Professional Documents

Culture Documents

Max Allowable Stress

Uploaded by

Pieka DaudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Max Allowable Stress

Uploaded by

Pieka DaudCopyright:

Available Formats

Introduction to CuNi 90/10 and CuNi 70/30

Chemical Compsition

The chemical composition of alloys 90/10 and CuNi 70/30 have been optimised in collaboration with th o

our customers in order

to maximize the behaviour of the metal under the most strigent conditions of seawater corroison. Additionally,

iona CuNi 90/10 and

CuNi 70/30 meet all requires of the most international standards.

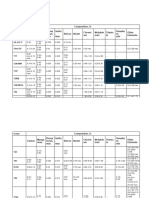

Comparison Table of International Standards for CuNi 90/10

Ni% Fe% Mn% C% Pb% S% P% Zn% Zr% Other imp. Cu%

10.0- max max max max max max max 0.10

CuNi 90/10 11.0 1.5-1.8 0.5-1.0 0.05 0.01 0.005 0.02 0.05 0.03 Sn+Pb Balance

max 0.03

NFA max max max max 0.10

9.0-11.0 1.0-2.0 0.3-1.0 0.05 - 0.02 - 0.5 - Sn+Pb Balance

51 - 102 max 0.05

DIN 17664 9.0-11.0 1.0-2.0 0.5-1.0 max max max max max - max 0.30 Balance

2.0872 0.05 0.03 0.02 0.02 0.5

DIN 86019 9.0-11.0 1.5-1.8 0.5-1.0 max max max max max max max 0.30 Balance

2.1972 0.05 0.03 0.015 0.02 0.15 0.03

EEMUA 144 10.0- 1.5-2.0 0.5-1.0 max max max max max - max 0.30 Balance

UNS 7060x 11.0 0.05 0.01 0.02 0.02 0.20

BS 2871 10.0- 1.0-2.0 0.5-1.0 max max max - - - max 0.30 Balance

CN 102 11.0 0.05 0.01 0.05

10.0- 1.0-2.0 0.5-1.0 max max max - - - max 0.30 Balance

NES 779 11.0 0.05 0.01 0.05

MIL-T-16420K 9.0-11.0 1.0-1.8 max 1.0 max max max max max - - mini 86.5

C70600 0.05 0.02 0.02 0.02 0.50

ASTM B466 9.0-11.0 1.0-1.8 max 1.0 max max max max max - - Balance

C70600 0.05 0.02 0.02 0.02 0.50

JIS H 3300 max max Cu+Ni

9.0-11.0 1.0-1.8 0.2-1.0 - 0.05 - - 0.50 - - +Fe+Mn

C7060 min 99.5

Comparison Table of International Standards for CuNi 70/30

Ni% Fe% Mn% C% Pb% S% P% Zn% A1% Bi% B% Si% Other imp. Cu%

30.0- 0.6-0.7 0.5-1.0 max max max max max max max max max max 0.10 Balance

CuNi 70/30 32.0 0.05 0.01 0.005 0.01 0.05 0.03 0.002 0.02 0.05

NFA 29.0- max max max max 0.10

32.0 0.4-0.7 0.5-1.5 0.06 - 0.02 - 0.5 - - - - Sn+Pb Balance

51 - 102 max 0.05

DIN 17664 30.0- 0.4-1.0 0.5-1.5 max max max max max - - - - max 0.30 Balance

2.0882 32.0 0.05 0.03 0.02 0.02 0.5

BS 2871 30.0- 0.4-1.0 0.5-1.5 max max max - - - - - - max 0.30 Balance

CN 107 32.0 0.06 0.01 0.08

DGS 30.0- 0.4-1.0 0.5-1.5 max max max max - - max max - max 0.30 Balance

320 32.0 0.06 0.01 0.02 0.01 0.002 0.02

30.0- 0.6-1.0 0.5-1.5 max max max max - max max max max max 0.30 mini 66.5

NES 780 32.0 0.06 0.01 0.02 0.01 0.03 0.002 0.02 0.05

MIL-T-16420K 29.0- 0.4-1.0 max 1.0 max max max max max - - - - max 0.50 mini 65.0

