Production Technologies

Introduction to Separators

�Introduction to Separators: Course Objectives

After completing this module, you should be able to :

1. Understand why separators are important and generic types

available

2. Learn where separators are located in the process and what

function they serve

3. Be able to enumerate the key factors that effect separation design

and selection

4. Understand and define the fours (4) distinct sections of a separator

5. Learn why retention time is important and how to calculate it for

any vessel

6. Understand and describe the key internal parts of a separator,

[inlet/wave breakers/demisters]

7. Recognize why and define the differences between a horizontal or

vertical separator

8. Understand and identify key operational issues in separators such

as foam, re-entrainment, paraffin, or blowby.

�Introduction

�Introduction

A typical oil & gas facility

1. As highlighted in previous

A schematic example of an oil and gas process system

modules oil and gas production

system consist of the following

segments:

a. Wellhead

b. Manifold/Gathering

c. Separator

d. Gas compressor

e. Pipeline

f. Some optional facilities may be

required

I. Heat exchanger

II. Scrubber and Reboiler

2. In this module we will discuss

the flow out of a pipeline into

the manifold and then into

separator/s.

�Introduction

Manifold/Gathering

1. Individual wells are brought into the

production process facilities using a

network of gathering pipelines that

are then connected to a production

manifold system.

2. The manifolds control production

flow by well set or group and

evenly distribute flow where more

than one process train is available.

3. Manifolds can be placed on surface,

on platform or on seafloor,

depending on the production system.

Example manifold systems

�Introduction

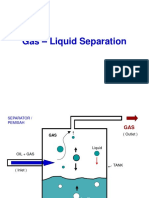

Produced Fluids and Separators

1. As noted in earlier modules produced fluids are complex

2.

3.

4.

5.

6.

7.

mixtures with different densities, vapor pressures, and other

physical characteristics.

As these fluids flow from the petroleum reservoir, they

experience pressure and temperature reductions.

Gases evolve from the liquids and the fluid/s chemistry change.

The velocity of the gas carries liquid droplets, the liquid carries

gas bubbles.

The goal for an ideal separator is to separate the well stream

into liquid-free gas and gas-free liquid.

Ideally, the gas and liquids reach equilibrium at the existing

conditions of pressure and temperature within the vessel.

In some cases, the process equipment and conditions

downstream of a separator will dictate the necessary degree of

separation.

�Introduction

Produced Fluids and Separators

8. Gas, oil and water separation was achieved by the difference in

gravity, or weight, of each fluid.

9. Production separator do the same job, except they are built to

handle a continuous-flow stream and have features to improve

separation efficiency under flow conditions.

10. A oil and gas separator are designed to mechanically separate the

liquid and gas components at a given temperature and pressure.

11. Proper separator design is important as a separator vessel is

normally the initial processing vessel and improper design can

"bottleneck" or reduce the capacity of the entire facility.

�Introduction

Separator Types

1. Separators are classified

as "two-phase" if they

separate gas from the total

liquid stream and "threephase" if they also

separate the liquid stream

into its crude oil and water

components.

2. Separators are sometimes

called "gas scrubbers"

when the ratio of gas rate

to liquid rate is very high.

3. Some operators use the

term "traps" to designate

separators that handle

flow directly from wells.

�The Separation Process

�The Separation Process

FACTORS AFFECTING SEPARATION

1. The physical and chemicals characteristics of the flow stream will

greatly affect the design and operation of a separator.

2. The following factors are used to select a separator and are

important when trying to identify an operating problem :

a. Proportions of gas and liquids composing the inlet stream.

b. Differences between the densities of the gas and liquids.

c. Differences between the viscosities of the gas and liquids.

d. Temperature and pressure at which separation is to be made.

e. Gas and liquid flow rates (minimum, average, and peak)

f. Operating and design pressures and temperatures

g. Surging or slugging tendencies of the feed streams

h. Presence of impurities (paraffin, sand, scale, etc.)

i. Foaming tendencies of the crude oil

j. Corrosive tendencies of the liquids or gas

k. Particle sizes of liquids in the gas phase or gas in the liquid phase.

l. Identification of impurities such as H 2S, CO2, pipe scale, dust, etc

�The Separation Process

All separators have at least three and

usually four sections comprising the

separation process:

1. The primary separation section

2. The secondary separation section

3. The liquid accumulation section

4. The mist extractor section

�The Separation Process

Primary Separator Section

1. This section is the portion of the vessel adjacent to the inlet where

the energy of the entering well stream is dissipated.

