“Improved Rotor Speed Brushless DC Motor

Using Fuzzy Controller,” Indones. J. Electr. Nomenclature

Jm equivalent moment of inertial of motor and load

Eng. Informatics, vol. 3, no. 2, pp. 78–88, 2015. referred to motor shaft

[24] N. K. Saxena, S. Gebrehiwot, and D. Mena, Bm equivalent viscous friction coefficient of motor and

load referred to motor shaft

“Controller Design for Electric Motor Derived La inductance of armature winding

Vehicle,” Indones. J. Electr. Eng. Informatics, Ra resistance of the armature winding

vol. 6, no. 2, pp. 6–12, 2018. Vb back emf (volts)

Tm Torque developed by the motor

[25] H. Wong and V. Kapila, “Internet-based remote TL load Torque (Nm)

control of a DC motor using an embedded ωm angular velocity of motor shaft

ethernet microcontroller,” Comput. Educ. J., Kt, Kb motor torque constant and back emf constant

vol. 15, no. 3, pp. 57–67, 2005. H Hamilton’s function

L Lagrange’s function

[26] M. F. Işik, “Design and implementation of a T kinetic energy

training set for distributed system and U potential energy

mechatronic applications: project based G, R Rayleigh’s dissipative function

learning,” Teh. Vjesn. - Tech. Gaz., vol. 23, no. pi momentum of the i-th numbe

6, pp. 1609–1616, 2016.

Ayodeji OKUBANJO Oluwadamilola OYETOLA

A.A. Okubanjo received B.Sc. Degree in Electrical & O.K. Oyetola is a faculty member at the department

Electronics Engineering with First Class Honour of Computer and Electrical Engineering, Olabisi

from Olabisi Onabanjo University, Nigeria in 2009 Onabanjo University, Nigeria. He received B.Sc.

and completed M.Sc. in Control Systems Degree in Electrical and Electronic Engineering from

Engineering from HAN University of Applied the same University in 2009. In 2016, he completed

Sciences, the Netherlands in 2016. Presently, he is a M.Tech in Electrical and Electronic Engineering at

doctorate student at Tshwane University of Ladoke Akintola University, Ogbomosho, Nigeria.

Technology, Pretoria, South Africa. He is a lecturer Presently, he is a doctorate student at University of

in the Department of Computer and Electrical & KwaZulu-Natal South Africa. He is a shrewd

Electronics Engineering at Olabisi Onabanjo academician with interest in Smart grid, Energy

University. He is a shrewd academician with interest management, Software Engineering, Cloud

in Control System and Instrumentation, Renewable computing, IoT, Big data and Digital

Energy, Mechatronics, Safety and Systems, communication.

Information technology and Image processing. He

has attended workshops, seminars and conferences

related to control systems Engineering and he has

also published and submitted papers for review on

the listed areas of interests.

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

100 Okubanjo, Oyetola, Olaluwoye, Alao, Olateju, Abatan / Gazi Mühendislik Bilimleri Dergisi 5 (1). (2019) 91-100

Olawale OLALUWOYE Adeyemi OLATEJU

O.O. Olaluwoye obtained his B.Sc. Degree in A.I. Adeyemi obtained his B.Sc. Degree in

Electrical/Electronics Engineering from Olabisi Electrical/Electronics Engineering from Olabisi

Onabanjo University, Nigeria in 2008. He completed Onabanjo University, Nigeria in 2008. He completed

his M.Tech program in Electrical and Electronic his M.Sc. program in Electronic and

Engineering from Ladoke Akintola University of Telecommunication Engineering from Sheffield

Technology, Ogbomosho, Nigeria in 2016. Presently, Hallam University United Kingdom in 2016. He is

he is a doctorate student at Federal University of currently a lecturer at Moshood Abiola Polytechnic,

agriculture, Abeokuta, Nigeria. He is a registered Nigeria. His research interests are in mobile IP,

Engineer with the Council of Regulation of Wireless sensor Network, Antenna Propagation and

Electronics.