C71500 33.0 0.05 0.02 0.02 0.02 0.50

ASTM B466 29.0- 0.4-1.0 max 1.0 max max max max max - - - - max 0.50 Balance

C71500 33.0 0.05 0.02 0.02 0.02 0.50

JIS H 3300 29.0- max max Cu+Ni

33.0 0.4-1.0 0.2-1.0 - 0.05 - - 0.50 - - - - - +Fe+Mn

C7150 min 99.5

Athical Engineering Pte Ltd

Tel: +65 6863 3378 Fax: +65 6863 3398 Email: enquiry@athical.com Website: www.athical.com

4

Introduction to CuNi 90/10 and CuNi 70/30

Physical Properties

Typical Values Units CuNi 90/10 CuNi 70/30

Density (20°C) kg/m3 8900 8900

Electrical Resistivity (20°C annealed) μΩ.cm 19 34

Thermal Conductivity (20°C to 200°C) W/m.°K 50 30

Coefficient of Expansion (20°C to 200°C) C x 10-6 17 16

Modulus of Elasticity (20°C annealed) Mpa 126 000 126 000

Annealing Temperature °C 760 - 800 760 - 820

Melting Interval °C 1100 - 1150 1180 - 1240

Magnetic Permeability (20°C annealed) 1.08 - 1.80 < 1.05

Mechanical Properties (Annealed Temper)

Typical Values Units CuNi 90/10 CuNi 70/30

Tensile Strength (UTS),(Rm) MPa ≥ 310 ≥ 350

ksi ≥ 44 ≥ 51

Proof Stress (YS 0,2), (Rp 0,2) MPa ≥ 110 ≥ 130

ksi ≥ 16 ≥ 19

Elongation (E 5,65 √S) % ≥ 35 ≥ 30

Hardness (HB10 D2 ) ≥ 70 ≥ 80

Mechanical Properties According to Temperature

°C

-200 -150 -100 -50 0 50 100 150 200 250 300 350

Units

CuNi 90/10

T.S MPa 450 390 330 310 300 300 290 280 270 260 250 230

Y.S. MPa 150 145 140 130 100 100 100 95 90 85 80 65

E (E 5,65 √S) %> 35 32 28 26 24 23 21 20

CuNi 70/30 ksi

T.S MPa 480 420 380 360 350 350 340 320 320 310 300 280

Y.S. MPa 110 175 150 140 130 130 130 125 120 115 110 110

E (E 5,65 √S) %> 30 28 24 23 22 20 19 18

Contrary to steels, CuNi 90/10 and CuNi 70/30 do not become fragile at low temperatures

Maximum Permissible Stress According to Service Temperature as per ASME Code, Section III

°C 20 40 75 100 125 150 175 200 225 250

Units

CuNi 90/10 MPa 70 69 67 66 65 63 62 60 58 57

CuNi 70/30 MPa 84 83 77 75 74 72 71 70 70 70

Athical Engineering Pte Ltd

Tel: +65 6863 3378 Fax: +65 6863 3398 Email: enquiry@athical.com Website: www.athical.com

5

Introduction to CuNi 90/10 and CuNi 70/30

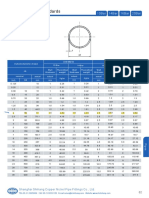

Working Pressures as per ASME Code, Section lll (Without Safety Coefficient)