2. The purpose of this section is to make the initial separation of liquid

from gas using deflectors or impingement baffles.

3. The bulk of the liquid is diverted to the liquid accumulation section.

4. The larger quantities of liquid and large liquid drops immediately

start falling as a result of the gravitational force.

5. In vertical separators, the inlet deflector forces the liquid to change

direction toward the vessel shell where it spreads out in a thin film,

allowing solution gas to break out.

6. In horizontal separators, the liquid is usually directed against a

deflector plate which may or may not be dish shaped. The liquid is

thrown against the vessel shell to divert it from the main gas stream

and allow rapid release of solution gas.

7. In some cases, impingement baffles are used in horizontal separators

to break the liquid stream into smaller streams and droplets so that

solution gas can be more readily released.

�The

Separation

Process

1. The immediately beyond the inlet deflector, between

Secondary Separator Section

the liquid accumulation section, and the mist extractor

(or outlet head where a mist extractor is not used) is

called the secondary separation section.

2. In this section the velocity of the gas and liquid is

reduced because of the increased cross-sectional area.

3. Velocity reduction allows the liquid particles to begin

falling toward the liquid accumulation section as a result

of gravitational force on the mass of the liquid particle.

4. In vertical separators the upward gas velocity tends to

counter the gravitational force effect on the liquid

particles. If the particle is large, the gravitational force

will be the greater force and the particle will settle to

the bottom.

�The Separation Process

Secondary Separator Section

5. Very small particles will be carried along with the gas as

entrainment and will leave the separator, if not removed

by some other device such as a mist extractor.

6. In horizontal separators the drag force is exerted at right

angles to the gravitational force and does not hinder the

particles' fall to the liquid accumulation section.

7. The resultant path of the particle is a diagonal path or

trajectory toward the outlet of the separator.

8. The horizontal separator must be large enough in crosssection and long enough so the reduction of the gas

velocity and the diagonal paths for the bulk of the liquid

particles will carry them into the liquid accumulation

section.

�The Separation Process

Liquid Accumulation Section

1. All separators provide an area for collected liquid from the primary

separation and secondary separation sections and the mist extractor.

2. The liquid retention time is normally one minute for two phase (i.e.,

liquid-gas) separation. This will normally allow time for the solution

gas to break out of the accumulated liquid.

3. In vertical separators a baffle plate is positioned between the liquid

accumulation section and the secondary separation section to limit reentrainment of liquid into gas and minimize wave action/turbulence

on the liquid surface which may upset the level control system.

4. Horizontal separators utilize approximately half of the cross-section

for liquid accumulation but have less surge capacity than vertical

separators.

5. Importantly in Horizontal separators the large surface area of the

gas liquid interface provides excellent release of solution gas.

6. In both separators wave breakers or stilling baffles may be used to

stop wave action caused by gas eddy currents near the gas-liquid

interface to prevent liquid re-entrainment into the gas stream.

�The Separation Process

Retention Time

1. An important concept unique to each facility is retention time

as this ensures liquid and gas resident reach equilibrium at

separator pressure a certain liquid storage is required.

2. Retention Time" or the average time a molecule of liquid is

retained in the vessel assuming plug flow. Retention time may

be defined as the volume of the liquid storage section in the

vessel divided by the liquid flow rate.

3. For most applications retention times of between 30 seconds

and 3 minutes have been found to be sufficient. [Examples below]

4. Where foaming crude is present retention times up to four

times this amount may be needed.

Two-Phase Separators

Oil Gravity

>35 API

20 to 30 API

10 to 20 API

Three-Phase Separators

Retention Time

(Minutes)

1

1-2

2-4

Oil Gravity

Retention Time

(Minutes)

>35 API

<35 API @ 38 C

<35 API @ 26 C

<35 API @ 16 C

3-5

5-10

10-20

20-30

�VESSEL INTERNALS

Mist Extraction Section

1. The purpose of the mist extraction section is to condition the gas.

2. The two types of mist extractors most commonly used in

oil and gas separators are knitted wire mesh and vanes.

a. Mist extractors cause small entrained particles [liquid

droplets] to impinge on the matted wires and coalesce into

larger droplets.

b. When the droplets reach sufficient size to overcome the lifting

force imposed by the gas velocity, they will fall into the liquid

accumulation section of the separator.

c. The effectiveness of wire mesh depends largely on the gas

flow operating in design criteria velocity range.

d. If the velocities are too high, the liquids knocked out will be

re-entrained.

e. If the velocities are low, the vapor just drifts through the

mesh element without the droplets impinging and coalescing.

