Professional Documents

Culture Documents

Grasa

Uploaded by

eduardoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grasa

Uploaded by

eduardoCopyright:

Available Formats

Premalube Xtreme ™

Heat Shield

Extreme Temperature Grease

The only patented grease specifically

formulated to protect equipment exposed

to extremely high temperatures.

Provides superior protection for equipment

against extreme heat, contaminants and

heavy loads.

PRODUCT OF CHOICE FOR EXTREME

TEMPERATURE APPLICATIONS

Provides Superior Equipment Protection for:

• Brick Plants • Mining

• Steel Mills • Glass Manufacturing

• Asphalt Plants • Forges and foundries

• Kilns, Furnaces, and Ovens

Extreme Temperature Performance

up to 1000°C intermittent with

monitored lubrication intervals. Premalube Xtreme Heat Shield

Meets or Exceeds these

Patented* Calcium Sulfonate Grease with

High Moly and Graphite Content Performance Requirements:

• US Steel Mill Grease Specifications:

- Roll Neck Grease, Req. No. 340

Prolongs Bearing and Equipment Life - Extreme Pressure Grease Req. No. 350

- Extra Duty EP Grease. Req. No. 352

- Extreme-Temp. Req. No. 355, 370 & 372

Extends Lubrication Intervals by Up - Ball and Roller Bearing, Req. No. 371

to 10 Times - Mill Utility Grease Req. No. 375

• Military Spec. MIL-G-23549C, MIL-G-2345C

Excellent High Temperature • Federal Specification VV-G-632a

Performance - Protects up to 1000°C • Caterpillar MPGM

Intermittently. • Chrysler MS 3551E (Part # 2264833)

• General Motors Specification GM 6031-M

At Temperatures Above 320°C the • DIN 51 825, DIN 51 818

Premium Base Oil Evaporates Cleanly

Leaving Solid Lubricants Behind to

Protect Equipment

* U.S. Patent # 5,126,062

CERTIFIED LABORATORIES, A Division of NCH India Pvt. Ltd.

2 C/ 8 SIDCO Developed Plot , Ambattur Industrial Estate, Chennai – 600058

Tel: 44 -65157384 / 26257753 Email: support@certifiedindia.com

Consult the label for complete directions and precautions

before using this product. Website:www.certifedlabs.in

PREMALUBE XTREME HEAT SHIELD

contains a total additive package for

outstanding long-term performance.

Additives User Benefits

Superior grade, highly refined base oil resists oxidation, hardening and high-

Premium Grade Base Oil

temperature breakdown to maintain better lubricity.

Withstands high heat and provides additional extreme pressure protection under

Calcium Sulfonate Base heavy loads. Extremely water resistant, heavier than water to resist washouts

even in submerged environments.

Highly-elastic polymers hold grease together and in place to reduce squeeze-

Adhesive and Cohesive Polymers,

out, channeling and sling-off. Prevents loss of lubricant that leaves bearings

Tackiness Agents

"starved".

Blocks out corrosive elements such as acids, water, condensate and steam by

Rust and Corrosion Inhibitors

forming a protective barrier on equipment surfaces to prevent chemical wear.

A heat seeking additive that prevents the cold welding that can occur under

Extreme Pressure (EP) Agents

heavy loads. Minimizes wear while helping equipment run cooler.

Prevents metal-to-metal contact, two-surface wear, vibration and chatter. Keeps

Anti-Wear and Friction Reducing

high friction surfaces, such as bearings, properly lubricated to prevent metal

Additives

loss, downtime, and replacement expenses.

Extends lubricant service life by retarding the oxidation process. Provides a

Oxidation Inhibitors

chemical shield that prevents the oxidizing effects of oxygen and water.

Cushions impact to minimize the stress, vibration and chatter that can occur

Shock Load Reducers

under heavy loads and during start-stop operations.

Plates metal surface asperities completely with a premium lubricant coating that

Molybdenum Disulfide withstands high pressures, heavy loads and shear conditions. Reduces

abrasive wear, too.

High concentration offers extreme temperature protection and stability while

Graphite

guarding against contaminants, heavy loads,and water washout.

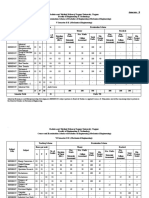

PHYSICAL PROPERTIES

Premalube

Description Xtreme Heat

Shield

Penetration ASTM D 217 330

Ideal for use on:Extreme heat applications

Multistroke penetration ASTM D 217 335 including brick plants, kiln cars, furnaces,

Four-ball Index ASTM D 2596 101 ovens, steel mills, asphalt plants, mining,

Four-ball (weld) ASTM D 2596 1000+ glass manufacturing, forges and foundries,

Four-ball (wear scar) ASTM D 2596 0.341 etc.

