Professional Documents

Culture Documents

MAK Hitemp Xtra SM Grease

Uploaded by

Anand Padhiyar0 ratings0% found this document useful (0 votes)

39 views1 pageMak hitemp xtra sm grease pds

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMak hitemp xtra sm grease pds

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views1 pageMAK Hitemp Xtra SM Grease

Uploaded by

Anand PadhiyarMak hitemp xtra sm grease pds

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Product Data Sheet

MAK HITEMP XTRA SM GREASE

High performance heavy duty grease for sugar mill journal bearing

MAK Hitemp Xtra SM Grease is a premium quality clay Reduced Consumption – extra tackiness of the grease

thickened non-soap base smooth and tacky grease combined with high viscosity base oil forms a strong

formulated using superior quality high viscosity mineral tenacious film of the journal bearing surface and minimises

base oil and high performance additives. Sugar mill journal grease loss as compared to conventional oils/ greases.

bearings work under arduous conditions and the lubricant

has to bear severe conditions of loading and water washout. Excellent Rust Protection – antirust and anticorrosion

MAK Hitemp Xtra SM Grease is characterised by very high additives in the formulation impart ability to protect

dropping point, outstanding oxidation stability and excellent bearings from rusting and early degradation. Hence longer

water resistance property. It also offers very high load bearing life.

carrying ability and good rust and corrosion protection. The

grease is fortified with 3% molybdenum disulphide (MoS2) Performance Level/ Specification:

as solid lubricant for protection of moving parts under Proprietary Grade

severe shock load conditions.

Typical Physico-Chemical Data: MAK Hitemp Xtra SM

Applications: Grease

MAK Hitemp Xtra SM Grease is specially recommended for Characteristics Method Value

lubrication of crushing mill journal bearings of sugar mill NLGI Grade - 2

industries. It is also suitable as industrial grease for arduous Appearance Visual Smooth

slow speed plain bearing applications. Color Visual Grey Black

Type of Thickener - Clay

Performance/ Benefits: Worked Penetration,@ 25OC, 60 ASTM D217 285

High Drop Point – high drop point demonstrates ability to strokes

handle high temperatures and provides excellent high Drop Point, OC ASTM D2265 >280

temperature performance. Base Oil Kinematic Viscosity, 40 OC, cSt ASTM D445 1200

Operating Temperature Range, OC - 0 to 170

High Oxidation Stability – offers high resistance to oxidation MoS2 Content, % wt. IS 1448 P:58 3

and thermal break down. Ensures reliability, longer Copper Corrosion at @100 OC for 24 ASTM D4048 Negative

operating life and less maintenance. hrs.

Excellent Shock Load Carrying Ability – due to presence of Storage & Handling:

MoS2 in the formulation, it has good shock loading carrying The product should be stored inside. Keep it properly sealed

ability, making it suitable to protect and lubricate the to avoid contamination. Avoid freezing. Shelf life is 2 yrs.

machine components even under intermittent loads. under protected conditions.

Excellent Water Resistance – offers excellent water Health & Safety:

washout resistance and does not get washed away due to It is unlikely to be hazardous when properly used in

water ingress/ contact thereby providing superior recommended applications. Contamination of the grease

lubrication and protection in wet environments. from other oils, greases, chemicals, dirty water etc. can

occur during the use. It should be avoided. Regular

Very Good Pumpability – exhibits very good pumpability monitoring of the in-use product is recommended.

even at low temperatures making it ideal for centralised

lubrication systems.

Bharat Petroleum Corporation Ltd. 1/1

Product and Application Development Deptt.

BPCL, “A” Installation, Sewree Fort Road, Sewree (East),

Mumbai – 400015 E-mail: MAKcustomercare2@bharatpetroleum.in Tel No.: 022-24176351

You might also like

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- MAK Graphite Grease SpecialDocument1 pageMAK Graphite Grease SpecialVardhman SalesNo ratings yet

- MAK Hitemp GreaseDocument1 pageMAK Hitemp GreaseVardhman SalesNo ratings yet

- MAK Lanthax EP GreaseDocument2 pagesMAK Lanthax EP GreaseshobhaNo ratings yet

- MAK Ruby Grease 3Document1 pageMAK Ruby Grease 3Sam90o GamingNo ratings yet

- MAK GARONEX R 250Document1 pageMAK GARONEX R 250Vardhman SalesNo ratings yet

- mak quenching oil cDocument1 pagemak quenching oil cPaviter SinghNo ratings yet

- Velloils High Temperature & Speciality Grease Velloplex GreaseDocument6 pagesVelloils High Temperature & Speciality Grease Velloplex GreaseBhusarapu SrinivasNo ratings yet