�The Separation Process

FACTORS AFFECTING SEPARATION

A summary of the key functions of the Separation

Process are graphically presented below

�Vessel Internals

�VESSEL INTERNALS

Inlet Diverters

1. There are many types of inlet diverters. The two main types are baffle

plates and centrifugal diverters.

2.

A baffle plate can be

a. a spherical dish, flat plate, angle iron, cone, or just about

anything that will accomplish a rapid change in direction and

velocity of the fluids and thus disengage the gas and liquid.

b. Design of the baffles is governed principally by the structural

supports required to resist the impact-momentum load.

c. The advantage of using devices such as a half sphere or cone is

that they create less disturbance than plates or angle iron,

cutting down on re-entrainment or emulsifying problems.

�VESSEL INTERNALS

Inlet Diverters

3. Centrifugal inlet diverters use

centrifugal force, rather than

mechanical agitation, to disengage the

oil and gas.

a. These devices can have a

cyclonic chimney or may use a

tangential fluid race around

the walls.

b. Centrifugal inlet diverters are

proprietary but generally use

an inlet nozzle sufficient to

create a fluid velocity of about

20 fps.

c. Centrifugal diverters work well

in initial gas separation and

help to prevent foaming in

crudes

An example of a centrifugal inlet diverter

�VESSEL INTERNALS

Wave Breakers

1. In long horizontal vessels it is necessary

to install wave breakers, which are

nothing more than vertical baffles

spanning the gas-liquid interface and

perpendicular to the flow.

Defoaming Plates

2. Foam at the interface may occur when

gas bubbles are liberated from the liquid.

3. An effective solution is to force the foam

to pass through a series of inclined

parallel plates or tubes [as shown in the bottom

photo] so as to aid in coalescence of the

foam bubbles.

4. Many times this foam must be stabilized

with the addition of chemicals at the inlet

as a foam issue was not identified during

the design phase.

�VESSEL INTERNALS

Mist Extractor

1. Knitted Wire Extractors consist of

horizontal or vertical pads of knitted

stainless steel or monel wire mesh

either in layers or wound,

2. On vertical separators the pad is

placed in the horizontal position near

the top of the vessel.

3. Horizontal separators use vertical

pads near the gas outlet end.

4. The pads are generally 4" to 6" thick

and can vary depending upon the

particle size to be removed and the

efficiency of removal desired.

5. Wire mesh mist extractors normally

are designed to remove 99% of all

liquid particles which are 10 microns

or larger.

Example wire mesh mist eliminator

(photo courtesy of AMISTCO Industries]

�VESSEL INTERNALS

Vane Type Mist Extractors

1. Vane type mist extractors are

most efficient where large

volumes of gas must be handled

with small liquid loads.

2. Vane-type eliminators are sized

by manufacturers to assure both

laminar flow and minimum

pressure drop.

3. Vane extractors consist of a

series of parallel impingement

baffles which provide the

surface area for entrained

particles to collide and coalesce

into larger drops.

�VESSEL INTERNALS

Vane Type Mist Extractors

1. Vane eliminators force the gas flow

to be laminar between parallel plates

that contain directional changes.

2. The vanes are also arranged to cause

the gas stream to change direction

and velocity;

a. Creating a centrifugal force

and

b. Improving the collection and

coalescing of the small liquid

particles.

3. Vane type mist extractors are the

best units to use with fluids

containing paraffin or wax since they

do not plug as readily as the knitted

wire mist units.

Example vane mist eliminator (photo

courtesy of AMISTCO Industries]

�VESSEL INTERNALS

Vortex Breaker

1. Liquid outlet connections in either

vertical or horizontal separators

are usually located as far away

from the inlet as possible to assure

maximum liquid retention time and

to keep a vortex from developing

when the control valve is open.

2. Most outlets are also designed with

anti-vortex baffles or siphon type

drains to prevent vortex

development.

3. Development of a vortex at the

liquid outlet can cause gas to be

re-entrained in the liquid being

discharged.

�Separator Vessel Types

�Separator Vessel Types

Horizontal Separators

1. Horizontal separators are ideally suited to high gas-oil ratios,

constant flow, and small liquid surge characteristics.

2. In addition to being easier to hook-up, easier to service, and

easier to skid-mount, horizontal separators can be stacked in

piggy-back fashion to form stage separation assemblies and

minimize horizontal space requirements.