Timken method ASTM D 2509 70 Note: Equipment operated continuously

Rust test ASTM D 1743 Pass above 320o C will require frequent

Copper corrosion ASTM D 130 1B monitoring and re-lubrication.

Low Temperature Limit C -6

High Temperature Limit C 1093

Base Oil Viscosity @40C 113

Base Oil Viscosity @100C 12.1

Base Oil Viscosity Index 96

You might also like

- Premalube Xtreme (Tech Sheet)Document2 pagesPremalube Xtreme (Tech Sheet)adit0% (1)

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziNo ratings yet

- Castrol Molub-Alloy 243 ArcticDocument2 pagesCastrol Molub-Alloy 243 ArcticMaciejNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Mobilgrease XHP 222 Pds PDFDocument3 pagesMobilgrease XHP 222 Pds PDFStefan Cel MareNo ratings yet

- Shell Turbo Oil T 32 TDSDocument2 pagesShell Turbo Oil T 32 TDSBahim BahimanNo ratings yet

- 26 GlxxengrsespolyrexemDocument3 pages26 GlxxengrsespolyrexemVirender KumarNo ratings yet

- Extreme pressure aluminum grease protects heavy equipmentDocument3 pagesExtreme pressure aluminum grease protects heavy equipmentIngeniero aicNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDocument3 pagesGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianNo ratings yet

- Product Data Sheet: Optimol OptipitDocument2 pagesProduct Data Sheet: Optimol OptipitFBNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- 3750-3752 Product Info PDFDocument2 pages3750-3752 Product Info PDFfherreraenesaNo ratings yet

- Shell Turbo T32: Performance, Features & Benefits Main ApplicationsDocument3 pagesShell Turbo T32: Performance, Features & Benefits Main ApplicationsPandu SatrioNo ratings yet

- Premium Heavy Duty GreaseDocument2 pagesPremium Heavy Duty GreaseRoger ObregonNo ratings yet

- MFG 460 - 3M - TDS - 2 - 12.10.22Document1 pageMFG 460 - 3M - TDS - 2 - 12.10.22RUTA TLAXCALA (SHELL)No ratings yet

- SUPRESS 412 MS EP & Multipurpose GreaseDocument1 pageSUPRESS 412 MS EP & Multipurpose GreaseRuslan SlusarNo ratings yet

- Mobilgrease XHP 222Document2 pagesMobilgrease XHP 222Stefan Cel MareNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Mobilgrease XHP 222 & Special PDSDocument3 pagesMobilgrease XHP 222 & Special PDScatoeraleifNo ratings yet

- Velloils High Temperature & Speciality Grease Velloplex GreaseDocument6 pagesVelloils High Temperature & Speciality Grease Velloplex GreaseBhusarapu SrinivasNo ratings yet

- Heavy Duty Grease Moly PremiumDocument2 pagesHeavy Duty Grease Moly PremiumWawanDarmawanNo ratings yet

- Cepsa Engranajes HPDocument1 pageCepsa Engranajes HPRamonNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- PDS - Mobilgrease XHP 460 SeriesDocument3 pagesPDS - Mobilgrease XHP 460 SeriesJuanSantillanNo ratings yet

- Industrial Gear Oil Ep 68, 100, 150, 220, 320, 460, 680Document1 pageIndustrial Gear Oil Ep 68, 100, 150, 220, 320, 460, 680FilipposNo ratings yet

- 1233-1235 Product InfoDocument2 pages1233-1235 Product InfoJeisson HolguinNo ratings yet

- Mobil Grease SpecialDocument2 pagesMobil Grease SpecialRaghavendra MurthyNo ratings yet

- 76 Grasa Megaplex XD3Document2 pages76 Grasa Megaplex XD3Gustavo De Haro GonzálezNo ratings yet

- Mobil Mobilgrease XHP222 DatasheetDocument3 pagesMobil Mobilgrease XHP222 Datasheetphankhoa83-1No ratings yet

- Brosur DTL 051 (English)Document2 pagesBrosur DTL 051 (English)Deltalube TangerangNo ratings yet

- Polyurea Grease TdsDocument2 pagesPolyurea Grease TdsBanti SidhiwalaNo ratings yet

- Shell Gadus S2 OG 85Document2 pagesShell Gadus S2 OG 85Anonymous oAbjbl4HNo ratings yet

- MAK Hitemp Xtra SM GreaseDocument1 pageMAK Hitemp Xtra SM GreaseAnand PadhiyarNo ratings yet