- GL XX Mobilgear SHC XMP SeriesDocument4 pagesGL XX Mobilgear SHC XMP Seriesanibal_rios_rivasNo ratings yet

- MAK Camex CompoundDocument1 pageMAK Camex CompoundVardhman SalesNo ratings yet

- GL XX Mobil SHC Grease 460 WTDocument3 pagesGL XX Mobil SHC Grease 460 WTRakka HardiyantaNo ratings yet

- GrasaDocument2 pagesGrasaeduardoNo ratings yet

- SUPRESS 412 MS EP & Multipurpose GreaseDocument1 pageSUPRESS 412 MS EP & Multipurpose GreaseRuslan SlusarNo ratings yet

- Mak 4T NXT: Premium Quality Semi-Synthetic Engine Oil For MotorcyclesDocument1 pageMak 4T NXT: Premium Quality Semi-Synthetic Engine Oil For MotorcyclesAnand PadhiyarNo ratings yet

- Technical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Document2 pagesTechnical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Mohamed IsmailNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Technical Data Sheet for High Performance Multi-purpose Extreme Pressure GreaseDocument2 pagesTechnical Data Sheet for High Performance Multi-purpose Extreme Pressure GreaseMuhammad SaputraNo ratings yet

- Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT SeriesDocument3 pagesMobilgrease HT Series Mobilgrease HT Series Mobilgrease HT Series Mobilgrease HT SeriesAyon HossenNo ratings yet

- GL XX Mobil SHC Grease 460 WTDocument3 pagesGL XX Mobil SHC Grease 460 WTMallikarjunareddy PNo ratings yet

- MAK Diamond 15W-40Document1 pageMAK Diamond 15W-40Indus StoreNo ratings yet

- Premalube Xtreme (Tech Sheet)Document2 pagesPremalube Xtreme (Tech Sheet)adit0% (1)

- Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic GreaseDocument3 pagesMobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic GreasedhowardjNo ratings yet

- MAK 4T RoyalDocument1 pageMAK 4T RoyalVardhman SalesNo ratings yet

- Technical Data Sheet for Shell Gadus S2 V220AC 2 GreaseDocument2 pagesTechnical Data Sheet for Shell Gadus S2 V220AC 2 GreaseRoger ObregonNo ratings yet

- Catálogo Grasas - SinopecDocument20 pagesCatálogo Grasas - SinopecMario GonzalesNo ratings yet

- Mobilgrease XHP 222 Pds PDFDocument3 pagesMobilgrease XHP 222 Pds PDFStefan Cel MareNo ratings yet

- Ultratack Mill Grease SG 4001Document1 pageUltratack Mill Grease SG 4001arkpNo ratings yet

- Heavy Duty Grease Moly PremiumDocument2 pagesHeavy Duty Grease Moly PremiumWawanDarmawanNo ratings yet

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziNo ratings yet

- MFG 460 - 3M - TDS - 2 - 12.10.22Document1 pageMFG 460 - 3M - TDS - 2 - 12.10.22RUTA TLAXCALA (SHELL)No ratings yet

- Product Information Sheet: Description: ApplicationDocument2 pagesProduct Information Sheet: Description: ApplicationgalaxiprinceNo ratings yet

- .Au ProductsAndServices Pages LubricantProDocument3 pages.Au ProductsAndServices Pages LubricantProabid azizNo ratings yet

- HT Mobilux Ep 2 EngDocument2 pagesHT Mobilux Ep 2 EngdgslimaNo ratings yet

- LUBCON Turmotemp LP 2502 ENDocument2 pagesLUBCON Turmotemp LP 2502 ENNuno AlvesNo ratings yet

- 1482402756balmerol Licom 2 PremiumDocument2 pages1482402756balmerol Licom 2 PremiumSabari SreekumarNo ratings yet

- RDP Castrol Premium Heavy Duty Grease Product Data Sheet PDFDocument2 pagesRDP Castrol Premium Heavy Duty Grease Product Data Sheet PDFAnis ElghadiNo ratings yet

- Mobil-Iocaengrsmomobilith SHC PMDocument3 pagesMobil-Iocaengrsmomobilith SHC PM황철No ratings yet

- Balmerol GreaseDocument3 pagesBalmerol GreaselifttecNo ratings yet

- PETRONAS Urania Optimo 10W-40Document1 pagePETRONAS Urania Optimo 10W-40Hazrulnizam HassanNo ratings yet

- High-performance greaseDocument2 pagesHigh-performance greaserstec pyNo ratings yet

- Shell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsGera BdNo ratings yet