Working Pressure Working Pressure

Tubes Bar Tubes Bar

O.D. x W.T. CuNi 90/10 CuNi 70/30 O.D. x W.T. CuNi 90/10 CuNi 70/30

10 x 1.0 152 183 368 x 6.5 25 30

12 x 1.0 125 150 368 x 8.0 31 37

16 x 1.0 92 111 419.1 x 4.0 13 16

16 x 2.0 194 233 419.1 x 6.0 20 24

20 x 1.0 73 88 419.1 x 7.0 24 28

20 x 2.0 152 183 457.2 x 4.0 12 15

25 x 1.5 88 106 457.2 x 6.0 19 22

25 x 2.0 120 144 457.2 x 8.0 25 30

30 x 1.5 73 88 457.2 x 9.5 30 35

30 x 2.5 125 150 508 x 4.5 12 15

38 x 1.5 57 68 508 x 6.5 18 22

38 x 2.5 97 117 508 x 8.5 24 28

44.5 x 1.5 48 58 508 x 11.0 31 37

44.5 x 2.5 82 99 610 x 5.0 12 14

57 x 1.5 38 45 610 x 8.0 19 22

57 x 2.5 64 76 610 x 10.5 24 29

76.1 x 2.0 38 45 610 x 13.0 30 36

76.1 x 2.5 47 57 711 x 6.0 12 14

88.9 x 2.0 32 38 711 x 9.0 18 21

88.9 x 2.5 40 48 711 x 12.0 24 29

108 x 2.5 33 40 711 x 15.0 30 36

108 x 3.0 40 48 813 x 6.0 10 12

133 x 2.5 27 32 813 x 10.0 17 21

133 x 3.0 32 39 813 x 13.5 24 28

159 x 2.5 22 27 813 x 17.0 30 36

159 x 3.0 27 32 914 x 8.0 12 15

159 x 3.5 31 38 914 x 11.0 17 20

193.7 x 2.5 18 22 914 x 15.5 24 29

193.7 x 3.0 22 26 914 x 19.0 30 36

193.7 x 3.5 26 31

219.1 x 3.0 19 23

Breaking Pressure

219.1 x 3.5 23 27

219.1 x 4.0 26 31 Tubes Bar

219.1 x 4.5 29 35 O.D. x W.T. CuNi 90/10 CuNi 70/30

267 x 3.0 16 19 25 x 1.5 410 450

267 x 4.0 21 25 30 x 1.5 380 420

267 x 4.5 24 29 38 x 1.5 320 350

267 x 5.5 29 35 44.5 x 1.5 260 270

323.9 x 4.0 17 21 57 x 1.5 180 200

323.9 x 5.0 22 26 76.1 x 2.0 180 200

323.9 x 5.5 24 29 88.9 x 2.0 175 190

323.9 x 7.0 31 37 108 x 2.5 165 180

368 x 4.0 15 18 133 x 2.5 145 160

368 x 5.5 21 25 159 x 2.5 125 135

2e P P 2e

Wall thickness calculation formula as per the ASME code : = or =

Di C-0.6P C Di + 1.2e

Maximum permissible stress (C).

In compliance with international standards e = tube thickness

and main third party inspection organizations. Di = tube inside diameter

C = maximum stress at working temperature

CuNi 90/10 : 70 N/mm² P = pressure difference between inside and outside of the tube

CuNi 70/30 : 84 N/mm²

Athical Engineering Pte Ltd

Tel: +65 6863 3378 Fax: +65 6863 3398 Email: enquiry@athical.com Website: www.athical.com

6

Introduction to CuNi 90/10 and CuNi 70/30

Corrosion Behaviour

CuNi 90/10 and CuNi 70/30 have an excellent behaviour when exposed to all forms of marine corrosion. This property is

mainly due to the fact that the alloy prevents dissolution by forming a very strong protective surface film.

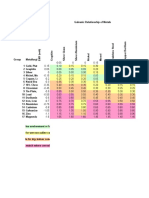

CuNi 90/10 and CuNi 70/30 Possible Factors of Corrosion

Corrosive Environment Probable Corrosion Behaviour In Service

Clean sea water circulation

Uniform Or General 0.0025 - 0.025 mm/an

at a velocity of up to 1 m/s

Clean sea water circulation

at a velocity of up to 3.5 m/s* : CuNi 90/10 Impact Corrosion Satisfactory

and 4.5 m/s* : CuNi 70/30

General Corrosion

Polluted Sea Water and Accelerated Less Resistance

Pitting Corrosion

Deposits accumulated at the surface Local Attack Generally Good

Corrosion + stress Stress Corrosion Very Resistant

* the local speeds resulting from obstructions can be higher

Behaviour of CuNi 90/10 and CuNi 70/30

in the Presence of Sea Water, Brine and Sea Atmospheric Exposures

Type of Corrosion Behaviour

Slightly sensitive to this type of corrosion

General Corrosion

Corrosion rate is less than 25 μ/year

Insensitive to this type of attack

Pitting Corrosion

Penetration rate less than 25/130 μ/year

Insensitive

Selective Corrosion

Do not lose the alloying component like brasses and aluminium bronzes

Stress Corrosion Never affected by this type of corrosion

Insensitive

Fouling Corrosion Even at a low circulation speed, and although not affected by general corrosion, perfectly

resist to the build-up of marine organisms

Very slightly sensitive

Corrosion-Erosion

The addition of an optimum quantity of iron improves the nature of the protective film and

(impingement attack)

makes the alloy very resistant to this type of aggression

Behaviour of CuNi 90/10 and CuNi 70/30 in Other Environments

• Good resistance in ammoniacal environment.