- Shell Gadus S2 U1000: High Performance Heavy Duty GreaseDocument2 pagesShell Gadus S2 U1000: High Performance Heavy Duty Greasenutchai2538No ratings yet

- GL XX Mobil SHC Grease 460 WTDocument3 pagesGL XX Mobil SHC Grease 460 WTRakka HardiyantaNo ratings yet

- Ficha Tecnicas Royal Hammer Paste PDS XDocument2 pagesFicha Tecnicas Royal Hammer Paste PDS XAndres AgudeloNo ratings yet

- GL XX Mobilgrease SpecialDocument2 pagesGL XX Mobilgrease SpecialTiago PaivaNo ratings yet

- TDS - Shell Gadus S3 V460 1 - EN PDFDocument2 pagesTDS - Shell Gadus S3 V460 1 - EN PDFdtcuongNo ratings yet

- Shell Gadus S2 OG 40: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 OG 40: Performance, Features & BenefitsAmanNo ratings yet

- Ceran-Xm-220 TDS v171128Document2 pagesCeran-Xm-220 TDS v171128phucdc095041No ratings yet

- Amsoil Water Resistant Lithium g1281Document2 pagesAmsoil Water Resistant Lithium g1281amsoilromaniaNo ratings yet

- S3 V460D 2 - TDS PDFDocument2 pagesS3 V460D 2 - TDS PDFWawanDarmawanNo ratings yet

- PDS Gadus S3 V460D 2 - SHELLDocument2 pagesPDS Gadus S3 V460D 2 - SHELLGilmer Williams Cáceres BenaventeNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- Shell Gadus S5 T460 1 5 TDSDocument2 pagesShell Gadus S5 T460 1 5 TDSSuresh RajanNo ratings yet

- 1232 TDB FlyerDocument2 pages1232 TDB FlyerDeltalube TangerangNo ratings yet

- Mobil-Iocaengrsmomobilith SHC PMDocument3 pagesMobil-Iocaengrsmomobilith SHC PM황철No ratings yet

- Shell Gadus S2 High Speed Coupling Grease Technical Data SheetDocument3 pagesShell Gadus S2 High Speed Coupling Grease Technical Data Sheetjuan felipe diazgranados santosNo ratings yet

- 1482402436balmerol Grease Seal Guard HTDocument2 pages1482402436balmerol Grease Seal Guard HTdurgaprasad.svanmoppesNo ratings yet

- GPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1Document2 pagesGPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1abid azizNo ratings yet

- Mobil Rarus 800 Series FactsheetDocument2 pagesMobil Rarus 800 Series FactsheetSiswantoro Adi WibowoNo ratings yet

- 3750-3752 Product InfoDocument2 pages3750-3752 Product InfoVendy KurniawanNo ratings yet

- Tesco: Biodegradable Hydraulic Oil BIO 68Document2 pagesTesco: Biodegradable Hydraulic Oil BIO 68lucas ronaldo coronel mendozaNo ratings yet

- High Temp Grease for Heavy IndustryDocument2 pagesHigh Temp Grease for Heavy IndustryMudabbir Shan Ahmed100% (1)

- 2400 Series Data SheetDocument3 pages2400 Series Data Sheetmartino223No ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsMOHAMED GamalNo ratings yet

- GPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFDocument2 pagesGPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFSefa yıldızNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Lincoln Instruction Manual PN 1828 and 1830Document2 pagesLincoln Instruction Manual PN 1828 and 1830eduardoNo ratings yet

- Lincoln Instruction Manual PN v325035000 v325120000 and v325400000Document10 pagesLincoln Instruction Manual PN v325035000 v325120000 and v325400000eduardoNo ratings yet

- 308953EN-S GL-1 Injector ManualDocument6 pages308953EN-S GL-1 Injector ManualeduardoNo ratings yet

- Molub-Alloy 6040 460-1.5Document2 pagesMolub-Alloy 6040 460-1.5eduardoNo ratings yet

- Cat 2 Micron Pehp9522 - 01Document4 pagesCat 2 Micron Pehp9522 - 01sanigzl100% (1)

- Catalogo Sellos MecanicosDocument2 pagesCatalogo Sellos MecanicoseduardoNo ratings yet

- Manual de Válvula FisherDocument48 pagesManual de Válvula FishereduardoNo ratings yet

- Brochure M100Document2 pagesBrochure M100eduardoNo ratings yet

- Preform Design For PET BottlesDocument4 pagesPreform Design For PET BottleseduardoNo ratings yet

- WheelHorse Power Take Off Manual 8-3411Document4 pagesWheelHorse Power Take Off Manual 8-3411Kevins Small Engine and Tractor ServiceNo ratings yet