- Gadus S3 V460D 2Document2 pagesGadus S3 V460D 2Lubricants ServerNo ratings yet

- Mak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial GearsDocument2 pagesMak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial Gearschandan sahooNo ratings yet

- Henan Dongsen Lubrication Technology Co., LTD: Multipurpose Calcium GreaseDocument1 pageHenan Dongsen Lubrication Technology Co., LTD: Multipurpose Calcium Greasesunhell1611No ratings yet

- Premium Heavy Duty GreaseDocument2 pagesPremium Heavy Duty GreaseRoger ObregonNo ratings yet

- PDS - Mobilgrease XHP 460 SeriesDocument3 pagesPDS - Mobilgrease XHP 460 SeriesJuanSantillanNo ratings yet

- Petronas Grease LiX EP 2/380 and LiX MEP Advanced Industrial Lithium Complex and Heavy Duty GreasesDocument2 pagesPetronas Grease LiX EP 2/380 and LiX MEP Advanced Industrial Lithium Complex and Heavy Duty GreasesSolomon Nebiyu100% (1)

- Gazpromneft Grease L Moly EP 2 - Eng Ficha TecnicaDocument1 pageGazpromneft Grease L Moly EP 2 - Eng Ficha TecnicaMarvin MoraNo ratings yet

- 1482402436balmerol Grease Seal Guard HTDocument2 pages1482402436balmerol Grease Seal Guard HTdurgaprasad.svanmoppesNo ratings yet

- GulfSea Hyperbar LCM2 PDFDocument2 pagesGulfSea Hyperbar LCM2 PDFObydur RahmanNo ratings yet

- Mobiltemp Series Product Data SheetDocument3 pagesMobiltemp Series Product Data SheetRonaldo RossiNo ratings yet

- Shell Paper Machine Oil S3 M 220Document3 pagesShell Paper Machine Oil S3 M 220DENNY BAYUAJINo ratings yet

- Gear OilDocument26 pagesGear OilRohit Ramamurthy TevnanNo ratings yet

- Sinopec Grease: SINOPEC Moly-Lithium Grease SINOPEC Heavy Duty LC Mining GreaseDocument2 pagesSinopec Grease: SINOPEC Moly-Lithium Grease SINOPEC Heavy Duty LC Mining GreaseSumaya AkterNo ratings yet

- ServocoatDocument1 pageServocoatbrpnaidu2157No ratings yet

- As XX Mobil Super Moto 3r 4t 20w50 1Document2 pagesAs XX Mobil Super Moto 3r 4t 20w50 1NiltonNo ratings yet

- Puma HD Drive Train 10W 30 40 50 TDSDocument2 pagesPuma HD Drive Train 10W 30 40 50 TDSHakim AmmorNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriesShailesh BarbateNo ratings yet

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaNo ratings yet

- Gadus S2 OG Clear Oil 20000Document2 pagesGadus S2 OG Clear Oil 20000JUAN BAUTISTANo ratings yet

- Mas Premier League - ScheduleDocument2 pagesMas Premier League - ScheduleAnand PadhiyarNo ratings yet

- Mobile Services: Your Account Summary This Month'S ChargesDocument7 pagesMobile Services: Your Account Summary This Month'S ChargesAnand PadhiyarNo ratings yet

- GB enDocument2 pagesGB ensalamrefighNo ratings yet

- Chart 15Document1 pageChart 15baddressNo ratings yet

- Mobiconnect - Mobile Application For BPCL Internal EmployessDocument9 pagesMobiconnect - Mobile Application For BPCL Internal EmployessAnand PadhiyarNo ratings yet

- Mobile Services: Your Account Summary This Month'S ChargesDocument6 pagesMobile Services: Your Account Summary This Month'S ChargesAnand PadhiyarNo ratings yet

- Mak 4T NXT: Premium Quality Semi-Synthetic Engine Oil For MotorcyclesDocument1 pageMak 4T NXT: Premium Quality Semi-Synthetic Engine Oil For MotorcyclesAnand PadhiyarNo ratings yet

- BPCL MAK LUBRICANT Process FlowDocument22 pagesBPCL MAK LUBRICANT Process FlowAnand Padhiyar100% (1)

- Composites VIMPDocument60 pagesComposites VIMPAnand PadhiyarNo ratings yet

- Poka YokeDocument39 pagesPoka Yokeapi-3770121No ratings yet

- StandarduniformStandardtriangular PDFDocument1 pageStandarduniformStandardtriangular PDFAnand PadhiyarNo ratings yet