• The behaviour of copper nickel in the presence of crude petroleum is correct in the vapour phase, with however, the risk of

the protective film being destroyed.

Resistance of CuNi 90/10 to Fire

Test of resistance to fire have been made in simulating the service conditions of a pipeline during an offshore fire:

piping empty - during 5 minutes - at 700°C, partly in the flame, then 15 minutes on water (with the start of the sprinklers).

They have shown the total reliabitiy of CuNi 90/10 : no rupture of the weld or of the brazing, no leakage, no permanent

deformation.

After the end of the fire, the piping in CuNi 90/10 has needed no replacement.

Athical Engineering Pte Ltd

Tel: +65 6863 3378 Fax: +65 6863 3398 Email: enquiry@athical.com Website: www.athical.com

7

You might also like

- Seamless Steel PipeDocument1 pageSeamless Steel PipewangfaNo ratings yet

- Spring MaterialsDocument3 pagesSpring MaterialsS. VeeravelNo ratings yet

- Copper Nickel Pipe Din86089 Eemua145Document1 pageCopper Nickel Pipe Din86089 Eemua145Araby GamalNo ratings yet

- SB-619 - ASME BPVC 2021 Sección II Part BDocument8 pagesSB-619 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Steel Grades HandbookDocument6 pagesSteel Grades Handbookbhavin178No ratings yet

- SB-622 - ASME BPVC 2021 Sección II Part BDocument8 pagesSB-622 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Grade & SpcficDocument6 pagesGrade & SpcficANBUNo ratings yet

- Low Alloy Steels Part2 PDFDocument1 pageLow Alloy Steels Part2 PDFnedunchiNo ratings yet

- Guidelines For WeldingDocument64 pagesGuidelines For WeldingshahNo ratings yet

- Torbali Müh - Welding - Heat Treatment - NDT ProcedureDocument69 pagesTorbali Müh - Welding - Heat Treatment - NDT ProcedureHÜSEYİN ALBAYRAKNo ratings yet

- 8) Copper & Copper Alloy SpecificationsDocument3 pages8) Copper & Copper Alloy Specificationsnavas1972No ratings yet

- Fdocuments - in - Jindal Steel Product Catalogue - MergeDocument62 pagesFdocuments - in - Jindal Steel Product Catalogue - MergephanikrishnabNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Chemical Compo - TupiplDocument2 pagesChemical Compo - TupiplMadhubalan AlagarNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4kazdanoNo ratings yet

- Chemical and Physical Requirements of Seamless PipeDocument1 pageChemical and Physical Requirements of Seamless PipeS.KAMBANNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- ASTM A234 2010 (No Oficial)Document10 pagesASTM A234 2010 (No Oficial)Santiago Loría NavaNo ratings yet

- Non Ferrous MaterialsDocument8 pagesNon Ferrous MaterialsSH1961No ratings yet

- Tpmcsteel: Welded Pipe For Pressure PurposeDocument2 pagesTpmcsteel: Welded Pipe For Pressure Purpose兆緯No ratings yet

- Plate A36 (2016)Document4 pagesPlate A36 (2016)eko kusumoNo ratings yet

- Din 17174Document7 pagesDin 17174djmattmNo ratings yet

- MATERIALS FOR PRESSURE PARTS - CompositionDocument3 pagesMATERIALS FOR PRESSURE PARTS - CompositionprabodhvkNo ratings yet

- Seamless Pipes - API 5L Grade X65 PSL 2Document2 pagesSeamless Pipes - API 5L Grade X65 PSL 2isan.structural TjsvgalavanNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- STD Material Composition List For LabDocument14 pagesSTD Material Composition List For LabAshok DevihosurNo ratings yet