- Mechanical Engineering Semester SchemeDocument35 pagesMechanical Engineering Semester Schemesantvan jagtapNo ratings yet

- Experiment No. 5 BCD To 7-Segment Decoder/Driver: I.ObjectivesDocument9 pagesExperiment No. 5 BCD To 7-Segment Decoder/Driver: I.ObjectivesJun TobiasNo ratings yet

- The Difficult Patient' As Perceived by Family Physicians: Dov Steinmetz and Hava TabenkinDocument6 pagesThe Difficult Patient' As Perceived by Family Physicians: Dov Steinmetz and Hava TabenkinRomulo Vincent PerezNo ratings yet

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- BTP Presentation - Sem 8Document24 pagesBTP Presentation - Sem 8Nihal MohammedNo ratings yet

- Design of Grounding System For GIS Indoor SubstationDocument4 pagesDesign of Grounding System For GIS Indoor Substationzerferuz67% (3)

- CIMA Introduction To NLPDocument4 pagesCIMA Introduction To NLPsambrefoNo ratings yet

- Meritor 210 220 230 240 2SpeedSingleAxlesDocument27 pagesMeritor 210 220 230 240 2SpeedSingleAxlesYhojan DiazNo ratings yet

- The Beatles Album Back CoverDocument1 pageThe Beatles Album Back CoverSophia AvraamNo ratings yet

- How To Sell Hillstone 306. Cloudhive v2.8Document98 pagesHow To Sell Hillstone 306. Cloudhive v2.8Emmanuel CoriaNo ratings yet

- Republic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsDocument23 pagesRepublic of The Philippines, Petitioner, vs. Sandiganbayan, Major General Josephus Q. Ramas and Elizabeth Dimaano, RespondentsKenzo RodisNo ratings yet

- Indexed Addressing & Flow Rate AveragingDocument5 pagesIndexed Addressing & Flow Rate AveragingMestrecal MeloNo ratings yet

- Feasibility ReportDocument10 pagesFeasibility ReportAdityaNo ratings yet

- A Teacher Education ModelDocument128 pagesA Teacher Education ModelMelinda LabianoNo ratings yet

- Assignment 1 Front Sheet: Qualification BTEC Level 4 HND Diploma in BusinessDocument14 pagesAssignment 1 Front Sheet: Qualification BTEC Level 4 HND Diploma in BusinessQuan PhanNo ratings yet

- A Study On Consumer Changing Buying Behaviour From Gold Jewellery To Diamond JewelleryDocument9 pagesA Study On Consumer Changing Buying Behaviour From Gold Jewellery To Diamond JewellerynehaNo ratings yet

- Dhi-Ehs-Hsm-028 Work Over Water Rev0Document5 pagesDhi-Ehs-Hsm-028 Work Over Water Rev0Phạm Đình NghĩaNo ratings yet

- Athus Souza - ResumeDocument2 pagesAthus Souza - ResumeArielBen-ShalomBarbosaNo ratings yet

- Bank Account Details and Contact NumbersDocument38 pagesBank Account Details and Contact NumbersD-Blitz StudioNo ratings yet

- Live Sound 101: Choosing Speakers and Setting Up a Sound SystemDocument14 pagesLive Sound 101: Choosing Speakers and Setting Up a Sound Systemohundper100% (1)

- Study of The Pre-Processing Impact in A Facial Recognition SystemDocument11 pagesStudy of The Pre-Processing Impact in A Facial Recognition Systemalmudena aguileraNo ratings yet

- Bayes Slides1Document146 pagesBayes Slides1Panagiotis KarathymiosNo ratings yet

- Drilling Products and Solutions CatalogDocument141 pagesDrilling Products and Solutions CatalogAlex Boz100% (1)

- Coordination in Distributed Agile Software Development: A Systematic ReviewDocument12 pagesCoordination in Distributed Agile Software Development: A Systematic ReviewAbdul Shakoor sabirNo ratings yet

- Standards in Nursing Education ProgrammeDocument13 pagesStandards in Nursing Education ProgrammeSupriya chhetryNo ratings yet

- Vargas V YapticoDocument4 pagesVargas V YapticoWilfredo Guerrero IIINo ratings yet

- Iwan Lab Guide v1.1 FinalDocument63 pagesIwan Lab Guide v1.1 FinalRicardo SicheranNo ratings yet

- Monographie BtttyrtIPM-5 Tables Vol7Document246 pagesMonographie BtttyrtIPM-5 Tables Vol7arengifoipenNo ratings yet

- Anand FDocument76 pagesAnand FSunil BharadwajNo ratings yet