- Ceramics - VimpDocument70 pagesCeramics - VimpAnand PadhiyarNo ratings yet

- Mercado 2001 Modeling Flow and Heat Transfer in Tubes Using A Fast CFD FormulationDocument10 pagesMercado 2001 Modeling Flow and Heat Transfer in Tubes Using A Fast CFD FormulationeliastorcaNo ratings yet

- Hoja de Datos PSVDocument6 pagesHoja de Datos PSVMarc MarNo ratings yet

- 5b. Konsep Aliran Air (Hidrodinamika) 1Document19 pages5b. Konsep Aliran Air (Hidrodinamika) 1BaarmecideNo ratings yet

- Comparative Investigation of River Water Quality by OWQI, NSFWQI and Wilcox Indexes (Case Study: The Talar River - IRAN)Document8 pagesComparative Investigation of River Water Quality by OWQI, NSFWQI and Wilcox Indexes (Case Study: The Talar River - IRAN)NguyễnThịBíchPhượngNo ratings yet

- Melab 2Document14 pagesMelab 2Phil John FernandezNo ratings yet

- Chapter 13 Flow in Closed ConduitsDocument17 pagesChapter 13 Flow in Closed Conduitspedrillo100% (1)

- Properties of Sediment ParticlesDocument22 pagesProperties of Sediment ParticlesWalter F SilvaNo ratings yet

- Measurement of a Flat Plate Boundary LayerDocument12 pagesMeasurement of a Flat Plate Boundary LayerRahulNo ratings yet

- Shell Lubricants Albida Alvania Multiservice GreasesDocument1 pageShell Lubricants Albida Alvania Multiservice GreasesvinothNo ratings yet

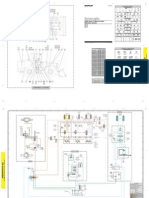

- Mechanical Equipment IndexDocument11 pagesMechanical Equipment IndexP RobertsonNo ratings yet

- Advanced Production Engineering Chapter # 2 Choke PerformanceDocument50 pagesAdvanced Production Engineering Chapter # 2 Choke PerformanceRaghadaNo ratings yet

- Fluid Mechanics Lecture 101820Document1 pageFluid Mechanics Lecture 101820John Dalton ValenciaNo ratings yet

- 12 Finally EditedDocument98 pages12 Finally Editedelias chernetNo ratings yet

- Refrigeration Cycle Components ExplainedDocument23 pagesRefrigeration Cycle Components ExplainedkamkarapnaNo ratings yet

- Heavy Oil and Gas LiftDocument5 pagesHeavy Oil and Gas Liftadsnah0% (1)

- Fresh Air Louver Selection - 11-10-2015Document1 pageFresh Air Louver Selection - 11-10-2015organicspolybondNo ratings yet

- Resolução ANP #50 DE 23 - 12 - 2013 - S10 & S500Document2 pagesResolução ANP #50 DE 23 - 12 - 2013 - S10 & S500Daniel CaldasNo ratings yet

- 938 GhidraulicaDocument2 pages938 GhidraulicaHenry Quisp100% (1)

- Chapter 8-Design of The Rotor of A TurbomachineDocument18 pagesChapter 8-Design of The Rotor of A TurbomachineSiraj Mohammed100% (2)

- Is 4558 1995 PDFDocument11 pagesIs 4558 1995 PDFshabenoorNo ratings yet

- Slideshare Upload Login SignupDocument26 pagesSlideshare Upload Login SignupAbok AduogoNo ratings yet

- 10-Drying of Milk Dairy and Food EngineeringDocument7 pages10-Drying of Milk Dairy and Food Engineeringariyani yantoNo ratings yet

- Surface Tension and Wettability Terms DefinedDocument5 pagesSurface Tension and Wettability Terms DefinedAli MahmoudNo ratings yet

- Tib 10 Pump InducersDocument5 pagesTib 10 Pump InducersscubazNo ratings yet

- Chapter 8 23 PDFDocument1 pageChapter 8 23 PDFAlwin WanNo ratings yet

- ME 101 Lecture on Turbomachinery Classification and ApplicationsDocument12 pagesME 101 Lecture on Turbomachinery Classification and ApplicationsAbeer Hossain AneekNo ratings yet

- Introduction to Separators: Key Concepts and Design Factors in 40 CharactersDocument37 pagesIntroduction to Separators: Key Concepts and Design Factors in 40 Charactersjps21No ratings yet

- 2510.practical Aspects of Finite Element Modelling of Polymer Processing by Vahid NassehiDocument282 pages2510.practical Aspects of Finite Element Modelling of Polymer Processing by Vahid Nassehihalukg26No ratings yet

- Fluid Mechanics Lab ManualDocument53 pagesFluid Mechanics Lab ManualprashanthreddyhNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)