- CF8 ASTM A351 Min. Max: Chemical Composition Grade Standard Ratio C SI MN S P CR NI MO CU W Sr. NoDocument6 pagesCF8 ASTM A351 Min. Max: Chemical Composition Grade Standard Ratio C SI MN S P CR NI MO CU W Sr. NoSiraj PatelNo ratings yet

- OSNA10 Copper-Nickel Sheathing On Offshore StructuresDocument8 pagesOSNA10 Copper-Nickel Sheathing On Offshore Structuresbello imamNo ratings yet

- Sampel Wedges ADocument1 pageSampel Wedges ARuDdy GunawanNo ratings yet

- Din 17102 PDFDocument10 pagesDin 17102 PDFEvriMert RüzgArdaNo ratings yet

- Astm B333Document5 pagesAstm B333Jota JacquesNo ratings yet

- Customer Standard TS2 17-23 Supplier Standard Jsw-Bsk46 Chemical Remarks Customer Standard JSW StandradDocument2 pagesCustomer Standard TS2 17-23 Supplier Standard Jsw-Bsk46 Chemical Remarks Customer Standard JSW StandradMuthu GaneshNo ratings yet

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- Amnd No 2 IS 6911Document16 pagesAmnd No 2 IS 6911Rakesh Soti (JSHL-QUALITY)No ratings yet

- Structural Plate Astm A36: Plates, Shapes, and Sheet PilingDocument4 pagesStructural Plate Astm A36: Plates, Shapes, and Sheet Pilingeko kusumoNo ratings yet

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Table: Joint Displacements Joint Outputcase Casetype Steptype U1 U2 U3 R1 R2Document4 pagesTable: Joint Displacements Joint Outputcase Casetype Steptype U1 U2 U3 R1 R2Gianpierre Echevarria LozanoNo ratings yet

- Alüminyum AlaşımlarıDocument11 pagesAlüminyum AlaşımlarıMahmut IspirNo ratings yet

- Rev01 - Report - Analysis - JK-JKS-0077 TEBET BARAT DALAM 8Document65 pagesRev01 - Report - Analysis - JK-JKS-0077 TEBET BARAT DALAM 8salman alfarisyNo ratings yet

- WS412Document7 pagesWS412Martin OusephNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- CuNi NUFITDocument16 pagesCuNi NUFIT9823458877No ratings yet

- Metode Cross NandaDocument17 pagesMetode Cross NandaNandaAyuFNo ratings yet

- Iso 2604-2Document15 pagesIso 2604-2Yusri WyeuserieyNo ratings yet

- Composición Quimica AleadosDocument1 pageComposición Quimica AleadosPere Salinas PradesNo ratings yet

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- Piping Code Comparison TableDocument52 pagesPiping Code Comparison TableRobert SmallNo ratings yet

- Daily Analytical Report Urea Unit: Time Urea% V-212 Time Urea% Hpac (E-209) NH % CO % H O% NH %Document13 pagesDaily Analytical Report Urea Unit: Time Urea% V-212 Time Urea% Hpac (E-209) NH % CO % H O% NH %XheikhKaleemNo ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data Sheetispat_jagadeeshNo ratings yet

- Balance Metalurgico: Datos Calculados Datos CalculadosDocument4 pagesBalance Metalurgico: Datos Calculados Datos CalculadosPedro Alonso Machuca GarcíaNo ratings yet

- Chemical& Mechanical Properties of Various Grades of Stainless SteelDocument3 pagesChemical& Mechanical Properties of Various Grades of Stainless SteelaselabollegalaNo ratings yet

- Carbon - EquivalentsDocument3 pagesCarbon - EquivalentsAliAkarNo ratings yet

- 316 316L Technical Information SheetDocument5 pages316 316L Technical Information SheetfejlongNo ratings yet

- Comparison of MaterialDocument1 pageComparison of Materialzohaib rafiqNo ratings yet

- QuadriDocument76 pagesQuadrisvenNo ratings yet

- En 10268Document4 pagesEn 10268Alex LacerdaNo ratings yet

- BM Full CatalogueDocument109 pagesBM Full CatalogueMiguelNo ratings yet

- Rejected Billets To MDDocument1 pageRejected Billets To MDrahul srivastavaNo ratings yet