3. Horizontal separators are smaller and less expensive than

vertical separators for a given gas capacity. Horizontal

separators have a much greater gas-liquid interface area

than other types, which aids in the release of solution gas

and reduction of foam.

4. Use is best suited for liquid-liquid-gas, or three phase,

separations because of the large interfacial area available

between the two liquid phases.

5. A de-foaming section is used when severe foaming of the

inlet stream is anticipated.

�Separator Vessel Types

Horizontal Separator Ideal Application;

1. Areas where there are vertical

height limitations.

2. Foamy production where the larger

liquid surface area available will

allow greater gas breakout and

foam breakdown.

3. Three phase separation applications

for efficient liquid-liquid separation.

4. Upstream of process equipment,

which will not tolerate entrained

liquid droplets in the gas.

5. Downstream of equipment causing

liquid formation.

6. Hydrocarbon fluid streams with a

high gas to oil ratio and constant

flow with little or no liquid surges.

�Separator Vessel Types

Vertical Separator

1. Vertical Separators are typically used in

areas having horizontal space limitations,

but little or no vertical height limitations.

2. Vertical Separators Handle low to

moderate Gas to Oil ratio production

3. Vertical Separators are more capable of

handling large slugs of liquids

4. Vertical Separators are well suited for

removal of excessive quantities of sand,

mud, and sediment.

5. Because the natural upward flow of gas

opposes the falling liquid droplets,

vertical separators may be larger and

more expensive than a horizontal

separator for the same gas handling

capacity.

�POTENTIAL OPERATING PROBLEMS

�POTENTIAL OPERATING

PROBLEMS

Foamy Crudes

1. The major cause of foam in crude oil is of impurities which

are impractical to remove before the stream reaches the

separator.

2. Foam typically presents no problem within a separator if the

internal design assures adequate time or sufficient coalescing

surface for the foam to "break.

�POTENTIAL OPERATING

PROBLEMS

Foamy Crudes

3. Foaming in a separator vessel is a

threefold operating problem:

a. Mechanical control of the liquid level is

aggravated because any control device

must deal with essentially three liquid

phases instead of two.

b. Foam has a large volume-to-weight ratio.

Therefore, it can occupy much of the

vessel space that would otherwise be

available in the liquid collecting or

gravity settling sections.

c. In an uncontrolled foam bank, it becomes

impossible to remove separated gas or

degassed oil from the vessel without

entraining some of the foamy material in

either the liquid or gas outlets.

�POTENTIAL OPERATING PROBLEMS

Foamy Crudes

4. The amount of foam noted is dependent on the pressure

drop to which the inlet liquid is subjected, as well as the

characteristics of the liquid at separator conditions.

5. In some cases, the effect of temperature may be

significant.

6. Chemicals to prevent foam often will do a good job in

increasing the capacity of a given separator.

7. However, the use of an effective depressant should not be

assumed because characteristics of the crude and of the

foam may change during the life of the field.

�POTENTIAL OPERATING PROBLEMS

Re-entrainment

1. Re-entrainment is a phenomenon caused by high gas

velocity at the gas-liquid interface of a separator.

a. Momentum transfer from the gas to the liquid causes

waves and ripples in the liquid

b. Then droplets are broken away from the liquid phase

and carried in the gas.

2. Re-entrainment should be considered where highpressure separators are sized on gas-capacity

constraints.

3. Re-entrainment is more likely to occur at higher

operating pressures (>1,000 psig) and higher oil

viscosities (<30 API).

�POTENTIAL OPERATING PROBLEMS

Paraffin

1. Separator operation can be adversely affected by

an accumulation of paraffin.

2. Coalescing plates in the liquid section and mesh

pad mist extractors in the gas section are

particularly prone to plugging by accumulations of

paraffin.

3. Where it is determined that paraffin is an actual or

potential problem, the use of plate-type or

centrifugal mist extractors should be considered.

4. Important to successful operation is maintaining

the process fluid temperature above the cloud

point of the crude oil.

�POTENTIAL OPERATING PROBLEMS

Sand

1. Sand production may cause

a. Cutout of valve trim,

b. Plugging of separator

internals, and

c. Accumulation that reduces

vessel volume in the

bottom of the separator.

2. Special hard trim [Corrosion

Resistant Alloys] can

minimize the effects of sand

on the valves.

3. Accumulations of sand can

be alleviated by the use of

sand jets and drains.