Engineering in Nigeria (COREN). His research

interests are in Power Systems Engineering,

Taiwo ABATAN

Renewable Systems, Software Development

T.T.Abatan obtained his B.Sc. Degree in

Systems, Smart Grids and Systems Reliability. He

Electrical/Electronics Engineering from Olabisi

has worked in the Nigerian Electricity sector. He is

Onabanjo University, Nigeria in 2017. A Senior

currently a lecturer at Olabisi Onabanjo University,

Technologist in the Department of Computer

Nigeria.

Engineering of Moshood Abiola Polytechnic,

Nigeria. A German Dual vocational trainer in

Olufemi ALAO

O.P. Alao is a faculty member at the department of Industrial Electrical/Electronic Engineering. His

Computer and Electrical Engineering, Olabisi research interests are in Embedded System and Smart

Onabanjo University, Nigeria. He received B.Sc. system.

Degree in Electrical and Electronic Engineering from

Obafemi Awolowo University, Ile-Ife, Nigeria in

1997. He completed his M.Sc. program in Electronic

and Telecommunication Engineering from

University of Lagos in 2011. Presently, he is a

doctorate student at Ladeko Akintola University of

Technology, Nigeria. He is a shrewd academician

with interest in wireless power transmission system,

Communication, software and electronic.

PRINT ISSN: 2149-4916 E-ISSN: 2149-9373 © 2017 Gazi Akademik Yayıncılık

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- TD AopDocument4 pagesTD AopAbdel HassibNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Beginners Python Cheat Sheet PCC All PDFDocument26 pagesBeginners Python Cheat Sheet PCC All PDFName100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cours1 Electronique-AppliqueeDocument7 pagesCours1 Electronique-AppliqueeAbdel HassibNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Pid DemoDocument1 pagePid Demolxz5101100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Map-Sensor Bosch 3bar 5vDocument1 pageMap-Sensor Bosch 3bar 5vFranjoDubravcicNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 40PC Series: Fully Signal Conditioned Pressure TransducerDocument8 pages40PC Series: Fully Signal Conditioned Pressure TransducerAbdel HassibNo ratings yet

- MPX5500 PDFDocument7 pagesMPX5500 PDFAkbar NovelNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- D D D D D D D D: OP07C, OP07D, OP07Y Precision Operational AmplifiersDocument7 pagesD D D D D D D D: OP07C, OP07D, OP07Y Precision Operational Amplifiersssasuke3No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Modeling and Simulation of DC Motor Using Simelectronics and Simulink (#557073) - 700506 PDFDocument10 pagesModeling and Simulation of DC Motor Using Simelectronics and Simulink (#557073) - 700506 PDFAbdel HassibNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Manual UPA Portugues PDFDocument4 pagesManual UPA Portugues PDFRogério NevesNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- D D D D D D D D: OP07C, OP07D, OP07Y Precision Operational AmplifiersDocument7 pagesD D D D D D D D: OP07C, OP07D, OP07Y Precision Operational Amplifiersssasuke3No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- L-9 (DK) (Pe) ( (Ee) Nptel)Document36 pagesL-9 (DK) (Pe) ( (Ee) Nptel)Htet AungNo ratings yet

- Introduction To Boltzmann LearningDocument2 pagesIntroduction To Boltzmann LearningnvbondNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Thermo SyllabusDocument5 pagesThermo SyllabusErica BradleyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A - Flexible - High - and - Low - Level - Multi - Task - Behavior - Framework - For - Multi-Agent - Systems - in - Complex - EnvironmentsDocument5 pagesA - Flexible - High - and - Low - Level - Multi - Task - Behavior - Framework - For - Multi-Agent - Systems - in - Complex - EnvironmentsjcaodduoNo ratings yet