- Norma Geral Astm Bronze Alumínio - b150b150m.19198Document7 pagesNorma Geral Astm Bronze Alumínio - b150b150m.19198EduardoNo ratings yet

- Technical Supply Conditions For Threaded Steel Fasteners: IS: 1367 (Part VII) - 1980Document3 pagesTechnical Supply Conditions For Threaded Steel Fasteners: IS: 1367 (Part VII) - 1980somnath senNo ratings yet

- Cast IronsDocument8 pagesCast IronsAlberto LunaNo ratings yet

- Stoichiometry AP Exam QuestionsDocument12 pagesStoichiometry AP Exam QuestionsAllen Jerry AriesNo ratings yet

- Astm B 209M-04Document30 pagesAstm B 209M-04Faraz Gill100% (1)

- Its Details: Typical Conduit Hanger AttachmentsDocument1 pageIts Details: Typical Conduit Hanger AttachmentsrbudimanNo ratings yet

- TANK Design DetailingDocument17 pagesTANK Design DetailingTiffany Vabiola100% (8)

- WWW - One School - Net Notes Chemistry SPM Chemistry Formula List Form5Document15 pagesWWW - One School - Net Notes Chemistry SPM Chemistry Formula List Form5Nur AmaleenaNo ratings yet

- EutecTrode 66NDocument2 pagesEutecTrode 66NJose Luis Arriola RuizNo ratings yet

- Centering and ShutteringDocument7 pagesCentering and ShutteringpreethiNo ratings yet

- Grey Iron Castings - Specification: Indian StandardDocument1 pageGrey Iron Castings - Specification: Indian StandardSvapneshNo ratings yet

- Week 8 Sheet Metal FormingDocument69 pagesWeek 8 Sheet Metal FormingashkansoheylNo ratings yet

- Galvanic Relationship of MetalsDocument2 pagesGalvanic Relationship of MetalsRay FaiersNo ratings yet

- 123Document20 pages123Dacy ChowNo ratings yet

- Brake Applications CatalogDocument159 pagesBrake Applications CatalogvidarlovikNo ratings yet

- 8g Test Mark Scheme 2008Document2 pages8g Test Mark Scheme 2008Victor Barber Sanchis67% (9)

- Commercial Valves: For Safe and Healthy SurroundingsDocument4 pagesCommercial Valves: For Safe and Healthy SurroundingsAntony MylvaganamNo ratings yet

- API CI-4 Plus Performance Category: Test Type Purpose Parameter RequirementDocument2 pagesAPI CI-4 Plus Performance Category: Test Type Purpose Parameter RequirementPorfirio Duarte ZarateNo ratings yet

- Fixture Could Be Used To Hold Workpiece To WorktableDocument6 pagesFixture Could Be Used To Hold Workpiece To WorktableM Shahrul IzuanNo ratings yet

- STI-Cat2015 Complete 1 13 15Document52 pagesSTI-Cat2015 Complete 1 13 15blazerman3No ratings yet

- The Purpose of PreheatDocument6 pagesThe Purpose of PreheatSankar GaneshNo ratings yet

- Sheet Metal Probelm BendingDocument3 pagesSheet Metal Probelm BendingSridharan VenkatNo ratings yet

- Composite MaterialsDocument58 pagesComposite MaterialsOceman KhanNo ratings yet

- Sdi 117Document12 pagesSdi 117Anonymous 4pltIKNo ratings yet

- Technical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014Document3 pagesTechnical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014shazanNo ratings yet

- Sample Questions & Practice Examination For D1.1Document21 pagesSample Questions & Practice Examination For D1.1Earl HarbertNo ratings yet

- DIN St37.2Document6 pagesDIN St37.2hdierkeNo ratings yet

- LT0780 4 Extrait Catalogue ERICO AnglaisDocument11 pagesLT0780 4 Extrait Catalogue ERICO AnglaisMattelecNo ratings yet

- Series 38 Super Durable 20091125 173441Document8 pagesSeries 38 Super Durable 20091125 173441K-fioNo ratings yet

- Walworth Cast Steel Catalog 2012 1 PDFDocument0 pagesWalworth Cast Steel Catalog 2012 1 PDFrambo1978No ratings yet