- RL Monograph1Document42 pagesRL Monograph1ChainszzNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Stability of Nonlinear Dissipative Systems PDFDocument4 pagesThe Stability of Nonlinear Dissipative Systems PDFRafael AcostaNo ratings yet

- 06 - Building and Energy Management SystemsDocument24 pages06 - Building and Energy Management Systemsnallamal1006No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Performance Modeling: A System-Based Approach To Exercise SelectionDocument8 pagesPerformance Modeling: A System-Based Approach To Exercise SelectionAngelos BarbasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lecture On 23-09-2020Document4 pagesLecture On 23-09-2020neemarawat11No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- DisadvantagesDocument2 pagesDisadvantagesSarthakGupta80% (5)

- Backpropagation Working Error Computation Adjusting WeightsDocument12 pagesBackpropagation Working Error Computation Adjusting WeightsSenthil PrakashNo ratings yet

- Maintenance Engineering Q&a PDFDocument27 pagesMaintenance Engineering Q&a PDFRaviggg100% (3)

- ME 592 2016 Lab ResultDocument8 pagesME 592 2016 Lab ResultarindamckbtNo ratings yet

- IDBS BiTs Set2Document4 pagesIDBS BiTs Set2Kumara Swamy BNo ratings yet

- Case Study On Trust Region Policy Optimization (TRPO) in RoboticsDocument2 pagesCase Study On Trust Region Policy Optimization (TRPO) in RoboticsPayal ChandakNo ratings yet

- CPM PertDocument1 pageCPM Pertapi-3788255No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Ncert Solutions Class 11 Chemistry Chapter 6 Thermodynamics - 0Document13 pagesNcert Solutions Class 11 Chemistry Chapter 6 Thermodynamics - 0Raghav VermaNo ratings yet

- Unit 3Document46 pagesUnit 3Vinod Srinivasan100% (1)

- Variable Impedance Control A Reinforcement LearninDocument9 pagesVariable Impedance Control A Reinforcement Learnin이재봉No ratings yet

- Session 1: An Overview of Software Processes: Materi Week 2 Information System Analysis & DesignDocument26 pagesSession 1: An Overview of Software Processes: Materi Week 2 Information System Analysis & Designrachel tobingNo ratings yet

- Heat Engines Lab ReportDocument3 pagesHeat Engines Lab Reportapi-257546392No ratings yet

- Mimo SystemDocument6 pagesMimo Systemharis shehzadNo ratings yet

- Management Thoughts and Philosophy Classified in TDocument13 pagesManagement Thoughts and Philosophy Classified in TAbdulwasiuNo ratings yet

- HW 5Document2 pagesHW 5Saied Aly SalamahNo ratings yet

- Thermodynamic Processes: Analysis of Thermodynamic Processes by Applying 1 & 2 Law of ThermodynamicsDocument10 pagesThermodynamic Processes: Analysis of Thermodynamic Processes by Applying 1 & 2 Law of Thermodynamicsmohdmehrajanwar1860No ratings yet

- Basic TPS HandbookDocument33 pagesBasic TPS HandbookSumith KobewattaNo ratings yet

- System Dynamics Applied To Project Managemen-A Survey-Assessment and Directions For Future ResearchDocument33 pagesSystem Dynamics Applied To Project Managemen-A Survey-Assessment and Directions For Future ResearchIndra Budhi KurniawanNo ratings yet

- Ece006 Labexercise12Document15 pagesEce006 Labexercise12Krizzia Anne ShengNo ratings yet

- System Analysis Design TamilDocument4 pagesSystem Analysis Design TamilRangith UthayakumaranNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Google Ai Engineer Resume Example AOZINDocument1 pageGoogle Ai Engineer Resume Example AOZINMuhammad Bin AslamNo ratings yet

- 004 1 EE 232 Signals and SystemsDocument2 pages004 1 EE 232 Signals and SystemsShaharyar WaliullahNo ratings yet